JEEP YJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 171 of 2158

(17) Remove nuts attaching master cylinder to

booster studs and remove cylinder (Fig. 16).

(18) Remove master cylinder reservoir cap and

drain fluid.

RESERVOIR REPLACEMENT (2-PIECE MASTER

CYLINDER)

(1) Remove reservoir cap and empty fluid into

drain container.

(2) Remove pins that retain reservoir to master

cylinder. Use hammer and pin punch to remove pins

(Fig. 17).

(3) Clamp cylinder body in vise with brass protec-

tive jaws.

(4) Loosen reservoir from grommets with pry tool

(Fig. 18).

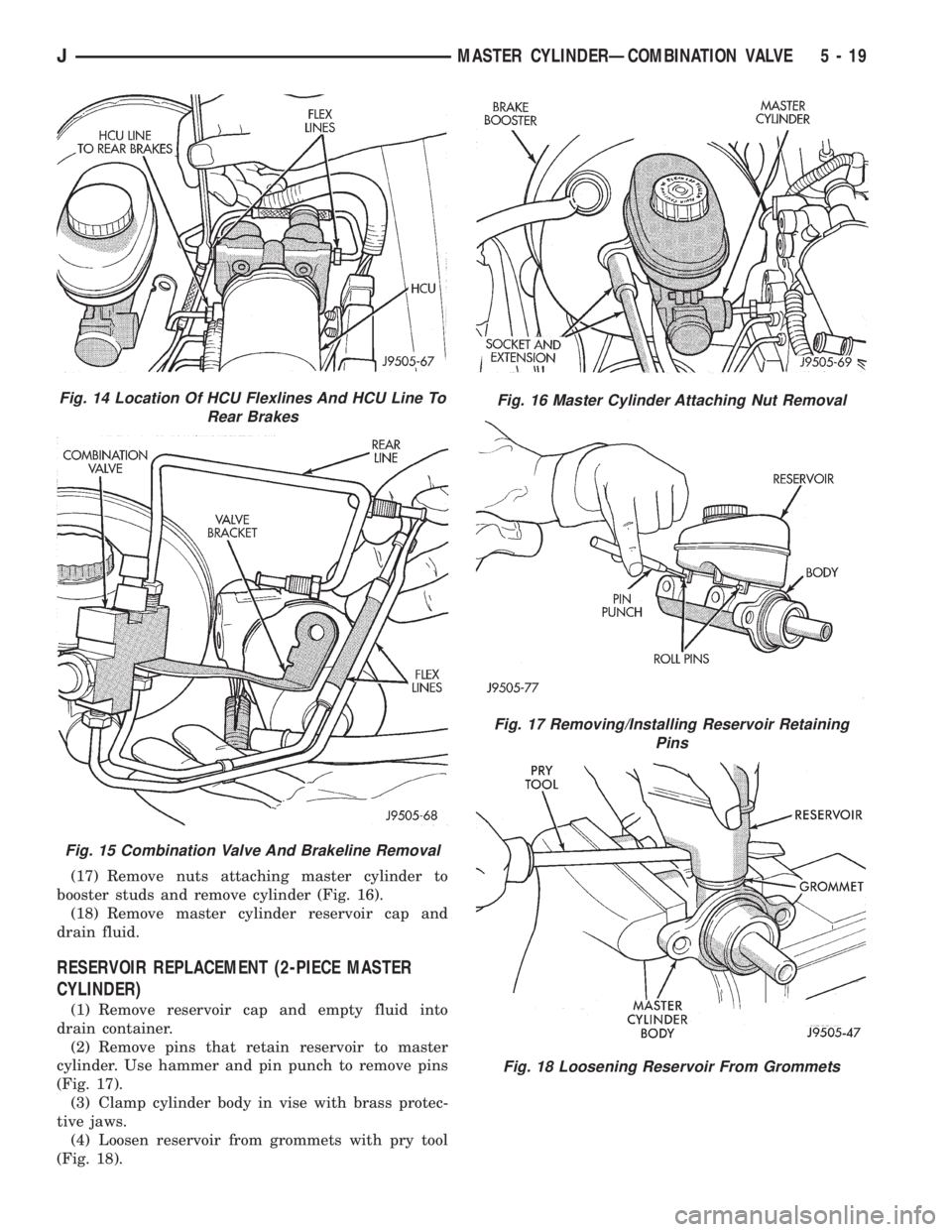

Fig. 14 Location Of HCU Flexlines And HCU Line To

Rear Brakes

Fig. 15 Combination Valve And Brakeline Removal

Fig. 16 Master Cylinder Attaching Nut Removal

Fig. 17 Removing/Installing Reservoir Retaining

Pins

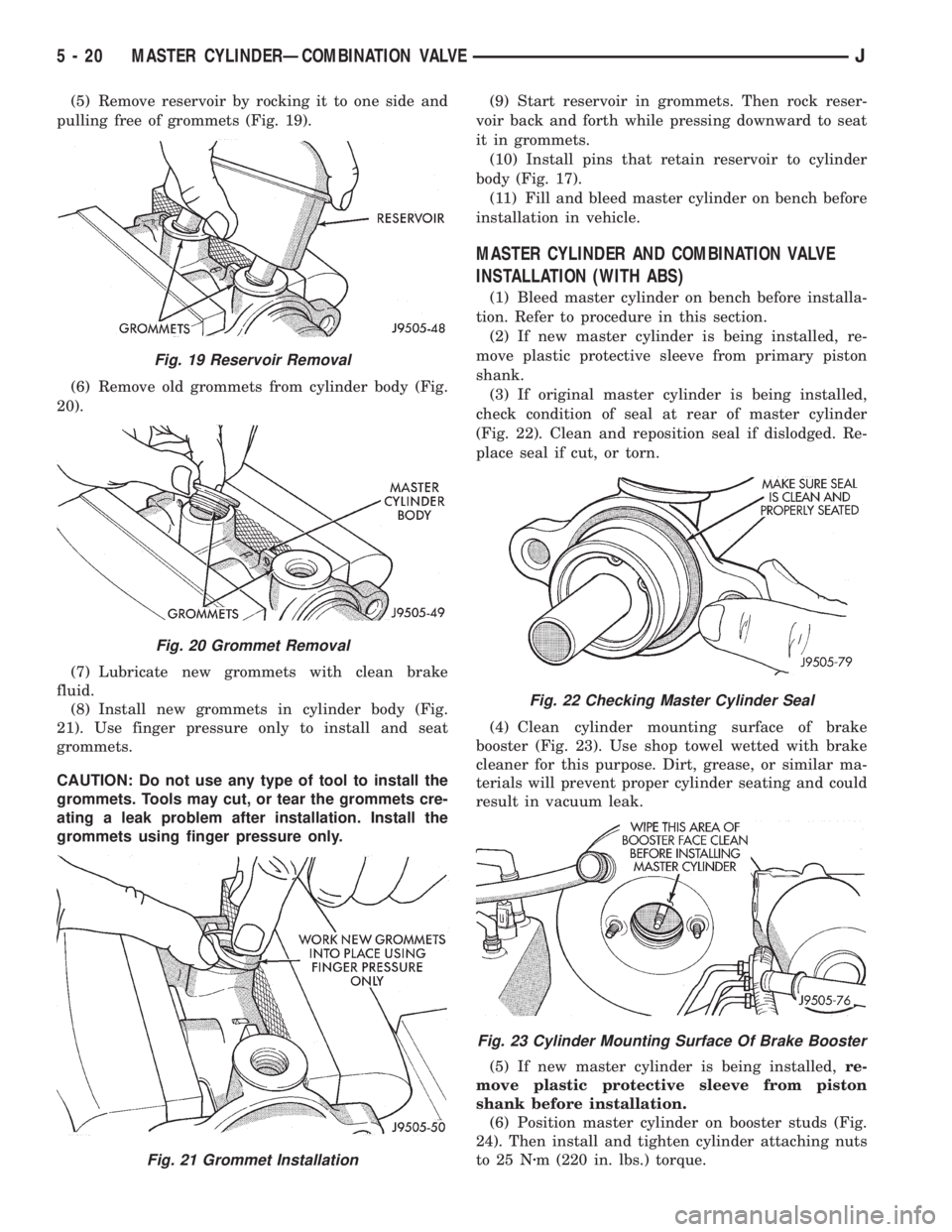

Fig. 18 Loosening Reservoir From Grommets

JMASTER CYLINDERÐCOMBINATION VALVE 5 - 19

Page 172 of 2158

(5) Remove reservoir by rocking it to one side and

pulling free of grommets (Fig. 19).

(6) Remove old grommets from cylinder body (Fig.

20).

(7) Lubricate new grommets with clean brake

fluid.

(8) Install new grommets in cylinder body (Fig.

21). Use finger pressure only to install and seat

grommets.

CAUTION: Do not use any type of tool to install the

grommets. Tools may cut, or tear the grommets cre-

ating a leak problem after installation. Install the

grommets using finger pressure only.(9) Start reservoir in grommets. Then rock reser-

voir back and forth while pressing downward to seat

it in grommets.

(10) Install pins that retain reservoir to cylinder

body (Fig. 17).

(11) Fill and bleed master cylinder on bench before

installation in vehicle.

MASTER CYLINDER AND COMBINATION VALVE

INSTALLATION (WITH ABS)

(1) Bleed master cylinder on bench before installa-

tion. Refer to procedure in this section.

(2) If new master cylinder is being installed, re-

move plastic protective sleeve from primary piston

shank.

(3) If original master cylinder is being installed,

check condition of seal at rear of master cylinder

(Fig. 22). Clean and reposition seal if dislodged. Re-

place seal if cut, or torn.

(4) Clean cylinder mounting surface of brake

booster (Fig. 23). Use shop towel wetted with brake

