wheel KIA CARNIVAL 2007 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 857 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

The Seat Belt Buckle Pretensioners (BUPT) are installed in the right side of the driver seat and the left side of the

passenger seat. When a vehicle crashes with a certain degree of frontal impact, the seat belt buckle pretensioner

helps to reduce the severity of injury to the front seat occupants by retracting the seat belt buckle. This prevents the

front occupants from thrusting forward and hitting the steering wheel or the instrument panel when the vehicle crashes.

Never attempt to measure the circuit resistance of the Seat Belt Buckle Pretensioner (BUPT) even if you are

using the specified tester. If the circuit resistance is measured with a tester, the pretensioner will be ignited

accidentally. This will result in serious personal injury.

Page 864 of 1575

e.master cylinder cap seal

f. damaged brake lines replace

replace

Brake Chatter Brake chatter is usually caused by loose or worn components, or

glazed or burnt linings. Rotors with hard spots can also contribute to

brake chatter. Additional causes of chatter are out - of- tolerance rotors,

brake lining not securely attached to the shoes, loose wheel bearings

and contaminated brake lining.

Page 866 of 1575

TIGHTENING TORQUE

ItemsNmkgf.m lb - ft

Master cylinder to booster mounting nut 8 ~ 120.8 ~ 1.2 5.8 ~ 8.7

Brake booster mounting nut 13 ~ 161.3 ~ 1.6 9.4 ~ 11.6

Bleeder screw 7 ~ 130.7 ~ 1.3 5.06 ~ 9.4

Brake tube nut, brake hose 13 ~ 171.3 ~ 1.7 9.4 ~ 12.3

Caliper guide rod bolt (Front) 22 ~ 322.2 ~ 3.215.9 ~ 23.1

Caliper guide rod bolt (Rear) 22 ~ 322.2 ~ 3.215.9 ~ 23.1

Caliper assembly to knuckle (Front) 85 ~ 1008.5 ~ 1061.5 ~ 72.3

Caliper assembly to knuckle (Rear) 50 ~ 605.0 ~ 6.036.2 ~ 43.4

Brake hose to front caliper 25 ~ 302.5 ~ 3.018.1 ~ 21.7

Brake pedal assembly bracket mounting nut 10 ~ 151.0 ~ 1.5 7.2 ~ 10.8

Brake pedal mounting nut 13 ~ 161.3 ~ 1.6 9.4 ~ 11.6

Stop lamp switch mounting nut 8 ~ 100.8 ~ 1.0 5.8 ~ 7.23

Active wheel speed sensor mounting bolt on

the brake plate 7 ~ 10

0.7 ~ 1.0 5.1 ~ 7.2

HECU mounting bracket bolt 17 ~ 261.7 ~ 2.612.3 ~ 18.8

HECU mounting nut 6 ~ 100.6 ~ 1.0 4.3 ~ 7.2

Yaw rate & lateral acceleration sensor bolt 5 ~ 80.5 ~ 0.8 3.62 ~ 5.8

SPECIFICATION (ABS)

Part ItemStandard valueRemark

HECU(Hydraulic and

Electronic Control

Unit) System

4 channel 4 sensor

(Solenoid)

·ABS system:ABS &

EBD control

Type

Motor, valve relay

intergrated type

Operating voltage 8 V ~ 16 V(DC)

Operating temperature - 40 ~ 120 °C

( - 40 ~ 248 °F)

Warning lamp Operating voltage

12 V·ABS W/L:ABS failure

·Brake W/L:Parking,

brake oil, EBD failure

Current consumption 80 mA

Acitve wheel speed

sensor Supply voltage

DC 4.5 ~ 2.0 V

Operating temperature - 40 ~ 150 °C

Output current low 5.9 ~ 8.4 mATyp.7 mA

Output current High 11.8 ~ 16.8 mATyp.14 mA

Frequency range 1 ~ 2500 HZ

Air gap Front

0.15 ~ 1.5 mm Typ.0.7 mm

Rear 0.2 ~ 1.2 mm Typ.0.7 mm

Tone wheel 48 teeth

Output duty 30~70 %

SPECIFICATION(ESP)

