lug pattern JEEP YJ 1995 Service And User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1366 of 2158

(8) Lower the vehicle.

(9) Install the engine cylinder head, push rods,

rocker arms, bridges, pivots and engine cylinder head

cover.

(10) Fill the crankcase with engine oil.

CRANKSHAFT MAIN BEARINGS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the spark plugs.

(3) Raise the vehicle.

(4) Remove the oil pan and oil pump.

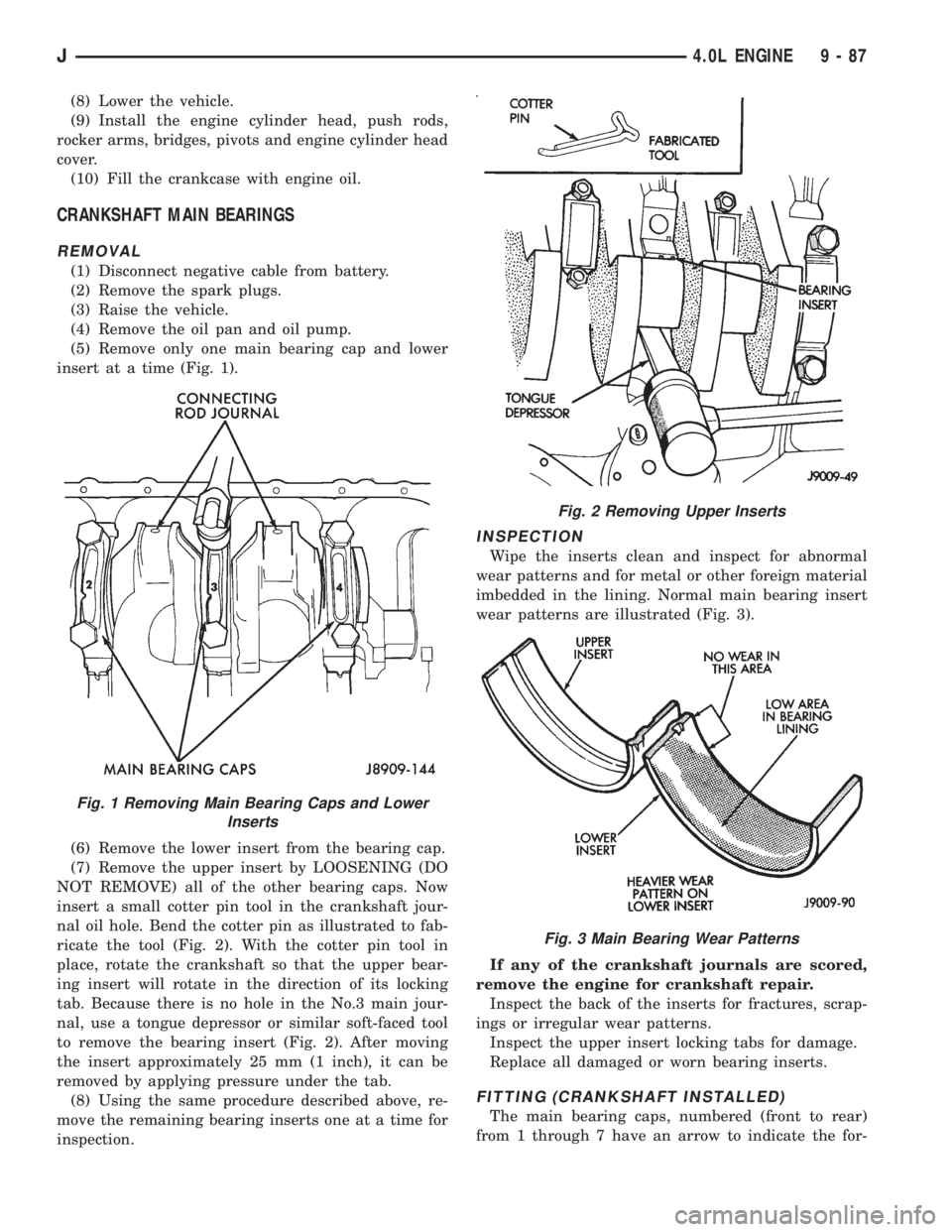

(5) Remove only one main bearing cap and lower

insert at a time (Fig. 1).

(6) Remove the lower insert from the bearing cap.

(7) Remove the upper insert by LOOSENING (DO

NOT REMOVE) all of the other bearing caps. Now

insert a small cotter pin tool in the crankshaft jour-

nal oil hole. Bend the cotter pin as illustrated to fab-

ricate the tool (Fig. 2). With the cotter pin tool in

place, rotate the crankshaft so that the upper bear-

ing insert will rotate in the direction of its locking

tab. Because there is no hole in the No.3 main jour-

nal, use a tongue depressor or similar soft-faced tool

to remove the bearing insert (Fig. 2). After moving

the insert approximately 25 mm (1 inch), it can be

removed by applying pressure under the tab.

(8) Using the same procedure described above, re-

move the remaining bearing inserts one at a time for

inspection.

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated (Fig. 3).

If any of the crankshaft journals are scored,

remove the engine for crankshaft repair.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

FITTING (CRANKSHAFT INSTALLED)

The main bearing caps, numbered (front to rear)

from 1 through 7 have an arrow to indicate the for-

Fig. 1 Removing Main Bearing Caps and Lower

Inserts

Fig. 2 Removing Upper Inserts

Fig. 3 Main Bearing Wear Patterns

J4.0L ENGINE 9 - 87

Page 1564 of 2158

TRANSMISSION IDENTIFICATION

The AX 4/5 identification code is on the bottom sur-

face of the transmission case near the fill plug (Fig. 2).

The first number is year of manufacture. The second

and third numbers indicate month of manufacture. The

next series of numbers is the transmission serial num-

ber.

GEAR RATIOS

Gear ratios for the AX 4 and AX 5 are as follows:

²First gear: 3.93:1

²Second gear: 2.33:1

²Third gear: 1.45:1

²Fourth gear: 1.00:1

²Fifth gear (AX 5): 0.85:1

²Reverse gear: 4.74:1

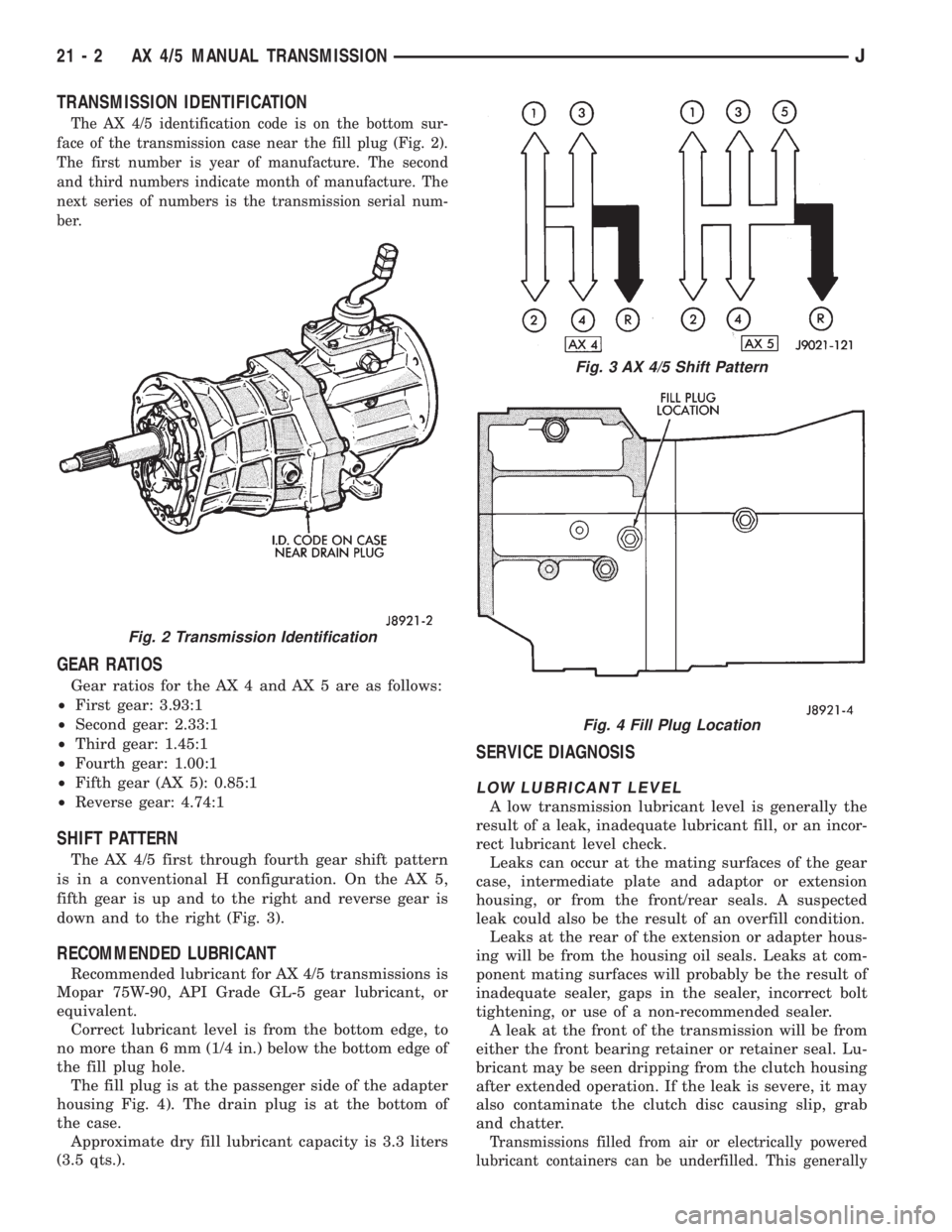

SHIFT PATTERN

The AX 4/5 first through fourth gear shift pattern

is in a conventional H configuration. On the AX 5,

fifth gear is up and to the right and reverse gear is

down and to the right (Fig. 3).

