air bleeding JEEP YJ 1995 Service And Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 162 of 2158

BRAKE FLUIDÐBRAKE BLEEDINGÐBRAKELINES AND HOSES

INDEX

page page

Brake Bleeding (With ABS Brakes)............ 11

Brake Bleeding (With Standard Brakes)......... 11

Brake Bleeding Recommendations............ 10

Brake Fluid Contamination.................. 10Brake Fluid Level......................... 10

Brakeline Charts.......................... 12

Brakelines and Hoses...................... 12

Recommended Brake Fluid.................. 10

RECOMMENDED BRAKE FLUID

Recommended brake fluid for Jeep vehicles is Mo-

par brake fluid, or an equivalent fluid meeting SAE

J1703 and DOT 3 standards. The recommendation

applies to models with standard or ABS brakes.

Use new brake fluid to top off the master cyl-

inder or refill the system. Never use reclaimed

fluid, fluid not meeting the SAE/DOT standards

or fluid from an unsealed container. Do not use

fluid from any container that has been left

open for any length of time. Fluid in open con-

tainers can absorb moisture.

BRAKE FLUID LEVEL

Always clean the master cylinder reservoir and

cover or cap before adding fluid. This avoids having

dirt from the cap or reservoir exterior fall into the

fluid.

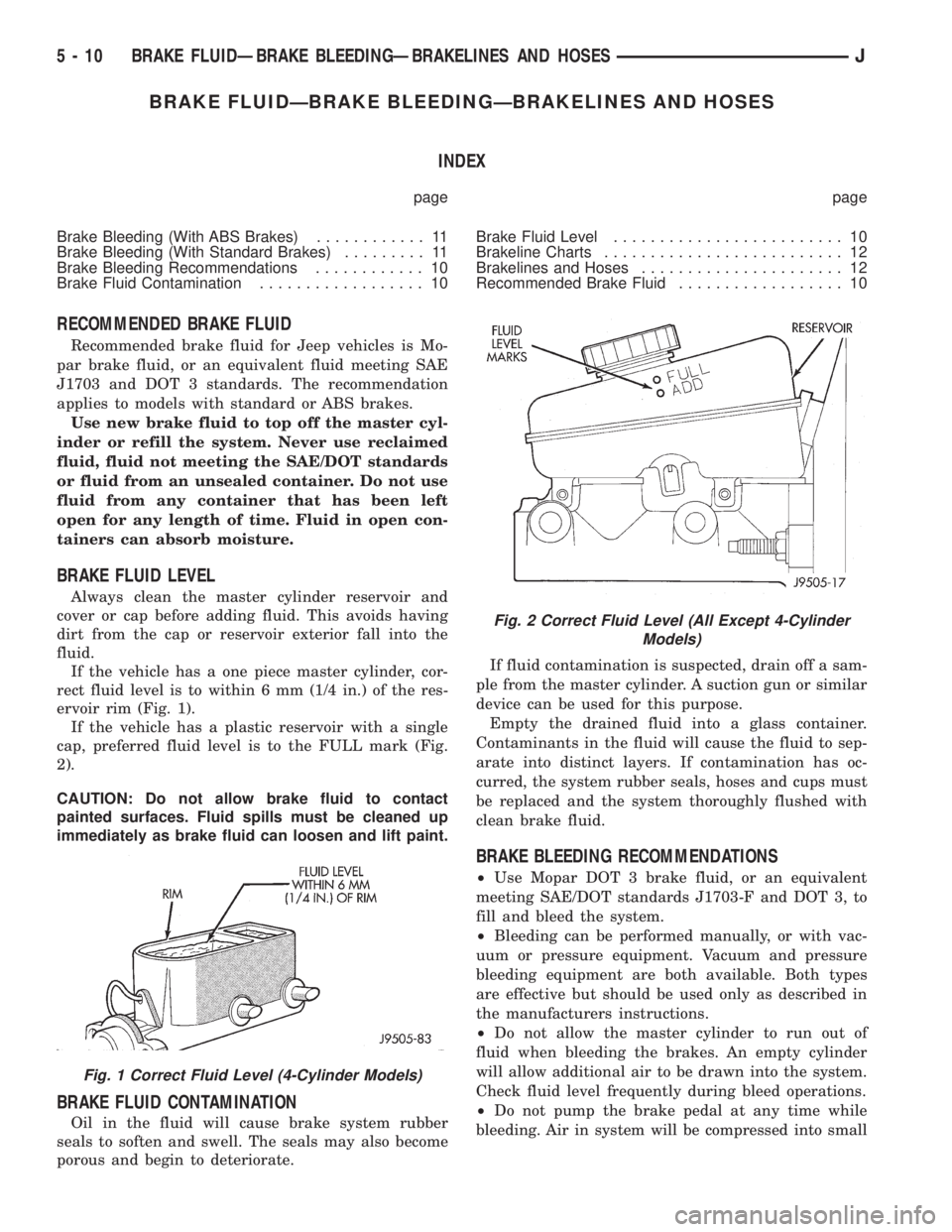

If the vehicle has a one piece master cylinder, cor-

rect fluid level is to within 6 mm (1/4 in.) of the res-

ervoir rim (Fig. 1).

If the vehicle has a plastic reservoir with a single

cap, preferred fluid level is to the FULL mark (Fig.

2).

CAUTION: Do not allow brake fluid to contact

painted surfaces. Fluid spills must be cleaned up

immediately as brake fluid can loosen and lift paint.

BRAKE FLUID CONTAMINATION

Oil in the fluid will cause brake system rubber

seals to soften and swell. The seals may also become

porous and begin to deteriorate.If fluid contamination is suspected, drain off a sam-

ple from the master cylinder. A suction gun or similar

device can be used for this purpose.

Empty the drained fluid into a glass container.

Contaminants in the fluid will cause the fluid to sep-

arate into distinct layers. If contamination has oc-

curred, the system rubber seals, hoses and cups must

be replaced and the system thoroughly flushed with

clean brake fluid.

BRAKE BLEEDING RECOMMENDATIONS

²Use Mopar DOT 3 brake fluid, or an equivalent

meeting SAE/DOT standards J1703-F and DOT 3, to

fill and bleed the system.

²Bleeding can be performed manually, or with vac-

uum or pressure equipment. Vacuum and pressure

bleeding equipment are both available. Both types

are effective but should be used only as described in

the manufacturers instructions.

²Do not allow the master cylinder to run out of

fluid when bleeding the brakes. An empty cylinder

will allow additional air to be drawn into the system.

Check fluid level frequently during bleed operations.

²Do not pump the brake pedal at any time while

bleeding. Air in system will be compressed into small

Fig. 1 Correct Fluid Level (4-Cylinder Models)

Fig. 2 Correct Fluid Level (All Except 4-Cylinder

Models)

5 - 10 BRAKE FLUIDÐBRAKE BLEEDINGÐBRAKELINES AND HOSESJ

Page 163 of 2158

bubbles that are distributed throughout the hydrau-

lic system. This will make extra bleeding operations

necessary.

