washer fluid JEEP YJ 1995 Service And Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 23 of 2158

MAINTENANCE SCHEDULES

INTRODUCTION

There are two maintenance schedules that show

proper service intervals for Jeep Cherokee and Jeep

Wrangler vehicles. Use the schedule that best de-

scribes the conditions the vehicle is operated under.

When mileage and time is listed, follow the interval

that occurs first.

ScheduleÐAlists all the scheduled maintenance

to be performed under normal operating conditions.

ScheduleÐBis a schedule for vehicles that are

usually operated under one or more of the following

conditions.

²Frequent short trip driving less than 5 miles (8

km).

²Frequent driving in dusty conditions.

²Trailer towing or heavy load hauling.

²Frequent long periods of engine idling.

²Sustained high speed operation.

²Desert operation.

²Frequent starting and stopping.

²Cold climate operation.

²Off road driving.

²Commercial service.

²Snow plow operation.

²More than half of vehicle operation occurs in

heavy city traffic during hot weather (above 90É F).

AT EACH STOP FOR GASOLINE

²Check engine oil level and add as required.

²Check windshield washer solvent and add as re-

quired.

ONCE A MONTH

²Check tire pressure and look for unusual tire wear

or damage.

²Check fluid levels of coolant reservoir, brake mas-

ter cylinder, power steering and transmission. Add

fluid as required.

²Check all lights and other electrical items for cor-

rect operation.

²Inspect battery and clean and tighten terminals as

required.

²Check rubber seals on each side of the radiator for

proper fit.

AT EACH OIL CHANGE

²Inspect exhaust system.

²Inspect brake hoses.

²Rotate the tires at each oil change interval shown

on ScheduleÐA: (7,500 Miles) or every other interval

shown on ScheduleÐB: (6,000 Miles).

²Check engine coolant level, hoses, and clamps.

²Lubricate 4x4 steering linkage.

²Lubricate propeller shaft universal joints and slip

spline, if equipped.After completion of off-road (4WD) operation, the

underside of the vehicle should be thoroughly in-

spected. Examine threaded fasteners for looseness.

HARSH SURFACE ENVIRONMENTS

After vehicle operation in a harsh surface environ-

ment, the following components should be inspected

and cleaned as soon as possible:

²Brake drums.

²Brake linings.

²Front wheel bearings (2WD vehicles only).

²Axle coupling joints.

This will prevent wear and/or unpredictable brake

action.

EMISSION CONTROL SYSTEM MAINTENANCE

The schedule emission maintenance listed inbold

typeon the following schedules, must be done at the

mileage specified to assure the continued proper

functioning of the emission control system. These,

and all other maintenance services included in this

manual, should be done to provide the best vehicle

performance and reliability. More frequent mainte-

nance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

SCHEDULEÐA

7,500 MILES (12 000 KM) OR AT 6 MONTHS

²Change engine oil.

²Replace engine oil filter.

²Lubricate steering linkage (4x4).

15,000 MILES (24 000 KM) OR AT 12 MONTHS

²Change engine oil.

²Replace engine oil filter.

²Lubricate steering linkage.

22,500 MILES (36 000 KM) OR AT 18 MONTHS

²Change engine oil.

²Replace engine oil filter.

²Lubricate steering linkage (4x4).

²Inspect brake linings.

30,000 MILES (48 000 KM) OR AT 24 MONTHS

²Replace air cleaner element.

²Replace spark plugs.

²Adjust belt tension on non-automatic tensioning

drive belts.

²Change engine oil.

²Replace engine oil filter.

²Lubricate steering linkage.

²Drain and refill automatic transmission.

²Drain and refill transfer case.

0 - 4 LUBRICATION AND MAINTENANCEJ

Page 48 of 2158

hose unless the caliper must also be removed

for maintenance.Support the caliper with a

hanger to prevent brake fluid hose damage.

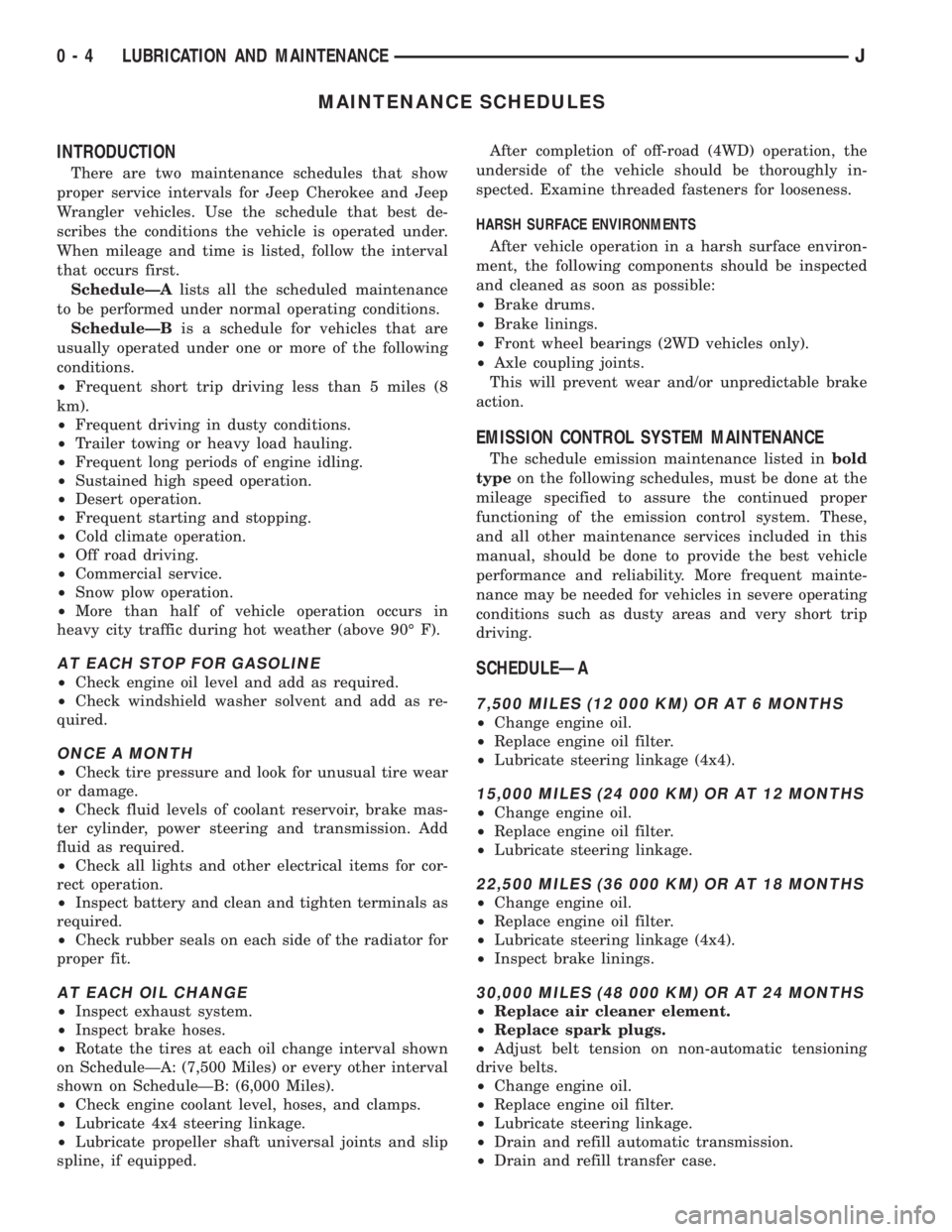

(2) Remove the dust cap, the cotter pin, the nut re-

tainer, the adjustment nut, and the thrust washer

from the spindle (Fig. 3). Discard the cotter pin.