cleaner for this purpose. Dirt, grease, or similar ma-

terials will prevent proper cylinder seating and could

result in vacuum leak.

(5) If new master cylinder is being installed,re-

move plastic protective sleeve from piston

shank before installation.

(6) Position master cylinder on booster studs (Fig.

24). Then install and tighten cylinder attaching nuts

to 25 Nzm (220 in. lbs.) torque.

Fig. 19 Reservoir Removal

Fig. 20 Grommet Removal

Fig. 21 Grommet Installation

Fig. 22 Checking Master Cylinder Seal

Fig. 23 Cylinder Mounting Surface Of Brake Booster

5 - 20 MASTER CYLINDERÐCOMBINATION VALVEJ

Page 173 of 2158

(7) Install combination valve as follows:

(a) Work combination valve and brakelines into

position.

(b) Slide combination valve bracket onto booster

stud closest to driver side fender (Fig. 25). Then in-

stall bracket attaching nut but do not fully tighten

nut at this time.

(c) Connect flex lines to HCU. Start lines by

hand to avoid cross threading.

(8) Swing rear brakeline around and connect it to

master cylinder. Then install and connect frontbrakeline to combination valve and master cylinder.

Start brakelines by hand to avoid cross threading.

(9) Tighten combination valve bracket attaching

nut to 25 Nzm (220 in. lbs.) torque.

(10) Install S-clip on lines from master cylinder to

combination valve.

(11) Connect wire to pressure differential switch in

combination valve.

(12) Fill and bleed brake system.

(13) Tighten brakeline fittings to 15-18 Nzm (130-

160 in. lbs.) at HCU and master cylinder and to

18-24 Nzm (160-210 in. lbs.) at combination valve.

(14) Connect brake booster and canister vacuum

hoses to manifold fittings.

(15) Install air cleaner housing, filter, cover, and

hose.

(16) Connect PCV hose.MASTER CYLINDER BENCH BLEEDING

The bench bleeding procedure for both master cyl-

inder types is basically the same. The only difference,

is that both bleed tubes go in the same filler neck

opening on cylinders with the nylon reservoir.

(1) On models with integral master cylinder, fill

each reservoir to within 6 mm (1/4 in.) of rim. On

two-piece cylinder, fill reservoir to FULL mark.

(2) Fabricate and install master cylinder bleed

tubes. Be sure tube ends are submerged in brake

fluid. Tubes can be fabricated from rubber hose, or

copper tubing and spare brakeline fittings.