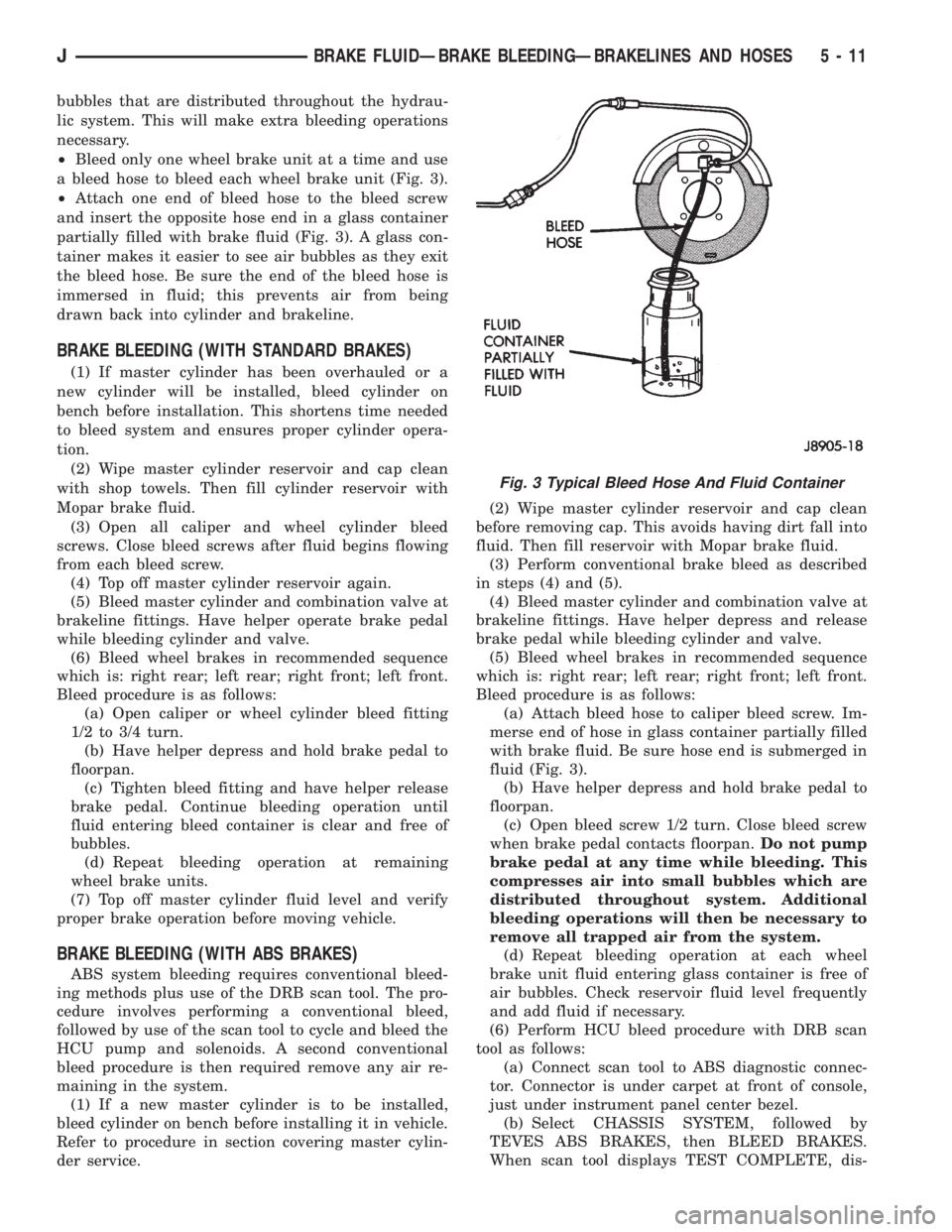

²Bleed only one wheel brake unit at a time and use

a bleed hose to bleed each wheel brake unit (Fig. 3).

²Attach one end of bleed hose to the bleed screw

and insert the opposite hose end in a glass container

partially filled with brake fluid (Fig. 3). A glass con-

tainer makes it easier to see air bubbles as they exit

the bleed hose. Be sure the end of the bleed hose is

immersed in fluid; this prevents air from being

drawn back into cylinder and brakeline.

BRAKE BLEEDING (WITH STANDARD BRAKES)

(1) If master cylinder has been overhauled or a

new cylinder will be installed, bleed cylinder on

bench before installation. This shortens time needed

to bleed system and ensures proper cylinder opera-

tion.

(2) Wipe master cylinder reservoir and cap clean

with shop towels. Then fill cylinder reservoir with

Mopar brake fluid.

(3) Open all caliper and wheel cylinder bleed

screws. Close bleed screws after fluid begins flowing

from each bleed screw.

(4) Top off master cylinder reservoir again.

(5) Bleed master cylinder and combination valve at

brakeline fittings. Have helper operate brake pedal

while bleeding cylinder and valve.

(6) Bleed wheel brakes in recommended sequence

which is: right rear; left rear; right front; left front.

Bleed procedure is as follows:

(a) Open caliper or wheel cylinder bleed fitting

1/2 to 3/4 turn.

(b) Have helper depress and hold brake pedal to

floorpan.

(c) Tighten bleed fitting and have helper release

brake pedal. Continue bleeding operation until

fluid entering bleed container is clear and free of

bubbles.

(d) Repeat bleeding operation at remaining

wheel brake units.

(7) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

BRAKE BLEEDING (WITH ABS BRAKES)

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-

cedure involves performing a conventional bleed,

followed by use of the scan tool to cycle and bleed the

HCU pump and solenoids. A second conventional

bleed procedure is then required remove any air re-

maining in the system.

(1) If a new master cylinder is to be installed,

bleed cylinder on bench before installing it in vehicle.

Refer to procedure in section covering master cylin-

der service.(2) Wipe master cylinder reservoir and cap clean

before removing cap. This avoids having dirt fall into

fluid. Then fill reservoir with Mopar brake fluid.

(3) Perform conventional brake bleed as described

in steps (4) and (5).

(4) Bleed master cylinder and combination valve at

brakeline fittings. Have helper depress and release

brake pedal while bleeding cylinder and valve.

(5) Bleed wheel brakes in recommended sequence

which is: right rear; left rear; right front; left front.

Bleed procedure is as follows:

(a) Attach bleed hose to caliper bleed screw. Im-

merse end of hose in glass container partially filled

with brake fluid. Be sure hose end is submerged in

fluid (Fig. 3).

(b) Have helper depress and hold brake pedal to

floorpan.

(c) Open bleed screw 1/2 turn. Close bleed screw

when brake pedal contacts floorpan.Do not pump

brake pedal at any time while bleeding. This

compresses air into small bubbles which are

distributed throughout system. Additional

bleeding operations will then be necessary to

remove all trapped air from the system.

(d) Repeat bleeding operation at each wheel

brake unit fluid entering glass container is free of

air bubbles. Check reservoir fluid level frequently

and add fluid if necessary.

(6) Perform HCU bleed procedure with DRB scan

tool as follows:

(a) Connect scan tool to ABS diagnostic connec-

tor. Connector is under carpet at front of console,

just under instrument panel center bezel.

(b) Select CHASSIS SYSTEM, followed by

TEVES ABS BRAKES, then BLEED BRAKES.

When scan tool displays TEST COMPLETE, dis-

Fig. 3 Typical Bleed Hose And Fluid Container

JBRAKE FLUIDÐBRAKE BLEEDINGÐBRAKELINES AND HOSES 5 - 11

Page 164 of 2158

connect scan tool and proceed to next step.

(7)Repeatconventional bleed procedure described

in steps (4) and (5).

(8) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

BRAKELINES AND HOSES

Metal brakelines and rubber brake hoses should be

inspected periodically and replaced if damaged.

Rubber brake hoses should be replaced if cut,

cracked, swollen, or leaking. Rubber hoses must be

replaced as they are not repairable.

Steel brakelines should be inspected any time the

vehicle is in for normal maintenance. This is impor-

tant on high mileage vehicles. It is especially impor-

tant when the vehicle is operated on roads that are

salted during winter months.

Heavily rusted/corroded brake rotors, drums,

support plates, and brakelines should be

cleaned and carefully inspected. Heavy rust

buildup can hide severe damage to a compo-

nent. Severely rusted parts should be replaced

if condition is suspect.

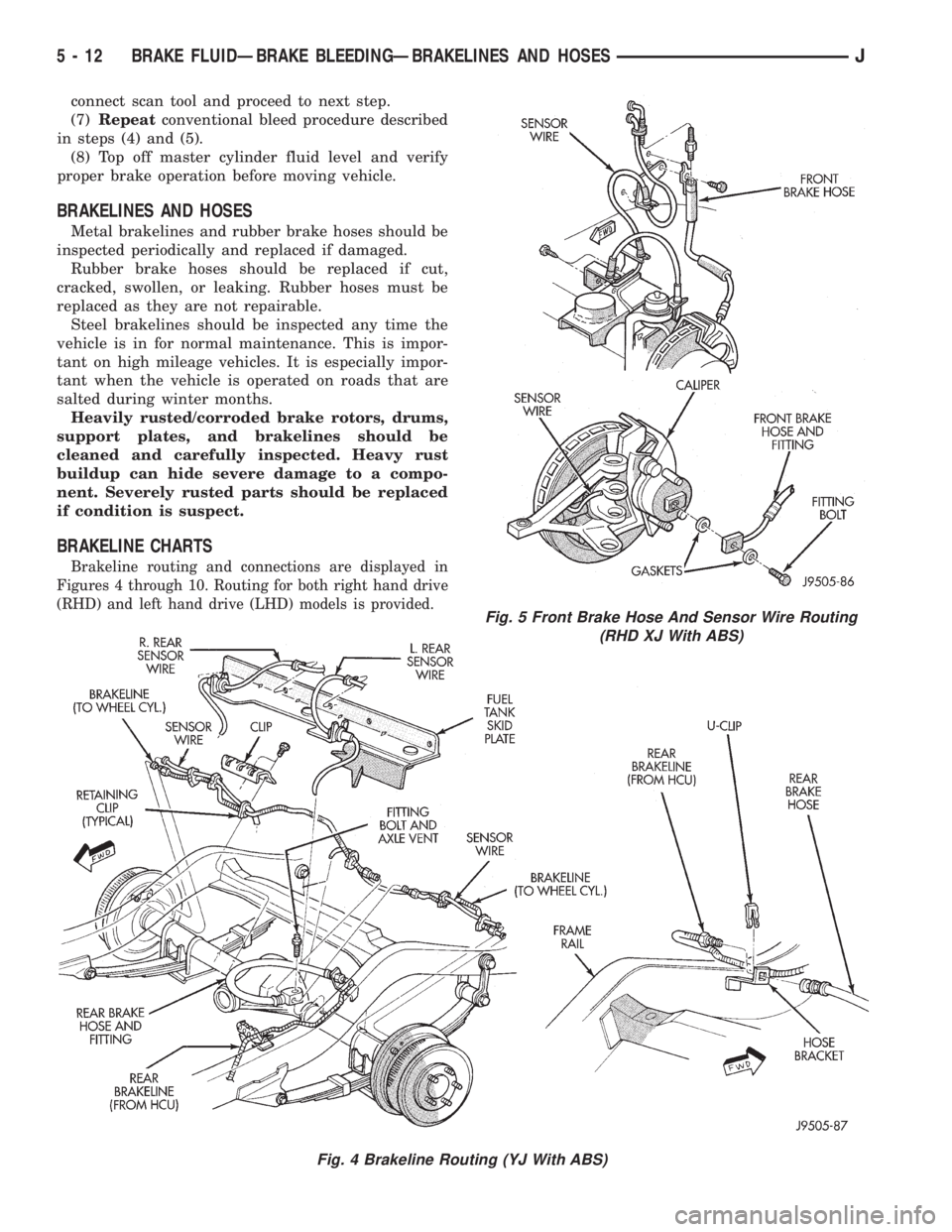

BRAKELINE CHARTS

Brakeline routing and connections are displayed in

Figures 4 through 10. Routing for both right hand drive

(RHD) and left hand drive (LHD) models is provided.