(3) Remove the wheel outer bearing from the hub.

(4) Remove the wheel hub/disc brake rotor from

the spindle.

(5) Remove the seal and the inner wheel bearing

from the hub cavity.

(6) After removal, inspect both front wheel bearing

races for indications of pitting, brinelling and exces-

sive heat.

(7) Wipe the spindle clean and apply a small

amount of chassis/wheel bearing lubricant (NLGI

GC-LB lubricant) to prevent rust. Wipe the wheel

hub cavity clean.

CAUTION: Do not over-fill the wheel hub cavity with

lubricant. Excessive lubricant can cause overheat-

ing and bearing damage. Also, excessive lubricant

can be forced out of the wheel hub cavity and con-

taminate the brake rotor/pads.

(8) Partially fill the wheel hub cavity with chassis/

wheel bearing lubricant (NLGI GC-LB lubricant).

(9) Pack the wheel bearings with chassis/wheel

bearing lubricant (NLGI GC-LB lubricant). Ensure

that sufficient lubricant is forced between the bear-

ing rollers.

(10) Install the wheel inner bearing in the wheel

hub and install a replacement seal.

(11) Clean the disc brake rotor contact surfaces, if

necessary.

(12) Install the wheel hub/disc brake rotor on the

spindle.

(13) Install the wheel outer bearing, the thrust

washer, and the spindle nut.(14) Tighten the spindle nut with 28 Nzm (21 ft.

lbs.) torque while rotating the disc brake rotor to

seat the bearings.

(15) Loosen the spindle nut 1/2 turn. While rotat-

ing the disc brake rotor, tighten the spindle nut with

2Nzm (19 in. lbs.) torque.

(16) Install the nut retainer and a replacement cot-

ter pin.

(17) Clean the dust cap and apply wheel bearing

lubricant to the inside surface.Do not fill the dust

cap with lubricant.

(18) Install the dust cap.

(19) Install the disc brake caliper.

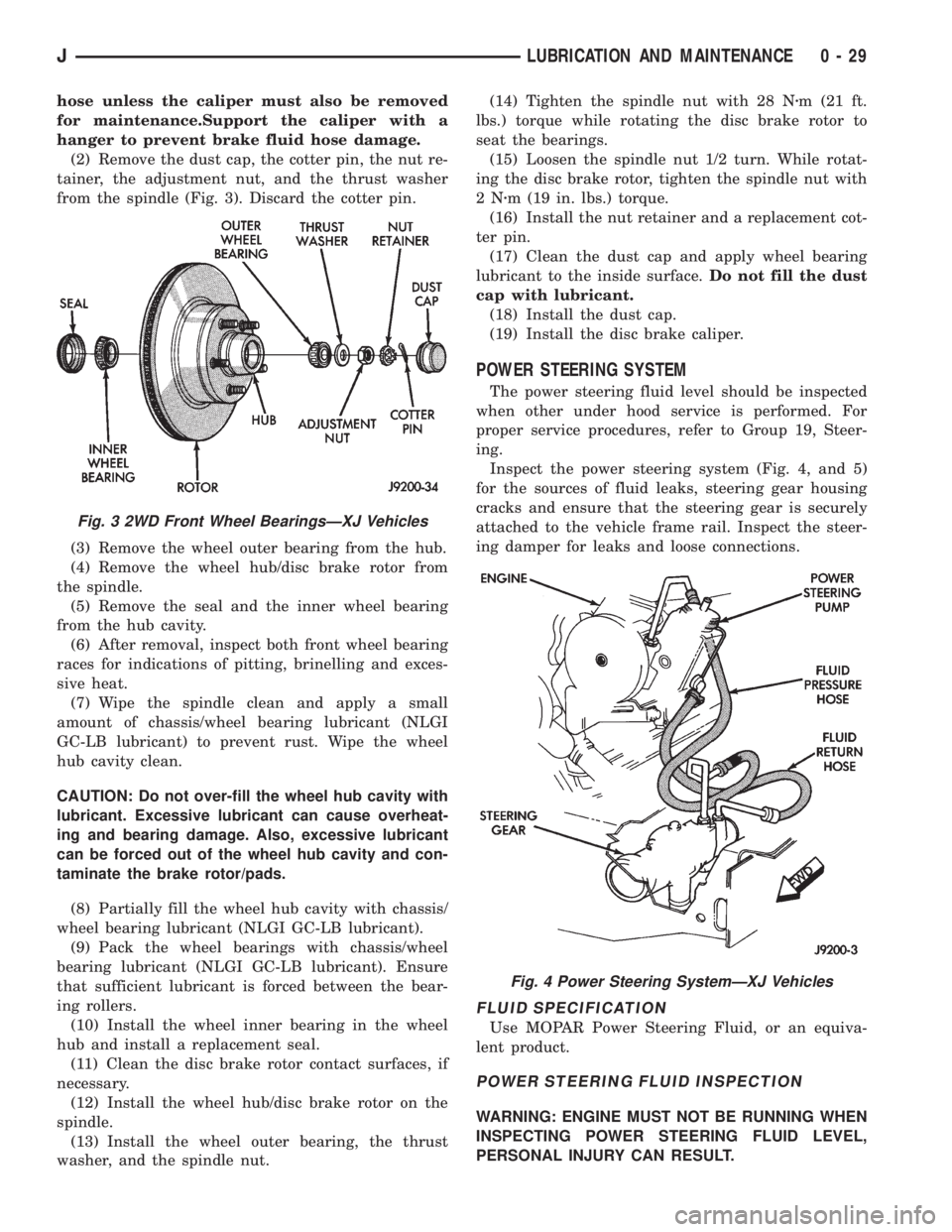

POWER STEERING SYSTEM

The power steering fluid level should be inspected

when other under hood service is performed. For

proper service procedures, refer to Group 19, Steer-

ing.

Inspect the power steering system (Fig. 4, and 5)

for the sources of fluid leaks, steering gear housing

cracks and ensure that the steering gear is securely

attached to the vehicle frame rail. Inspect the steer-

ing damper for leaks and loose connections.

FLUID SPECIFICATION

Use MOPAR Power Steering Fluid, or an equiva-

lent product.

POWER STEERING FLUID INSPECTION

WARNING: ENGINE MUST NOT BE RUNNING WHEN

INSPECTING POWER STEERING FLUID LEVEL,

PERSONAL INJURY CAN RESULT.

Fig. 3 2WD Front Wheel BearingsÐXJ Vehicles

Fig. 4 Power Steering SystemÐXJ Vehicles

JLUBRICATION AND MAINTENANCE 0 - 29

Page 118 of 2158

(10) Inspect the roller bearing contact surface on

the axle shaft for signs of brinelling, spalling and pit-

ting.