(3) Using push rod or wooden dowel (Fig. 26),

stroke cylinder pistons fully into bore;then allow pis-

tons to return under spring pressure. Repeat this op-

eration until air bubbles cease to appear in fluid.

(4) Remove bleed tubes, cap outlet ports, and in-

stall reservoir cap, or cover and seal.

Fig. 24 Master Cylinder Installation

Fig. 25 Combination Valve Installation

Fig. 26 Typical Method Of Bleeding Master Cylinder

(One-Piece Cylinder Shown)

JMASTER CYLINDERÐCOMBINATION VALVE 5 - 21

Page 174 of 2158

POWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCH

INDEX

page page

Brake Pedal Installation..................... 31

Brake Pedal Removal...................... 31

Brakelight Switch Adjustment................. 32

Brakelight Switch Installation................. 32

Brakelight Switch Removal.................. 32

General Information....................... 22

Power Brake Booster Installation (XJ with ABS) . . . 27

Power Brake Booster Installation (XJ Without ABS).. 30

Power Brake Booster Installation (YJ).......... 30

Power Brake Booster Operation.............. 23

Power Brake Booster Removal (XJ with ABS).... 24

Power Brake Booster Removal (XJ Without ABS) . . 29

Power Brake Booster Removal (YJ)............ 30

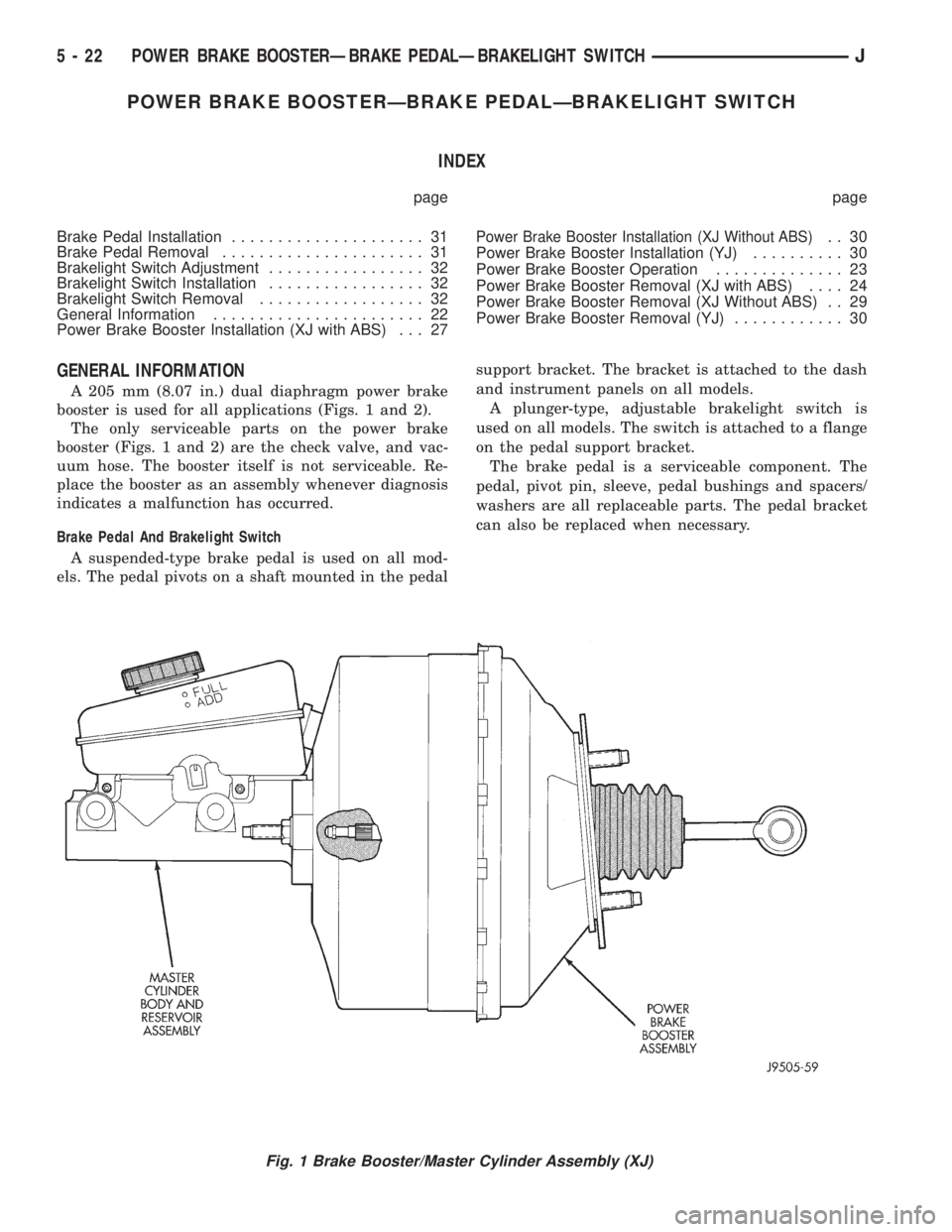

GENERAL INFORMATION

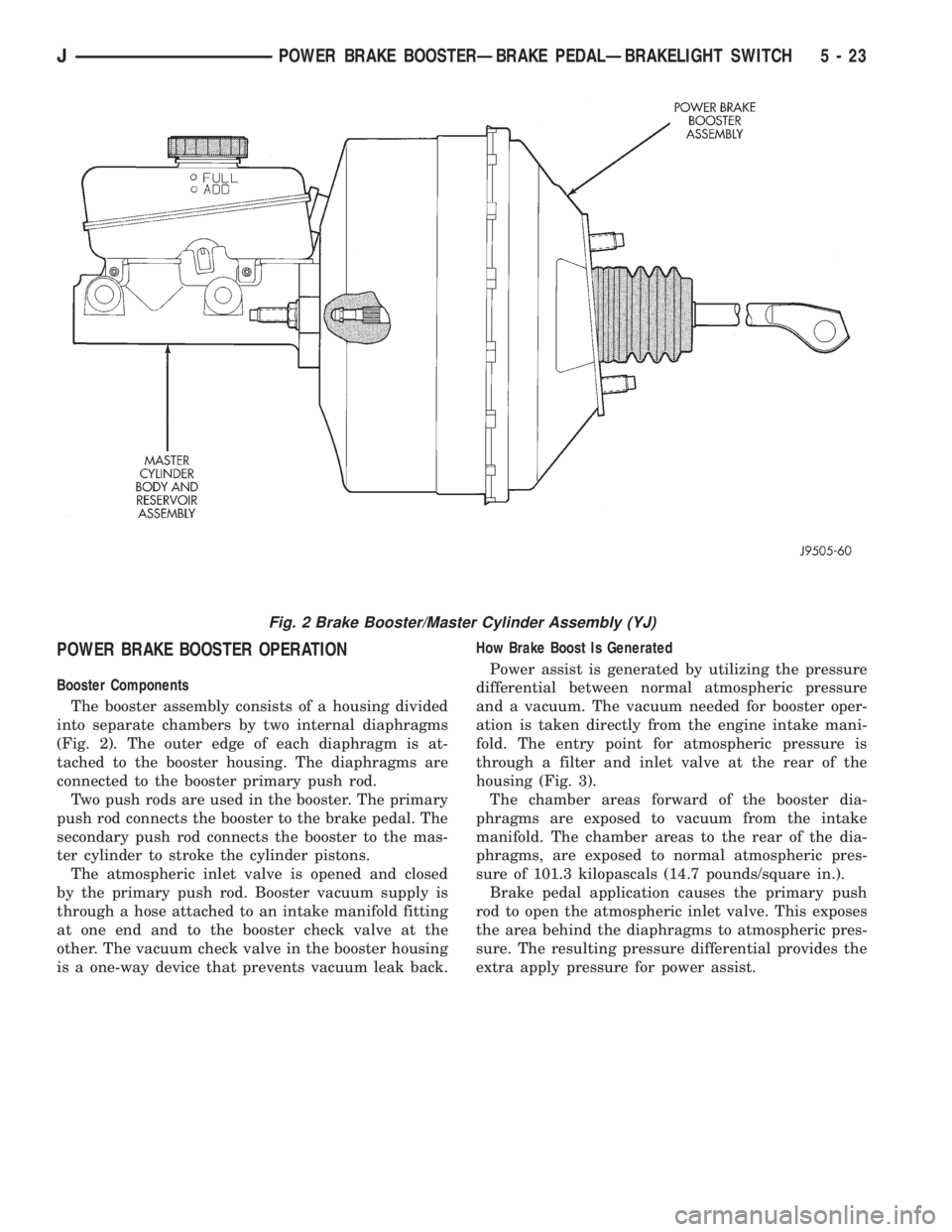

A 205 mm (8.07 in.) dual diaphragm power brake

booster is used for all applications (Figs. 1 and 2).

The only serviceable parts on the power brake

booster (Figs. 1 and 2) are the check valve, and vac-

uum hose. The booster itself is not serviceable. Re-

place the booster as an assembly whenever diagnosis

indicates a malfunction has occurred.

Brake Pedal And Brakelight Switch

A suspended-type brake pedal is used on all mod-

els. The pedal pivots on a shaft mounted in the pedalsupport bracket. The bracket is attached to the dash

and instrument panels on all models.

A plunger-type, adjustable brakelight switch is

used on all models. The switch is attached to a flange

on the pedal support bracket.

The brake pedal is a serviceable component. The

pedal, pivot pin, sleeve, pedal bushings and spacers/

washers are all replaceable parts. The pedal bracket

can also be replaced when necessary.

Fig. 1 Brake Booster/Master Cylinder Assembly (XJ)

