oil KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 668 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Check the condenser fins for clogging and damage. If clogged, clean them with water, and blow them with

compressed air. If bent, gently bend them using a screwdriver or pliers.

2. Check the condenser connections for leakage, and repair or replace it, if required.

REPLACEMENT

CONDENSER ASSEMBLY

1. Recover the refrigerant with a recovery/ recycling/ charging station (Refer to HA - 8).

2. Disconnect the negative ( - ) battery terminal.

3. Remove the radiator. (Refer to EM group)

4. Remove 2 bolts, and then remove the condenser (A) by lifting it up. Be careful not to damage the radiator and

condenser fins when removing the condenser.

5.Install in the reverse order of removal, and note these items :

a. If you're installing a new condenser, add refrigerant oil ND- OIL8.

b. Replace the O - rings with new ones at each fitting, and apply a thin coat of refrigerant oil before installing them.

Be sure to use the right O - rings for R- 134a to avoid leakage.

c. Be careful not to damage the radiator and condenser fins when installing the condenser.

d. Be sure to install the lower mount cushions of condenser securely into the holes.

e. Charge the system, and test its performance. (Refer to HA - 9)

DESICCANT

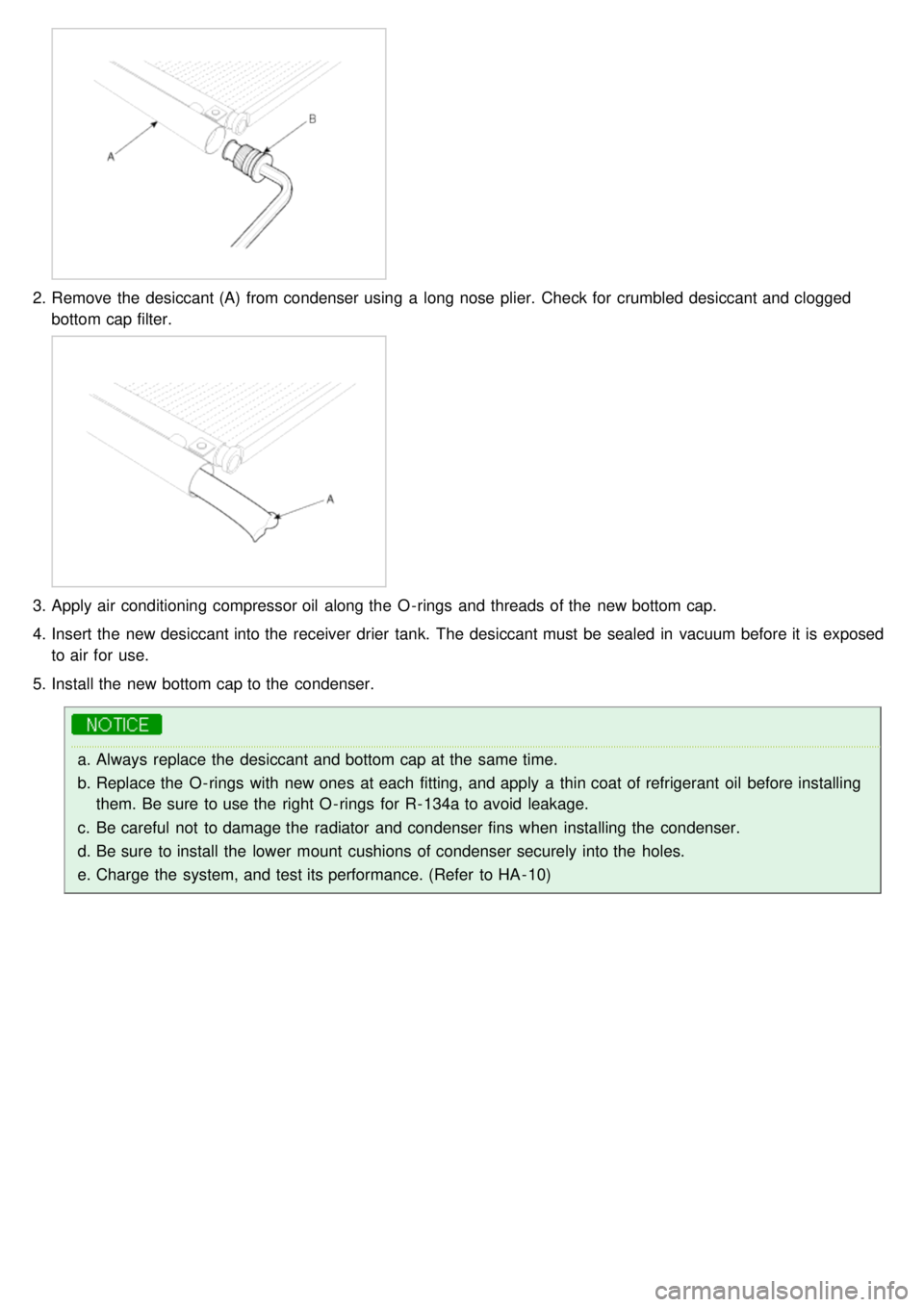

1.Remove the condenser, and then remove the bottom cap (B) with L wrench (A) from the condenser.

TORQUE: 20~25N.m (2.0~2.5kgf•m, 14.5~18.2lb - ft)

Page 669 of 1575

2.Remove the desiccant (A) from condenser using a long nose plier. Check for crumbled desiccant and clogged

bottom cap filter.

3.Apply air conditioning compressor oil along the O - rings and threads of the new bottom cap.

4. Insert the new desiccant into the receiver drier tank. The desiccant must be sealed in vacuum before it is exposed

to air for use.

5. Install the new bottom cap to the condenser.

a.Always replace the desiccant and bottom cap at the same time.

b. Replace the O - rings with new ones at each fitting, and apply a thin coat of refrigerant oil before installing