(11) If any of these conditions exist, the axle shaft

and bearing or seal must be replaced.

INSTALLATION

(1) Lubricate the bearing bore and seal lip with

gear lubricant. Insert the axle shaft through the seal,

bearing, and engage it with the side gear splines.

Use care to prevent the shaft splines from dam-

aging the axle shaft seal lip.

(2) Insert the C-clip lock in the end of the axle

shaft. Push the axle shaft outward to seat the C-clip

lock in the side gear.

(3) Insert the mate shaft into the case and through

the thrust washers and pinion gears. Align the hole

in shaft with the hole in the differential case and in-

stall the lock screw with Loctiteton the threads.

Tighten the screw to 19 Nzm (14 ft. lbs.) torque.

(4) Install the cover and add fluid. Refer to the

Drain and Refill in this section.

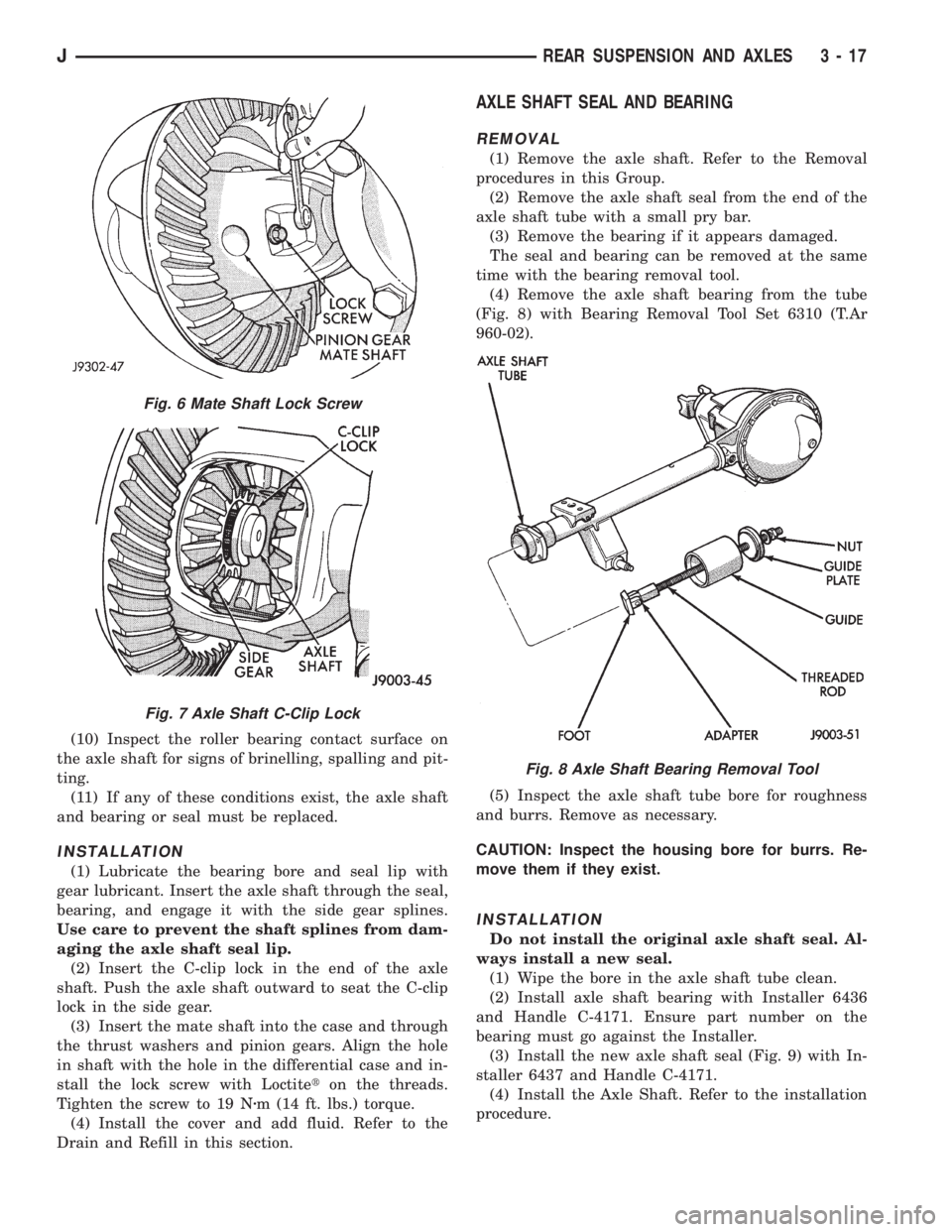

AXLE SHAFT SEAL AND BEARING

REMOVAL

(1) Remove the axle shaft. Refer to the Removal

procedures in this Group.

(2) Remove the axle shaft seal from the end of the

axle shaft tube with a small pry bar.

(3) Remove the bearing if it appears damaged.

The seal and bearing can be removed at the same

time with the bearing removal tool.

(4) Remove the axle shaft bearing from the tube

(Fig. 8) with Bearing Removal Tool Set 6310 (T.Ar

960-02).

(5) Inspect the axle shaft tube bore for roughness

and burrs. Remove as necessary.

CAUTION: Inspect the housing bore for burrs. Re-

move them if they exist.

INSTALLATION

Do not install the original axle shaft seal. Al-

ways install a new seal.

(1) Wipe the bore in the axle shaft tube clean.

(2) Install axle shaft bearing with Installer 6436

and Handle C-4171. Ensure part number on the

bearing must go against the Installer.

(3) Install the new axle shaft seal (Fig. 9) with In-

staller 6437 and Handle C-4171.

(4) Install the Axle Shaft. Refer to the installation

procedure.

Fig. 6 Mate Shaft Lock Screw

Fig. 7 Axle Shaft C-Clip Lock

Fig. 8 Axle Shaft Bearing Removal Tool

JREAR SUSPENSION AND AXLES 3 - 17

Page 139 of 2158

(6) If removed, heat ring gear with a heat lamp or

by immersing in a hot fluid. The temperature should

not exceed 149ÉC (300ÉF).Do not use a torch to

heat the ring gear.

(7) Position heated rear gear on case. Use two

equally spaced Pilot Studs C-3288-B to align the gear

with the flange holes (Fig. 18).

(8) Install replacement ring gear bolts (with left

hand threads). Alternately and evenly tighten each

bolt to 95 Nzm (70 ft. lbs.) torque.

CAUTION: When installing a differential bearing,

never apply force to the bearing cage because bear-

ing damage will result.