5 - 22 POWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCHJ

Page 175 of 2158

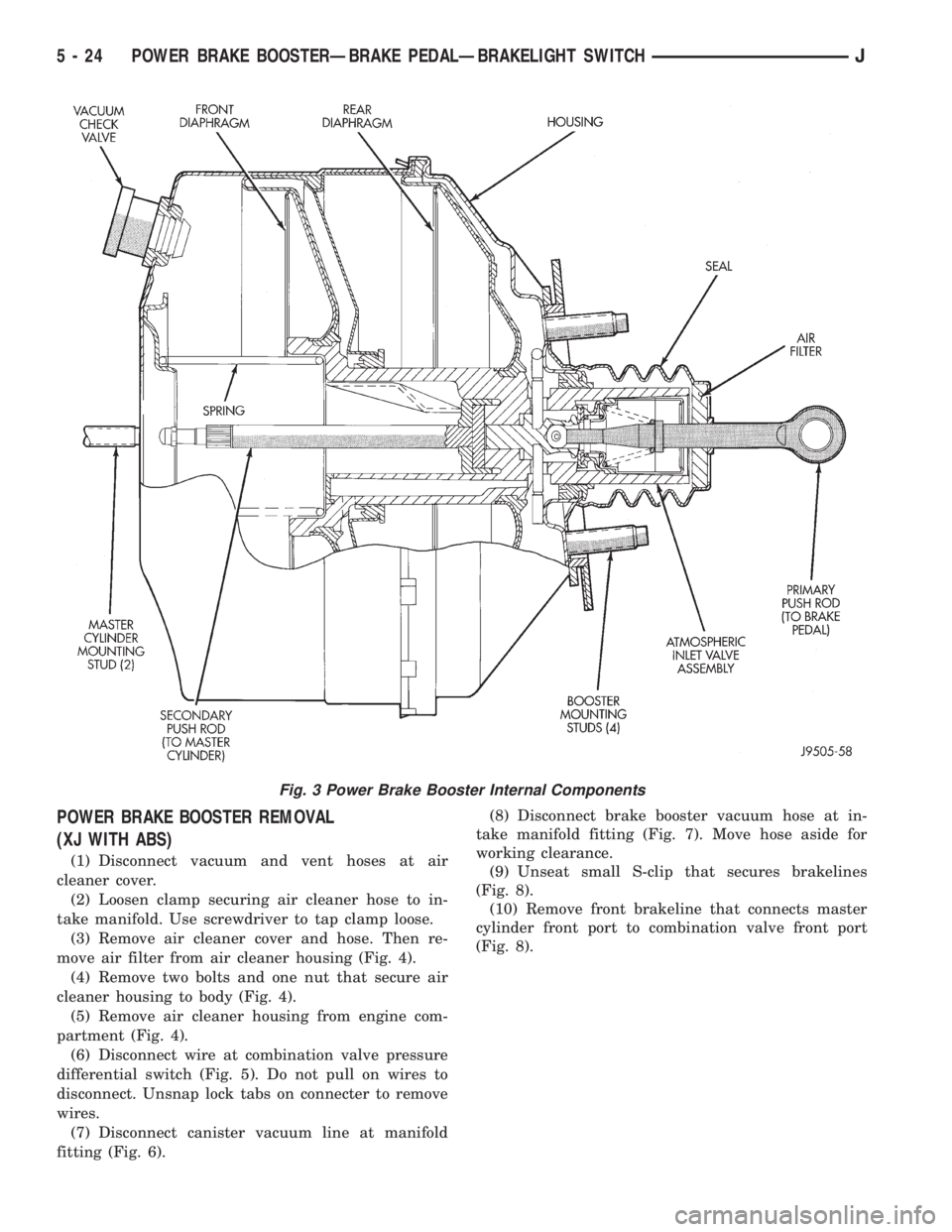

POWER BRAKE BOOSTER OPERATION

Booster Components

The booster assembly consists of a housing divided

into separate chambers by two internal diaphragms

(Fig. 2). The outer edge of each diaphragm is at-

tached to the booster housing. The diaphragms are

connected to the booster primary push rod.

Two push rods are used in the booster. The primary

push rod connects the booster to the brake pedal. The

secondary push rod connects the booster to the mas-

ter cylinder to stroke the cylinder pistons.

The atmospheric inlet valve is opened and closed

by the primary push rod. Booster vacuum supply is

through a hose attached to an intake manifold fitting

at one end and to the booster check valve at the

other. The vacuum check valve in the booster housing

is a one-way device that prevents vacuum leak back.How Brake Boost Is Generated

Power assist is generated by utilizing the pressure

differential between normal atmospheric pressure

and a vacuum. The vacuum needed for booster oper-

ation is taken directly from the engine intake mani-

fold. The entry point for atmospheric pressure is

through a filter and inlet valve at the rear of the

housing (Fig. 3).

The chamber areas forward of the booster dia-

phragms are exposed to vacuum from the intake

manifold. The chamber areas to the rear of the dia-

phragms, are exposed to normal atmospheric pres-

sure of 101.3 kilopascals (14.7 pounds/square in.).

Brake pedal application causes the primary push

rod to open the atmospheric inlet valve. This exposes

the area behind the diaphragms to atmospheric pres-

sure. The resulting pressure differential provides the

extra apply pressure for power assist.

Fig. 2 Brake Booster/Master Cylinder Assembly (YJ)

JPOWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCH 5 - 23

Page 176 of 2158

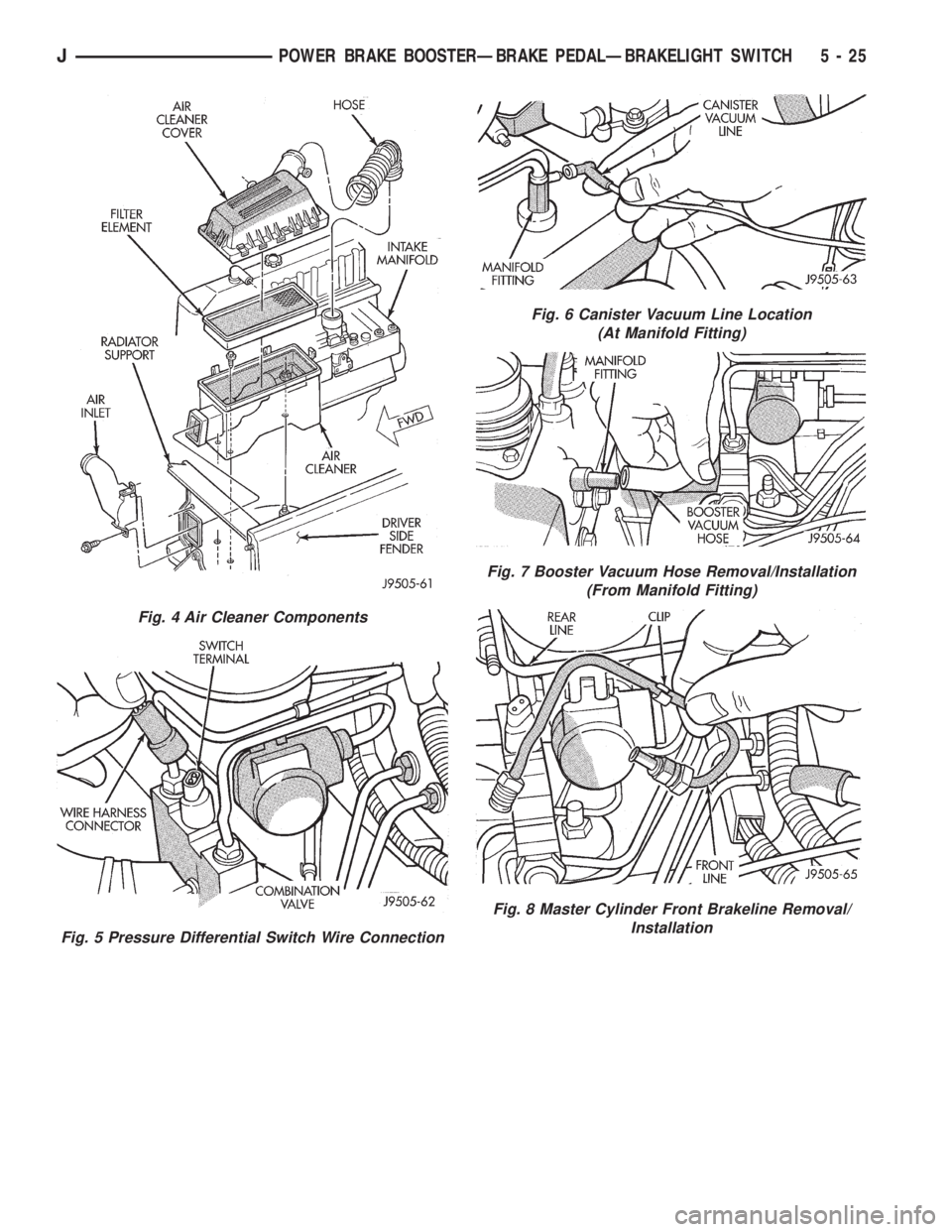

POWER BRAKE BOOSTER REMOVAL

(XJ WITH ABS)

(1) Disconnect vacuum and vent hoses at air

cleaner cover.