Page 867 of 1575

PartItemStandard ValueRemark

HECU(Hydraulic and

Electronic Control

Unit) System

4 channel 4

sensor(Solenoid)

·Total control(ABS,

EBD, TCS, ESP)

Type

Motor, valve relay

intergrated type

Operating voltage 8 V ~ 16 V(DC)

Operating temperature - 40 ~ 120 °C(- 40 ~

248 °F)

Warning lamp Operating voltage

12 V

·ESP Operating Lamp

·ESP Warning Lamp

Current consumption 80 mA

Active wheel speed

sensor Supply voltage

DC 4.5 ~ 20V

Operating temperature - 40 ~ 150 °C

Output current low 5.9 ~ 8.4 mA

Output current high 11.8 ~ 16.8 mA

Tone wheel 48 teeth

Frequency range 1 ~ 2500 HZ

Airgap Front

0.15 ~ 1.5 mm Typ. 0.7 mm

Rear 0.2 ~ 1.2 mm Typ. 0.7 mm

Steering Wheel Angle

Sensor Operating Voltage

8V ~ 16 V

Current Consumption Max 150 mA

Operating Angular velocity Max ± 780 °/sec

Yaw - rate & Lateral G

sensor Operating Voltage

8 V ~ 16 V

Current Consumption Max. 120 mA

Output Voltage high 4.35 V~ 4.65 VTyp. 4.5 V

Output Voltage low 0.35 ~ 0.65 VTyp. 0.5 V

Yaw Sensor Operating Range ±100 ° /s

G Sensor Operating Range ±1.8 G

Reference voltage output 2.464 ~ 2.536 VTyp. 2.5 V

LUBRICANT

Item Recommended lubricantQuantity

Brake fluid DOT 3 or DOT 4As required

Brake pedal bushing and brake pedal bolt Chassis greaseAs required

Parking brake shoe and backing plate contact surfaces Bearing greaseAs required

Caliper guide rod and boot RX - 2 grease0.8 ~ 1.3 g

Rear caliper guide rod and boot Rubber grease0.8 ~ 1.3g

Page 899 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

Frequent inhalation of brake pad dust, regardless of material composition, could be hazardous to your health.

a. Avoid breathing dust particles.

b. Never use on air hose or brush to clean brake assemblies.

1. Loosen the front wheel nuts slightly. Raise the front of the vehicle, and make sure it is securely supported. Remove

the front wheels.

2. Remove the guide rod bolt (B), After raise the caliper assembly (A), support it with a wire.

3.Remove pad shim (A), pad retainer (B) and pad assembly (C) in the caliper bracket.

INSTALLATION

1.Install the pad retainers (A) on the caliper bracket.

2.Install pad shims (A) and the brake pads (B) with the wear indicator on the inside.