(9) Install a differential bearing on each hub with

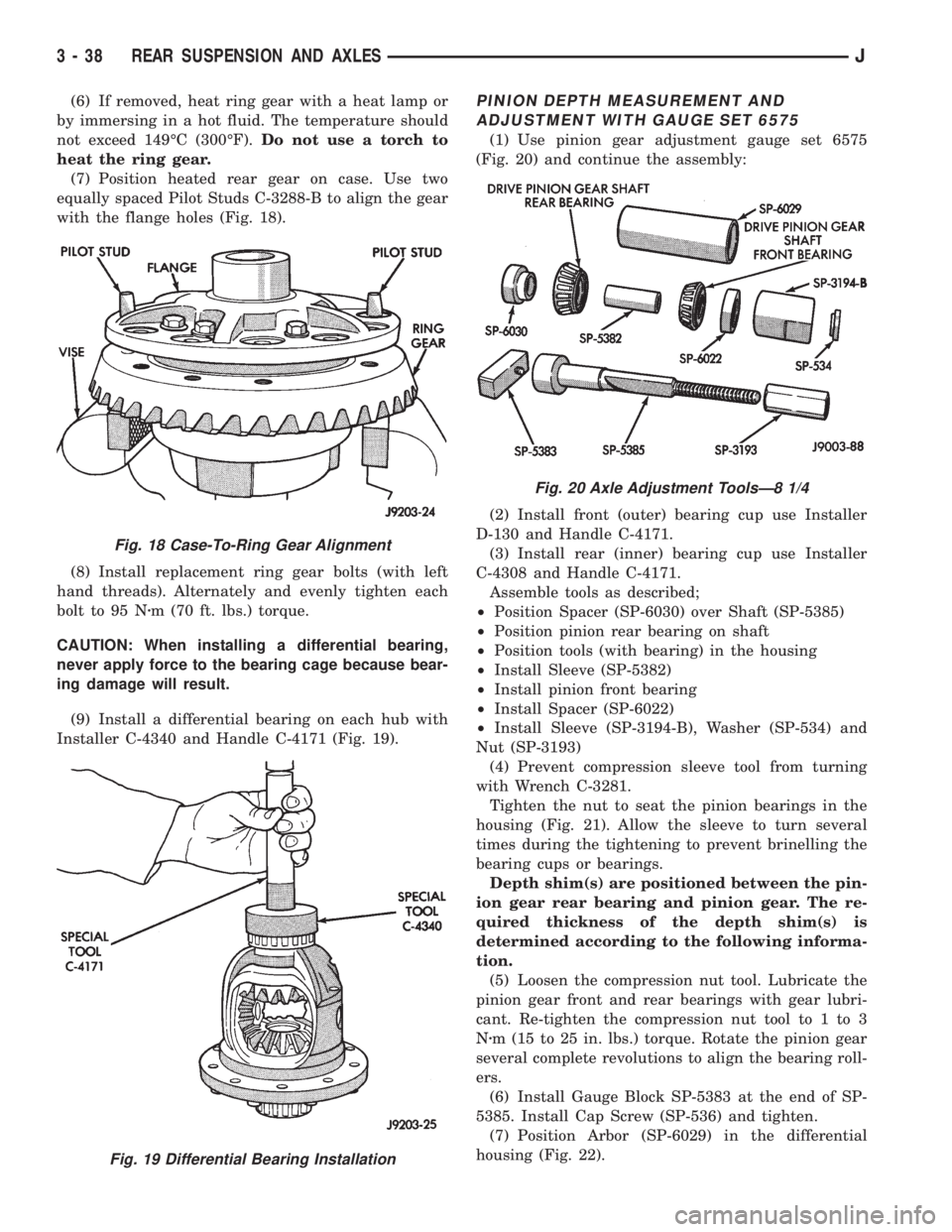

Installer C-4340 and Handle C-4171 (Fig. 19).PINION DEPTH MEASUREMENT AND

ADJUSTMENT WITH GAUGE SET 6575

(1) Use pinion gear adjustment gauge set 6575

(Fig. 20) and continue the assembly:

(2) Install front (outer) bearing cup use Installer

D-130 and Handle C-4171.

(3) Install rear (inner) bearing cup use Installer

C-4308 and Handle C-4171.

Assemble tools as described;

²Position Spacer (SP-6030) over Shaft (SP-5385)

²Position pinion rear bearing on shaft

²Position tools (with bearing) in the housing

²Install Sleeve (SP-5382)

²Install pinion front bearing

²Install Spacer (SP-6022)

²Install Sleeve (SP-3194-B), Washer (SP-534) and

Nut (SP-3193)

(4) Prevent compression sleeve tool from turning

with Wrench C-3281.

Tighten the nut to seat the pinion bearings in the

housing (Fig. 21). Allow the sleeve to turn several

times during the tightening to prevent brinelling the

bearing cups or bearings.

Depth shim(s) are positioned between the pin-

ion gear rear bearing and pinion gear. The re-

quired thickness of the depth shim(s) is

determined according to the following informa-

tion.

(5) Loosen the compression nut tool. Lubricate the

pinion gear front and rear bearings with gear lubri-

cant. Re-tighten the compression nut tool to 1 to 3

Nzm (15 to 25 in. lbs.) torque. Rotate the pinion gear

several complete revolutions to align the bearing roll-

ers.

(6) Install Gauge Block SP-5383 at the end of SP-

5385. Install Cap Screw (SP-536) and tighten.

(7) Position Arbor (SP-6029) in the differential

housing (Fig. 22).

Fig. 18 Case-To-Ring Gear Alignment

Fig. 19 Differential Bearing Installation

Fig. 20 Axle Adjustment ToolsÐ8 1/4

3 - 38 REAR SUSPENSION AND AXLESJ

Page 237 of 2158

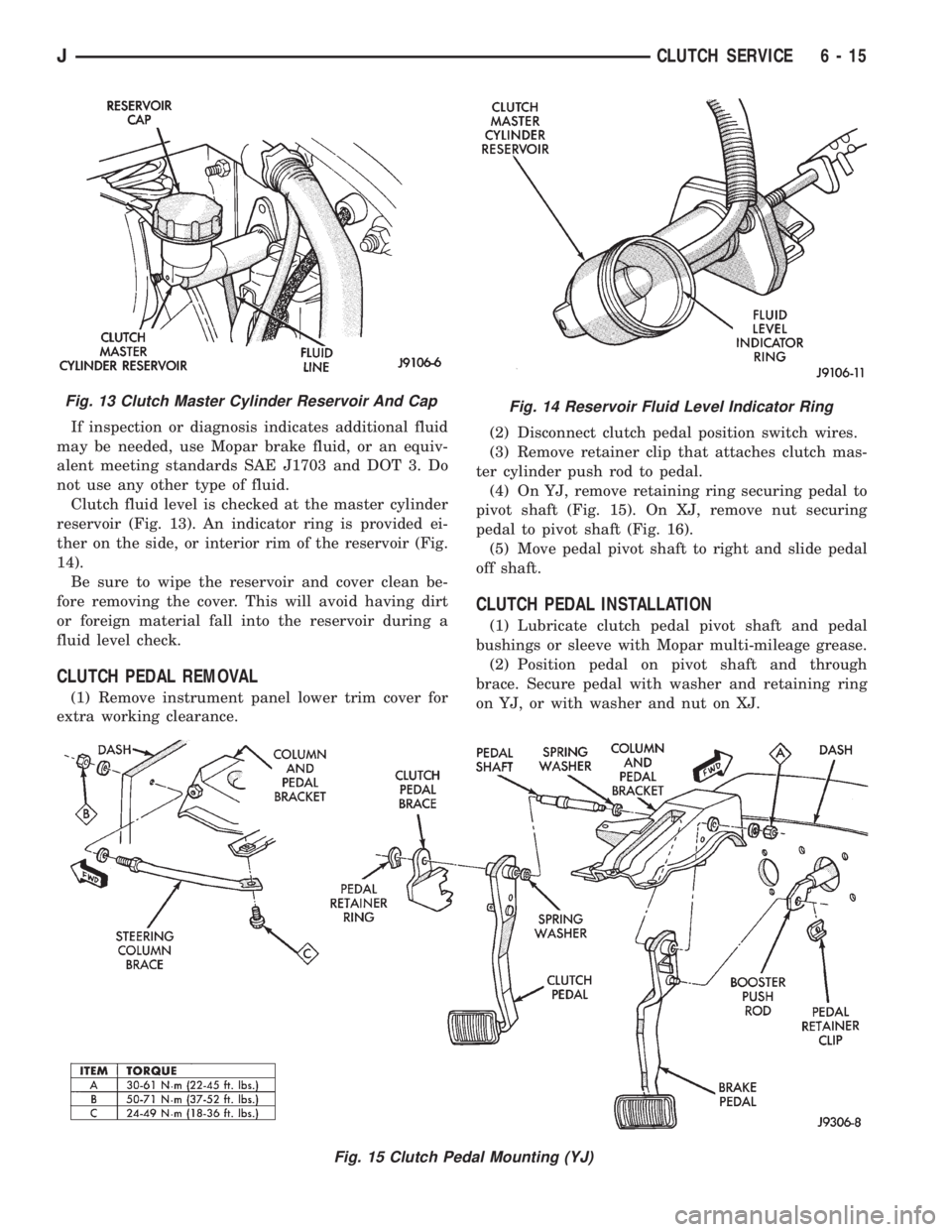

If inspection or diagnosis indicates additional fluid

may be needed, use Mopar brake fluid, or an equiv-

alent meeting standards SAE J1703 and DOT 3. Do

not use any other type of fluid.

Clutch fluid level is checked at the master cylinder

reservoir (Fig. 13). An indicator ring is provided ei-

ther on the side, or interior rim of the reservoir (Fig.

14).

Be sure to wipe the reservoir and cover clean be-

fore removing the cover. This will avoid having dirt

or foreign material fall into the reservoir during a

fluid level check.

CLUTCH PEDAL REMOVAL

(1) Remove instrument panel lower trim cover for

extra working clearance.(2) Disconnect clutch pedal position switch wires.

(3) Remove retainer clip that attaches clutch mas-

ter cylinder push rod to pedal.

(4) On YJ, remove retaining ring securing pedal to

pivot shaft (Fig. 15). On XJ, remove nut securing

pedal to pivot shaft (Fig. 16).

(5) Move pedal pivot shaft to right and slide pedal

off shaft.

CLUTCH PEDAL INSTALLATION

(1) Lubricate clutch pedal pivot shaft and pedal

bushings or sleeve with Mopar multi-mileage grease.

(2) Position pedal on pivot shaft and through

brace. Secure pedal with washer and retaining ring

on YJ, or with washer and nut on XJ.

Fig. 13 Clutch Master Cylinder Reservoir And CapFig. 14 Reservoir Fluid Level Indicator Ring

Fig. 15 Clutch Pedal Mounting (YJ)

JCLUTCH SERVICE 6 - 15

Page 329 of 2158

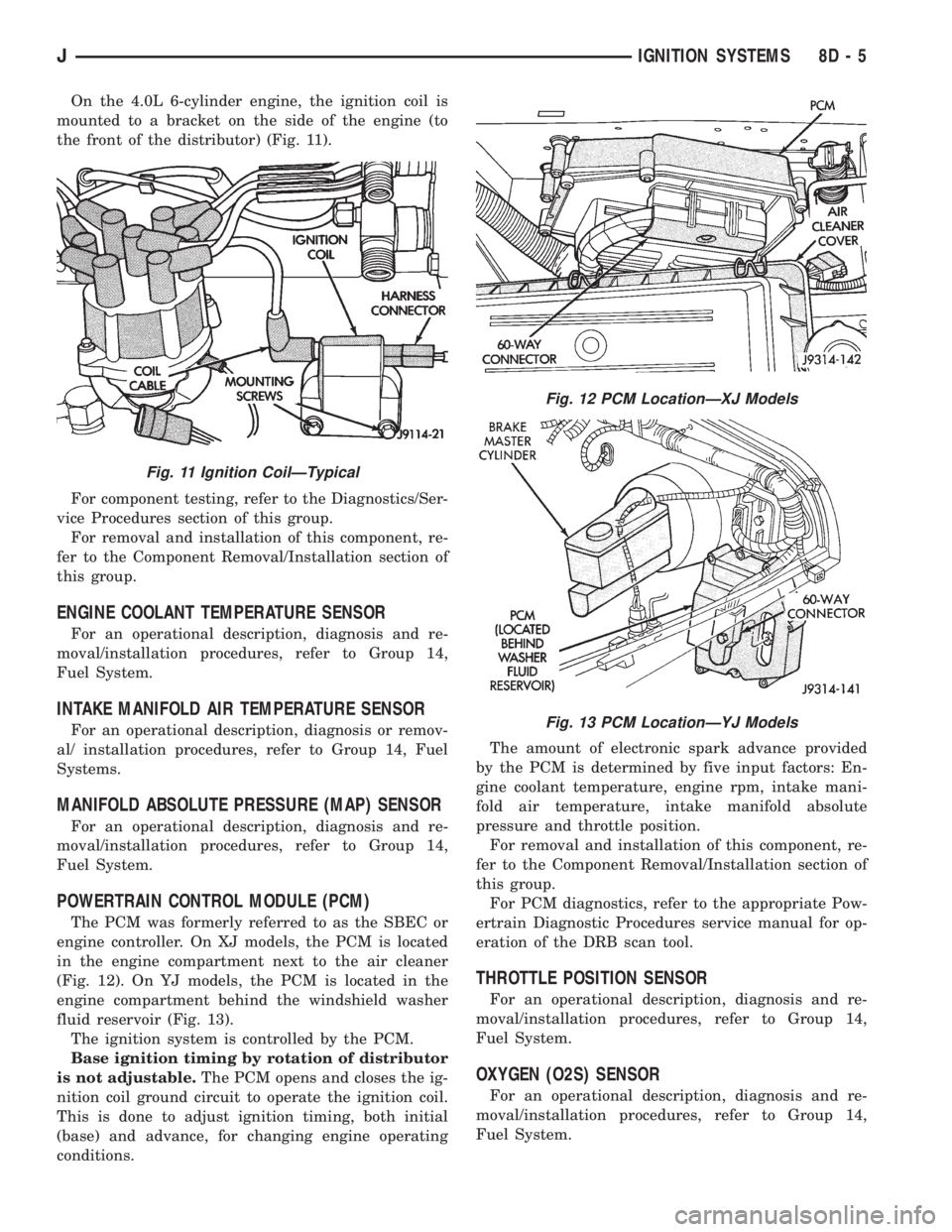

On the 4.0L 6-cylinder engine, the ignition coil is

mounted to a bracket on the side of the engine (to

the front of the distributor) (Fig. 11).

For component testing, refer to the Diagnostics/Ser-

vice Procedures section of this group.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

ENGINE COOLANT TEMPERATURE SENSOR

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

For an operational description, diagnosis or remov-

al/ installation procedures, refer to Group 14, Fuel

Systems.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

POWERTRAIN CONTROL MODULE (PCM)

The PCM was formerly referred to as the SBEC or

engine controller. On XJ models, the PCM is located

in the engine compartment next to the air cleaner

(Fig. 12). On YJ models, the PCM is located in the

engine compartment behind the windshield washer

fluid reservoir (Fig. 13).

The ignition system is controlled by the PCM.

Base ignition timing by rotation of distributor

is not adjustable.The PCM opens and closes the ig-

nition coil ground circuit to operate the ignition coil.

This is done to adjust ignition timing, both initial

(base) and advance, for changing engine operating

conditions.The amount of electronic spark advance provided

by the PCM is determined by five input factors: En-

gine coolant temperature, engine rpm, intake mani-

fold air temperature, intake manifold absolute

pressure and throttle position.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

For PCM diagnostics, refer to the appropriate Pow-

ertrain Diagnostic Procedures service manual for op-

eration of the DRB scan tool.

THROTTLE POSITION SENSOR

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

OXYGEN (O2S) SENSOR

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

Fig. 11 Ignition CoilÐTypical

Fig. 12 PCM LocationÐXJ Models

Fig. 13 PCM LocationÐYJ Models

JIGNITION SYSTEMS 8D - 5

Page 335 of 2158

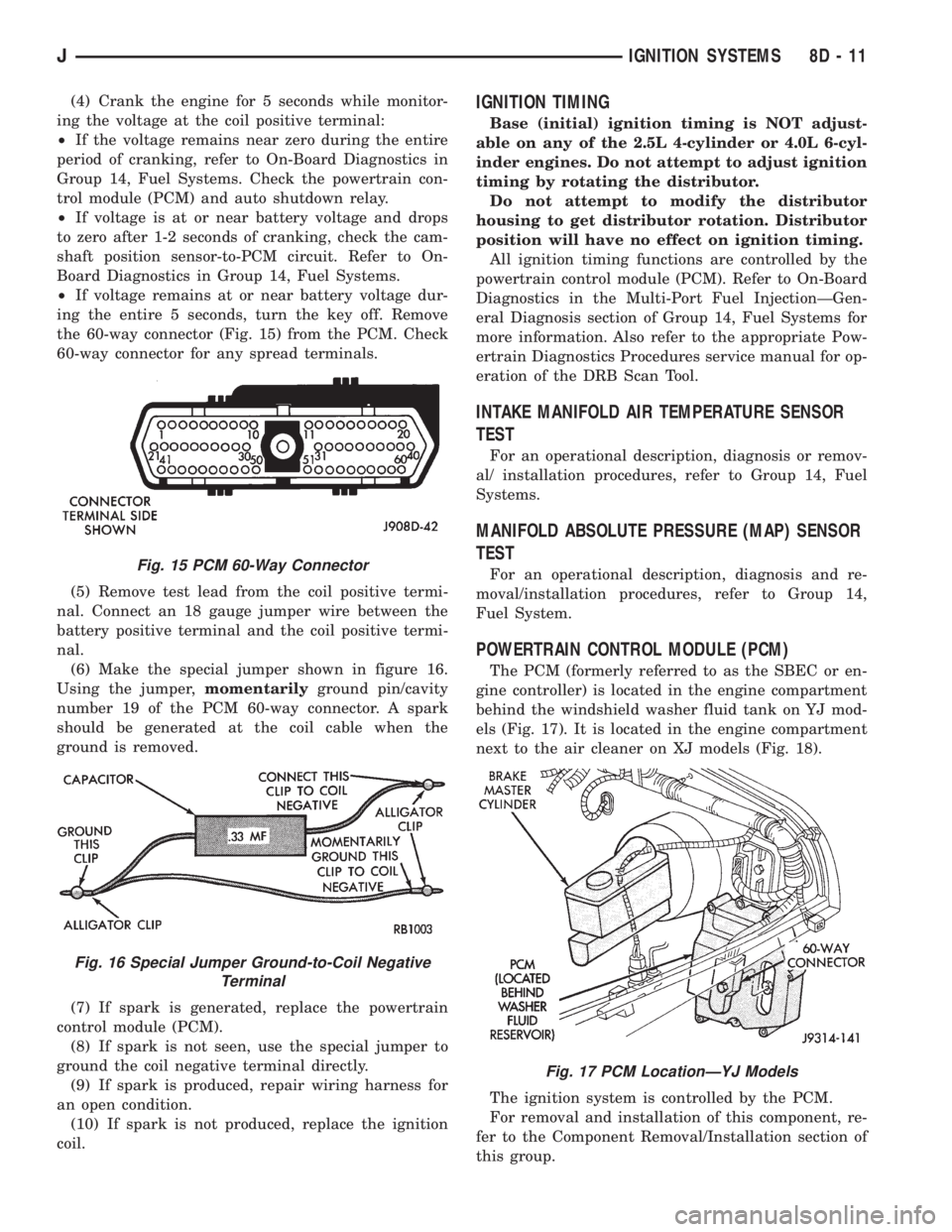

(4) Crank the engine for 5 seconds while monitor-

ing the voltage at the coil positive terminal:

²If the voltage remains near zero during the entire

period of cranking, refer to On-Board Diagnostics in

Group 14, Fuel Systems. Check the powertrain con-

trol module (PCM) and auto shutdown relay.

²If voltage is at or near battery voltage and drops

to zero after 1-2 seconds of cranking, check the cam-

shaft position sensor-to-PCM circuit. Refer to On-

Board Diagnostics in Group 14, Fuel Systems.

²If voltage remains at or near battery voltage dur-

ing the entire 5 seconds, turn the key off. Remove

the 60-way connector (Fig. 15) from the PCM. Check

60-way connector for any spread terminals.

(5) Remove test lead from the coil positive termi-

nal. Connect an 18 gauge jumper wire between the

battery positive terminal and the coil positive termi-

nal.

(6) Make the special jumper shown in figure 16.

Using the jumper,momentarilyground pin/cavity

number 19 of the PCM 60-way connector. A spark

should be generated at the coil cable when the

ground is removed.

(7) If spark is generated, replace the powertrain

control module (PCM).

(8) If spark is not seen, use the special jumper to

ground the coil negative terminal directly.

(9) If spark is produced, repair wiring harness for

an open condition.

(10) If spark is not produced, replace the ignition

coil.IGNITION TIMING

Base (initial) ignition timing is NOT adjust-

able on any of the 2.5L 4-cylinder or 4.0L 6-cyl-

inder engines. Do not attempt to adjust ignition

timing by rotating the distributor.

Do not attempt to modify the distributor

housing to get distributor rotation. Distributor

position will have no effect on ignition timing.

All ignition timing functions are controlled by the

powertrain control module (PCM). Refer to On-Board

Diagnostics in the Multi-Port Fuel InjectionÐGen-

eral Diagnosis section of Group 14, Fuel Systems for

more information. Also refer to the appropriate Pow-

ertrain Diagnostics Procedures service manual for op-

eration of the DRB Scan Tool.

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

TEST

For an operational description, diagnosis or remov-

al/ installation procedures, refer to Group 14, Fuel

Systems.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

TEST

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

POWERTRAIN CONTROL MODULE (PCM)

The PCM (formerly referred to as the SBEC or en-

gine controller) is located in the engine compartment

behind the windshield washer fluid tank on YJ mod-

els (Fig. 17). It is located in the engine compartment

next to the air cleaner on XJ models (Fig. 18).

The ignition system is controlled by the PCM.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

Fig. 15 PCM 60-Way Connector

Fig. 16 Special Jumper Ground-to-Coil Negative

Terminal

Fig. 17 PCM LocationÐYJ Models

JIGNITION SYSTEMS 8D - 11

Page 347 of 2158

(3) Remove ignition coil mounting bolts (nuts are

used on back side of bracket). Remove coil.

INSTALLATION

(1) Install ignition coil to bracket on cylinder block

with mounting bolts and nuts.

(2) Connect engine harness connector to coil.

(3) Connect ignition coil cable to ignition coil.

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

For an operational description, diagnosis or remov-

al/ installation procedures, refer to Group 14, Fuel

Systems.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

OXYGEN (O2S) SENSOR

For an operational description, diagnosis or remov-

al/ installation procedures, refer to Group 14, Fuel

Systems.

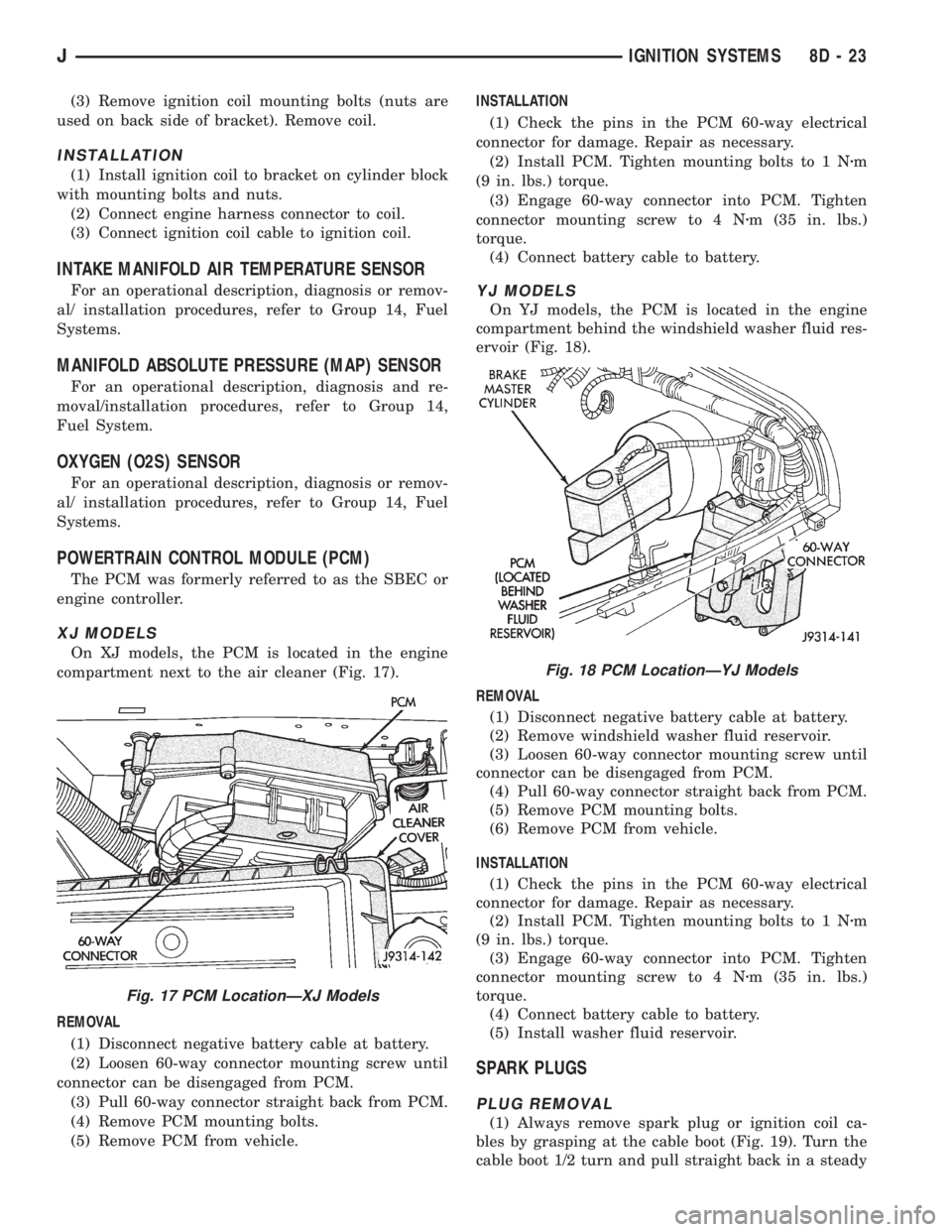

POWERTRAIN CONTROL MODULE (PCM)

The PCM was formerly referred to as the SBEC or

engine controller.

XJ MODELS

On XJ models, the PCM is located in the engine

compartment next to the air cleaner (Fig. 17).

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Loosen 60-way connector mounting screw until

connector can be disengaged from PCM.

(3) Pull 60-way connector straight back from PCM.

(4) Remove PCM mounting bolts.

(5) Remove PCM from vehicle.INSTALLATION

(1) Check the pins in the PCM 60-way electrical

connector for damage. Repair as necessary.

(2) Install PCM. Tighten mounting bolts to 1 Nzm

(9 in. lbs.) torque.

(3) Engage 60-way connector into PCM. Tighten

connector mounting screw to 4 Nzm (35 in. lbs.)

torque.

(4) Connect battery cable to battery.

YJ MODELS

On YJ models, the PCM is located in the engine

compartment behind the windshield washer fluid res-

ervoir (Fig. 18).

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Remove windshield washer fluid reservoir.

(3) Loosen 60-way connector mounting screw until

connector can be disengaged from PCM.

(4) Pull 60-way connector straight back from PCM.

(5) Remove PCM mounting bolts.

(6) Remove PCM from vehicle.

INSTALLATION

(1) Check the pins in the PCM 60-way electrical

connector for damage. Repair as necessary.

(2) Install PCM. Tighten mounting bolts to 1 Nzm

(9 in. lbs.) torque.

(3) Engage 60-way connector into PCM. Tighten

connector mounting screw to 4 Nzm (35 in. lbs.)

torque.

(4) Connect battery cable to battery.

(5) Install washer fluid reservoir.