(2) Loosen clamp securing air cleaner hose to in-

take manifold. Use screwdriver to tap clamp loose.

(3) Remove air cleaner cover and hose. Then re-

move air filter from air cleaner housing (Fig. 4).

(4) Remove two bolts and one nut that secure air

cleaner housing to body (Fig. 4).

(5) Remove air cleaner housing from engine com-

partment (Fig. 4).

(6) Disconnect wire at combination valve pressure

differential switch (Fig. 5). Do not pull on wires to

disconnect. Unsnap lock tabs on connecter to remove

wires.

(7) Disconnect canister vacuum line at manifold

fitting (Fig. 6).(8) Disconnect brake booster vacuum hose at in-

take manifold fitting (Fig. 7). Move hose aside for

working clearance.

(9) Unseat small S-clip that secures brakelines

(Fig. 8).

(10) Remove front brakeline that connects master

cylinder front port to combination valve front port

(Fig. 8).

Fig. 3 Power Brake Booster Internal Components

5 - 24 POWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCHJ

Page 177 of 2158

Fig. 4 Air Cleaner Components

Fig. 5 Pressure Differential Switch Wire Connection

Fig. 6 Canister Vacuum Line Location

(At Manifold Fitting)

Fig. 7 Booster Vacuum Hose Removal/Installation

(From Manifold Fitting)

Fig. 8 Master Cylinder Front Brakeline Removal/

Installation

JPOWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCH 5 - 25

Page 178 of 2158

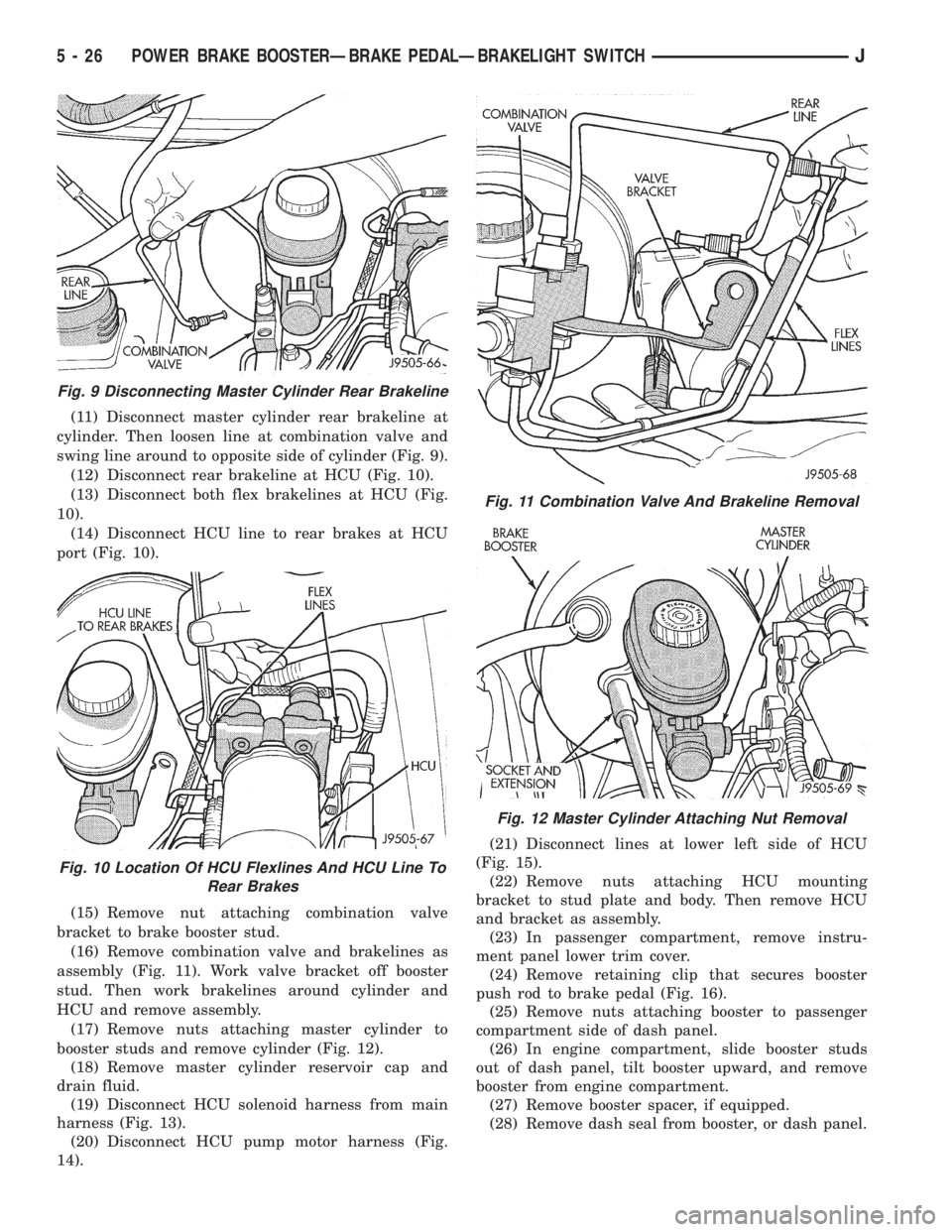

(11) Disconnect master cylinder rear brakeline at

cylinder. Then loosen line at combination valve and

swing line around to opposite side of cylinder (Fig. 9).

(12) Disconnect rear brakeline at HCU (Fig. 10).

(13) Disconnect both flex brakelines at HCU (Fig.

10).