RECOMMENDED LUBRICANT

Recommended lubricant for AX 4/5 transmissions is

Mopar 75W-90, API Grade GL-5 gear lubricant, or

equivalent.

Correct lubricant level is from the bottom edge, to

no more than 6 mm (1/4 in.) below the bottom edge of

the fill plug hole.

The fill plug is at the passenger side of the adapter

housing Fig. 4). The drain plug is at the bottom of

the case.

Approximate dry fill lubricant capacity is 3.3 liters

(3.5 qts.).

SERVICE DIAGNOSIS

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the

result of a leak, inadequate lubricant fill, or an incor-

rect lubricant level check.

Leaks can occur at the mating surfaces of the gear

case, intermediate plate and adaptor or extension

housing, or from the front/rear seals. A suspected

leak could also be the result of an overfill condition.

Leaks at the rear of the extension or adapter hous-

ing will be from the housing oil seals. Leaks at com-

ponent mating surfaces will probably be the result of

inadequate sealer, gaps in the sealer, incorrect bolt

tightening, or use of a non-recommended sealer.

A leak at the front of the transmission will be from

either the front bearing retainer or retainer seal. Lu-

bricant may be seen dripping from the clutch housing

after extended operation. If the leak is severe, it may

also contaminate the clutch disc causing slip, grab

and chatter.

Transmissions filled from air or electrically powered

lubricant containers can be underfilled. This generally

Fig. 2 Transmission Identification

Fig. 3 AX 4/5 Shift Pattern

Fig. 4 Fill Plug Location

21 - 2 AX 4/5 MANUAL TRANSMISSIONJ

Page 1595 of 2158

AX 15 MANUAL TRANSMISSION

INDEX

page page

General Information....................... 33

Service Diagnosis......................... 34

Transmission Assembly and Adjustment......... 52

Transmission Disassembly and Overhaul........ 37

Transmission Gear Ratios................... 34

Transmission Identification.................. 33Transmission Installation.................... 36

Transmission Lubricant..................... 34

Transmission Removal..................... 35

Transmission Shift Pattern................... 34

Transmission Switch and Plug Locations........ 34

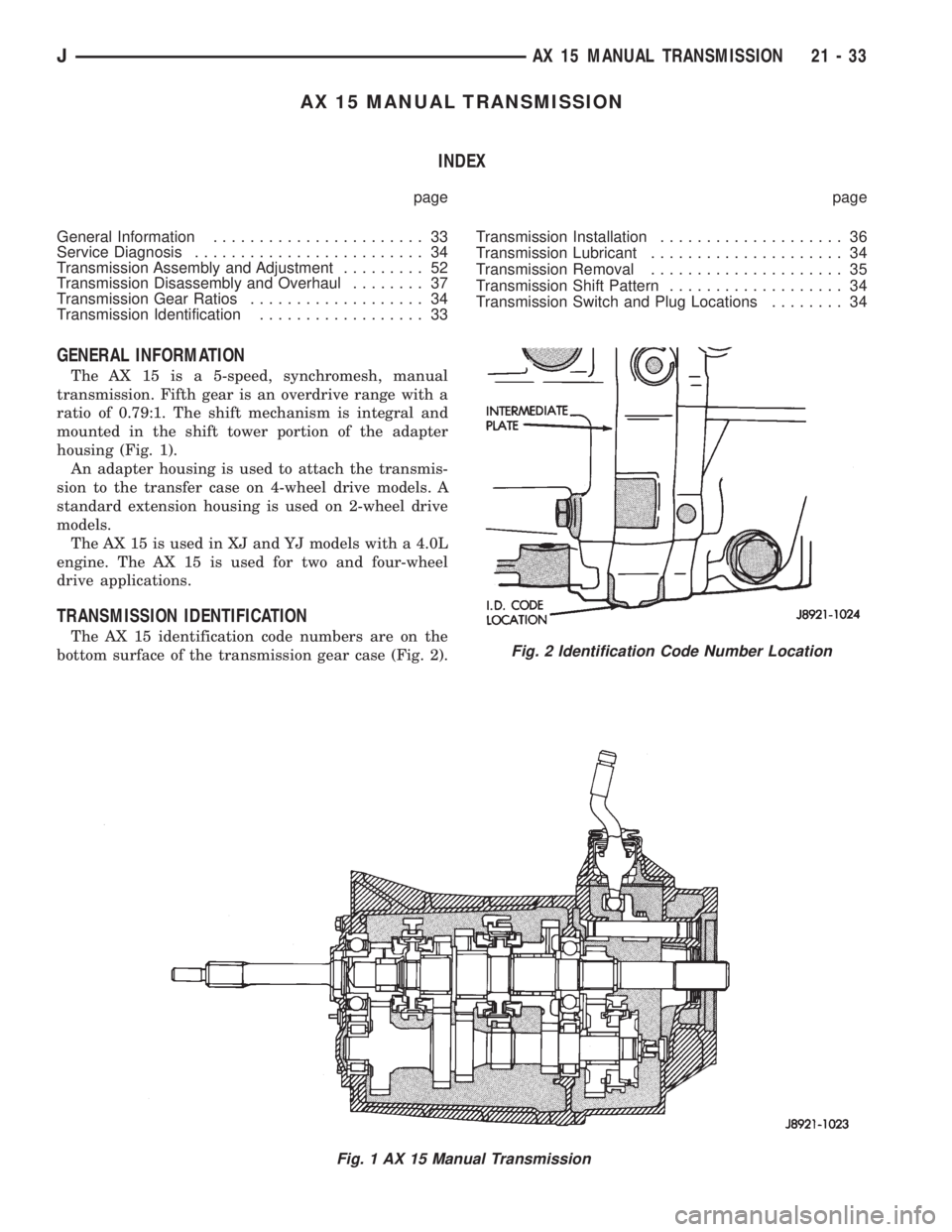

GENERAL INFORMATION

The AX 15 is a 5-speed, synchromesh, manual

transmission. Fifth gear is an overdrive range with a

ratio of 0.79:1. The shift mechanism is integral and

mounted in the shift tower portion of the adapter

housing (Fig. 1).

An adapter housing is used to attach the transmis-

sion to the transfer case on 4-wheel drive models. A

standard extension housing is used on 2-wheel drive

models.

The AX 15 is used in XJ and YJ models with a 4.0L

engine. The AX 15 is used for two and four-wheel

drive applications.

TRANSMISSION IDENTIFICATION

The AX 15 identification code numbers are on the

bottom surface of the transmission gear case (Fig. 2).

Fig. 1 AX 15 Manual Transmission

Fig. 2 Identification Code Number Location

JAX 15 MANUAL TRANSMISSION 21 - 33

Page 1596 of 2158

The first number is year of manufacture. The sec-

ond and third numbers indicate month of manufac-

ture. The next series of numbers is the transmission

serial number.

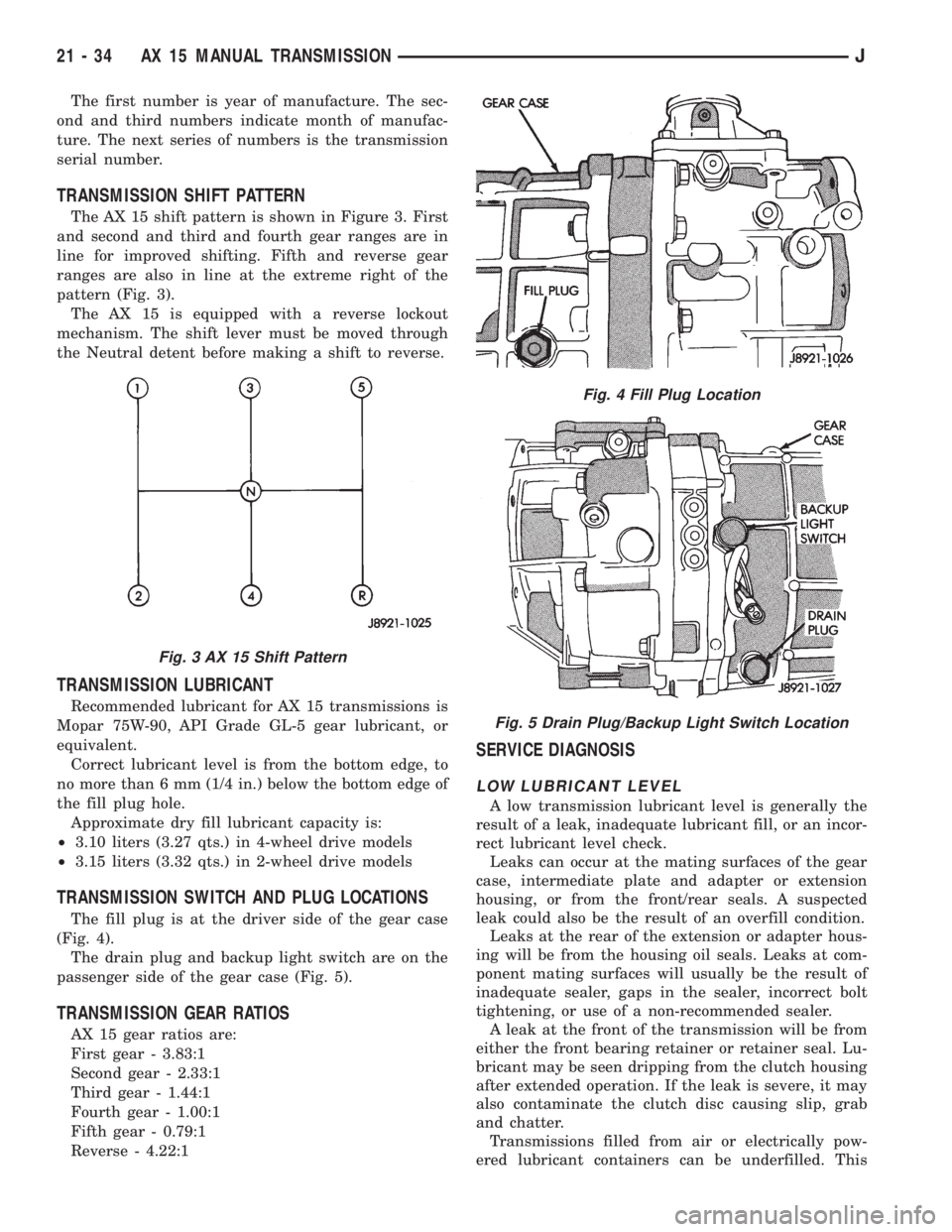

TRANSMISSION SHIFT PATTERN

The AX 15 shift pattern is shown in Figure 3. First

and second and third and fourth gear ranges are in

line for improved shifting. Fifth and reverse gear

ranges are also in line at the extreme right of the

pattern (Fig. 3).

The AX 15 is equipped with a reverse lockout

mechanism. The shift lever must be moved through

the Neutral detent before making a shift to reverse.

TRANSMISSION LUBRICANT

Recommended lubricant for AX 15 transmissions is

Mopar 75W-90, API Grade GL-5 gear lubricant, or

equivalent.

Correct lubricant level is from the bottom edge, to

no more than 6 mm (1/4 in.) below the bottom edge of

the fill plug hole.

Approximate dry fill lubricant capacity is:

²3.10 liters (3.27 qts.) in 4-wheel drive models

²3.15 liters (3.32 qts.) in 2-wheel drive models

TRANSMISSION SWITCH AND PLUG LOCATIONS

The fill plug is at the driver side of the gear case

(Fig. 4).

The drain plug and backup light switch are on the

passenger side of the gear case (Fig. 5).

TRANSMISSION GEAR RATIOS

AX 15 gear ratios are:

First gear - 3.83:1

Second gear - 2.33:1

Third gear - 1.44:1

Fourth gear - 1.00:1

Fifth gear - 0.79:1

Reverse - 4.22:1

SERVICE DIAGNOSIS

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the

result of a leak, inadequate lubricant fill, or an incor-

rect lubricant level check.

Leaks can occur at the mating surfaces of the gear

case, intermediate plate and adapter or extension

housing, or from the front/rear seals. A suspected

leak could also be the result of an overfill condition.

Leaks at the rear of the extension or adapter hous-

ing will be from the housing oil seals. Leaks at com-

ponent mating surfaces will usually be the result of

inadequate sealer, gaps in the sealer, incorrect bolt

tightening, or use of a non-recommended sealer.

A leak at the front of the transmission will be from

either the front bearing retainer or retainer seal. Lu-

bricant may be seen dripping from the clutch housing

after extended operation. If the leak is severe, it may

also contaminate the clutch disc causing slip, grab

and chatter.

Transmissions filled from air or electrically pow-

ered lubricant containers can be underfilled. This

Fig. 3 AX 15 Shift Pattern

Fig. 4 Fill Plug Location

Fig. 5 Drain Plug/Backup Light Switch Location

21 - 34 AX 15 MANUAL TRANSMISSIONJ

Page 1715 of 2158

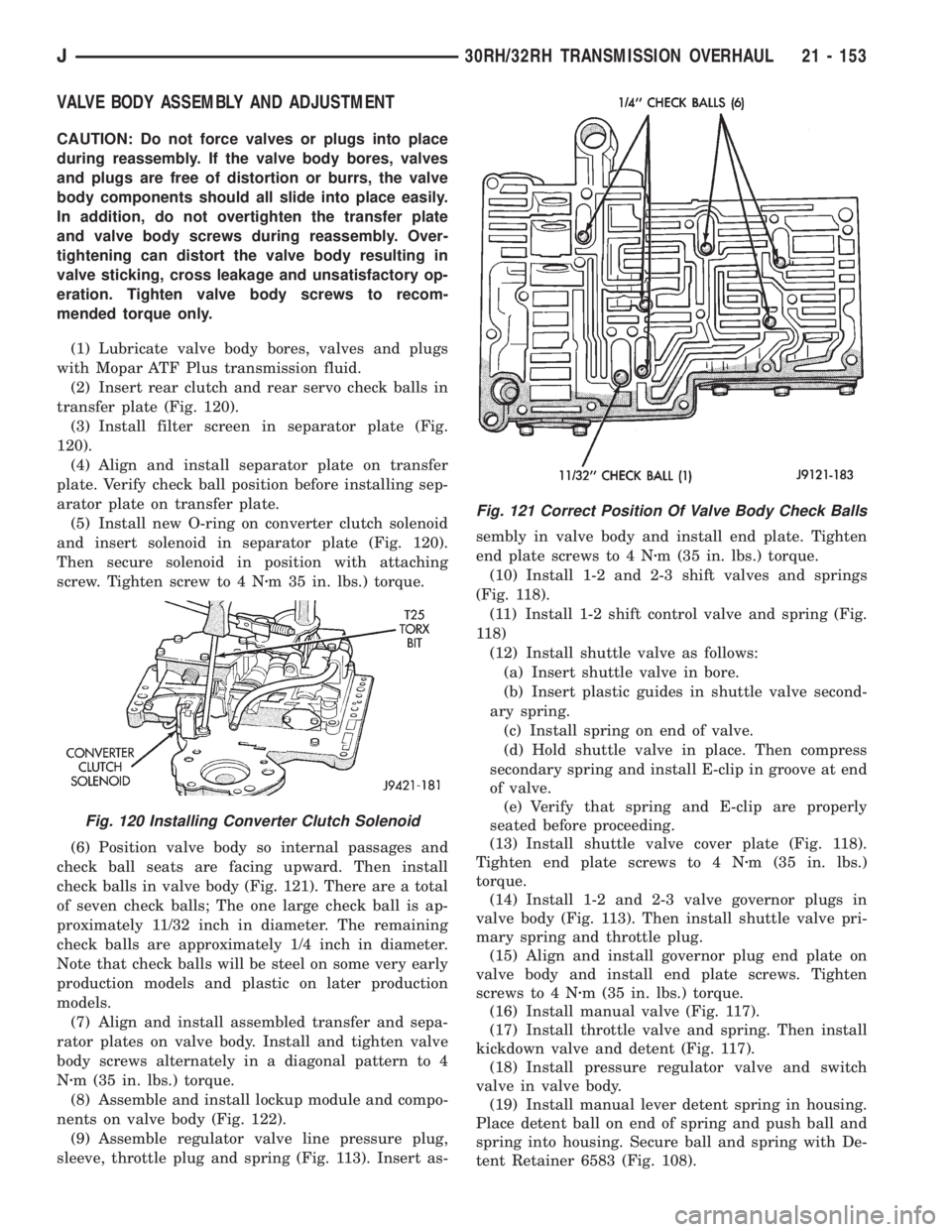

VALVE BODY ASSEMBLY AND ADJUSTMENT

CAUTION: Do not force valves or plugs into place

during reassembly. If the valve body bores, valves

and plugs are free of distortion or burrs, the valve

body components should all slide into place easily.

In addition, do not overtighten the transfer plate

and valve body screws during reassembly. Over-

tightening can distort the valve body resulting in

valve sticking, cross leakage and unsatisfactory op-

eration. Tighten valve body screws to recom-

mended torque only.

(1) Lubricate valve body bores, valves and plugs

with Mopar ATF Plus transmission fluid.

(2) Insert rear clutch and rear servo check balls in

transfer plate (Fig. 120).

(3) Install filter screen in separator plate (Fig.

120).

(4) Align and install separator plate on transfer

plate. Verify check ball position before installing sep-

arator plate on transfer plate.

(5) Install new O-ring on converter clutch solenoid

and insert solenoid in separator plate (Fig. 120).

Then secure solenoid in position with attaching

screw. Tighten screw to 4 Nzm 35 in. lbs.) torque.

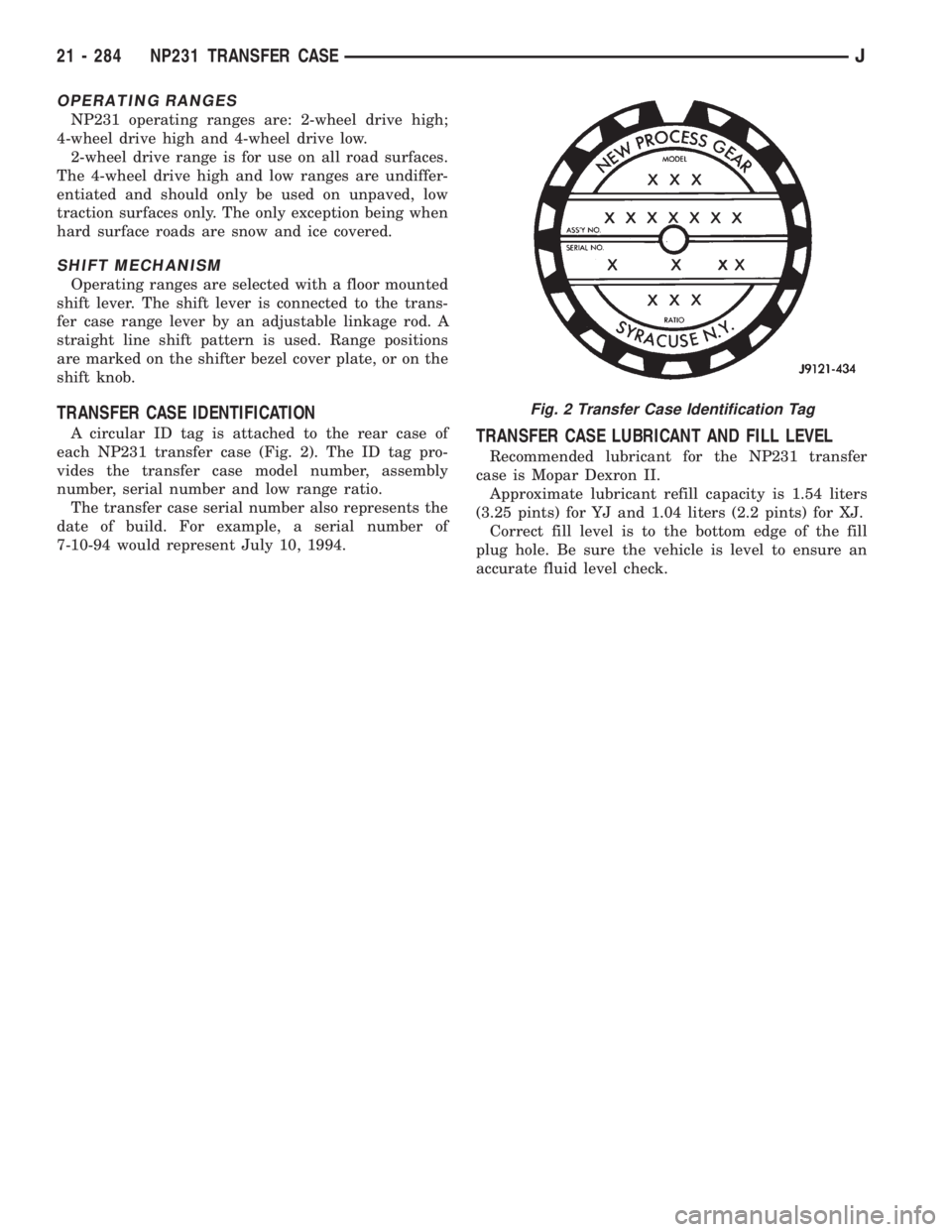

(6) Position valve body so internal passages and

check ball seats are facing upward. Then install

check balls in valve body (Fig. 121). There are a total

of seven check balls; The one large check ball is ap-

proximately 11/32 inch in diameter. The remaining

check balls are approximately 1/4 inch in diameter.

Note that check balls will be steel on some very early

production models and plastic on later production

models.

(7) Align and install assembled transfer and sepa-

rator plates on valve body. Install and tighten valve

body screws alternately in a diagonal pattern to 4

Nzm (35 in. lbs.) torque.

(8) Assemble and install lockup module and compo-

nents on valve body (Fig. 122).

(9) Assemble regulator valve line pressure plug,

sleeve, throttle plug and spring (Fig. 113). Insert as-sembly in valve body and install end plate. Tighten

end plate screws to 4 Nzm (35 in. lbs.) torque.

(10) Install 1-2 and 2-3 shift valves and springs

(Fig. 118).

(11) Install 1-2 shift control valve and spring (Fig.

118)

(12) Install shuttle valve as follows:

(a) Insert shuttle valve in bore.

(b) Insert plastic guides in shuttle valve second-

ary spring.

(c) Install spring on end of valve.

(d) Hold shuttle valve in place. Then compress

secondary spring and install E-clip in groove at end

of valve.

(e) Verify that spring and E-clip are properly

seated before proceeding.

(13) Install shuttle valve cover plate (Fig. 118).

Tighten end plate screws to 4 Nzm (35 in. lbs.)

torque.

(14) Install 1-2 and 2-3 valve governor plugs in

valve body (Fig. 113). Then install shuttle valve pri-

mary spring and throttle plug.

(15) Align and install governor plug end plate on

valve body and install end plate screws. Tighten

screws to 4 Nzm (35 in. lbs.) torque.

(16) Install manual valve (Fig. 117).

(17) Install throttle valve and spring. Then install

kickdown valve and detent (Fig. 117).

(18) Install pressure regulator valve and switch

valve in valve body.

(19) Install manual lever detent spring in housing.

Place detent ball on end of spring and push ball and

spring into housing. Secure ball and spring with De-

tent Retainer 6583 (Fig. 108).

Fig. 120 Installing Converter Clutch Solenoid

Fig. 121 Correct Position Of Valve Body Check Balls

J30RH/32RH TRANSMISSION OVERHAUL 21 - 153

Page 1724 of 2158

(6) Verify that reaction shaft support hub seal

rings are hooked together (Fig. 155).

(7) Coat front clutch thrust washer with petroleum

jelly to hold it in place. Then install washer over re-

action shaft hub and seat it on pump (Fig. 156).

CAUTION: The thrust washer bore (I.D.), is cham-

fered on one side. Make sure the chamfered side is

installed so it faces the pump.(8) Thread two Pilot Stud Tools C-3288-B into bolt

holes in oil pump flange (Fig. 157).

(9) Align and install oil pump gasket (Fig. 157).

(10) Lubricate oil pump seals with Mopar Door-

Ease, or Ru-Glyde, Door Eze, or ATF Plus.

(11) Install oil pump (Fig. 158). Align and position

pump on pilot studs. Slide pump down studs and

work it into front clutch hub and case by hand. Then

install two or three pump bolts to hold pump in

place.

(12) Remove pilot stud tools and install remaining

oil pump bolts. Tighten bolts alternately in diagonal

pattern to 20 Nzm (15 ft-lbs).

CHECKING INPUT SHAFT END PLAY

(1) Measure input shaft end play (Fig. 159).

(2) Attach dial indicator to converter housing. Po-

sition indicator plunger against input shaft and zero

indicator.

Fig. 153 Front Band Linkage Installation

Fig. 154 Installing Front Band Pivot Pin Access Plug

Fig. 155 Reaction Shaft Support Seal Rings

Fig. 156 Front Clutch Thrust Washer Installation

Fig. 157 Installing Pilot Studs And Oil Pump Gasket

21 - 162 30RH/32RH TRANSMISSION OVERHAULJ

Page 1846 of 2158

OPERATING RANGES

NP231 operating ranges are: 2-wheel drive high;

4-wheel drive high and 4-wheel drive low.

2-wheel drive range is for use on all road surfaces.

The 4-wheel drive high and low ranges are undiffer-

entiated and should only be used on unpaved, low

traction surfaces only. The only exception being when

hard surface roads are snow and ice covered.

SHIFT MECHANISM

Operating ranges are selected with a floor mounted

shift lever. The shift lever is connected to the trans-

fer case range lever by an adjustable linkage rod. A

straight line shift pattern is used. Range positions

are marked on the shifter bezel cover plate, or on the

shift knob.

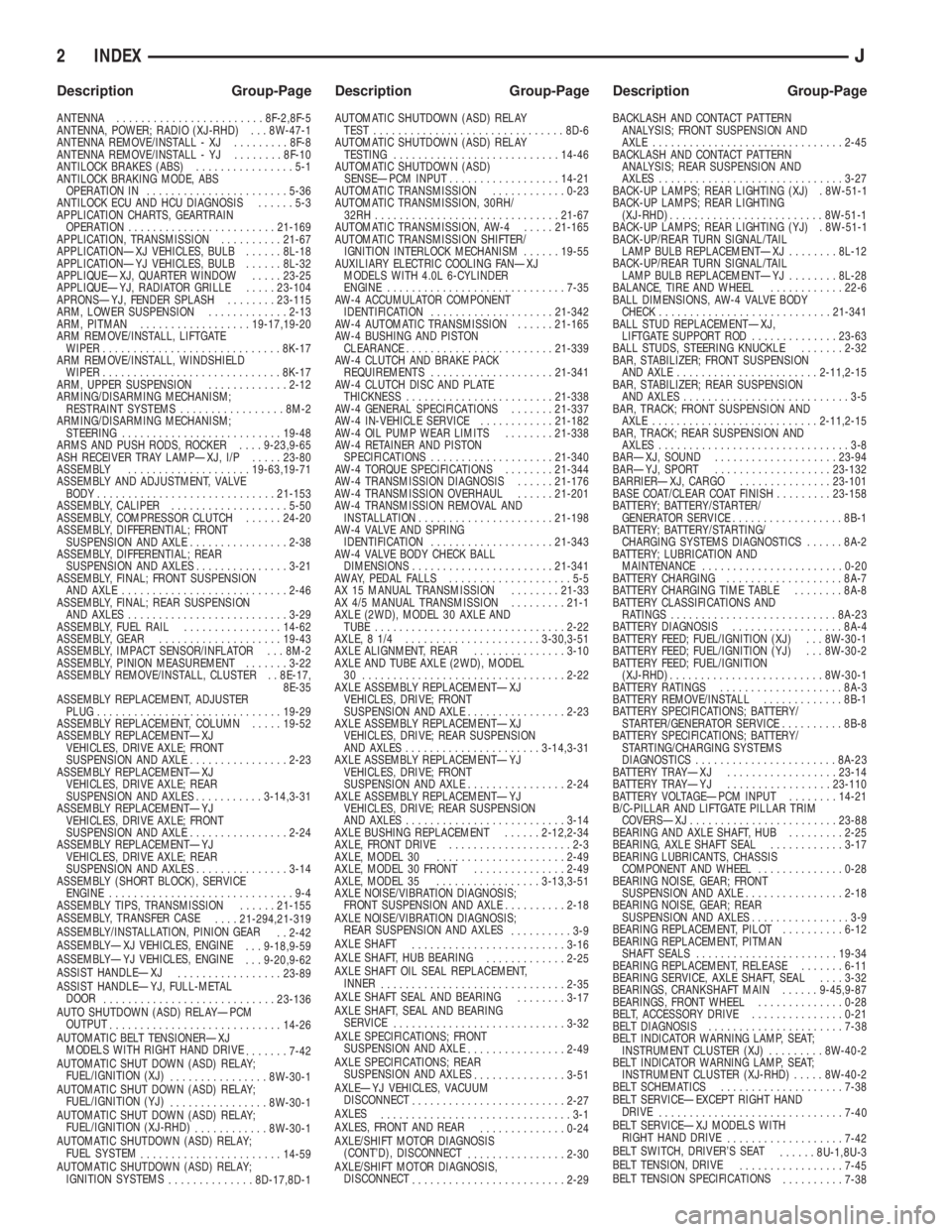

TRANSFER CASE IDENTIFICATION

A circular ID tag is attached to the rear case of

each NP231 transfer case (Fig. 2). The ID tag pro-

vides the transfer case model number, assembly

number, serial number and low range ratio.

The transfer case serial number also represents the

date of build. For example, a serial number of

7-10-94 would represent July 10, 1994.TRANSFER CASE LUBRICANT AND FILL LEVEL

Recommended lubricant for the NP231 transfer

case is Mopar Dexron II.

Approximate lubricant refill capacity is 1.54 liters

(3.25 pints) for YJ and 1.04 liters (2.2 pints) for XJ.

Correct fill level is to the bottom edge of the fill

plug hole. Be sure the vehicle is level to ensure an

accurate fluid level check.

Fig. 2 Transfer Case Identification Tag

21 - 284 NP231 TRANSFER CASEJ

Page 1912 of 2158

WHEELS

GENERAL INFORMATION

Original equipment wheels are designed for the

specified Maximum Vehicle Capacity.

All models use steel or cast aluminum drop center

wheels. The safety rim wheel (Fig. 1) has raised sec-

tions between the rim flanges and the rim well.

Initial inflation of the tire forces the bead over

these raised sections. In case of tire failure, the

raised sections hold the tire in position on the wheel

until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights and alignment equipment.

WHEEL INSTALLATION

The wheel studs and nuts are designed for specific

applications. They must be replaced with equivalent

parts. Do not use replacement parts of lesser quality

or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an en-

larged nose. This enlarged nose is necessary to en-

sure proper retention of the aluminum wheels.

Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces.

Ensure wheels are installed with good metal-to-metal

contact. Improper installation could cause loosening

of wheel nuts. This could affect the safety and han-

dling of your vehicle.

To install the wheel, first position it properly on

the mounting surface. All wheel nuts should then be

tightened just snug. Gradually tighten them in se-

quence to 129 Nzm (95 ft. lbs.) torque (Fig. 2).Never

use oil or grease on studs or nuts.

WHEEL REPLACEMENT

Wheels must be replaced if they have:²Excessive runout

²Bent or dented

²Leak air through welds

²Have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed.

Original equipment wheels are available through

your dealer. Replacement wheels from any other

source should be equivalent in:

²Load carrying capacity

²Diameter

²Width

²Offset

²Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle. Re-

placement withusedwheels is not recommended.

Their service history may have included severe treat-

ment.

Refer to the Specifications Chart for informa-

tion regarding above requirements.

WHEEL ORNAMENTATION

WARNING: HANDLE ALL WHEEL ORNAMENTATION

WITH EXTREME CARE DURING REMOVAL AND IN-

STALLATION. SHARP EDGES ON THE COVERS OR

CAPS CAN CAUSE PERSONAL INJURY.

TIRE AND WHEEL BALANCE

It is recommended that a two plane dynamic bal-

ancer be used when a wheel and tire assembly re-

quire balancing. Static should be used only when a

two plane balancer is not available.

For static imbalance, find location of heavy spot

causing imbalance. Counter balance wheel directly

Fig. 1 Wheel Safety Rim

Fig. 2 Lug Nut Tightening Pattern

22 - 6 WHEELS AND TIRESJ

Page 2126 of 2158

ANTENNA........................8F-2,8F-5

ANTENNA, POWER; RADIO (XJ-RHD) . . . 8W-47-1

ANTENNA REMOVE/INSTALL - XJ.........8F-8

ANTENNA REMOVE/INSTALL - YJ........8F-10

ANTILOCK BRAKES (ABS)................5-1

ANTILOCK BRAKING MODE, ABS

OPERATION IN.......................5-36

ANTILOCK ECU AND HCU DIAGNOSIS......5-3

APPLICATION CHARTS, GEARTRAIN

OPERATION........................21-169

APPLICATION, TRANSMISSION..........21-67

APPLICATIONÐXJ VEHICLES, BULB......8L-18

APPLICATIONÐYJ VEHICLES, BULB......8L-32

APPLIQUEÐXJ, QUARTER WINDOW.....23-25

APPLIQUEÐYJ, RADIATOR GRILLE.....23-104

APRONSÐYJ, FENDER SPLASH........23-115

ARM, LOWER SUSPENSION.............2-13

ARM, PITMAN..................19-17,19-20

ARM REMOVE/INSTALL, LIFTGATE

WIPER.............................8K-17

ARM REMOVE/INSTALL, WINDSHIELD

WIPER.............................8K-17

ARM, UPPER SUSPENSION.............2-12

ARMING/DISARMING MECHANISM;