Fig. 4 Brakeline Routing (YJ With ABS)

Fig. 5 Front Brake Hose And Sensor Wire Routing

(RHD XJ With ABS)

5 - 12 BRAKE FLUIDÐBRAKE BLEEDINGÐBRAKELINES AND HOSESJ

Page 167 of 2158

MASTER CYLINDERÐCOMBINATION VALVE

INDEX

page page

Combination Valve Replacement (Non-ABS)..... 16

General Service Information................. 15

Master Cylinder and Combination Valve Installation

(With ABS)............................. 20

Master Cylinder and Combination Valve Removal

(With ABS)............................. 17Master Cylinder Bench Bleeding.............. 21

Master Cylinder Installation (Non-ABS)......... 16

Master Cylinder Overhaul (4-Cylinder Models).... 16

Master Cylinder Removal (Non-ABS)........... 15

Reservoir Replacement (2-Piece Master Cylinder) . 19

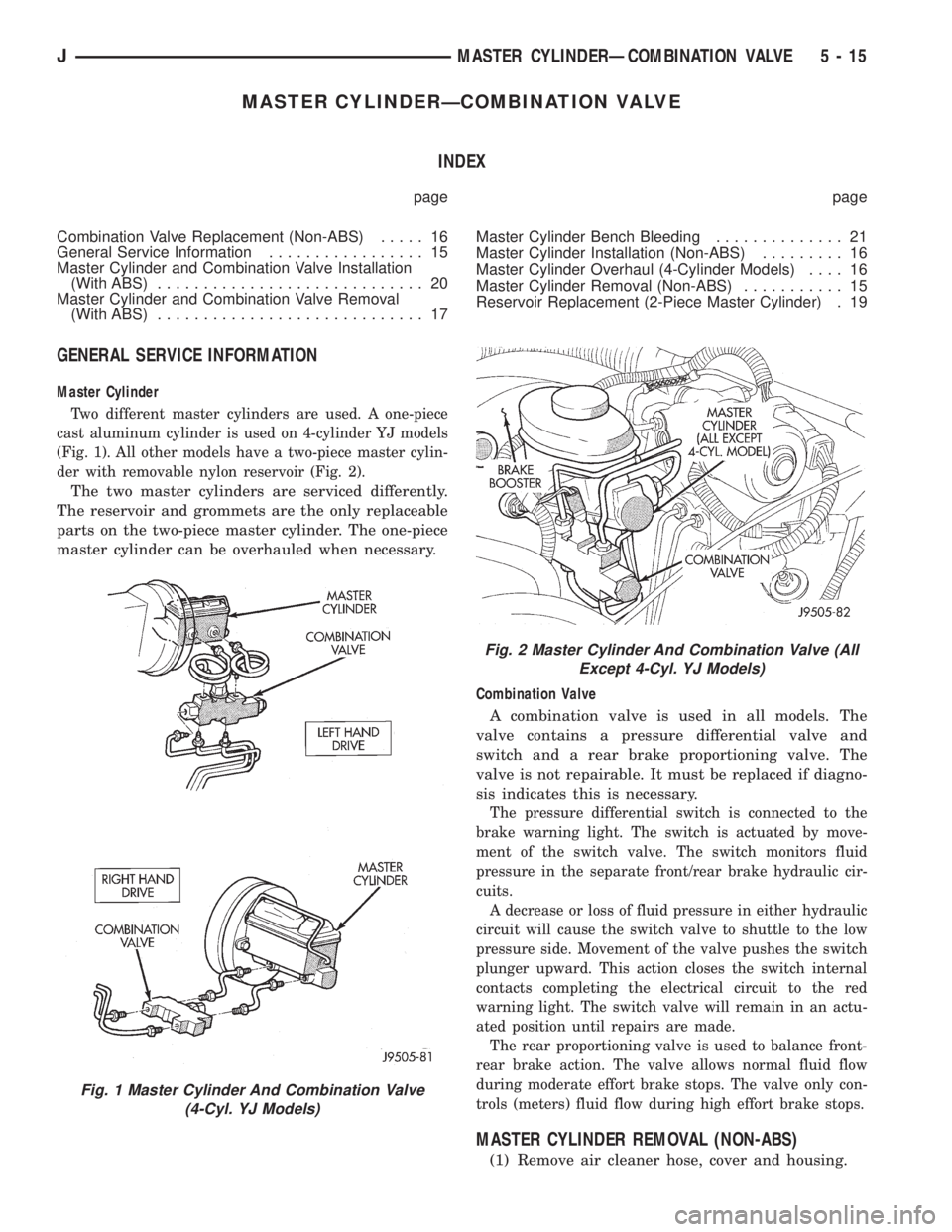

GENERAL SERVICE INFORMATION

Master Cylinder

Two different master cylinders are used. A one-piece

cast aluminum cylinder is used on 4-cylinder YJ models

(Fig. 1). All other models have a two-piece master cylin-

der with removable nylon reservoir (Fig. 2).

The two master cylinders are serviced differently.

The reservoir and grommets are the only replaceable

parts on the two-piece master cylinder. The one-piece

master cylinder can be overhauled when necessary.

Combination Valve

A combination valve is used in all models. The

valve contains a pressure differential valve and

switch and a rear brake proportioning valve. The

valve is not repairable. It must be replaced if diagno-

sis indicates this is necessary.

The pressure differential switch is connected to the

brake warning light. The switch is actuated by move-

ment of the switch valve. The switch monitors fluid

pressure in the separate front/rear brake hydraulic cir-

cuits.

A decrease or loss of fluid pressure in either hydraulic

circuit will cause the switch valve to shuttle to the low

pressure side. Movement of the valve pushes the switch

plunger upward. This action closes the switch internal

contacts completing the electrical circuit to the red

warning light. The switch valve will remain in an actu-

ated position until repairs are made.

The rear proportioning valve is used to balance front-

rear brake action. The valve allows normal fluid flow

during moderate effort brake stops. The valve only con-

trols (meters) fluid flow during high effort brake stops.

MASTER CYLINDER REMOVAL (NON-ABS)

(1) Remove air cleaner hose, cover and housing.

Fig. 1 Master Cylinder And Combination Valve

(4-Cyl. YJ Models)

Fig. 2 Master Cylinder And Combination Valve (All

Except 4-Cyl. YJ Models)

JMASTER CYLINDERÐCOMBINATION VALVE 5 - 15

Page 168 of 2158

(2) Disconnect brake lines at master cylinder and

combination valve.

(3) Remove nuts attaching master cylinder to

booster studs.

(4) Remove master cylinder.

(5) Remove cylinder cover and drain fluid.

(6) If two-piece master cylinder reservoir requires

service, refer to reservoir replacement procedure in

this section.

MASTER CYLINDER INSTALLATION (NON-ABS)

(1) Bleed master cylinder on bench before installa-

tion. Refer to procedure in this section.

(2) If new two-piece master cylinder is being in-

stalled, remove plastic protective sleeve from primary

piston shank. Also check condition of seal at rear of

cylinder body. Reposition seal if dislodged. Replace

seal if cut, or torn.

(3) Clean cylinder mounting surface of brake booster.

Use shop towel wetted with brake cleaner for this pur-

pose. Dirt, grease, or similar materials will prevent

proper cylinder seating and could result in vacuum leak.

(4) Slide master cylinder onto brake booster studs.

(5) Install nuts attaching master cylinder to booster

studs. Tighten nuts to 25 Nzm (220 in. lbs.) torque.

(6) Connect brakelines to master cylinder and com-

bination valve (Figs. 1 and 2).

(7) Fill and bleed brake system.

COMBINATION VALVE REPLACEMENT (NON-ABS)

The combination valve is not a repairable compo-

nent. The valve is serviced as an assembly whenever

diagnosis indicates replacement is necessary.