(14) Disconnect HCU line to rear brakes at HCU

port (Fig. 10).

(15) Remove nut attaching combination valve

bracket to brake booster stud.

(16) Remove combination valve and brakelines as

assembly (Fig. 11). Work valve bracket off booster

stud. Then work brakelines around cylinder and

HCU and remove assembly.

(17) Remove nuts attaching master cylinder to

booster studs and remove cylinder (Fig. 12).

(18) Remove master cylinder reservoir cap and

drain fluid.

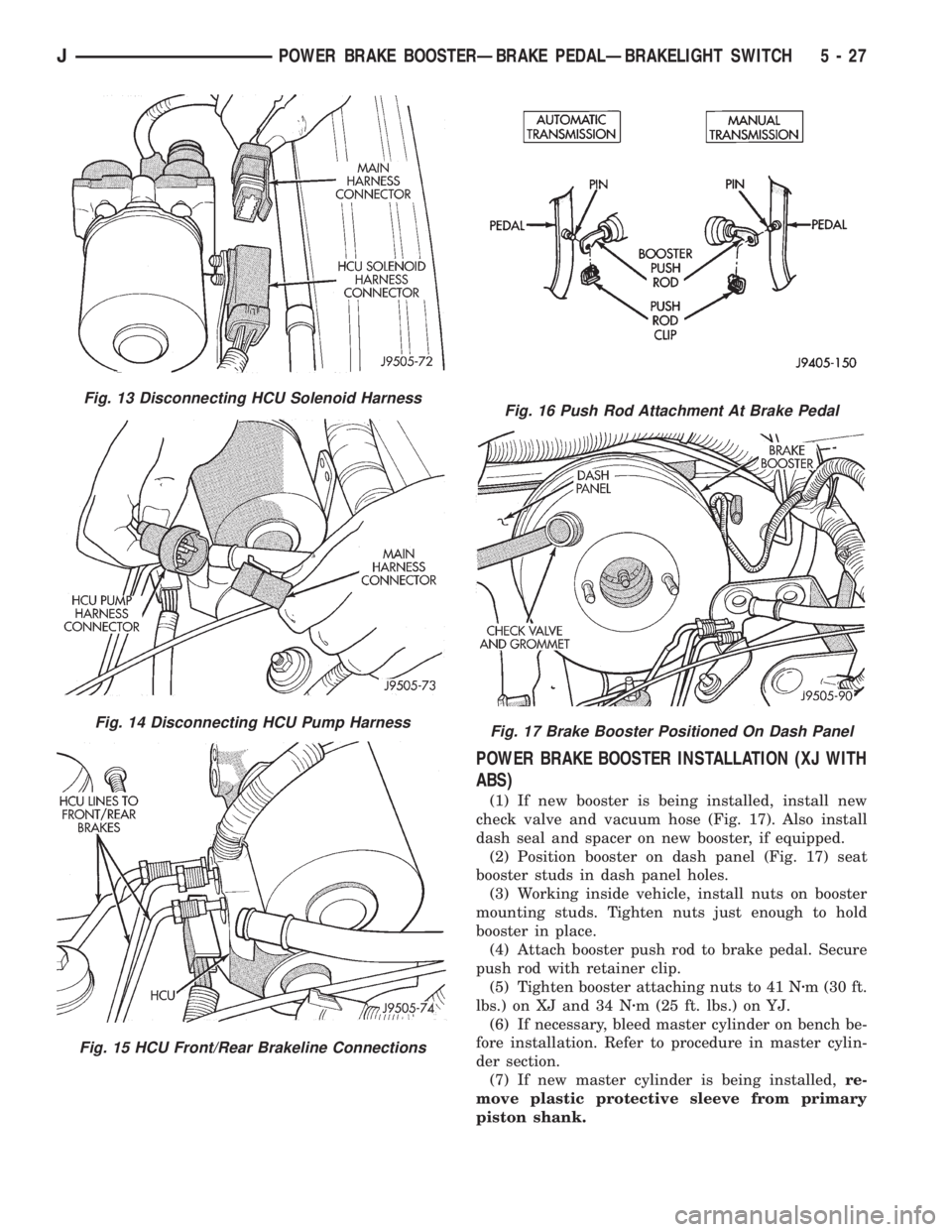

(19) Disconnect HCU solenoid harness from main

harness (Fig. 13).

(20) Disconnect HCU pump motor harness (Fig.

14).(21) Disconnect lines at lower left side of HCU

(Fig. 15).

(22) Remove nuts attaching HCU mounting

bracket to stud plate and body. Then remove HCU

and bracket as assembly.

(23) In passenger compartment, remove instru-

ment panel lower trim cover.

(24) Remove retaining clip that secures booster

push rod to brake pedal (Fig. 16).

(25) Remove nuts attaching booster to passenger

compartment side of dash panel.

(26) In engine compartment, slide booster studs

out of dash panel, tilt booster upward, and remove

booster from engine compartment.

(27) Remove booster spacer, if equipped.

(28) Remove dash seal from booster, or dash panel.

Fig. 9 Disconnecting Master Cylinder Rear Brakeline

Fig. 10 Location Of HCU Flexlines And HCU Line To

Rear Brakes

Fig. 11 Combination Valve And Brakeline Removal

Fig. 12 Master Cylinder Attaching Nut Removal

5 - 26 POWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCHJ

Page 179 of 2158

POWER BRAKE BOOSTER INSTALLATION (XJ WITH

ABS)