SPARK PLUGS

PLUG REMOVAL

(1) Always remove spark plug or ignition coil ca-

bles by grasping at the cable boot (Fig. 19). Turn the

cable boot 1/2 turn and pull straight back in a steady

Fig. 17 PCM LocationÐXJ Models

Fig. 18 PCM LocationÐYJ Models

JIGNITION SYSTEMS 8D - 23

Page 357 of 2158

INSTRUMENT PANEL AND GAUGES

GROUP INDEX

INSTRUMENT PANEL AND GAUGESÐXJ...... 1INSTRUMENT PANEL AND GAUGESÐYJ..... 24

INSTRUMENT PANEL AND GAUGESÐXJ

CONTENTS

page page

DIAGNOSIS............................. 5

GENERAL INFORMATION.................. 1SERVICE PROCEDURES.................. 17

SPECIFICATIONS........................ 23

GENERAL INFORMATION

Following are general descriptions of major instru-

ment panel components. Refer to Group 8W - Wiring

Diagrams for complete circuit descriptions and dia-

grams.

INSTRUMENT PANEL

Modular instrument panel construction allows all

gauges and controls to be serviced from the front of

the panel. In addition, most instrument panel wiring

or heater and air conditioning components can be ac-

cessed without complete instrument panel removal. If

necessary, the instrument panel can be rolled-down

and removed from the vehicle as an assembly.

Removal of the instrument cluster bezel allows ac-

cess to the cluster assembly, most switches, the cli-

mate controls, and the radio. Removal of the cluster

assembly allows access to the individual gauges, illu-

mination and indicator lamp bulbs, printed circuits,

and most wiring.

Removal of the lower instrument panel allows ac-

cess to heater and air conditioning components, the

fuseblock module, the relay center, and other wiring

and electrical components. Those models equipped

with a driver's-side airbag restraint have a knee

blocker and reinforcement behind the driver's-side

lower instrument panel.

The instrument panel layout is mirror image for

left-hand and right-hand drive vehicles. In most

cases, the diagnosis and service procedures found in

this group are applicable to either vehicle. Although,most illustrations represent only the typical left-hand

drive version. Exceptions are clearly identified as

Right-Hand Drive (RHD).

INSTRUMENT CLUSTERS

Two basic instrument cluster options are offered on

XJ (Cherokee) models. One is referred to as a low-

line cluster, and the other is referred to as a high-

line cluster. Each cluster is divided into two areas:

the gauge area, and the tell-tale area. Each area is

served by a separate printed circuit and wiring con-

nector. Some variations of each cluster exist due to

optional equipment and regulatory requirements.

The low-line cluster includes the following gauges:

²fuel gauge

²speedometer/odometer.

The low-line cluster includes provisions for the fol-

lowing indicator lamps:

²anti-lock brake system lamp

²brake warning lamp

²coolant temperature warning lamp

²four-wheel drive indicator lamps

²generator warning lamp

²headlamp high beam indicator lamp

²low oil pressure warning lamp

²low washer fluid warning lamp

²malfunction indicator (Check Engine) lamp

²seat belt reminder lamp

²turn signal indicator lamps

²upshift indicator lamp.

JINSTRUMENT PANEL AND GAUGES 8E - 1

Page 358 of 2158

The high-line cluster includes the following gauges:

²coolant temperature gauge

²fuel gauge

²oil pressure gauge

²speedometer/odometer

²tachometer

²trip odometer

²voltmeter.

The high-line cluster includes provisions for the fol-

lowing indicator lamps:

²anti-lock brake system lamp

²brake warning lamp

²four-wheel drive indicator lamps

²headlamp high beam indicator lamp

²low fuel warning lamp

²low washer fluid warning lamp

²malfunction indicator (Check Engine) lamp

²seat belt reminder lamp

²turn signal indicator lamps

²upshift indicator lamp.

GAUGES

With the ignition switch in the ON or START posi-

tion, voltage is supplied to all gauges through the in-

strument cluster gauge area printed circuit. With the

ignition switch in the OFF position, voltage is not

supplied to the gauges. A gauge pointer may remain

within the gauge scale after the ignition switch is

OFF. However, the gauges do not accurately indicate

any vehicle condition unless the ignition switch is

ON.

All gauges except the odometer are air core mag-

netic units. Two fixed electromagnetic coils are lo-

cated within the gauge. These coils are wrapped at

right angles to each other around a movable perma-

nent magnet. The movable magnet is suspended

within the coils on one end of a shaft. The gauge nee-

dle is attached to the other end of the shaft.

One of the coils has a fixed current flowing through

it to maintain a constant magnetic field strength.

Current flow through the second coil changes, which

causes changes in its magnetic field strength. The

current flowing through the second coil can be

changed by:

²a variable resistor-type sending unit (fuel level,

coolant temperature, or oil pressure)

²changes in electrical system voltage (voltmeter)

²electronic control circuitry (speedometer/odometer,

tachometer).

The gauge needle moves as the movable permanent

magnet aligns itself to the changing magnetic fields

created around it by the electromagnets.

COOLANT TEMPERATURE GAUGE

The coolant temperature gauge gives an indication

of engine coolant temperature. The coolant tempera-

ture sending unit is a thermistor that changes elec-

trical resistance with changes in engine coolanttemperature. High sending unit resistance causes

low coolant temperature readings. Low resistance

causes high coolant temperature readings.

The gauge will read at the high end of the scale

when the ignition switch is turned to the START po-

sition. This is caused by the bulb test circuit wiring

provision. The same wiring is used for the high-line

cluster with a coolant temperature gauge and the

low-line cluster with a coolant temperature warning

lamp. Sending unit resistance values are shown in a

chart in Specifications.

FUEL GAUGE

The fuel gauge gives an indication of the level of

fuel in the fuel tank. The fuel gauge sending unit has

a float attached to a swing-arm in the fuel tank. The

float moves up or down within the fuel tank as fuel

level changes. As the float moves, an electrical con-

tact on the swing-arm wipes across a resistor coil,

which changes sending unit resistance. High sending

unit resistance causes low fuel level readings. Low

resistance causes high fuel level readings. Sending

unit resistance values are shown in a chart in Spec-

ifications.

OIL PRESSURE GAUGE

The oil pressure gauge gives an indication of en-

gine oil pressure. The combination oil pressure send-

ing unit contains a flexible diaphragm. The

diaphragm moves in response to changes in engine

oil pressure. As the diaphragm moves, sending unit

resistance increases or decreases. High resistance on

the gauge side of the sending unit causes high oil

pressure readings. Low resistance causes low oil

pressure readings. Sending unit resistance values are

shown in a chart in Specifications.

SPEEDOMETER/ODOMETER

The speedometer/odometer gives an indication of

vehicle speed and travel distance. The speedometer

receives a vehicle speed pulse signal from the Vehicle

Speed Sensor (VSS). An electronic integrated circuit

contained within the speedometer reads and analyzes

the pulse signal. It then adjusts the ground path re-

sistance of one electromagnet in the gauge to control

needle movement. It also sends signals to an electric

stepper motor to control movement of the odometer

number rolls. Frequency values for the pulse signal

are shown in a chart in Specifications.

The VSS is mounted to an adapter near the trans-

mission (two-wheel drive) or transfer case (four-wheel

drive) output shaft. The sensor is driven through the

adapter by a speedometer pinion gear. The adapter

and pinion vary with transmission, transfer case,

axle ratio and tire size. Refer to Group 21 - Trans-

mission and Transfer Case for more information.

8E - 2 INSTRUMENT PANEL AND GAUGESÐXJJ