(1) Remove air cleaner cover and hose for access to

valve, if necessary.

(2) Disconnect differential pressure switch wire at

combination valve. Do not pull switch wire to discon-

nect. Unsnap connecter lock tabs to remove.

(3) Disconnect brakelines at combination valve and

remove valve.

(4) Connect brakelines to replacement valve. Start

line fittings by hand to avoid cross threading.

Tighten fittings snug but not to required torque at

this time.

(5) Connect wire to pressure differential switch.

(6) Bleed brakes.

(7) Tighten brakeline fittings to 18-24 Nzm

(160-210 in. lbs.) torque after bleeding.

MASTER CYLINDER OVERHAUL (4-CYLINDER

MODELS)

CYLINDER DISASSEMBLY

(1) Examine cylinder cover seal. Discard seal if

torn or distorted.

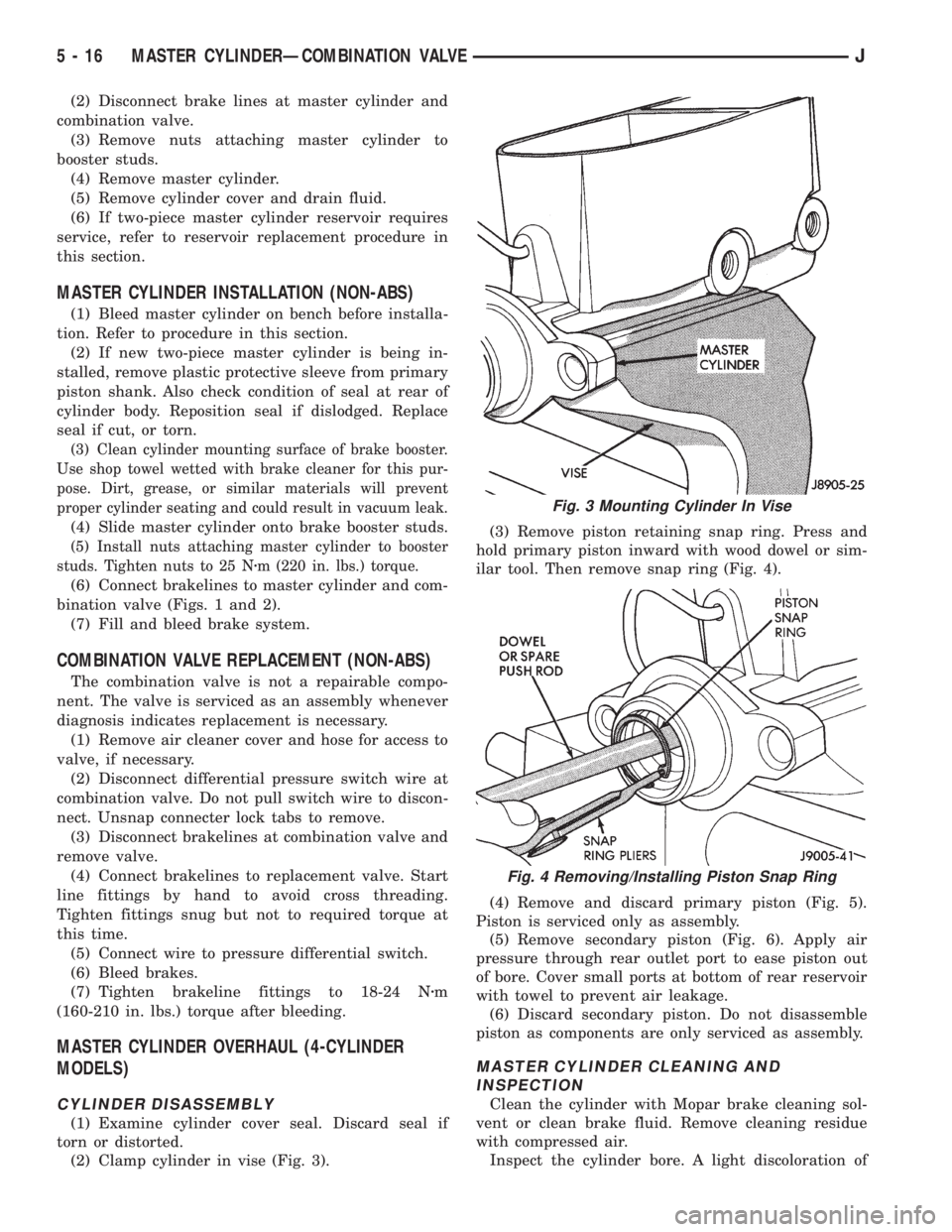

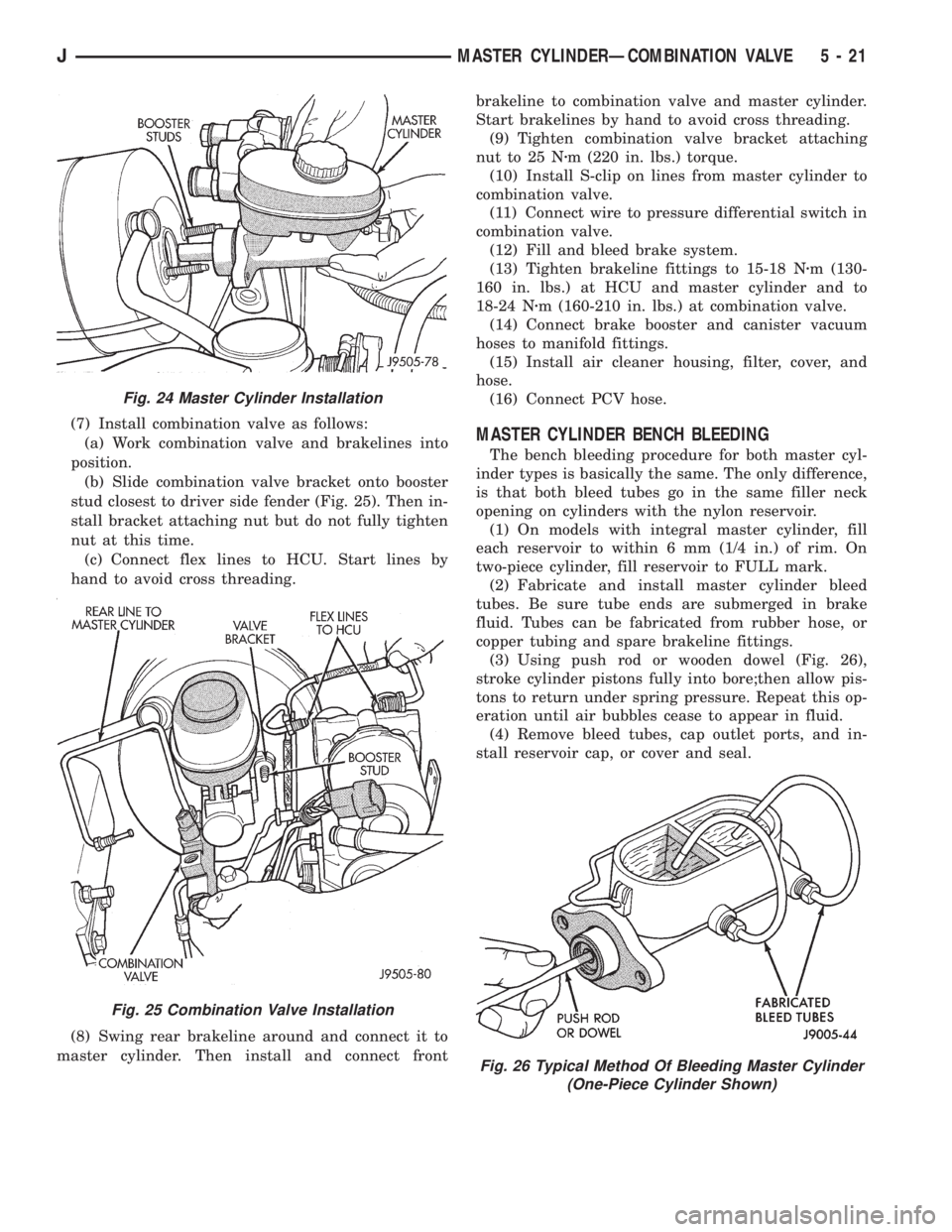

(2) Clamp cylinder in vise (Fig. 3).(3) Remove piston retaining snap ring. Press and

hold primary piston inward with wood dowel or sim-

ilar tool. Then remove snap ring (Fig. 4).

(4) Remove and discard primary piston (Fig. 5).

Piston is serviced only as assembly.

(5) Remove secondary piston (Fig. 6). Apply air

pressure through rear outlet port to ease piston out

of bore. Cover small ports at bottom of rear reservoir

with towel to prevent air leakage.

(6) Discard secondary piston. Do not disassemble

piston as components are only serviced as assembly.

MASTER CYLINDER CLEANING AND

INSPECTION

Clean the cylinder with Mopar brake cleaning sol-

vent or clean brake fluid. Remove cleaning residue

with compressed air.

Inspect the cylinder bore. A light discoloration of

Fig. 3 Mounting Cylinder In Vise

Fig. 4 Removing/Installing Piston Snap Ring

5 - 16 MASTER CYLINDERÐCOMBINATION VALVEJ

Page 173 of 2158

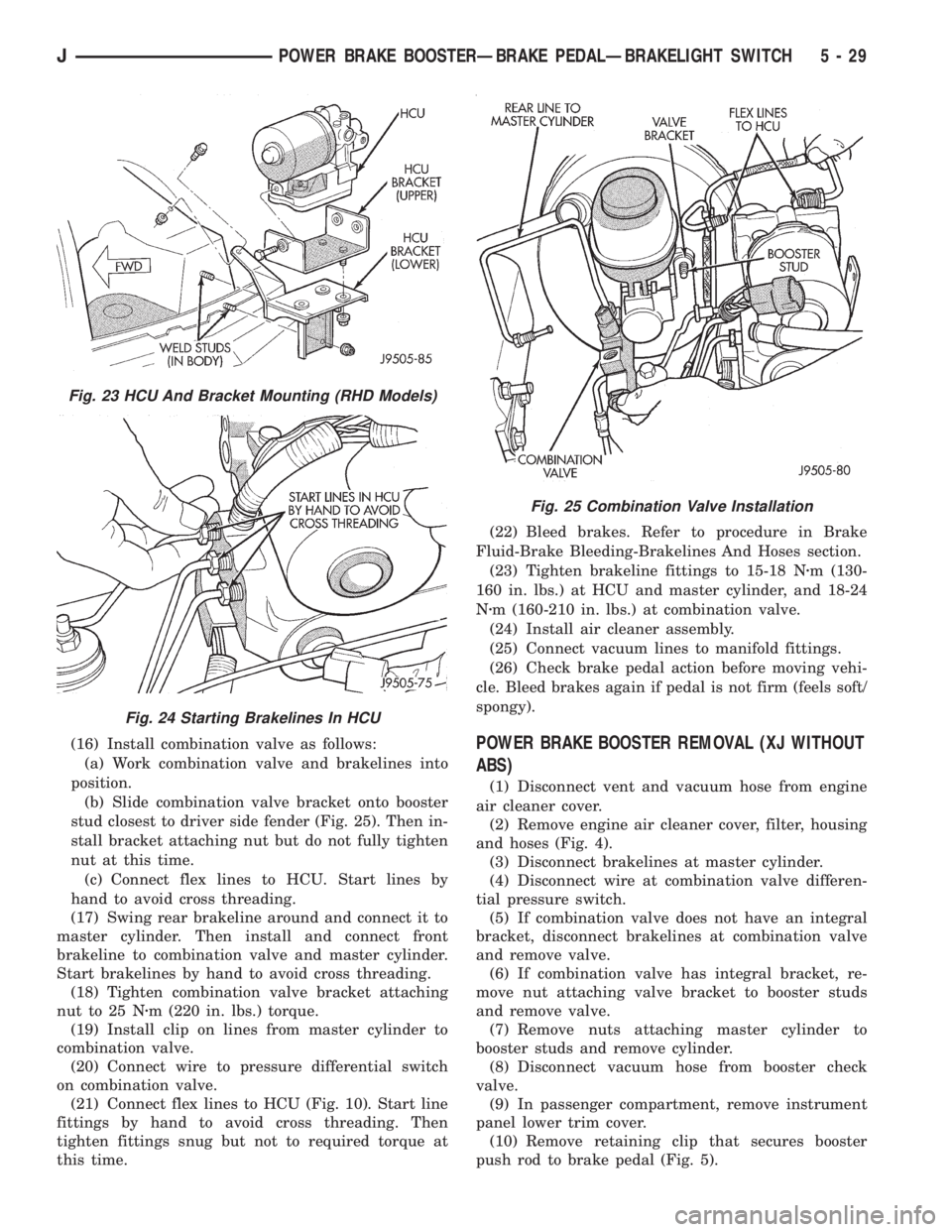

(7) Install combination valve as follows:

(a) Work combination valve and brakelines into

position.

(b) Slide combination valve bracket onto booster

stud closest to driver side fender (Fig. 25). Then in-

stall bracket attaching nut but do not fully tighten

nut at this time.

(c) Connect flex lines to HCU. Start lines by

hand to avoid cross threading.

(8) Swing rear brakeline around and connect it to

master cylinder. Then install and connect frontbrakeline to combination valve and master cylinder.

Start brakelines by hand to avoid cross threading.

(9) Tighten combination valve bracket attaching

nut to 25 Nzm (220 in. lbs.) torque.

(10) Install S-clip on lines from master cylinder to

combination valve.

(11) Connect wire to pressure differential switch in

combination valve.

(12) Fill and bleed brake system.

(13) Tighten brakeline fittings to 15-18 Nzm (130-

160 in. lbs.) at HCU and master cylinder and to

18-24 Nzm (160-210 in. lbs.) at combination valve.

(14) Connect brake booster and canister vacuum

hoses to manifold fittings.

(15) Install air cleaner housing, filter, cover, and

hose.

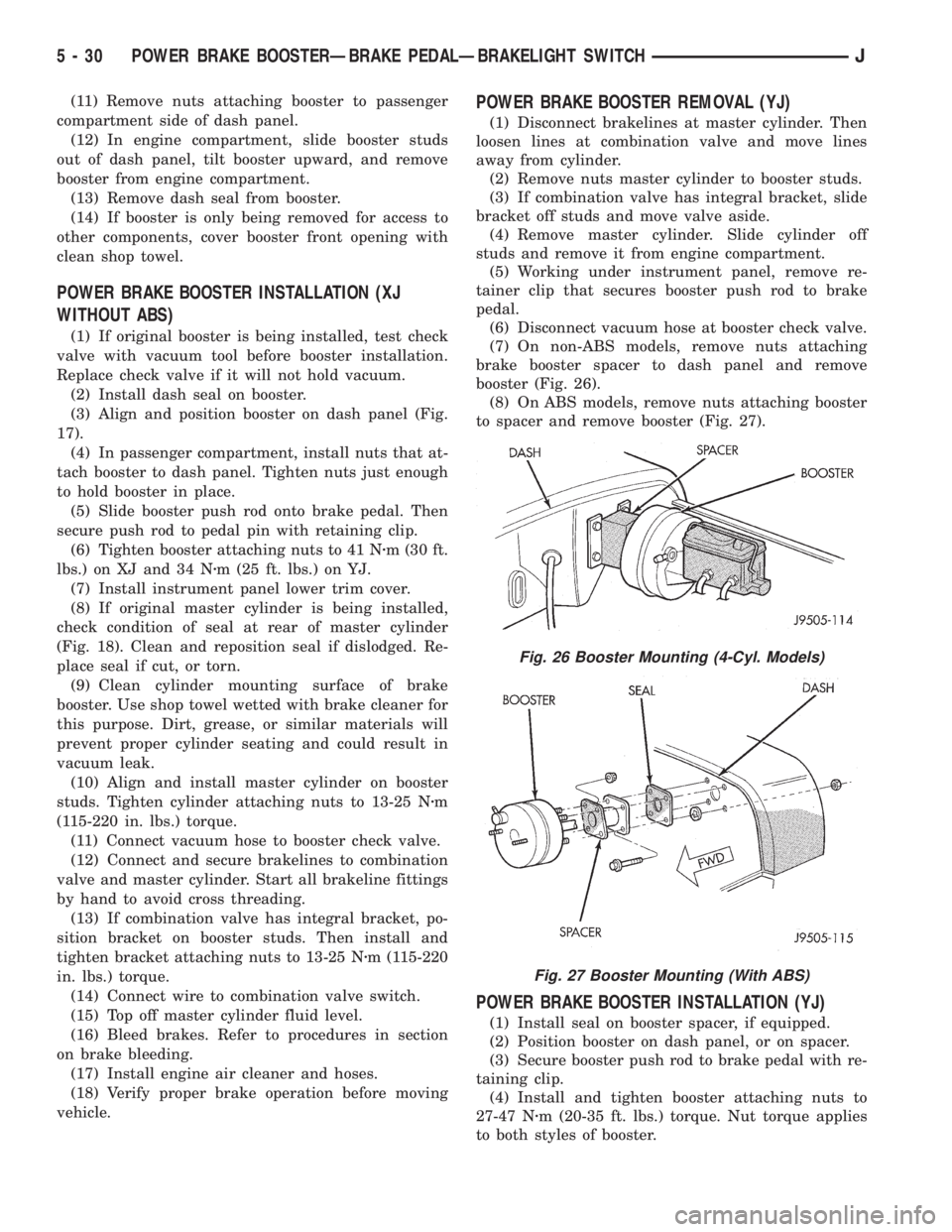

(16) Connect PCV hose.MASTER CYLINDER BENCH BLEEDING

The bench bleeding procedure for both master cyl-

inder types is basically the same. The only difference,

is that both bleed tubes go in the same filler neck

opening on cylinders with the nylon reservoir.

(1) On models with integral master cylinder, fill

each reservoir to within 6 mm (1/4 in.) of rim. On

two-piece cylinder, fill reservoir to FULL mark.

(2) Fabricate and install master cylinder bleed

tubes. Be sure tube ends are submerged in brake

fluid. Tubes can be fabricated from rubber hose, or

copper tubing and spare brakeline fittings.

(3) Using push rod or wooden dowel (Fig. 26),

stroke cylinder pistons fully into bore;then allow pis-

tons to return under spring pressure. Repeat this op-

eration until air bubbles cease to appear in fluid.

(4) Remove bleed tubes, cap outlet ports, and in-

stall reservoir cap, or cover and seal.

Fig. 24 Master Cylinder Installation

Fig. 25 Combination Valve Installation

Fig. 26 Typical Method Of Bleeding Master Cylinder

(One-Piece Cylinder Shown)

JMASTER CYLINDERÐCOMBINATION VALVE 5 - 21

Page 181 of 2158

(16) Install combination valve as follows:

(a) Work combination valve and brakelines into

position.

(b) Slide combination valve bracket onto booster

stud closest to driver side fender (Fig. 25). Then in-

stall bracket attaching nut but do not fully tighten

nut at this time.

(c) Connect flex lines to HCU. Start lines by

hand to avoid cross threading.

(17) Swing rear brakeline around and connect it to

master cylinder. Then install and connect front

brakeline to combination valve and master cylinder.

Start brakelines by hand to avoid cross threading.

(18) Tighten combination valve bracket attaching

nut to 25 Nzm (220 in. lbs.) torque.

(19) Install clip on lines from master cylinder to

combination valve.

(20) Connect wire to pressure differential switch

on combination valve.

(21) Connect flex lines to HCU (Fig. 10). Start line

fittings by hand to avoid cross threading. Then

tighten fittings snug but not to required torque at

this time.(22) Bleed brakes. Refer to procedure in Brake

Fluid-Brake Bleeding-Brakelines And Hoses section.

(23) Tighten brakeline fittings to 15-18 Nzm (130-

160 in. lbs.) at HCU and master cylinder, and 18-24

Nzm (160-210 in. lbs.) at combination valve.

(24) Install air cleaner assembly.

(25) Connect vacuum lines to manifold fittings.

(26) Check brake pedal action before moving vehi-

cle. Bleed brakes again if pedal is not firm (feels soft/

spongy).POWER BRAKE BOOSTER REMOVAL (XJ WITHOUT

ABS)

(1) Disconnect vent and vacuum hose from engine

air cleaner cover.

(2) Remove engine air cleaner cover, filter, housing

and hoses (Fig. 4).

(3) Disconnect brakelines at master cylinder.

(4) Disconnect wire at combination valve differen-

tial pressure switch.

(5) If combination valve does not have an integral

bracket, disconnect brakelines at combination valve

and remove valve.

(6) If combination valve has integral bracket, re-

move nut attaching valve bracket to booster studs

and remove valve.

(7) Remove nuts attaching master cylinder to

booster studs and remove cylinder.

(8) Disconnect vacuum hose from booster check

valve.

(9) In passenger compartment, remove instrument

panel lower trim cover.

(10) Remove retaining clip that secures booster

push rod to brake pedal (Fig. 5).

Fig. 23 HCU And Bracket Mounting (RHD Models)

Fig. 24 Starting Brakelines In HCU

Fig. 25 Combination Valve Installation

JPOWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCH 5 - 29

Page 182 of 2158

(11) Remove nuts attaching booster to passenger

compartment side of dash panel.

(12) In engine compartment, slide booster studs

out of dash panel, tilt booster upward, and remove

booster from engine compartment.

(13) Remove dash seal from booster.

(14) If booster is only being removed for access to

other components, cover booster front opening with

clean shop towel.

POWER BRAKE BOOSTER INSTALLATION (XJ

WITHOUT ABS)

(1) If original booster is being installed, test check

valve with vacuum tool before booster installation.

Replace check valve if it will not hold vacuum.

(2) Install dash seal on booster.

(3) Align and position booster on dash panel (Fig.

17).

(4) In passenger compartment, install nuts that at-

tach booster to dash panel. Tighten nuts just enough

to hold booster in place.

(5) Slide booster push rod onto brake pedal. Then

secure push rod to pedal pin with retaining clip.

(6) Tighten booster attaching nuts to 41 Nzm (30 ft.

lbs.) on XJ and 34 Nzm (25 ft. lbs.) on YJ.

(7) Install instrument panel lower trim cover.

(8) If original master cylinder is being installed,

check condition of seal at rear of master cylinder

(Fig. 18). Clean and reposition seal if dislodged. Re-

place seal if cut, or torn.

(9) Clean cylinder mounting surface of brake

booster. Use shop towel wetted with brake cleaner for

this purpose. Dirt, grease, or similar materials will

prevent proper cylinder seating and could result in

vacuum leak.

(10) Align and install master cylinder on booster

studs. Tighten cylinder attaching nuts to 13-25 Nzm

(115-220 in. lbs.) torque.

(11) Connect vacuum hose to booster check valve.

(12) Connect and secure brakelines to combination

valve and master cylinder. Start all brakeline fittings

by hand to avoid cross threading.

(13) If combination valve has integral bracket, po-

sition bracket on booster studs. Then install and

tighten bracket attaching nuts to 13-25 Nzm (115-220

in. lbs.) torque.

(14) Connect wire to combination valve switch.

(15) Top off master cylinder fluid level.

(16) Bleed brakes. Refer to procedures in section

on brake bleeding.

(17) Install engine air cleaner and hoses.

(18) Verify proper brake operation before moving

vehicle.

POWER BRAKE BOOSTER REMOVAL (YJ)

(1) Disconnect brakelines at master cylinder. Then

loosen lines at combination valve and move lines

away from cylinder.

(2) Remove nuts master cylinder to booster studs.

(3) If combination valve has integral bracket, slide

bracket off studs and move valve aside.

(4) Remove master cylinder. Slide cylinder off

studs and remove it from engine compartment.

(5) Working under instrument panel, remove re-

tainer clip that secures booster push rod to brake

pedal.

(6) Disconnect vacuum hose at booster check valve.

(7) On non-ABS models, remove nuts attaching

brake booster spacer to dash panel and remove

booster (Fig. 26).

(8) On ABS models, remove nuts attaching booster

to spacer and remove booster (Fig. 27).

POWER BRAKE BOOSTER INSTALLATION (YJ)

(1) Install seal on booster spacer, if equipped.

(2) Position booster on dash panel, or on spacer.

(3) Secure booster push rod to brake pedal with re-

taining clip.

(4) Install and tighten booster attaching nuts to

27-47 Nzm (20-35 ft. lbs.) torque. Nut torque applies

to both styles of booster.

Fig. 26 Booster Mounting (4-Cyl. Models)

Fig. 27 Booster Mounting (With ABS)