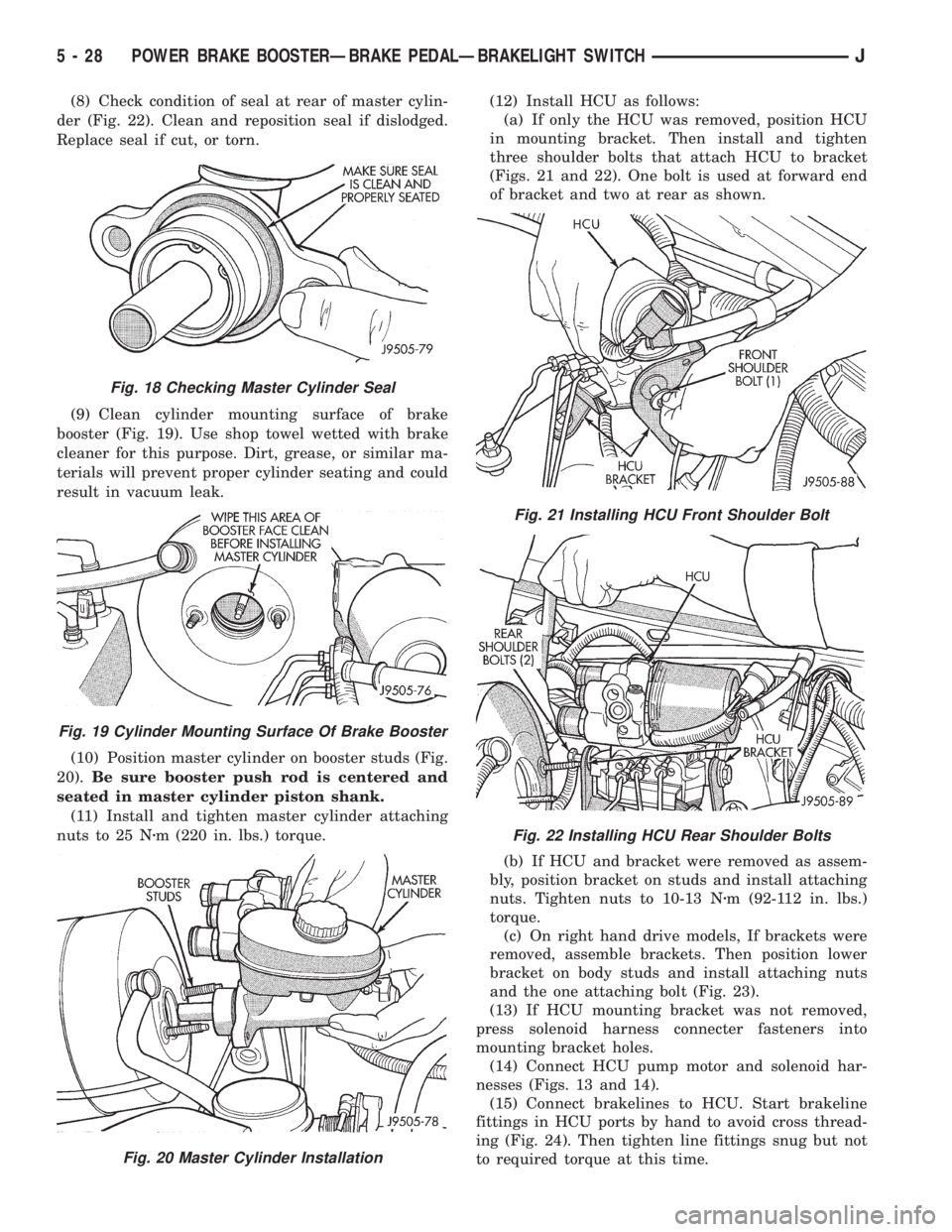

(1) If new booster is being installed, install new

check valve and vacuum hose (Fig. 17). Also install

dash seal and spacer on new booster, if equipped.

(2) Position booster on dash panel (Fig. 17) seat

booster studs in dash panel holes.

(3) Working inside vehicle, install nuts on booster

mounting studs. Tighten nuts just enough to hold

booster in place.

(4) Attach booster push rod to brake pedal. Secure

push rod with retainer clip.

(5) Tighten booster attaching nuts to 41 Nzm (30 ft.

lbs.) on XJ and 34 Nzm (25 ft. lbs.) on YJ.

(6) If necessary, bleed master cylinder on bench be-

fore installation. Refer to procedure in master cylin-

der section.

(7) If new master cylinder is being installed,re-

move plastic protective sleeve from primary

piston shank.

Fig. 13 Disconnecting HCU Solenoid Harness

Fig. 14 Disconnecting HCU Pump Harness

Fig. 15 HCU Front/Rear Brakeline Connections

Fig. 16 Push Rod Attachment At Brake Pedal

Fig. 17 Brake Booster Positioned On Dash Panel

JPOWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCH 5 - 27

Page 180 of 2158

(8) Check condition of seal at rear of master cylin-

der (Fig. 22). Clean and reposition seal if dislodged.

Replace seal if cut, or torn.

(9) Clean cylinder mounting surface of brake

booster (Fig. 19). Use shop towel wetted with brake

cleaner for this purpose. Dirt, grease, or similar ma-

terials will prevent proper cylinder seating and could

result in vacuum leak.

(10) Position master cylinder on booster studs (Fig.

20).Be sure booster push rod is centered and

seated in master cylinder piston shank.

(11) Install and tighten master cylinder attaching

nuts to 25 Nzm (220 in. lbs.) torque.(12) Install HCU as follows:

(a) If only the HCU was removed, position HCU

in mounting bracket. Then install and tighten

three shoulder bolts that attach HCU to bracket

(Figs. 21 and 22). One bolt is used at forward end

of bracket and two at rear as shown.

(b) If HCU and bracket were removed as assem-

bly, position bracket on studs and install attaching

nuts. Tighten nuts to 10-13 Nzm (92-112 in. lbs.)

torque.

(c) On right hand drive models, If brackets were

removed, assemble brackets. Then position lower

bracket on body studs and install attaching nuts

and the one attaching bolt (Fig. 23).

(13) If HCU mounting bracket was not removed,

press solenoid harness connecter fasteners into

mounting bracket holes.

(14) Connect HCU pump motor and solenoid har-

nesses (Figs. 13 and 14).

(15) Connect brakelines to HCU. Start brakeline

fittings in HCU ports by hand to avoid cross thread-

ing (Fig. 24). Then tighten line fittings snug but not

to required torque at this time.

Fig. 18 Checking Master Cylinder Seal

Fig. 19 Cylinder Mounting Surface Of Brake Booster

Fig. 20 Master Cylinder Installation

Fig. 21 Installing HCU Front Shoulder Bolt

Fig. 22 Installing HCU Rear Shoulder Bolts

5 - 28 POWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCHJ