KIA CARNIVAL 2007 Workshop Manual

CARNIVAL 2007

KIA

KIA

https://www.carmanualsonline.info/img/2/57045/w960_57045-0.png

KIA CARNIVAL 2007 Workshop Manual

Page 646 of 1575

2007 > 2.7L V6 GASOLINE >

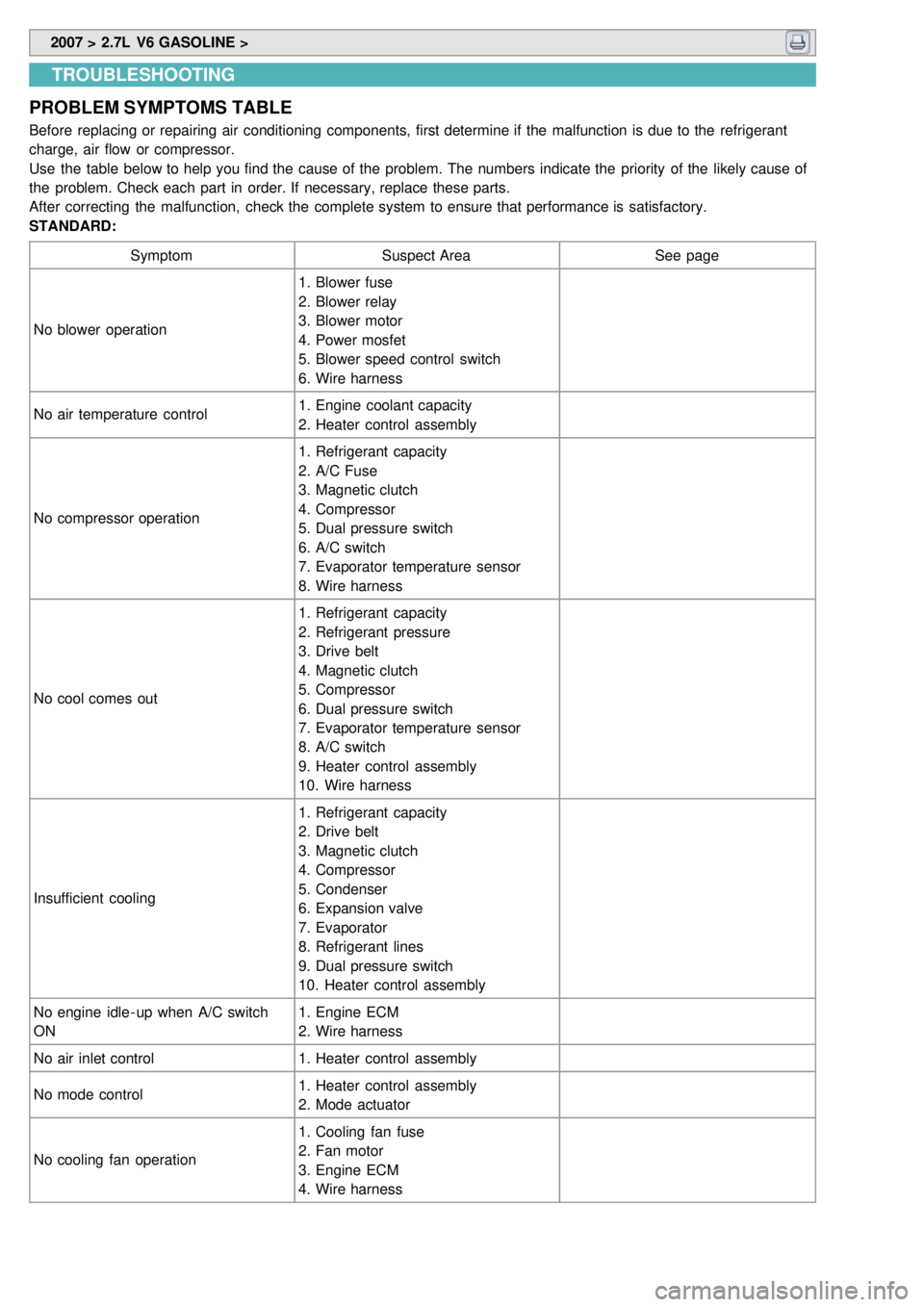

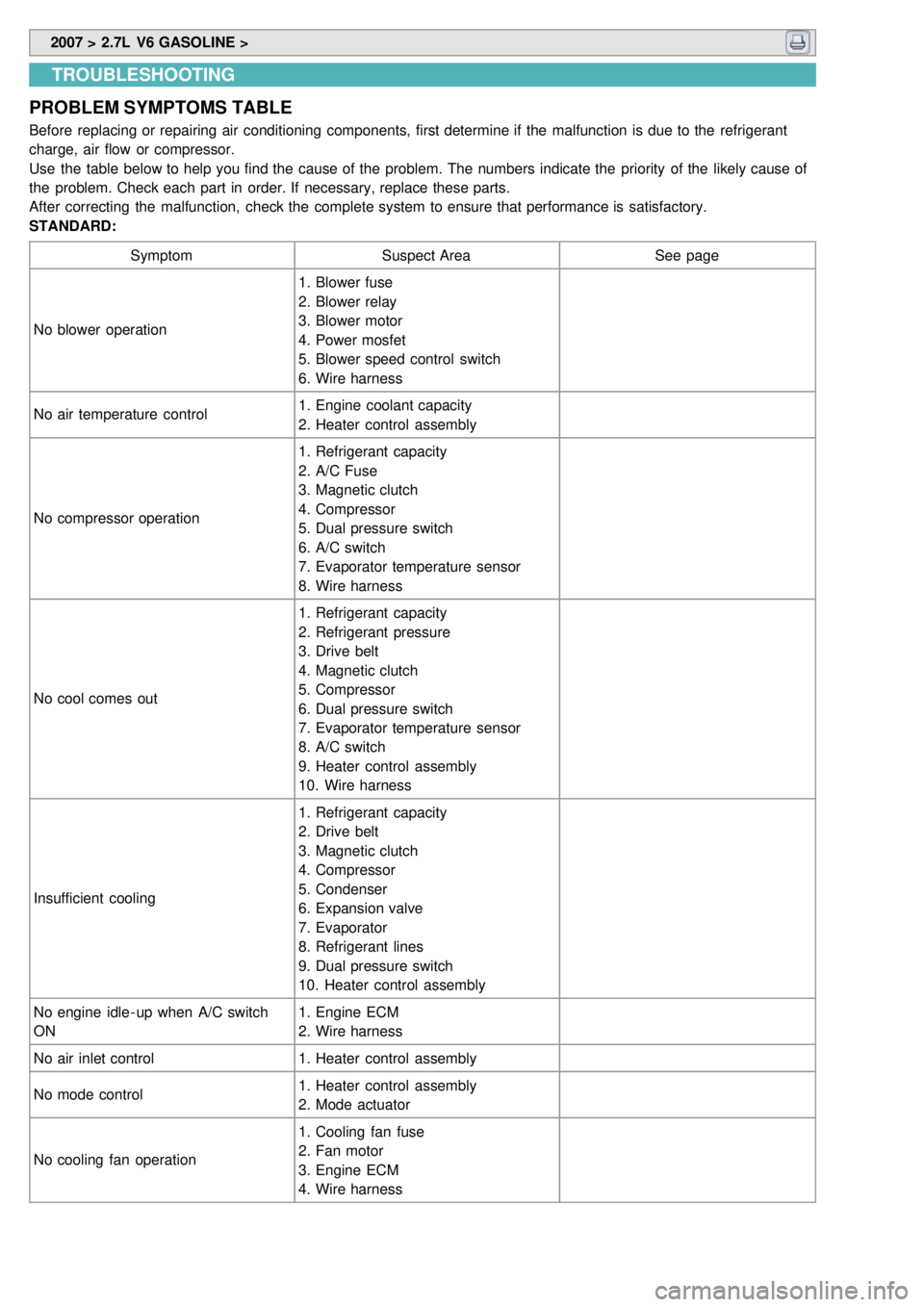

TROUBLESHOOTING

PROBLEM SYMPTOMS TABLE

Before replacing or repairing air conditioning components, first determine if the malfunction is due to the refrigerant

charge, air flow or compressor.

Use the table below to help you find the cause of the problem. The numbers indicate the priority of the likely cause of

the problem. Check each part in order. If necessary, replace these parts.

After correcting the malfunction, check the complete system to ensure that performance is satisfactory.

STANDARD:

Symptom Suspect Area See page

No blower operation 1. Blower fuse

2. Blower relay

3. Blower motor

4. Power mosfet

5. Blower speed control switch

6. Wire harness

No air temperature control 1. Engine coolant capacity

2. Heater control assembly

No compressor operation 1. Refrigerant capacity

2. A/C Fuse

3. Magnetic clutch

4. Compressor

5. Dual pressure switch

6. A/C switch

7. Evaporator temperature sensor

8. Wire harness

No cool comes out 1. Refrigerant capacity

2. Refrigerant pressure

3. Drive belt

4. Magnetic clutch

5. Compressor

6. Dual pressure switch

7. Evaporator temperature sensor

8. A/C switch

9. Heater control assembly

10. Wire harness

Insufficient cooling 1. Refrigerant capacity

2. Drive belt

3. Magnetic clutch

4. Compressor

5. Condenser

6. Expansion valve

7. Evaporator

8. Refrigerant lines

9. Dual pressure switch

10. Heater control assembly

No engine idle - up when A/C switch

ON 1. Engine ECM

2. Wire harness

No air inlet control 1. Heater control assembly

No mode control 1. Heater control assembly

2. Mode actuator

No cooling fan operation 1. Cooling fan fuse

2. Fan motor

3. Engine ECM

4. Wire harness

Page 647 of 1575

2007 > 2.7L V6 GASOLINE >

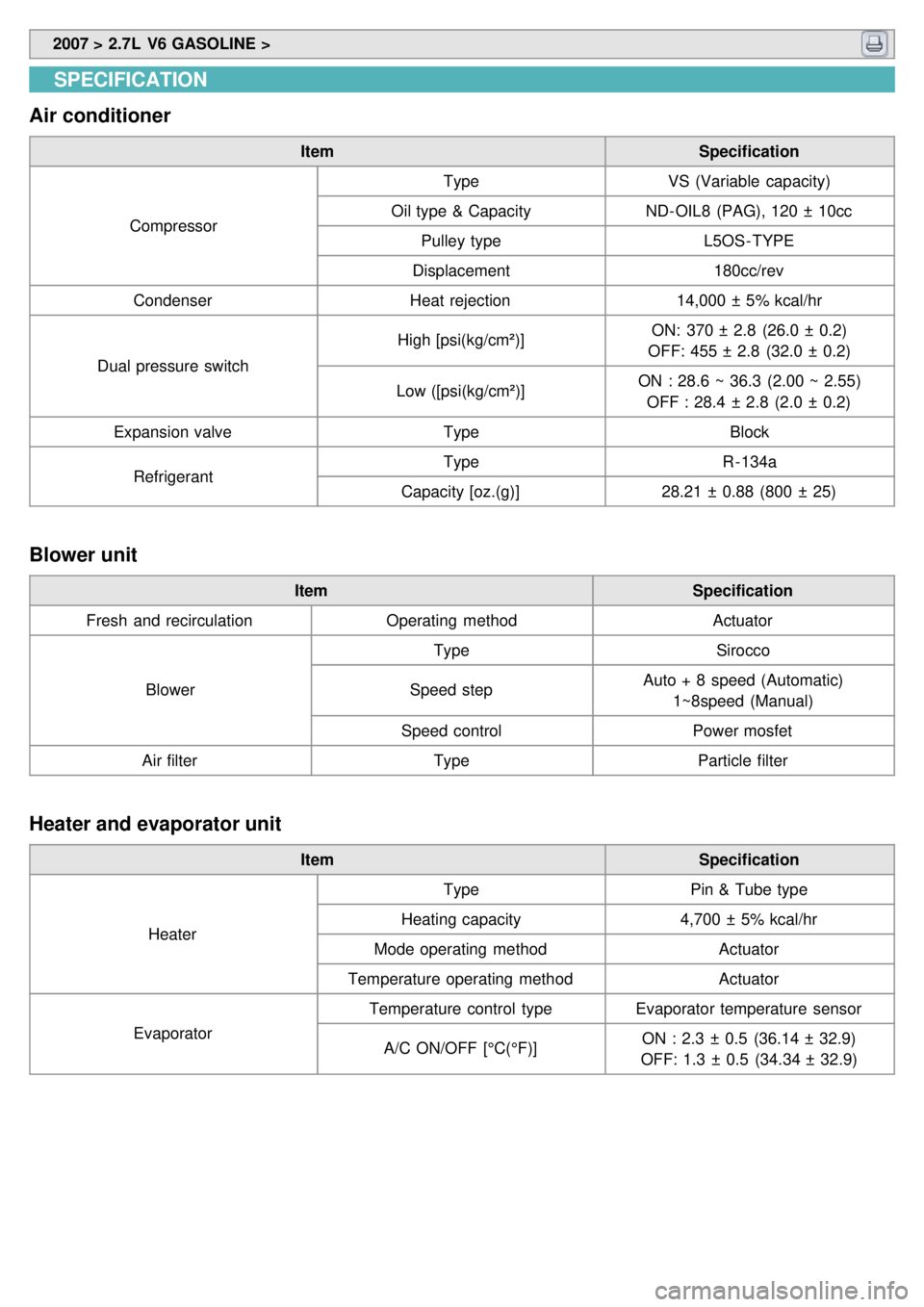

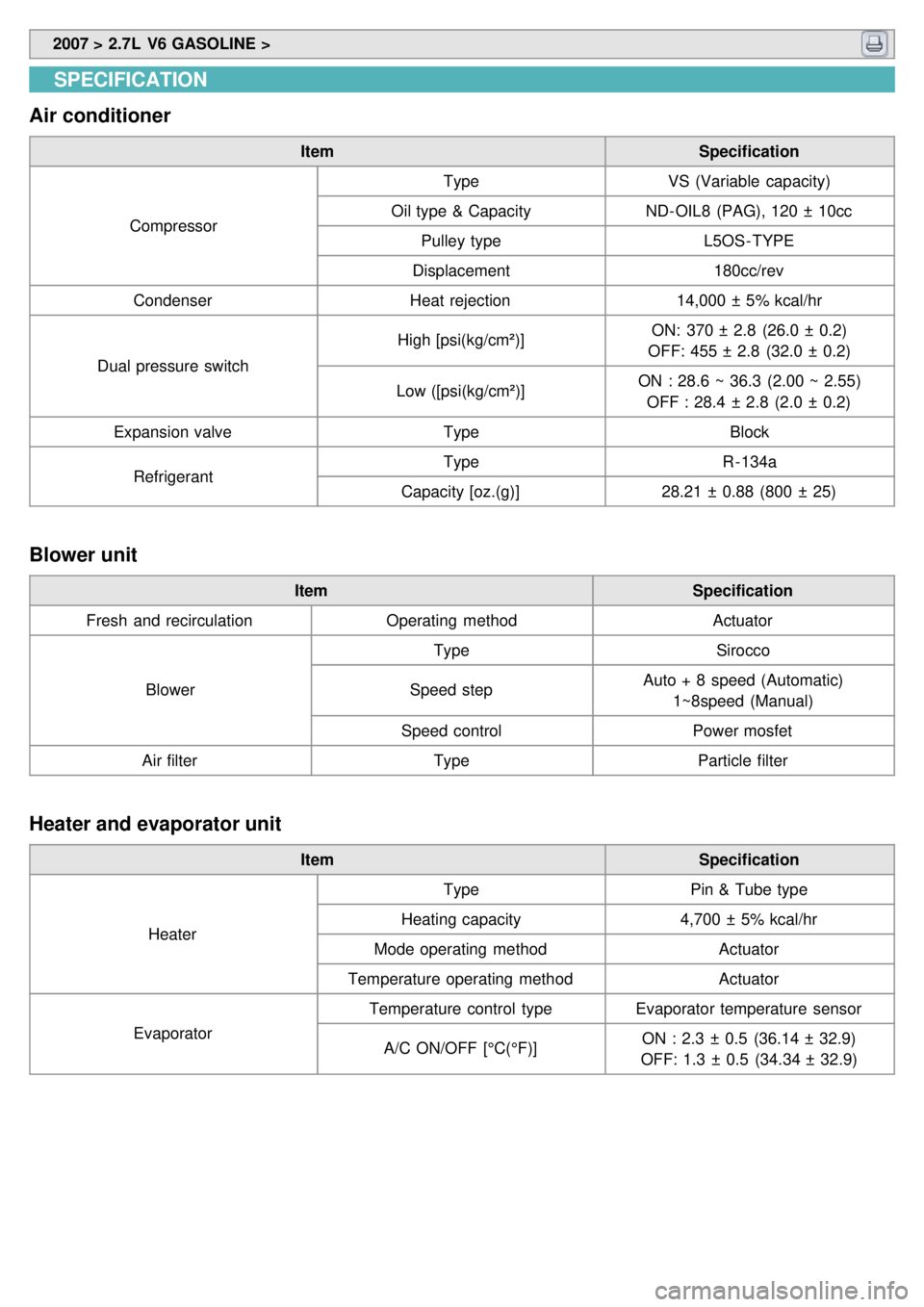

SPECIFICATION

Air conditioner

Item Specification

Compressor Type

VS (Variable capacity)

Oil type & Capacity ND- OIL8 (PAG), 120 ± 10cc

Pulley type L5OS - TYPE

Displacement 180cc/rev

Condenser Heat rejection14,000 ± 5% kcal/hr

Dual pressure switch High [psi(kg/cm²)]

ON: 370 ± 2.8 (26.0 ± 0.2)

OFF: 455 ± 2.8 (32.0 ± 0.2)

Low ([psi(kg/cm²)] ON : 28.6 ~ 36.3 (2.00 ~ 2.55)

OFF : 28.4 ± 2.8 (2.0 ± 0.2)

Expansion valve TypeBlock

Refrigerant Type

R- 134a

Capacity [oz.(g)] 28.21 ± 0.88 (800 ± 25)

Blower unit

Item Specification

Fresh and recirculation Operating method Actuator

Blower Type

Sirocco

Speed step Auto + 8 speed (Automatic)

1~8speed (Manual)

Speed control Power mosfet

Air filter TypeParticle filter

Heater and evaporator unit

Item Specification

Heater Type

Pin & Tube type

Heating capacity 4,700 ± 5% kcal/hr

Mode operating method Actuator

Temperature operating method Actuator

Evaporator Temperature control type

Evaporator temperature sensor

A/C ON/OFF [°C(°F)] ON : 2.3 ± 0.5 (36.14 ± 32.9)

OFF: 1.3 ± 0.5 (34.34 ± 32.9)

Page 677 of 1575

Evaporator Temperature Sensor

Page 679 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

The evaporator temperature sensor will detect the evaporator core temperature and interrupt compressor relay power

in order to prevent evaporator freezing by excessive cooling.

Page 680 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Ignition "OFF"

2. Disconnect evaporator temperature sensor.

3. Using the multi- tester, Measure resistance between terminal "1" and "2" of evaporator temperature sensor.

Specification

Evaporator core temperature [°C(°F)] Resistance [kΩ]

- 10(14) 13.6

0(32) 8

10(50) 4.9

15(59) 3.9

30(86) 2

40(104) 1.3

50(122) 0.9

4. If the measured resistance is not specification, substitute with a known- good evaporator temperature sensor and

check for proper operation.

5. If the problem is corrected, replace the evaporator temperature sensor.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the center lower side cover(B).

Page 681 of 1575

3.Disconnect the evaporator sensor connector (A).

4. Loosen 2 screws and then remove the evaporator sensor cover(B).

5. Remove the evaporator sensor.

Take care that evaporator core pins are not bent.

6. Installation is the reverse order of removal.

Page 682 of 1575

Page 684 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

1.In- car air temperature sensor is located at the center facia lower panel.

2. The sensor contains a thermistor which measures the temperature of the inside. The signal decided by the

resistance value which changes in accordance with perceived inside temperature, is delivered to heater control unit

and according to this signal the control unit regulates incar temperature to intended value.

3. It perceives the inside temperature, changes the resistance value, and enters the corresponding voltage into the

automatic temperature control module.

4. It will used for discharge temperature control, sensor failsafe, temperature door control, blower motor level control,

and A/C auto control.

Page 685 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Ignition "ON"

2. Blow air with changing temperature to the in car sensor air inlet. Measure sensor resistance between 2 and 4

terminals.

Specification

Temperature [°C(°F)] Resistance between terminals 2and 4 (kΩ)

0 (32) 97.83 ± 2.61%

15 (59) 47.12 ± 1.45%

25 (77) 30.00 ± 1.20%

35 (95) 19.60 ± 1.44%

50 (122) 10.82 ± 2.26%

In car sensor is negative type thermistor that resistance will rise with lower temperature, and reduce with

higher temperature.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the A/C control pannel. (Refer to BD group).

3. Disconnect the connector of in - car sensor (A).Loosen the mounting 2 screws and then remove the in - car sensor

(B).

4.Installation is the reverse order of removal.

Page 686 of 1575