5 - 30 POWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCHJ

Page 195 of 2158

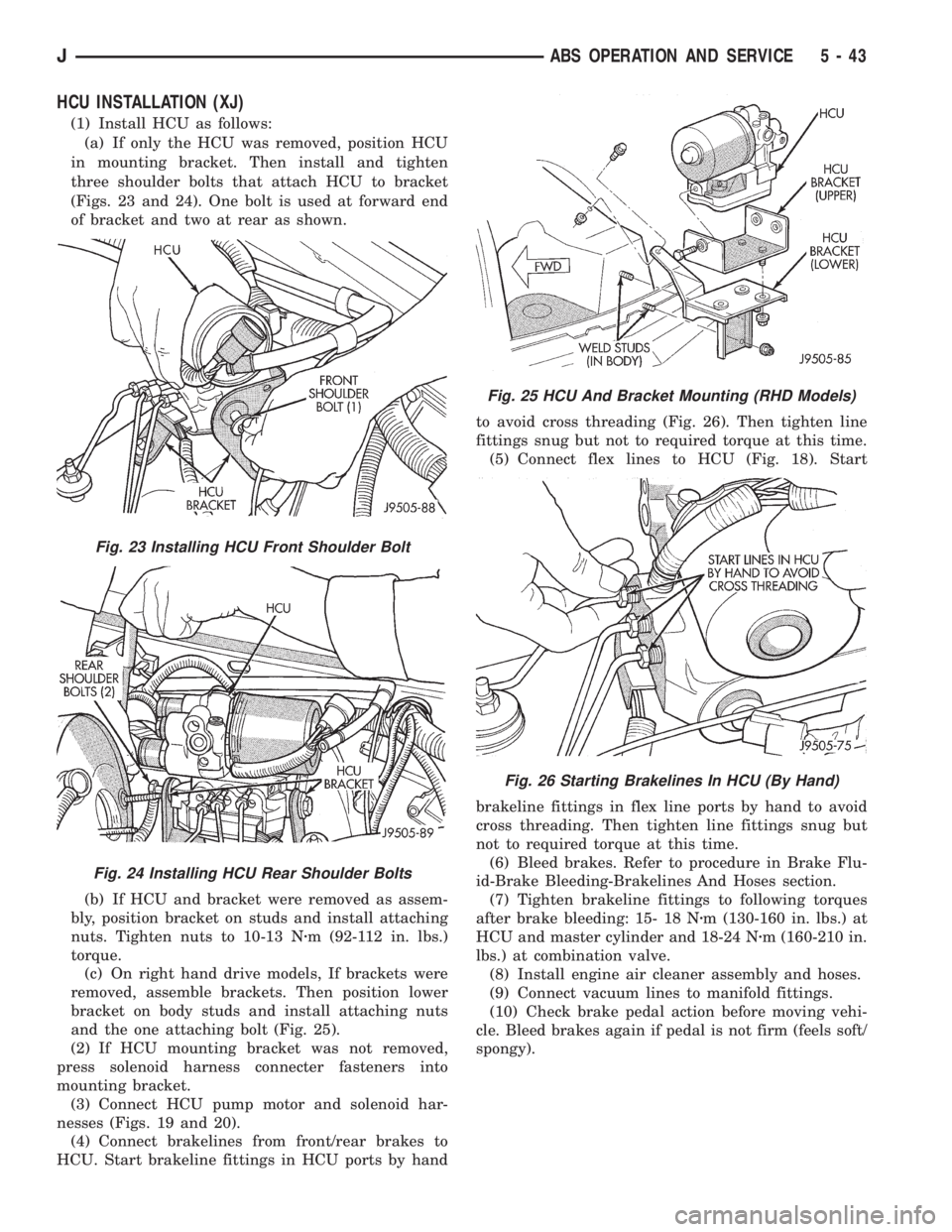

HCU INSTALLATION (XJ)

(1) Install HCU as follows:

(a) If only the HCU was removed, position HCU

in mounting bracket. Then install and tighten

three shoulder bolts that attach HCU to bracket

(Figs. 23 and 24). One bolt is used at forward end

of bracket and two at rear as shown.

(b) If HCU and bracket were removed as assem-

bly, position bracket on studs and install attaching

nuts. Tighten nuts to 10-13 Nzm (92-112 in. lbs.)

torque.

(c) On right hand drive models, If brackets were

removed, assemble brackets. Then position lower

bracket on body studs and install attaching nuts

and the one attaching bolt (Fig. 25).

(2) If HCU mounting bracket was not removed,

press solenoid harness connecter fasteners into

mounting bracket.

(3) Connect HCU pump motor and solenoid har-

nesses (Figs. 19 and 20).

(4) Connect brakelines from front/rear brakes to

HCU. Start brakeline fittings in HCU ports by handto avoid cross threading (Fig. 26). Then tighten line

fittings snug but not to required torque at this time.

(5) Connect flex lines to HCU (Fig. 18). Start

brakeline fittings in flex line ports by hand to avoid

cross threading. Then tighten line fittings snug but

not to required torque at this time.

(6) Bleed brakes. Refer to procedure in Brake Flu-

id-Brake Bleeding-Brakelines And Hoses section.

(7) Tighten brakeline fittings to following torques

after brake bleeding: 15- 18 Nzm (130-160 in. lbs.) at

HCU and master cylinder and 18-24 Nzm (160-210 in.

lbs.) at combination valve.

(8) Install engine air cleaner assembly and hoses.

(9) Connect vacuum lines to manifold fittings.

(10) Check brake pedal action before moving vehi-

cle. Bleed brakes again if pedal is not firm (feels soft/

spongy).

Fig. 23 Installing HCU Front Shoulder Bolt

Fig. 24 Installing HCU Rear Shoulder Bolts

Fig. 25 HCU And Bracket Mounting (RHD Models)

Fig. 26 Starting Brakelines In HCU (By Hand)