them. Be sure to use the right O - rings for R- 134a to avoid leakage.

c. Be careful not to damage the radiator and condenser fins when installing the condenser.

d. Be sure to install the lower mount cushions of condenser securely into the holes.

e. Charge the system, and test its performance. (Refer to HA - 10)

Page 715 of 1575

14.Remove the evaporator core(A).

15.Be careful that the inlet and outlet pipe are not bent during heater core removal, and pull out the heater core.

16. Install the heater core in the reverse order of removal.

17. Installation is the reverse order of removal, and note these items :

a. If you're installing a new evaporator, add refrigerant oil (ND - OIL8).

b. Replace the O - rings with new ones at each fitting, and apply a thin coat of refrigerant oil before installing

them. Be sure to use the right O - rings for R- 134a to avoid leakage.

c. Immediately after using the oil, replace the cap on the container, and seal it to avoid moisture absorption.

d. Do not spill the refrigerant oil on the vehicle ; it may damage the paint ; if the refrigerant oil contacts the paint,

wash it off immediately

e. Apply sealant to the grommets.

f. Make sure that there is no air leakage.

g. Charge the system and test its performance.

h. Do not interchange the inlet and outlet heater hoses and install the hose clamps securely.

i. Refill the cooling system with engine coolant.

Page 791 of 1575

2007 > 2.7L V6 GASOLINE >

Precautions

General Precautions

Please read the following precautions carefully before performing the airbag system service. Observe the instructions

described in this manual, or the airbags could accidentally deploy and cause damage or injuries. a. Except when performing electrical inspections, always turn the ignition switch OFF and disconnect the negative

cable from the battery, and wait at least three minutes before beginning work.

The contents in the memory are not erased even if the ignition switch is turned OFF or the battery cables are

disconnected from the battery.

b. Use the replacement parts which are manufactured to the same standards as the original parts and quality.

Do not install used SRS parts from another vehicle.

Use only new parts when making SRS repairs.

c. Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being dropped or improperly handled, such as dents, cracks or

deformation.

d.Before removing any of the SRS parts (including the disconnection of the connectors), always disconnect the SRS

connector.

Airbag Handling and Storage

Do not disassemble the airbags; it has no serviceable parts. Once an airbag has been deployed, it cannot be repaired

or reused.

For temporary storage of the air bag during service, please observe the following precautions.

a. Store the removed airbag with the pad surface up.

b. Keep free from any oil, grease, detergent, or water to prevent damage to the airbag assembly.

Page 792 of 1575

c.Store the removed airbag on secure, flat surface away from any high heat source (exceeding 85°C/185°F).

d. Never perform electrical inspections to the airbags, such as measuring resistance.

e. Do not position yourself in front of the airbag assembly during removal, inspection, or replacement.

f. Refer to the scrapping procedures for disposal of the damaged airbag.

g. Be careful not to bump or impact the SRS unit or the side impact sensors whenever the ignition switch is ON, wait

at least three minutes after the ignition switch is turned OFF before begin work.

h. During installation or replacement, be careful not to bump (by impact wrench, hammer, etc.) the area around the

SRS unit and the side impact sensor. The airbags could accidentally deploy and cause damage or injury.

i. After a collision in which the airbags were deployed, replace the front airbags and the SRS unit. After a collision in

which the side airbag was deployed, replace the side airbag, the front impact sensor and side impact sensor on

the side where the side airbag deployed and the SRS unit. After a collision in which the airbags or the side air

bags did not deploy, inspect for any damage or any deformation on the SRS unit and the side impact sensors. If

there is any damage, replace the SRS unit, the front impact sensor and/or the side impact sensors.

j. Do not disassemble the SRS unit, the front impact sensor or the side impact sensors

k. Turn the ignition switch OFF, disconnect the battery negative cable and wait at least three minutes before

beginning installation or replacement of the SRS unit.

l. Be sure the SRS unit, the front impact sensor and side impact sensors are installed securely with the mounting

bolts.

m. Do not spill water or oil on the SRS unit,or the front impact sensor or the side impact sensors and keep them

away from dust.

n. Store the SRS unit, the front impact sensor and the side impact sensors in a cool (less than 40°C/104°F) and dry

(less than 80% relative humidity, no moisture) area.

Wiring Precautions

SRS wiring can be identified by special yellow outer covering (except the SRS circuits under the front seats).

Observe the instructions described in this section.

a. Never attempt to modify, splice, or repair SRS wiring.

If there is an open or damage in SRS wiring, replace the harness.

Page 863 of 1575

2007 > 2.7L V6 GASOLINE >

TROUBLESHOOTING

PROBLEM SYMPTOMS TABLE

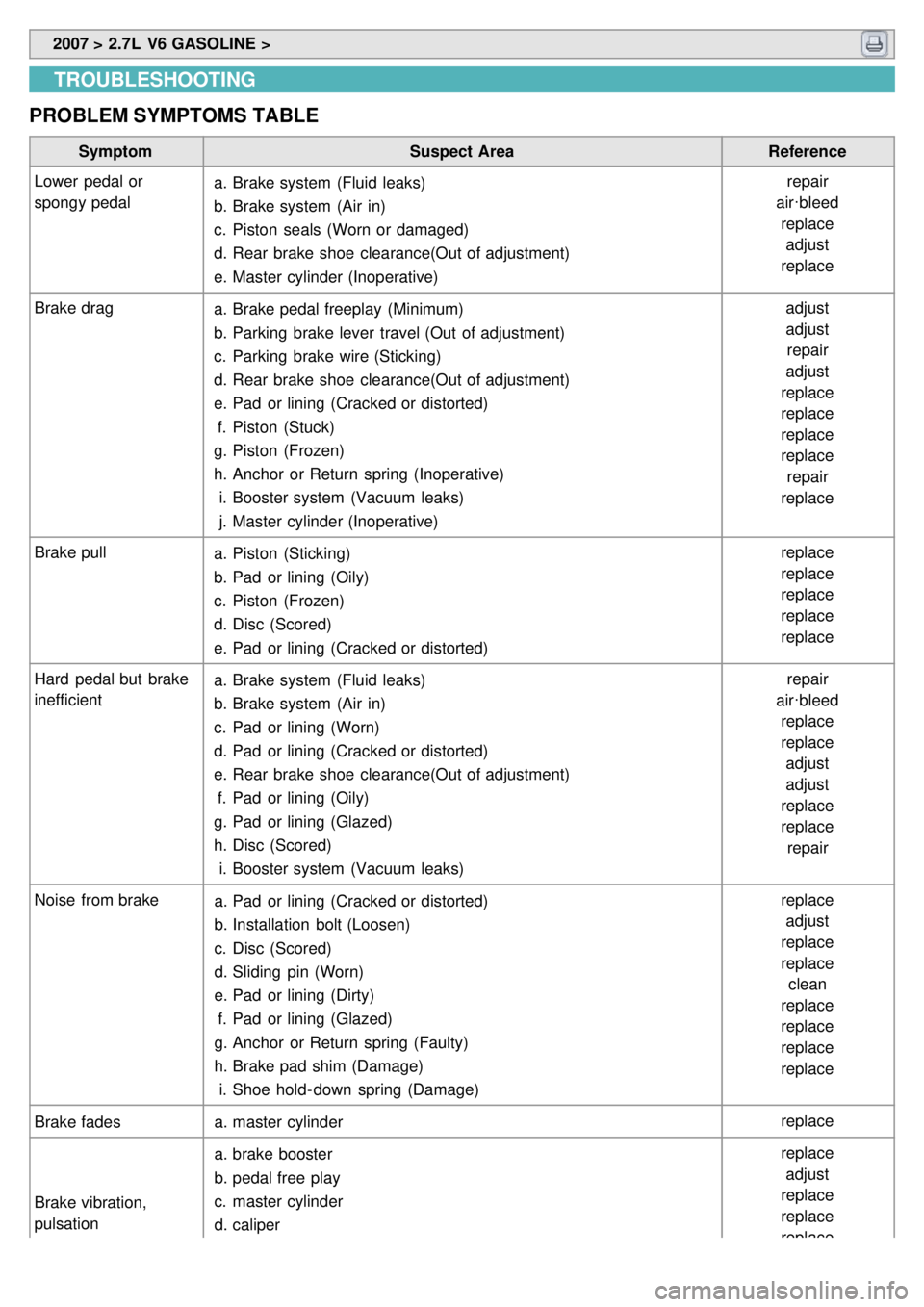

Symptom Suspect Area Reference

Lower pedal or

spongy pedal a.

Brake system (Fluid leaks)

b. Brake system (Air in)

c. Piston seals (Worn or damaged)

d. Rear brake shoe clearance(Out of adjustment)

e. Master cylinder (Inoperative) repair

air·bleed replaceadjust

replace

Brake drag a.Brake pedal freeplay (Minimum)

b. Parking brake lever travel (Out of adjustment)

c. Parking brake wire (Sticking)

d. Rear brake shoe clearance(Out of adjustment)

e. Pad or lining (Cracked or distorted)

f. Piston (Stuck)

g. Piston (Frozen)

h. Anchor or Return spring (Inoperative)

i. Booster system (Vacuum leaks)

j. Master cylinder (Inoperative) adjust

adjust

repair

adjust

replace

replace

replace

replace repair

replace

Brake pull a.Piston (Sticking)

b. Pad or lining (Oily)

c. Piston (Frozen)

d. Disc (Scored)

e. Pad or lining (Cracked or distorted) replace

replace

replace

replace

replace

Hard pedal but brake

inefficient a.

Brake system (Fluid leaks)

b. Brake system (Air in)

c. Pad or lining (Worn)

d. Pad or lining (Cracked or distorted)

e. Rear brake shoe clearance(Out of adjustment)

f. Pad or lining (Oily)

g. Pad or lining (Glazed)

h. Disc (Scored)

i. Booster system (Vacuum leaks) repair

air·bleed replace

replaceadjust

adjust

replace

replace repair

Noise from brake a.Pad or lining (Cracked or distorted)

b. Installation bolt (Loosen)

c. Disc (Scored)

d. Sliding pin (Worn)

e. Pad or lining (Dirty)

f. Pad or lining (Glazed)

g. Anchor or Return spring (Faulty)

h. Brake pad shim (Damage)

i. Shoe hold- down spring (Damage) replace

adjust

replace

replace clean

replace

replace

replace

replace

Brake fades a.master cylinder replace

Brake vibration,

pulsation a.

brake booster

b. pedal free play

c. master cylinder

d. caliper replace

adjust

replace

replace

replace

Page 866 of 1575

TIGHTENING TORQUE

ItemsNmkgf.m lb - ft

Master cylinder to booster mounting nut 8 ~ 120.8 ~ 1.2 5.8 ~ 8.7

Brake booster mounting nut 13 ~ 161.3 ~ 1.6 9.4 ~ 11.6

Bleeder screw 7 ~ 130.7 ~ 1.3 5.06 ~ 9.4

Brake tube nut, brake hose 13 ~ 171.3 ~ 1.7 9.4 ~ 12.3

Caliper guide rod bolt (Front) 22 ~ 322.2 ~ 3.215.9 ~ 23.1

Caliper guide rod bolt (Rear) 22 ~ 322.2 ~ 3.215.9 ~ 23.1

Caliper assembly to knuckle (Front) 85 ~ 1008.5 ~ 1061.5 ~ 72.3

Caliper assembly to knuckle (Rear) 50 ~ 605.0 ~ 6.036.2 ~ 43.4

Brake hose to front caliper 25 ~ 302.5 ~ 3.018.1 ~ 21.7

Brake pedal assembly bracket mounting nut 10 ~ 151.0 ~ 1.5 7.2 ~ 10.8

Brake pedal mounting nut 13 ~ 161.3 ~ 1.6 9.4 ~ 11.6

Stop lamp switch mounting nut 8 ~ 100.8 ~ 1.0 5.8 ~ 7.23

Active wheel speed sensor mounting bolt on

the brake plate 7 ~ 10

0.7 ~ 1.0 5.1 ~ 7.2

HECU mounting bracket bolt 17 ~ 261.7 ~ 2.612.3 ~ 18.8

HECU mounting nut 6 ~ 100.6 ~ 1.0 4.3 ~ 7.2

Yaw rate & lateral acceleration sensor bolt 5 ~ 80.5 ~ 0.8 3.62 ~ 5.8

SPECIFICATION (ABS)

Part ItemStandard valueRemark

HECU(Hydraulic and

Electronic Control

Unit) System

4 channel 4 sensor

(Solenoid)

·ABS system:ABS &

EBD control

Type

Motor, valve relay

intergrated type

Operating voltage 8 V ~ 16 V(DC)

Operating temperature - 40 ~ 120 °C

( - 40 ~ 248 °F)

Warning lamp Operating voltage

12 V·ABS W/L:ABS failure

·Brake W/L:Parking,

brake oil, EBD failure

Current consumption 80 mA

Acitve wheel speed

sensor Supply voltage

DC 4.5 ~ 2.0 V

Operating temperature - 40 ~ 150 °C

Output current low 5.9 ~ 8.4 mATyp.7 mA

Output current High 11.8 ~ 16.8 mATyp.14 mA

Frequency range 1 ~ 2500 HZ

Air gap Front

0.15 ~ 1.5 mm Typ.0.7 mm

Rear 0.2 ~ 1.2 mm Typ.0.7 mm

Tone wheel 48 teeth

Output duty 30~70 %

SPECIFICATION(ESP)

Page 889 of 1575

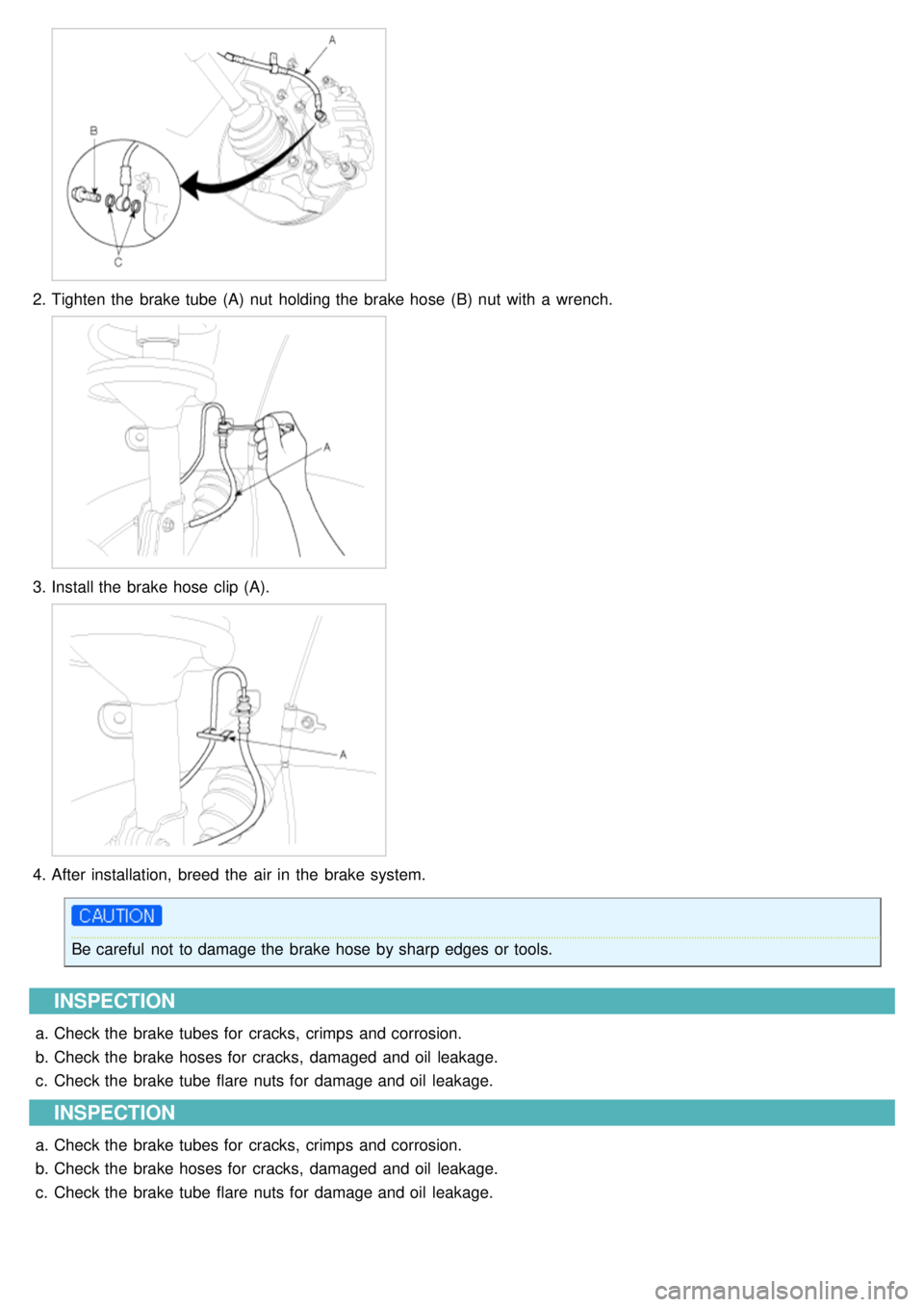

2.Tighten the brake tube (A) nut holding the brake hose (B) nut with a wrench.

3.Install the brake hose clip (A).

4.After installation, breed the air in the brake system.

Be careful not to damage the brake hose by sharp edges or tools.

INSPECTION

a.Check the brake tubes for cracks, crimps and corrosion.

b. Check the brake hoses for cracks, damaged and oil leakage.

c. Check the brake tube flare nuts for damage and oil leakage.

INSPECTION

a.Check the brake tubes for cracks, crimps and corrosion.

b. Check the brake hoses for cracks, damaged and oil leakage.

c. Check the brake tube flare nuts for damage and oil leakage.

Page 928 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

This specification applies to HCU(Hydraulic Control Unit) and ECU(Electronic Control Unit) of the HECU.(Hydraulic and

Electronic Control Unit)

This specification is for the wiring design and installation of ABS/TCS/ESC ECU.

This unit has the functions as follows.

a. Input of signal from Pressure sensor, Steering angle sensor, Yaw & Lateral G sensor, the wheel speed sensors

attached to each wheel.

b. Control of braking force / traction force/ yaw moment.

c. Failsafe function.

d. Self diagnosis function.

e. Interface with the external diagnosis tester.

Installation position : engine compartment a. Brake tube length from Master cylinder port to HECU inlet port should be max. 1m

b. The position should not be close to the engine block and not lower than the wheel.

OPERATION

The ECU shall be put into operation by switching on the operating voltage (IGN).

On completion of the initialization phase, the ECU shall be ready for operation.

In the operating condition, the ECU shall be ready, within the specified limits (voltage and temperature), to process the

signals offered by the various sensors and switches in accordance with the control algorithm defined by the software

and to control the hydraulic and electrical actuators.

Wheel Sensor signal processing

The ECU shall receive wheel speed signal from the four active wheel sensors.

The wheel signals are converted to voltage signal by the signal conditioning circuit after receiving current signal from

active wheel sensors and given as input to the MCU.

Solenoid Valve Control

When one side of the valve coil is connected to the positive voltage that is provided through the valve relay and the

other side is connected to the ground by the semiconductor circuit, the solenoid valve goes into operation.

The electrical function of the coils are always monitored by the valve test pulse under normal operation conditions.

Voltage limits

a.Overvoltage

When overvoltage is detected(above 16.8 V), the ECU switches off the valve relay and shuts down the system.

When voltage is returned to operating range, the system goes back to the normal condition after the initialization

phase.

b. Undervoltage

In the event of undervoltage(below 9.3 V), ABS control shall be inhibited and the warning lamp shall be turned on.

When voltage is returned to operating range, the warning lamp is switched off and ECU returns to normal operating

mode.

Pump Motor Checking

The ECU performs a pump motor test at a speed of 15km/h once after IGN is switched on.

Diagnostic Interface

Failures detected by the ECU are encoded on the ECU, stored in a EEPROM and read out by diagnostic equipment

when the ignition switch is turned on.

The diagnosis interface can also be used for testing the ECU during production of the ECU and for actuating the HCU

(Air - bleeding line or Roll and Brake Test line).

Warning Lamp module

Page 1097 of 1575

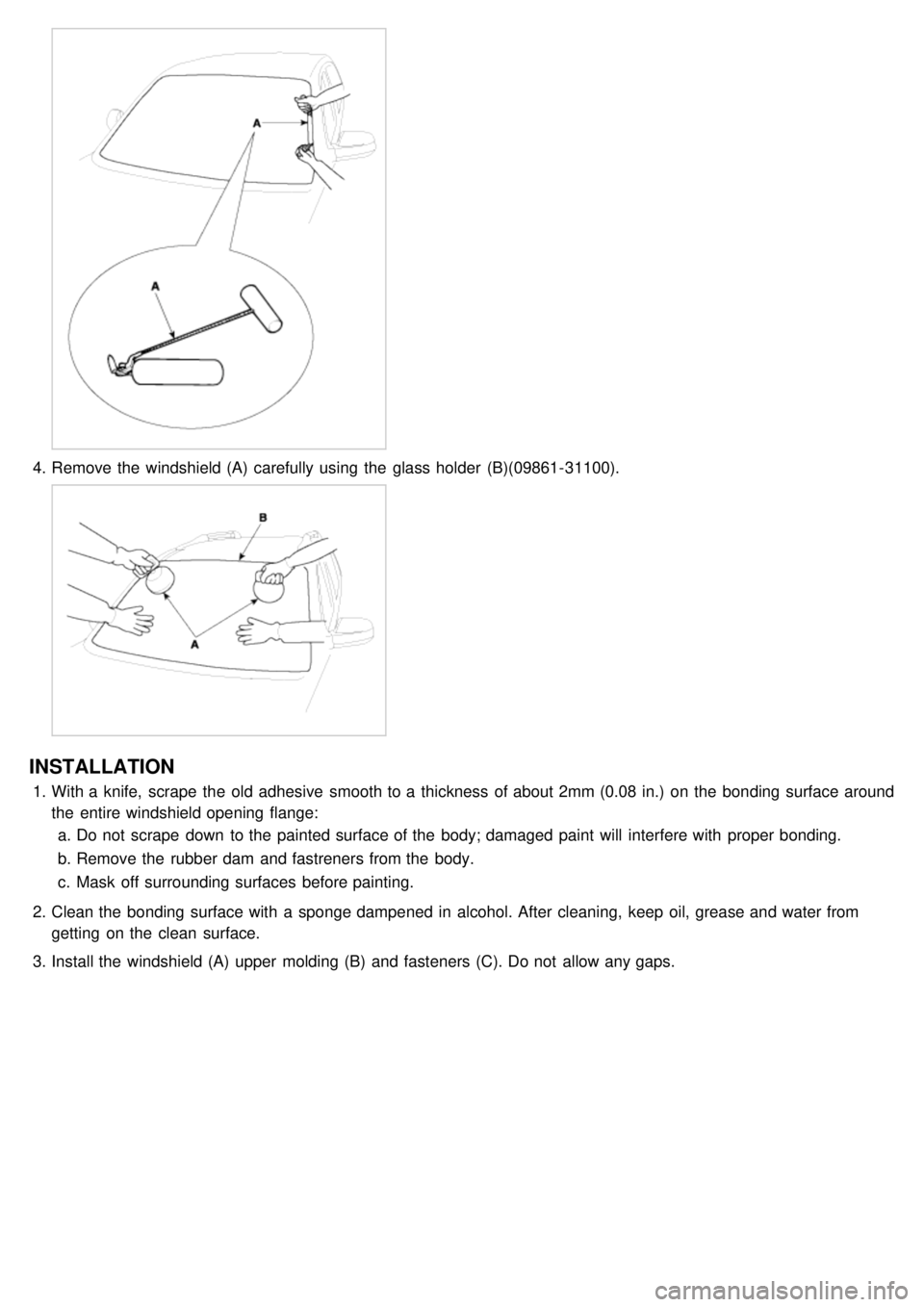

4.Remove the windshield (A) carefully using the glass holder (B)(09861- 31100).

INSTALLATION

1.With a knife, scrape the old adhesive smooth to a thickness of about 2mm (0.08 in.) on the bonding surface around

the entire windshield opening flange:

a. Do not scrape down to the painted surface of the body; damaged paint will interfere with proper bonding.

b. Remove the rubber dam and fastreners from the body.

c. Mask off surrounding surfaces before painting.

2. Clean the bonding surface with a sponge dampened in alcohol. After cleaning, keep oil, grease and water from

getting on the clean surface.

3. Install the windshield (A) upper molding (B) and fasteners (C). Do not allow any gaps.