RESTRAINT SYSTEMS.................8M-2

ARMING/DISARMING MECHANISM;

STEERING..........................19-48

ARMS AND PUSH RODS, ROCKER....9-23,9-65

ASH RECEIVER TRAY LAMPÐXJ, I/P.....23-80

ASSEMBLY....................19-63,19-71

ASSEMBLY AND ADJUSTMENT, VALVE

BODY.............................21-153

ASSEMBLY, CALIPER...................5-50

ASSEMBLY, COMPRESSOR CLUTCH......24-20

ASSEMBLY, DIFFERENTIAL; FRONT

SUSPENSION AND AXLE................2-38

ASSEMBLY, DIFFERENTIAL; REAR

SUSPENSION AND AXLES...............3-21

ASSEMBLY, FINAL; FRONT SUSPENSION

AND AXLE...........................2-46

ASSEMBLY, FINAL; REAR SUSPENSION

AND AXLES..........................3-29

ASSEMBLY, FUEL RAIL................14-62

ASSEMBLY, GEAR....................19-43

ASSEMBLY, IMPACT SENSOR/INFLATOR . . . 8M-2

ASSEMBLY, PINION MEASUREMENT.......3-22

ASSEMBLY REMOVE/INSTALL, CLUSTER . . 8E-17,

8E-35

ASSEMBLY REPLACEMENT, ADJUSTER

PLUG..............................19-29

ASSEMBLY REPLACEMENT, COLUMN.....19-52

ASSEMBLY REPLACEMENTÐXJ

VEHICLES, DRIVE AXLE; FRONT

SUSPENSION AND AXLE................2-23

ASSEMBLY REPLACEMENTÐXJ

VEHICLES, DRIVE AXLE; REAR

SUSPENSION AND AXLES...........3-14,3-31

ASSEMBLY REPLACEMENTÐYJ

VEHICLES, DRIVE AXLE; FRONT

SUSPENSION AND AXLE................2-24

ASSEMBLY REPLACEMENTÐYJ

VEHICLES, DRIVE AXLE; REAR

SUSPENSION AND AXLES...............3-14

ASSEMBLY (SHORT BLOCK), SERVICE

ENGINE..............................9-4

ASSEMBLY TIPS, TRANSMISSION......21-155

ASSEMBLY, TRANSFER CASE

....21-294,21-319

ASSEMBLY/INSTALLATION, PINION GEAR

. . 2-42

ASSEMBLYÐXJ VEHICLES, ENGINE

. . . 9-18,9-59

ASSEMBLYÐYJ VEHICLES, ENGINE

. . . 9-20,9-62

ASSIST HANDLEÐXJ

.................23-89

ASSIST HANDLEÐYJ, FULL-METAL

DOOR

............................23-136

AUTO SHUTDOWN (ASD) RELAYÐPCM

OUTPUT

............................14-26

AUTOMATIC BELT TENSIONERÐXJ

MODELS WITH RIGHT HAND DRIVE

.......7-42

AUTOMATIC SHUT DOWN (ASD) RELAY;

FUEL/IGNITION (XJ)

................8W-30-1

AUTOMATIC SHUT DOWN (ASD) RELAY;

FUEL/IGNITION (YJ)

................8W-30-1

AUTOMATIC SHUT DOWN (ASD) RELAY;

FUEL/IGNITION (XJ-RHD)

............8W-30-1

AUTOMATIC SHUTDOWN (ASD) RELAY;

FUEL SYSTEM

.......................14-59

AUTOMATIC SHUTDOWN (ASD) RELAY;

IGNITION SYSTEMS

..............8D-17,8D-1AUTOMATIC SHUTDOWN (ASD) RELAY

TEST...............................8D-6

AUTOMATIC SHUTDOWN (ASD) RELAY

TESTING...........................14-46

AUTOMATIC SHUTDOWN (ASD)

SENSEÐPCM INPUT..................14-21

AUTOMATIC TRANSMISSION............0-23

AUTOMATIC TRANSMISSION, 30RH/

32RH..............................21-67

AUTOMATIC TRANSMISSION, AW-4.....21-165

AUTOMATIC TRANSMISSION SHIFTER/

IGNITION INTERLOCK MECHANISM......19-55

AUXILIARY ELECTRIC COOLING FANÐXJ

MODELS WITH 4.0L 6-CYLINDER

ENGINE.............................7-35

AW-4 ACCUMULATOR COMPONENT

IDENTIFICATION....................21-342

AW-4 AUTOMATIC TRANSMISSION......21-165

AW-4 BUSHING AND PISTON

CLEARANCE........................21-339

AW-4 CLUTCH AND BRAKE PACK

REQUIREMENTS....................21-341

AW-4 CLUTCH DISC AND PLATE

THICKNESS........................21-338

AW-4 GENERAL SPECIFICATIONS.......21-337

AW-4 IN-VEHICLE SERVICE............21-182

AW-4 OIL PUMP WEAR LIMITS........21-338

AW-4 RETAINER AND PISTON

SPECIFICATIONS....................21-340

AW-4 TORQUE SPECIFICATIONS........21-344

AW-4 TRANSMISSION DIAGNOSIS......21-176

AW-4 TRANSMISSION OVERHAUL......21-201

AW-4 TRANSMISSION REMOVAL AND

INSTALLATION......................21-198

AW-4 VALVE AND SPRING

IDENTIFICATION....................21-343

AW-4 VALVE BODY CHECK BALL

DIMENSIONS.......................21-341

AWAY, PEDAL FALLS....................5-5

AX 15 MANUAL TRANSMISSION........21-33

AX 4/5 MANUAL TRANSMISSION.........21-1

AXLE (2WD), MODEL 30 AXLE AND

TUBE...............................2-22

AXLE, 8 1/4......................3-30,3-51

AXLE ALIGNMENT, REAR...............3-10

AXLE AND TUBE AXLE (2WD), MODEL

30 .................................2-22

AXLE ASSEMBLY REPLACEMENTÐXJ

VEHICLES, DRIVE; FRONT

SUSPENSION AND AXLE................2-23

AXLE ASSEMBLY REPLACEMENTÐXJ

VEHICLES, DRIVE; REAR SUSPENSION

AND AXLES......................3-14,3-31

AXLE ASSEMBLY REPLACEMENTÐYJ

VEHICLES, DRIVE; FRONT

SUSPENSION AND AXLE................2-24

AXLE ASSEMBLY REPLACEMENTÐYJ

VEHICLES, DRIVE; REAR SUSPENSION

AND AXLES..........................3-14

AXLE BUSHING REPLACEMENT......2-12,2-34

AXLE, FRONT DRIVE....................2-3

AXLE, MODEL 30.....................2-49

AXLE, MODEL 30 FRONT...............2-49

AXLE, MODEL 35.................3-13,3-51

AXLE NOISE/VIBRATION DIAGNOSIS;

FRONT SUSPENSION AND AXLE..........2-18

AXLE NOISE/VIBRATION DIAGNOSIS;

REAR SUSPENSION AND AXLES

..........3-9

AXLE SHAFT

.........................3-16

AXLE SHAFT, HUB BEARING

.............2-25

AXLE SHAFT OIL SEAL REPLACEMENT,

INNER

..............................2-35

AXLE SHAFT SEAL AND BEARING

........3-17

AXLE SHAFT, SEAL AND BEARING

SERVICE

............................3-32

AXLE SPECIFICATIONS; FRONT

SUSPENSION AND AXLE

................2-49

AXLE SPECIFICATIONS; REAR

SUSPENSION AND AXLES

...............3-51

AXLEÐYJ VEHICLES, VACUUM

DISCONNECT

.........................2-27

AXLES

...............................3-1

AXLES, FRONT AND REAR

..............0-24

AXLE/SHIFT MOTOR DIAGNOSIS

(CONT'D), DISCONNECT

................2-30

AXLE/SHIFT MOTOR DIAGNOSIS,

DISCONNECT

.........................2-29BACKLASH AND CONTACT PATTERN

ANALYSIS; FRONT SUSPENSION AND

AXLE...............................2-45

BACKLASH AND CONTACT PATTERN

ANALYSIS; REAR SUSPENSION AND

AXLES..............................3-27

BACK-UP LAMPS; REAR LIGHTING (XJ) . 8W-51-1

BACK-UP LAMPS; REAR LIGHTING

(XJ-RHD).........................8W-51-1

BACK-UP LAMPS; REAR LIGHTING (YJ) . 8W-51-1

BACK-UP/REAR TURN SIGNAL/TAIL

LAMP BULB REPLACEMENTÐXJ........8L-12

BACK-UP/REAR TURN SIGNAL/TAIL

LAMP BULB REPLACEMENTÐYJ........8L-28

BALANCE, TIRE AND WHEEL............22-6

BALL DIMENSIONS, AW-4 VALVE BODY

CHECK............................21-341

BALL STUD REPLACEMENTÐXJ,

LIFTGATE SUPPORT ROD..............23-63

BALL STUDS, STEERING KNUCKLE.......2-32

BAR, STABILIZER; FRONT SUSPENSION

AND AXLE.......................2-11,2-15

BAR, STABILIZER; REAR SUSPENSION

AND AXLES...........................3-5

BAR, TRACK; FRONT SUSPENSION AND

AXLE...........................2-11,2-15

BAR, TRACK; REAR SUSPENSION AND

AXLES...............................3-8

BARÐXJ, SOUND....................23-94

BARÐYJ, SPORT...................23-132

BARRIERÐXJ, CARGO...............23-101

BASE COAT/CLEAR COAT FINISH.........23-158

BATTERY; BATTERY/STARTER/

GENERATOR SERVICE..................8B-1

BATTERY; BATTERY/STARTING/

CHARGING SYSTEMS DIAGNOSTICS......8A-2

BATTERY; LUBRICATION AND

MAINTENANCE.......................0-20

BATTERY CHARGING...................8A-7

BATTERY CHARGING TIME TABLE........8A-8

BATTERY CLASSIFICATIONS AND

RATINGS...........................8A-23

BATTERY DIAGNOSIS..................8A-4

BATTERY FEED; FUEL/IGNITION (XJ) . . . 8W-30-1

BATTERY FEED; FUEL/IGNITION (YJ) . . . 8W-30-2

BATTERY FEED; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

BATTERY RATINGS....................8A-3

BATTERY REMOVE/INSTALL.............8B-1

BATTERY SPECIFICATIONS; BATTERY/

STARTER/GENERATOR SERVICE..........8B-8

BATTERY SPECIFICATIONS; BATTERY/

STARTING/CHARGING SYSTEMS

DIAGNOSTICS.......................8A-23

BATTERY TRAYÐXJ..................23-14

BATTERY TRAYÐYJ.................23-110

BATTERY VOLTAGEÐPCM INPUT........14-21

B/C-PILLAR AND LIFTGATE PILLAR TRIM

COVERSÐXJ........................23-88

BEARING AND AXLE SHAFT, HUB.........2-25

BEARING, AXLE SHAFT SEAL............3-17

BEARING LUBRICANTS, CHASSIS

COMPONENT AND WHEEL..............0-28

BEARING NOISE, GEAR; FRONT

SUSPENSION AND AXLE................2-18

BEARING NOISE, GEAR; REAR

SUSPENSION AND AXLES................3-9

BEARING REPLACEMENT, PILOT..........6-12

BEARING REPLACEMENT, PITMAN

SHAFT SEALS.......................19-34

BEARING REPLACEMENT, RELEASE.......6-11

BEARING SERVICE, AXLE SHAFT, SEAL....3-32

BEARINGS, CRANKSHAFT MAIN......9-45,9-87

BEARINGS, FRONT WHEEL..............0-28

BELT, ACCESSORY DRIVE...............0-21

BELT DIAGNOSIS......................7-38

BELT INDICATOR WARNING LAMP, SEAT;

INSTRUMENT CLUSTER (XJ).........8W-40-2

BELT INDICATOR WARNING LAMP, SEAT;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

BELT SCHEMATICS....................7-38

BELT SERVICEÐEXCEPT RIGHT HAND

DRIVE

..............................7-40

BELT SERVICEÐXJ MODELS WITH

RIGHT HAND DRIVE

...................7-42

BELT SWITCH, DRIVER'S SEAT

......8U-1,8U-3

BELT TENSION, DRIVE

.................7-45

BELT TENSION SPECIFICATIONS

..........7-38

2 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 2144 of 2158

PANEL (GOP)ÐXJ, GRILLE AND GRILLE

OPENING............................23-3

PANEL ILLUMINATION LAMPS,

INSTRUMENT; INTERIOR LIGHTING

(XJ).............................8W-44-1

PANEL ILLUMINATION LAMPS,

INSTRUMENT; INTERIOR LIGHTING

(XJ-RHD).........................8W-44-1

PANEL, INSTRUMENT.............8E-24,8E-1

PANEL INSULATOR PANELÐXJ, DASH....23-12

PANEL LAMP, ACCESSORY LAMP AND

HEATER CONTROL; INTERIOR

LIGHTING (YJ)....................8W-44-1

PANEL OUTLET VACUUM MOTOR

REPLACEMENT, HEATER/DEFROSTER/

INSTRUMENT.......................24-26

PANEL REMOVE/INSTALL, INSTRUMENT . . 8E-20

PANELÐXJ, DASH PANEL INSULATOR....23-12

PANELÐXJ, DOOR TRIM..............23-31

PANELÐXJ, FRONT INNER SCUFF

PLATE/COWL SIDE TRIM...............23-86

PANELÐXJ, LIFTGATE TRIM............23-59

PANELÐYJ, FULL-METAL DOOR TRIM . . . 23-137

PANELÐYJ, HOOD INSULATOR........23-107

PANELÐYJ, INSTRUMENT............23-151

PANELS AND SCUFF PLATESÐXJ,

INTERIOR TRIM......................23-84

PANELSÐXJ, QUARTER AND

WHEELHOUSE TRIM..................23-87

PARK GEAR OVERHAUL, GOVERNOR....21-127

PARK GEAR SERVICE, GOVERNOR......21-105

PARK INTERLOCK CABLE ADJUSTMENT . 21-195

PARK INTERLOCK CABLE ADJUSTMENT

(XJ)..............................21-101

PARK LOCK COMPONENT OVERHAUL,

ADAPTER/EXTENSION HOUSING

INSPECTION.......................21-127

PARK LOCK COMPONENT

REPLACEMENT.....................21-108

PARK NEUTRAL SWITCH..............14-63

PARK ROD AND PAWL SERVICE........21-190

PARKING BRAKE CABLE TENSIONER

ADJUSTMENT (XJ/YJ)..................5-69

PARKING BRAKE CABLE TENSIONER

REPLACEMENT (XJ)...................5-66

PARKING BRAKE FRONT CABLE

REPLACEMENT (YJ)...................5-67

PARKING BRAKE HANDLE COVERÐXJ....23-94

PARKING BRAKE LEVER INSTALLATION

(XJ WITH FULL CONSOLE)..............5-64

PARKING BRAKE LEVER INSTALLATION

(XJ WITH MINI CONSOLE)..............5-63

PARKING BRAKE LEVER INSTALLATION

(XJ WITHOUT CONSOLE)...............5-65

PARKING BRAKE LEVER REMOVAL (XJ

WITH FULL CONSOLE).................5-63

PARKING BRAKE LEVER REMOVAL (XJ

WITH MINI CONSOLE).................5-62

PARKING BRAKE LEVER REMOVAL (XJ

WITHOUT CONSOLE)...................5-64

PARKING BRAKE MALFUNCTIONS,

DIAGNOSING..........................5-8

PARKING BRAKE OPERATION............5-60

PARKING BRAKE PEDAL INSTALLATION

(YJ)................................5-66

PARKING BRAKE PEDAL REMOVAL (YJ) . . . 5-66

PARKING BRAKE REAR CABLE

REPLACEMENT (XJ)...................5-67

PARKING BRAKE REAR CABLE

REPLACEMENT (YJ)...................5-68

PARKING BRAKE SWITCH...............5-68

PARKING BRAKES.....................5-60

PARKING LAMPS; FRONT LIGHTING

(XJ).............................8W-50-1

PARKING LAMPS; FRONT LIGHTING

(XJ-RHD).........................8W-50-2

PARKING LAMPS; FRONT LIGHTING

(YJ).............................8W-50-1

PARK/NEUTRAL POSITION SWITCH;

FUEL/IGNITION (XJ)

................8W-30-4

PARK/NEUTRAL POSITION SWITCH;

FUEL/IGNITION (YJ)

................8W-30-4

PARK/NEUTRAL POSITION SWITCH;

TRANSMISSION AND TRANSFER CASE

. . 21-183

PARK/NEUTRAL POSITION SWITCH;

FUEL/IGNITION (XJ-RHD)

............8W-30-4

PARK/NEUTRAL POSITION SWITCH

SERVICE

..........................21-109PARK/NEUTRAL SWITCHÐPCM INPUT . . . 14-24

PARK/TURN SIGNAL LAMP BULB

REPLACEMENTÐXJ, FRONT.............8L-9

PARK/TURN SIGNAL LAMP BULB

REPLACEMENTÐYJ, FRONT............8L-25

PARTS INTERCHANGEABILITY,

TRANSMISSION CHANGES.............21-67

PARTS RECOMMENDATION,

LUBRICATION AND REPLACEMENT........0-2

PASSENGER'S POWER LOCK SWITCH.....8P-6

PASSENGER'S POWER WINDOW

SWITCH.............................8S-6

PATTERN ANALYSIS, BACKLASH AND

CONTACT; FRONT SUSPENSION AND

AXLE...............................2-45

PATTERN ANALYSIS, BACKLASH AND

CONTACT; REAR SUSPENSION AND

AXLES..............................3-27

PATTERN, SHIFT......................21-2

PATTERN, TRANSMISSION SHIFT........21-34

PATTERNS, TIRE WEAR................22-4

PAWL SERVICE, PARK ROD...........21-190

PCM SYSTEM SCHEMATICS............14-41

PEDAL, ACCELERATOR................14-17

PEDAL AND THROTTLE CABLE,

ACCELERATOR.................14-17,14-58

PEDAL BUSHINGS, CLUTCH AND BRAKE . . . 0-22

PEDAL INSTALLATION, BRAKE...........5-31

PEDAL INSTALLATION, CLUTCH..........6-15

PEDAL INSTALLATION (YJ), PARKING

BRAKE...............................5-66

PEDAL REMOVAL, BRAKE...............5-31

PEDAL REMOVAL, CLUTCH..............6-15

PEDAL REMOVAL (YJ), PARKING BRAKE . . . 5-66

PEDAL TRAVEL SENSOR, BRAKE;

ANTI-LOCK BRAKES (YJ)............8W-32-1

PEDALÐBRAKELIGHT SWITCH, POWER

BRAKE BOOSTERÐBRAKE..............5-22

PERFORMANCE, ENGINE.................9-2

PERFORMANCE TEMPERATURE AND

PRESSURE CHART, XJ................24-13

PERFORMANCE TEMPERATURE AND

PRESSURE CHART, YJ................24-13

PERFORMANCE TEST, REFRIGERANT

SERVICE...........................24-11

PERFORMANCE TESTS, AIR

CONDITIONING......................24-12

PILLAR TRIM COVERSÐXJ, B/C-PILLAR

AND LIFTGATE.......................23-88

PILOT BEARING REPLACEMENT..........6-12

PIN REPLACEMENT, CAMSHAFT......9-34,9-75

PIN REPLACEMENTÐXJ, DOOR

HINGE/HINGE.......................23-52

PINION GEAR ASSEMBLY/INSTALLATION . . . 2-42

PINION GEAR DEPTH INFORMATION;

FRONT SUSPENSION AND AXLE..........2-39

PINION GEAR DEPTH INFORMATION;

REAR SUSPENSION AND AXLES..........3-21

PINION GEAR DEPTH VARIANCE; FRONT

SUSPENSION AND AXLE................2-40

PINION GEAR DEPTH VARIANCE; REAR

SUSPENSION AND AXLES...........3-22,3-39

PINION MEASUREMENT AND ASSEMBLY . . . 3-22

PINION MEASUREMENT, DIFFERENTIAL....2-40

PINION REMOVAL/DISASSEMBLY; FRONT

SUSPENSION AND AXLE................2-36

PINION REMOVAL/DISASSEMBLY; REAR

SUSPENSION AND AXLES...............3-19

PINION SEAL REPLACEMENT; FRONT

SUSPENSION AND AXLE................2-25

PINION SEAL REPLACEMENT; REAR

SUSPENSION AND AXLES...............3-33

PINION SHAFT SEAL REPLACEMENT......3-15

PIPEÐXJ VEHICLES, EXHAUST..........11-3

PIPEÐYJ VEHICLES, EXHAUST..........11-4

PISTON AND TRANSMISSION CASE

OVERHAUL, FIRST-REVERSE BRAKE....21-247

PISTON AND WORM SHAFT

REPLACEMENT, RACK.................19-32

PISTON CLEARANCE, AW-4 BUSHING . . . 21-339

PISTON SPECIFICATIONS, AW-4

RETAINER.........................21-340

PISTONS AND CONNECTING RODS

. . . 9-39,9-81

PISTONS AND SPRINGS, ACCUMULATOR

. 21-189

PITMAN ARM

..................19-17,19-20

PITMAN SHAFT AND SIDE COVER

REPLACEMENT

......................19-28

PITMAN SHAFT SEAL REPLACEMENT

.....19-37PITMAN SHAFT SEALS AND BEARING

REPLACEMENT......................19-34

PITMAN SHAFT SEALSÐIN CAR

REPLACEMENT......................19-23

PIVOTS REMOVE/INSTALL, WINDSHIELD

WIPER LINKAGE.....................8K-17

PLANETARY GEAR AND CLUTCH

OVERHAUL, OVERDRIVE..............21-218

PLANETARY GEAR OVERHAUL, FRONT . . . 21-237

PLANETARY GEAR TRAIN OVERHAUL . . . 21-141

PLASTIC COMPONENT INSPECTION,

RUBBER............................0-20

PLASTIC HOSES/TUBING, RUBBER........0-26

PLASTIC INSERTÐXJ, REAR QUARTER

WINDOW GLASS/REAR QUARTER.......23-73

PLASTIGAGE, MEASURING WITH..........9-3

PLATE, FRONT SKID...................13-1

PLATE, FUEL TANK SKID...........13-15,13-3

PLATE LAMP HOUSINGÐXJ, LIFTGATE

LICENSE...........................23-65

PLATE LAMPÐXJ, LICENSE............8L-12

PLATE LAMPS, TAIL LAMPS AND

LICENSE.........................8W-51-1

PLATE LAMPS, TAIL LAMPS AND REAR

LICENSE; REAR LIGHTING (XJ).......8W-51-1

PLATE LAMPS, TAIL LAMPS AND REAR

LICENSE; REAR LIGHTING (XJ-RHD) . . . 8W-51-1

PLATE REPLACEMENT, SUPPORT.........5-58

PLATE SCREW ANCHOR AND BUMPERÐ

XJ, LIFTGATE LICENSE................23-65

PLATE SERVICE, CONVERTERÐPUMP

SEALÐDRIVE......................21-116

PLATE SPECIFICATIONS, 30RH/32RH

SNAP RING/THRUST WASHER/THRUST . . 21-335

PLATE THICKNESS, AW-4 CLUTCH DISC . 21-338

PLATE, TRANSFER CASE SKID......13-15,13-3

PLATE, VEHICLE CODE...............Intro.-4

PLATE, VEHICLE IDENTIFICATION

NUMBER (VIN).....................Intro.-4

PLATE/COWL SIDE TRIM PANELÐXJ,

FRONT INNER SCUFF.................23-86

PLATESÐXJ, INTERIOR TRIM PANELS

AND SCUFF.........................23-84

PLATESÐXJ, OUTER SCUFF............23-89

PLATESÐXJ, VEHICLE, LABELS........Intro.-2

PLATESÐYJ, VEHICLE, LABELS........Intro.-3

PLATFORMÐXJ, BUCKET SEAT.........23-82

PLUG ASSEMBLY REPLACEMENT,

ADJUSTER..........................19-29

PLUG CABLE RESISTANCE, SPARK......8D-14

PLUG, HOUSING END.................19-28

PLUG LOCATIONS, TRANSMISSION

SWITCH............................21-34

PLUG SECONDARY CABLES, SPARK.....8D-14,

8D-24

PLUGS, SPARK; IGNITION SYSTEMS....8D-12,

8D-23,8D-32

PLUGS, SPARK; LUBRICATION AND

MAINTENANCE.......................0-20

POLISHING, WET SANDING,BUFFING....23-158

POOR CONNECTIONS, INTERMITTENT;

WIRING DIAGRAMSÐGENERAL

INFORMATION (XJ)

...................8W-4

POSITION SENSOR, CAMSHAFT; FUEL

SYSTEM

............................14-60

POSITION SENSOR, CAMSHAFT;

FUEL/IGNITION (XJ)

................8W-30-3

POSITION SENSOR, CAMSHAFT;

FUEL/IGNITION (YJ)

................8W-30-3

POSITION SENSOR, CAMSHAFT;

IGNITION SYSTEMS

..............8D-17,8D-2

POSITION SENSOR, CAMSHAFT;

FUEL/IGNITION (XJ-RHD)

............8W-30-3

POSITION SENSOR, CRANKSHAFT; FUEL

SYSTEM

............................14-60

POSITION SENSOR, CRANKSHAFT;

FUEL/IGNITION (XJ)

................8W-30-3

POSITION SENSOR, CRANKSHAFT;

FUEL/IGNITION (YJ)

................8W-30-3

POSITION SENSOR, CRANKSHAFT;

IGNITION SYSTEMS

..............8D-17,8D-3

POSITION SENSOR, CRANKSHAFT;

FUEL/IGNITION (XJ-RHD)

............8W-30-3

POSITION SENSOR TEST, CAMSHAFT;

FUEL SYSTEM

.......................14-46

POSITION SENSOR TEST, CAMSHAFT;

IGNITION SYSTEMS

...................8D-6

20 INDEXJ

Description Group-Page Description Group-Page Description Group-Page