JABS OPERATION AND SERVICE 5 - 43

Page 2127 of 2158

BELT TENSIONERÐXJ MODELS WITH

RIGHT HAND DRIVE, AUTOMATIC........7-42

BELT TENSIONÐEXCEPT RIGHT HAND

DRIVE (RHD).........................7-38

BELT TENSIONÐEXCEPT RIGHT HAND

DRIVE (RHD) MODELS.................7-45

BELT TENSIONÐRIGHT HAND DRIVE

(RHD)..............................7-38

BELT/BUCKLEÐXJ, FRONT SHOULDER . . . 23-90

BELT/BUCKLEÐXJ, REAR SHOULDER/

LAP ...............................23-91

BELTLINE SEALÐYJ.................23-142

BELTS, ENGINE ACCESSORY DRIVE.......7-38

BELTSÐYJ, FRONT SHOULDER........23-154

BELTSÐYJ, REAR SHOULDER.........23-154

BENCH BLEEDING, MASTER CYLINDER....5-21

BENCH, GEAR ADJUSTMENTS ON.......19-44

BENCH SEATÐYJ, REAR..............23-153

BEZELÐXJ, INSTRUMENT CLUSTER.....23-80

BEZELÐYJ, INSTRUMENT CLUSTER....23-151

BIN REMOVE/INSTALL, SUNGLASSES

STORAGE...........................8C-7

BLADE REMOVE/INSTALL, WINDSHIELD

WIPER.............................8K-17

BLEEDING, MASTER CYLINDER BENCH....5-21

BLEEDING RECOMMENDATIONS, BRAKE . . . 5-10

BLEEDING (WITH ABS BRAKES), BRAKE . . . 5-11

BLEEDING (WITH STANDARD BRAKES),

BRAKE..............................5-11

BLEEDINGÐBRAKELINES AND HOSES,

BRAKE FLUIDÐBRAKE.................5-10

BLOCK, CYLINDER................9-49,9-91

BLOCK HEATER, ENGINE................7-44

BLOCKSÐTWO-DOOR VEHICLES, FRONT

DOOR SPACER......................23-53

BLOWER MOTOR; AIR CONDITIONING/

HEATER (XJ)......................8W-42-1

BLOWER MOTOR; AIR CONDITIONING/

HEATER (XJ-RHD)..................8W-42-1

BLOWER MOTOR; HEATING AND AIR

CONDITIONING......................24-17

BLOWER MOTOR, A/C.................24-35

BLOWER MOTOR, A/C-HEATER; AIR

CONDITIONING/HEATER (YJ).........8W-42-2

BLOWER MOTOR (HEATING)...........24-33

BLOWER MOTOR RESISTORS

REPLACEMENT......................24-31

BLOWER MOTOR SWITCH.............24-16

BLOWER MOTOR/AIR DOOR MOTOR

SWITCH REPLACEMENT...............24-32

BLOWER MOTOR/FAN REPLACEMENT....24-24

BODY ASSEMBLY AND ADJUSTMENT,

VALVE ............................21-153

BODY CHECK BALL DIMENSIONS, AW-4

VALVE ............................21-341

BODY CODE LETTERS, JEEP..............5-2

BODY LUBRICANT SPECIFICATIONS.......0-33

BODY OVERHAUL, TRANSMISSION

VALVE ............................21-250

BODY REMOVAL, TRANSMISSION VALVE . 21-186

BODY REMOVAL, VALVE..............21-104

BODY SERVICE INFORMATION, GENERAL . . 23-1

BODY SERVICE, VALVE...............21-104

BODY SIDE MOLDING/CLADDINGÐXJ....23-20

BODY SIDE STEP MOLDINGÐYJ.......23-115

BODY SOLENOIDS, TRANSMISSION

VALVE ............................21-184

BODY STRIPES/DECALSÐXJ...........23-21

BODY STRIPES/DECALSÐYJ..........23-116

BODY, THROTTLE...............14-33,14-64

BOLT IDENTIFICATION..............Intro.-14

BOLT STRENGTH..................Intro.-15

BOOSTER CHECK VALVE TEST, POWER.....5-9

BOOSTER INSTALLATION (XJ WITH

ABS), POWER BRAKE..................5-27

BOOSTER INSTALLATION (XJ WITHOUT

ABS), POWER BRAKE..................5-30

BOOSTER INSTALLATION (YJ), POWER

BRAKE..............................5-30

BOOSTER, MASTER CYLINDER/POWER

BRAKE

..............................5-34

BOOSTER OPERATION, POWER BRAKE

....5-23

BOOSTER REMOVAL (XJ WITH ABS),

POWER BRAKE

.......................5-24

BOOSTER REMOVAL (XJ WITHOUT ABS),

POWER BRAKE

.......................5-29

BOOSTER REMOVAL (YJ), POWER

BRAKE

..............................5-30BOOSTER TEST, MASTER CYLINDER/

POWER..............................5-8

BOOSTER VACUUM TEST, POWER.........5-9

BOOSTERÐBRAKE PEDALÐ

BRAKELIGHT SWITCH, POWER BRAKE....5-22

BORES, HONING CYLINDER..............9-2

BOX LAMP, GLOVE; INTERIOR LIGHTING

(XJ).............................8W-44-1

BOX LAMP, GLOVE; INTERIOR LIGHTING

(XJ-RHD).........................8W-44-1

BOXÐYJ, GLOVE...................23-152

BRACKET REPLACEMENTÐXJ, INTERIOR

REARVIEW MIRROR SUPPORT..........23-68

BRACKETÐYJ, REARVIEW MIRROR

RETAINING........................23-144

BRACKETSÐXJ, SPARE TIRE/WHEEL

HOLDDOWN AND FLOOR..............23-98

BRAKE ADJUSTMENT, DRUM............5-57

BRAKE BLEEDING RECOMMENDATIONS....5-10

BRAKE BLEEDING (WITH ABS BRAKES)....5-11

BRAKE BLEEDING (WITH STANDARD

BRAKES)............................5-11

BRAKE BOOSTER INSTALLATION (XJ

WITH ABS), POWER...................5-27

BRAKE BOOSTER INSTALLATION (XJ

WITHOUT ABS), POWER................5-30

BRAKE BOOSTER INSTALLATION (YJ),

POWER.............................5-30

BRAKE BOOSTER, MASTER CYLINDER/

POWER.............................5-34

BRAKE BOOSTER OPERATION, POWER....5-23

BRAKE BOOSTER REMOVAL (XJ WITH

ABS), POWER........................5-24

BRAKE BOOSTER REMOVAL (XJ

WITHOUT ABS), POWER................5-29

BRAKE BOOSTER REMOVAL (YJ),

POWER.............................5-30

BRAKE BOOSTERÐBRAKE PEDALÐ

BRAKELIGHT SWITCH, POWER...........5-22

BRAKE CABLE TENSIONER ADJUSTMENT

(XJ/YJ), PARKING.....................5-69

BRAKE CABLE TENSIONER

REPLACEMENT (XJ), PARKING...........5-66

BRAKE CHECK, PRELIMINARY............5-4

BRAKE COMPONENTS...................5-1

BRAKE DIAGNOSIS, ABS.................5-3

BRAKE DIAGNOSIS, SERVICE.............5-4

BRAKE DRUM REFINISHING.............5-58

BRAKE FLUID CONTAMINATION.......5-10,5-7

BRAKE FLUID LEVEL...................5-10

BRAKE FLUID, RECOMMENDED..........5-10

BRAKE FLUID/LUBRICANTS/CLEANING

SOLVENTS............................5-2

BRAKE FLUIDÐBRAKE BLEEDINGÐ

BRAKELINES AND HOSES...............5-10

BRAKE FRONT CABLE REPLACEMENT

(YJ), PARKING........................5-67

BRAKE HANDLE COVERÐXJ, PARKING . . . 23-94

BRAKE LEVER INSTALLATION (XJ WITH

FULL CONSOLE), PARKING..............5-64

BRAKE LEVER INSTALLATION (XJ WITH

MINI CONSOLE), PARKING..............5-63

BRAKE LEVER INSTALLATION (XJ

WITHOUT CONSOLE), PARKING..........5-65

BRAKE LEVER REMOVAL (XJ WITH FULL

CONSOLE), PARKING..................5-63

BRAKE LEVER REMOVAL (XJ WITH MINI

CONSOLE), PARKING..................5-62

BRAKE LEVER REMOVAL (XJ WITHOUT

CONSOLE), PARKING

..................5-64

BRAKE MALFUNCTIONS, DIAGNOSING

PARKING

.............................5-8

BRAKE NOISE

.........................5-7

BRAKE OPERATION, PARKING

...........5-60

BRAKE OVERHAUL, SECOND

..........21-241

BRAKE PACK REQUIREMENTS, AW-4

CLUTCH

...........................21-341

BRAKE PEDAL BUSHINGS, CLUTCH

.......0-22

BRAKE PEDAL INSTALLATION

............5-31

BRAKE PEDAL INSTALLATION (YJ),

PARKING

............................5-66

BRAKE PEDAL REMOVAL

...............5-31

BRAKE PEDAL REMOVAL (YJ), PARKING

. . . 5-66

BRAKE PEDAL TRAVEL SENSOR;

ANTI-LOCK BRAKES (YJ)

............8W-32-1

BRAKE PISTON AND TRANSMISSION

CASE OVERHAUL, FIRST-REVERSE

......21-247BRAKE REAR CABLE REPLACEMENT

(XJ), PARKING........................5-67

BRAKE REAR CABLE REPLACEMENT

(YJ), PARKING........................5-68

BRAKE ROTOR REFINISHING, DISC.......5-53

BRAKE ROTOR RUNOUT, DISC...........5-52

BRAKE ROTOR THICKNESS, DISC........5-52

BRAKE SAFETY PRECAUTIONS............5-2

BRAKE SWITCH......................14-59

BRAKE SWITCH INPUT; ANTI-LOCK

BRAKES (XJ)......................8W-32-2

BRAKE SWITCH INPUT; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-2

BRAKE SWITCH INPUT; ANTI-LOCK

BRAKES (YJ)......................8W-32-2

BRAKE SWITCH INPUT; FUEL/IGNITION

(XJ).............................8W-30-5

BRAKE SWITCH INPUT; FUEL/IGNITION

(YJ).............................8W-30-5

BRAKE SWITCH INPUT; FUEL/IGNITION

(XJ-RHD).........................8W-30-5

BRAKE SWITCH, PARKING..............5-68

BRAKE SWITCHÐPCM INPUT..........14-22

BRAKE SYSTEM, POWER...............0-30

BRAKE TORQUE SPECIFICATIONS.........5-70

BRAKE WARNING LAMP; INSTRUMENT

CLUSTER (XJ).....................8W-40-2

BRAKE WARNING LAMP; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-2

BRAKE WARNING LAMP; INSTRUMENT

CLUSTER (YJ)......................8W-40-2

BRAKE WARNING LIGHTS................5-1

BRAKELIGHT SWITCH ADJUSTMENT......5-32

BRAKELIGHT SWITCH INSTALLATION......5-32

BRAKELIGHT SWITCH REMOVAL.........5-32

BRAKELINE CHARTS...................5-12

BRAKELINES AND HOSES...............5-12

BRAKELINING, CONTAMINATED...........5-7

BRAKELINING MATERIAL................5-1

BRAKES (ABS), ANTILOCK...............5-1

BRAKES, DISC........................5-45

BRAKES DO NOT HOLD AFTER DRIVING

THROUGH DEEP WATER PUDDLES........5-7

BRAKES, DRUM......................5-55

BRAKES, PARKING....................5-60

BRAKESHOE INSTALLATION, DISC........5-47

BRAKESHOE INSTALLATION, DRUM.......5-55

BRAKESHOE REMOVAL, DISC............5-46

BRAKESHOE REMOVAL, DRUM...........5-55

BRAKING MODE, ABS OPERATION IN

ANTILOCK...........................5-36

BRAKING MODE, ABS OPERATION IN

NORMAL............................5-35

BREAK-IN, ENGINE....................0-15

BRUSH GUARDÐXJ...................23-3

BUCKET SEAT CUSHION AND COVERÐ

XJ ................................23-81

BUCKET SEAT PLATFORMÐXJ..........23-82

BUCKET SEATBACK COVER AND

FRAMEÐXJ.........................23-81

BUCKET SEATSÐXJ, FRONT............23-81

BUCKET SEATSÐYJ.................23-153

BULB APPLICATIONÐXJ VEHICLES......8L-18

BULB APPLICATIONÐYJ VEHICLES......8L-32

BULB REMOVE/INSTALL, READING/

COURTESY LAMP.....................8C-8

BULB REPLACEMENTÐXJ, BACK-UP/

REAR TURN SIGNAL/TAIL LAMP.........8L-12

BULB REPLACEMENTÐXJ, FRONT

PARK/TURN SIGNAL LAMP..............8L-9

BULB REPLACEMENTÐXJ, HEADLAMP....8L-7

BULB REPLACEMENTÐXJ, SIDE

MARKER LAMP......................8L-10

BULB REPLACEMENTÐXJ, UNDERHOOD

LAMP..............................8L-13

BULB REPLACEMENTÐYJ, BACK-UP/

REAR TURN SIGNAL/TAIL LAMP.........8L-28

BULB REPLACEMENTÐYJ, FRONT

PARK/TURN SIGNAL LAMP.............8L-25

BULB REPLACEMENTÐYJ, HEADLAMP . . . 8L-23

BULB REPLACEMENTÐYJ, SIDE

MARKER LAMP

......................8L-25

BULB REPLACEMENTÐYJ, UNDERHOOD

LAMP

..............................8L-29

BULB REPLACEMENTÐYJ VEHICLES,

HARDTOP DOME/CARGO LAMP

.........8L-31

BUMPER, FRONT

.................13-16,13-5

BUMPER, REAR

..................13-16,13-8

JINDEX 3

Description Group-Page Description Group-Page Description Group-Page