Page 905 of 1575

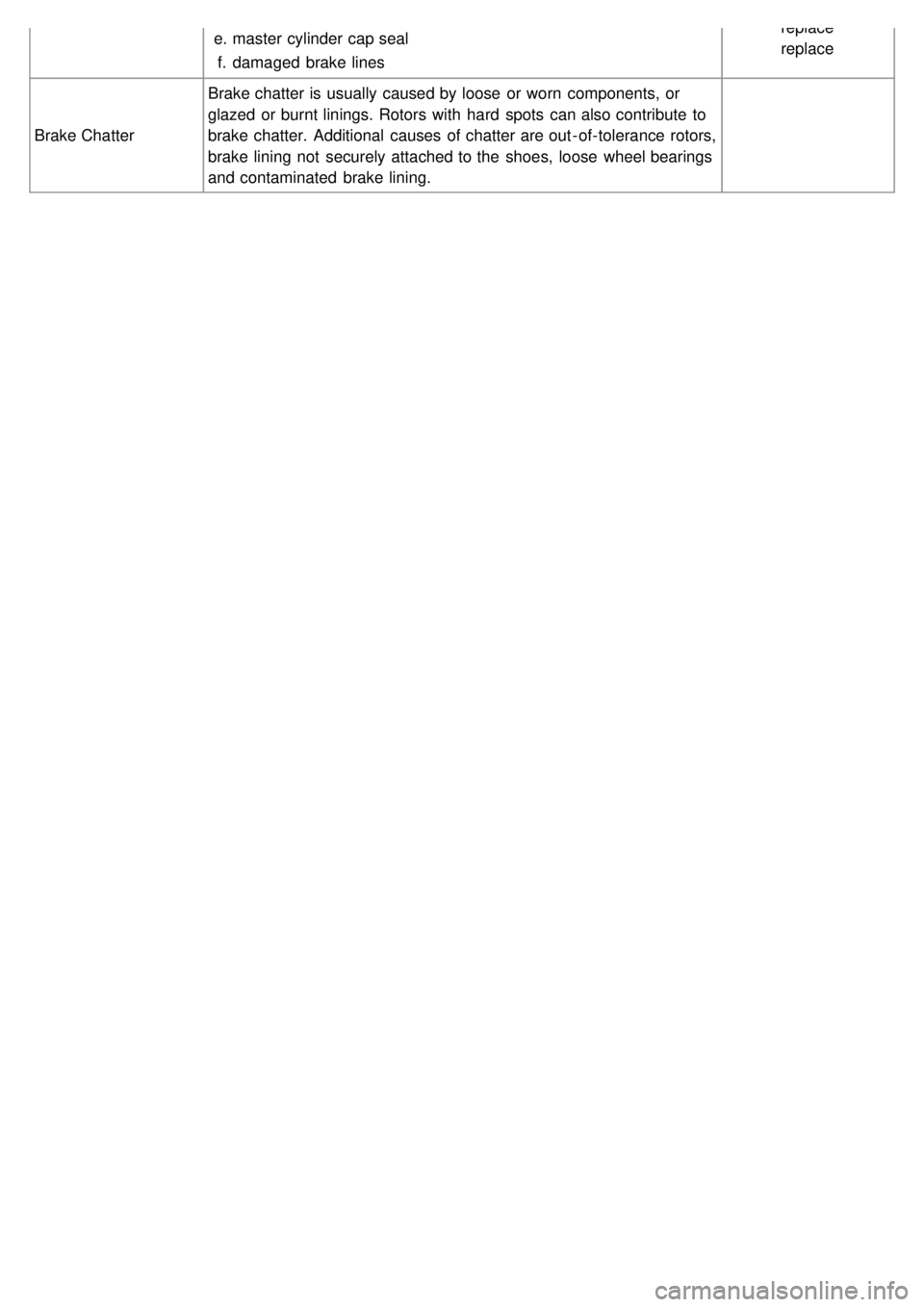

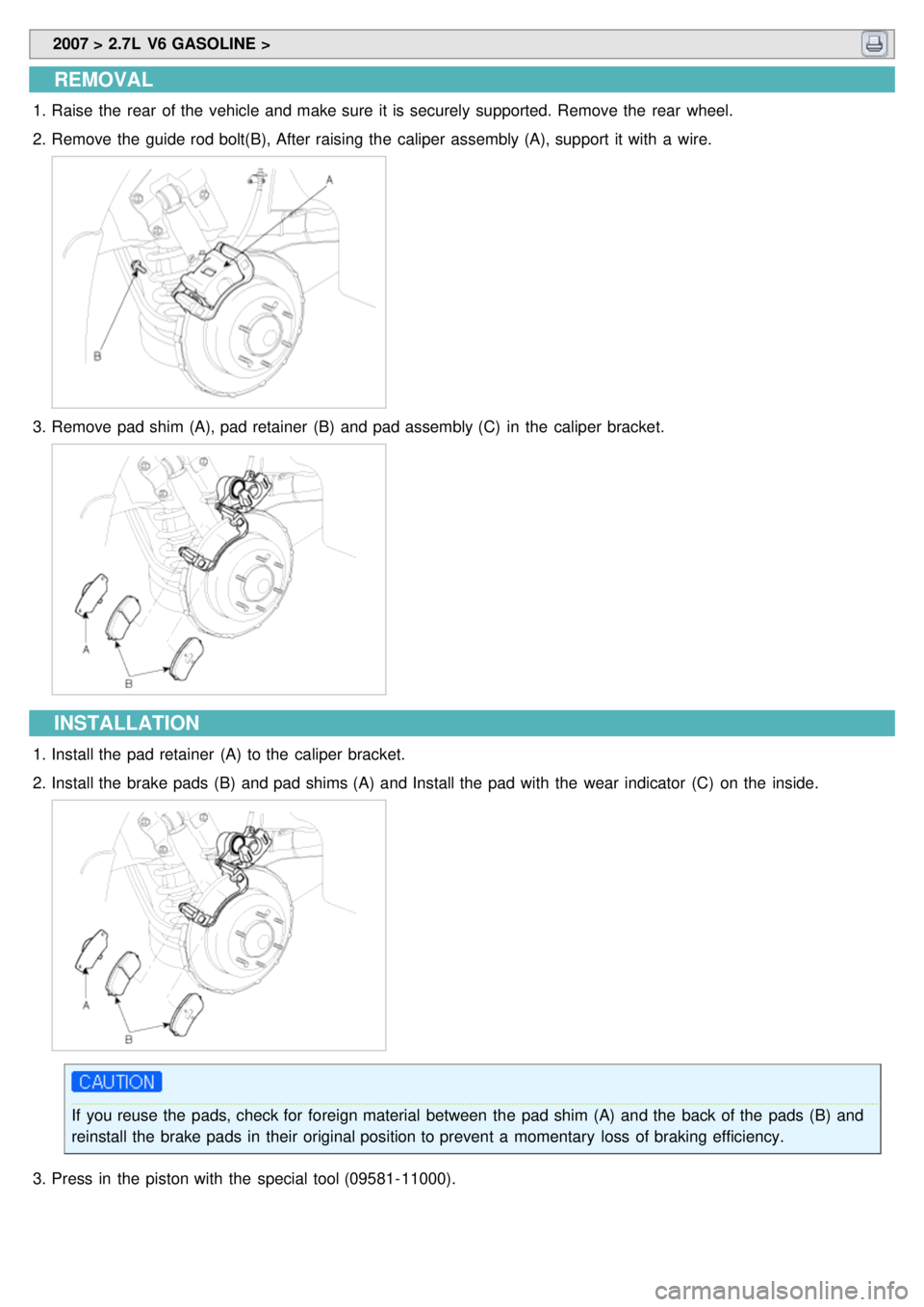

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Raise the rear of the vehicle and make sure it is securely supported. Remove the rear wheel.

2. Remove the guide rod bolt(B), After raising the caliper assembly (A), support it with a wire.

3.Remove pad shim (A), pad retainer (B) and pad assembly (C) in the caliper bracket.

INSTALLATION

1.Install the pad retainer (A) to the caliper bracket.

2. Install the brake pads (B) and pad shims (A) and Install the pad with the wear indicator (C) on the inside.

If you reuse the pads, check for foreign material between the pad shim (A) and the back of the pads (B) and

reinstall the brake pads in their original position to prevent a momentary loss of braking efficiency.

3. Press in the piston with the special tool (09581- 11000).

Page 916 of 1575

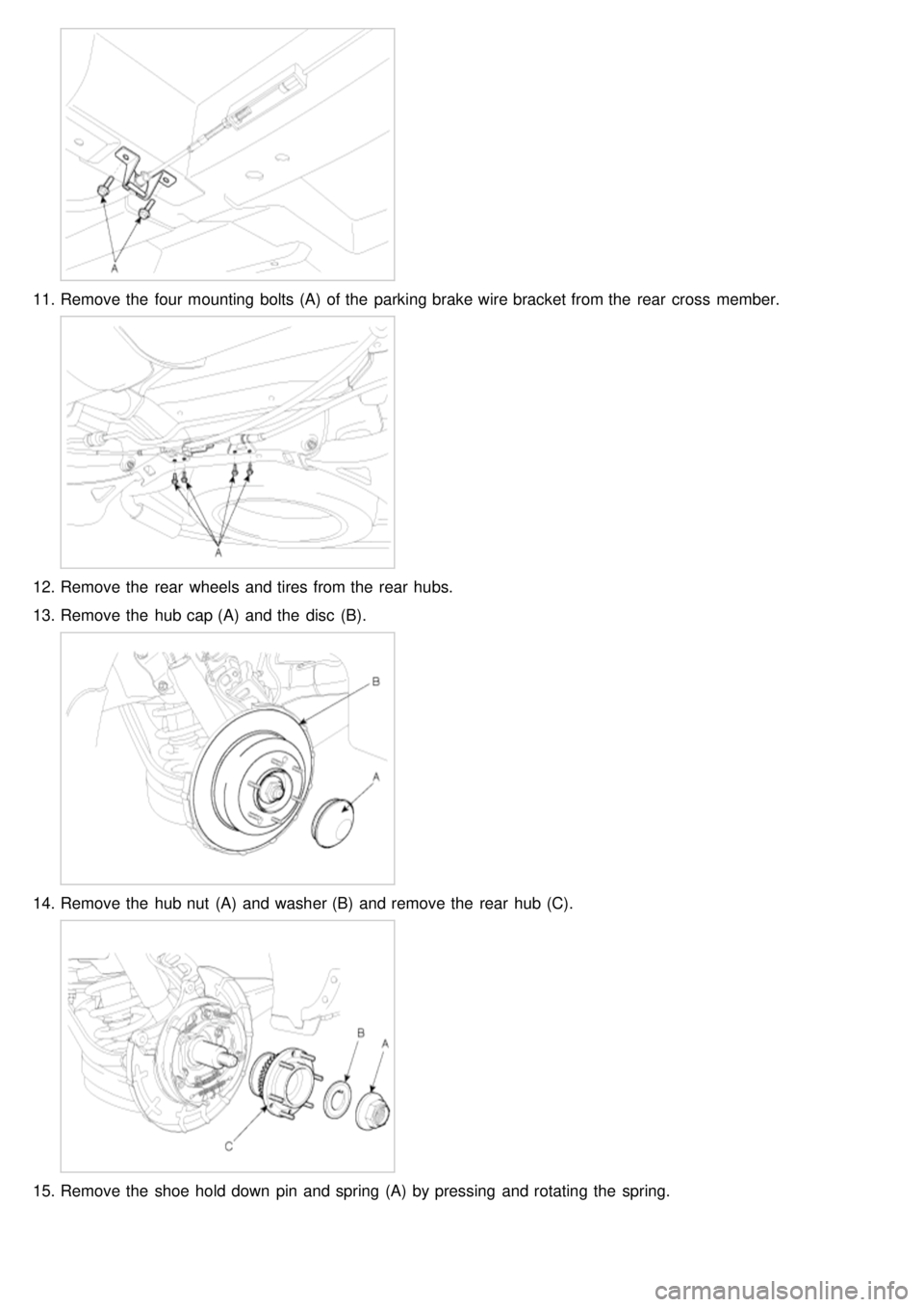

11.Remove the four mounting bolts (A) of the parking brake wire bracket from the rear cross member.

12.Remove the rear wheels and tires from the rear hubs.

13. Remove the hub cap (A) and the disc (B).

14.Remove the hub nut (A) and washer (B) and remove the rear hub (C).

15.Remove the shoe hold down pin and spring (A) by pressing and rotating the spring.

Page 919 of 1575

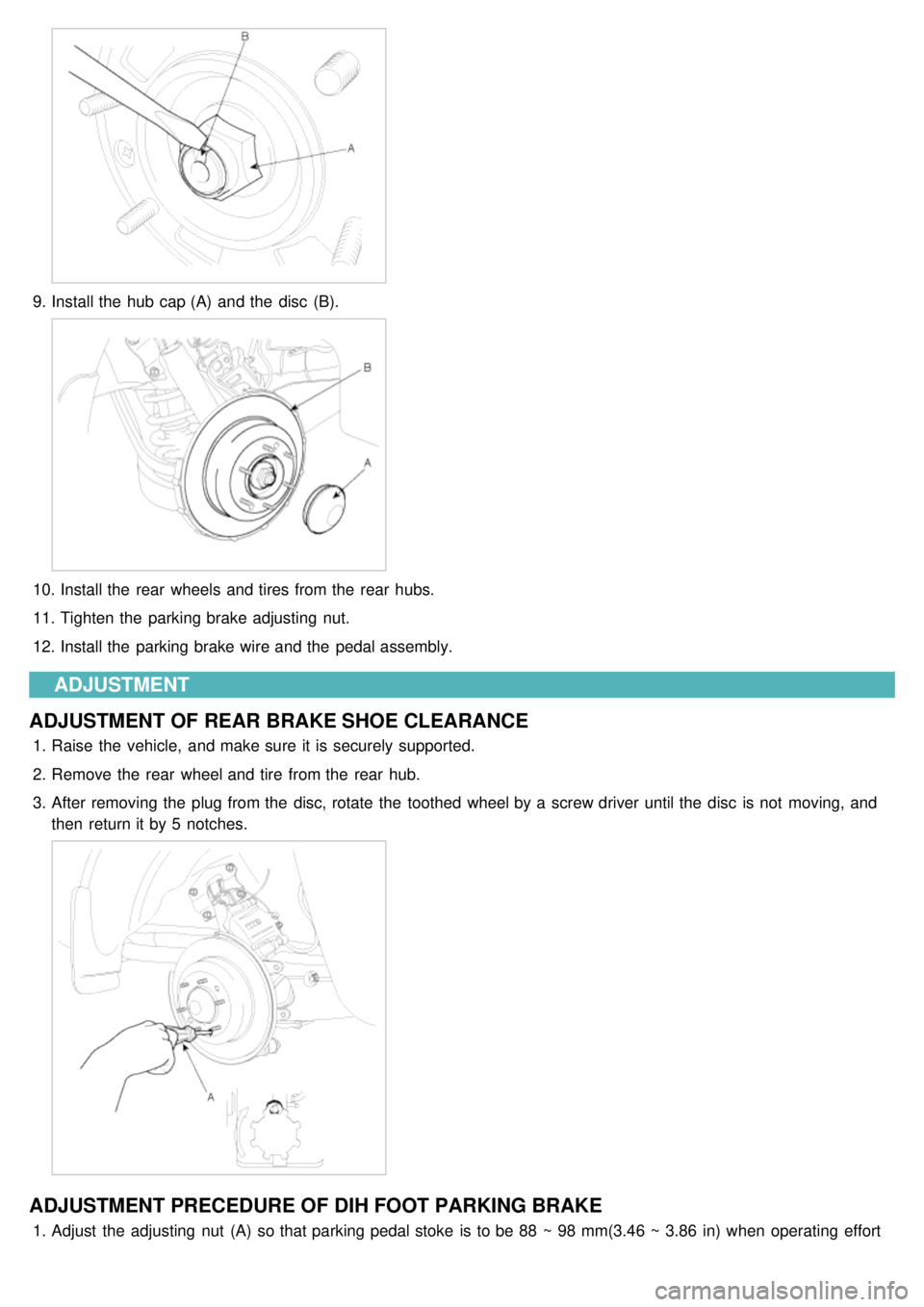

9.Install the hub cap (A) and the disc (B).

10. Install the rear wheels and tires from the rear hubs.

11. Tighten the parking brake adjusting nut.

12. Install the parking brake wire and the pedal assembly.

ADJUSTMENT

ADJUSTMENT OF REAR BRAKE SHOE CLEARANCE

1. Raise the vehicle, and make sure it is securely supported.

2. Remove the rear wheel and tire from the rear hub.

3. After removing the plug from the disc, rotate the toothed wheel by a screw driver until the disc is not moving, and

then return it by 5 notches.

ADJUSTMENT PRECEDURE OF DIH FOOT PARKING BRAKE

1.Adjust the adjusting nut (A) so that parking pedal stoke is to be 88 ~ 98 mm(3.46 ~ 3.86 in) when operating effort

is 200 N(20 kgf, 44 lb) after full stroke operation of parking pedal over 3 times for setting parking wire.

Page 926 of 1575

18Voltage for hybrid ECU 1 A500 mA 60200

5,10,17,19 signal wheel speed sensor FL,

FR, RL,RR

6 mA

16 mA 250200 to

ground 1.5M to bat

16,9,6,8 Voltage supply for the active

wheel speed sensor FL,FR,

RL, RR 6 mA

16 mA 250200 to

ground 1.5M to bat

14,24 wheel speed sensor output

(FR, RL) 20 mA

10 mA 250200

11 Diagnostic wire K 6 mA3 mA 250200

22 ABS - warning lamp actuation 30 mA5 mA 250200

12 EBD- warning lamp actuation 30 mA5 mA 250200

20 brake light switch 10 mA5 mA 250200

15 CAN Low 30 mA20 mA 250200

26 CAN High 30 mA20 mA 250200

ABS HECU CONNECTOR Connector terminal SpecificationCondition

Number Description

1 Ground for recirculation pump Current range: Min.10A

Max.20~39A Always

4 Ground for solenoid valves and

ECU Current range: Min.2.5A

Max.5~15A Always

2 Voltage supply for pump motor

Battery voltageAlways

3 Voltage supply for solenoid valves

16 Voltage supply for the active

wheel speed sensor FL,FR, RL, RR Battery voltage

IG ON

9

6

8

5

signal wheel speed sensor FL, FR, RL,RR Voltage(High) : 0.89~1.26 V

Voltage (Low) : 0.44~0.63 V On driving

10

17

19

11

Diagnostic wire K Voltage (High)

≥ 0.8 * IG ON

Voltage (Low) ≤ 0.2 * IG ON On SCAN TOOL

communication

18 Voltage for hybrid ECU Battery voltageKEY ON/OFF

20 Brake light switch Voltage (High)

≥ 0.8 * IG ON

Voltage (Low) ≤ 0.3 * IG ON BRAKE ON/OFF

SENSOR OUTPUT ON SCAN TOOL(ABS) Description AbbreviationUnitRemarks

1 Vehicle speed sensor VEH. SPDKm/h

2 Battery voltage BATT. VOLV

3 FL Wheel speed sensor FL WHEELKm/h

Page 927 of 1575

4FR Wheel speed sensor FR WHEELKm/h

5 RL Wheel speed sensor RL WHEELKm/h

6 RR Wheel speed sensor RR WHEELKm/h

7 ABS Warning lamp ABS LAMP-

8 EBD Warning lamp EBD LAMP-

9 Brake Lamp B/LAMP-

10 Pump relay state PUMP RLY-

11 Valve relay state VALVE RLY-

12 Motor MOTOR-

13 Front Left valve(IN) FL INLET-

14 Front Right valve (IN) FR INLET-

15 Rear Left valve (IN) RL INLET-

16 Rear Right valve (IN) RR INLET-

17 Front Left valve (OUT) FL OUTLET-

18 Front Right valve (OUT) FR OUTLET-

19 Rear Left valve(OUT) RL OUTLET-

20 Rear Right valve (OUT) RR OUTLET-