oil KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 485 of 1575

2007 > 2.7L V6 GASOLINE >

SPECIAL SERVICE TOOLS

Tool (Number and Name) IllustrationUse

09568 - 4A000

Ball joint remover

Removal of Ball joint

(Front upper arm/lower arm, & Rear

upper arm)

09532 - 11600

Preload socket

Measurement of the front lower arm

ball joint starting torque.

(Use with torque wrench)

09546 - 26000

Strut spring compressor

Compression of the coil spring

09214 - 32000

Mount bushing remover and installer

Removal & installation of lower arm

bushing(G)

(Use with 09216 - 21100)

09216 - 21100

Mount bushing remover and installer

Removal & installation of lower arm

bushing(G)

(Use with 09216 - 32000)

09216 - 21600

Mount bushing remover and installer

arbor

Removal and installation of trailing

arm bushing

(Use with 09552 - 38100)

09552 - 38100 Removal and installation of the rear

Page 498 of 1575

→NO

Replace bent or damaged parts.

CHECK THE REAR SUSPENSION

a.Measure the vehicle wheel base for LH and RH.

b. Compare the measurements.

● Are the measurements the same ?

→ YES

If the ride is smooth, vehicle is OK.

If the ride is rough, Go to Detailed Test

→ NO

Inspect the rear suspension components for wear or damage.

Repair or Install new components as necessary.

DETAILED TEST H : ROUGH RIDE CONDITIONS DETAILS/RESULTS/ACTIONS

CHECK THE FRONT SHOCK ABSORBER

a.Raise support the vehicle.

b. Inspect the front shock absorber for oil leaks or damage.

● Are the tires excessively worn or damaged ?

→ YES

Install new front shock absorbers.

→ NO

Go to

CHECK THE REAR SHOCK ABSORBERS Inspect the rear shock absorbers for oil leaks or damage.

● Are the rear shock absorbers leaking ?

→ YES

Install new rear shock absorbers.

→ NO

The vehicle is OK. Go to TROUBLESHOOTING.

DETAILED TEST I : EXCESSIVE NOISE CONDITIONS DETAILS/RESULTS/ACTIONS

INSPECT THE SUSPENSION

a.Raise and support the vehicle.

b. Inspect the shock absorber mounting bolts.

● Are the mounting bolts loose or broken ?

→ YES

Tighten or Install new shock absorber mounting bolts.

→ NO

Go to

INSPECT THE SPRING AND TORSION BARS Inspect the springs and stabilizer bars for damage.

● Are the spring or stabilizer bars damaged ?

→ YES

Install new spring and/or stabilizer bars.

Page 512 of 1575

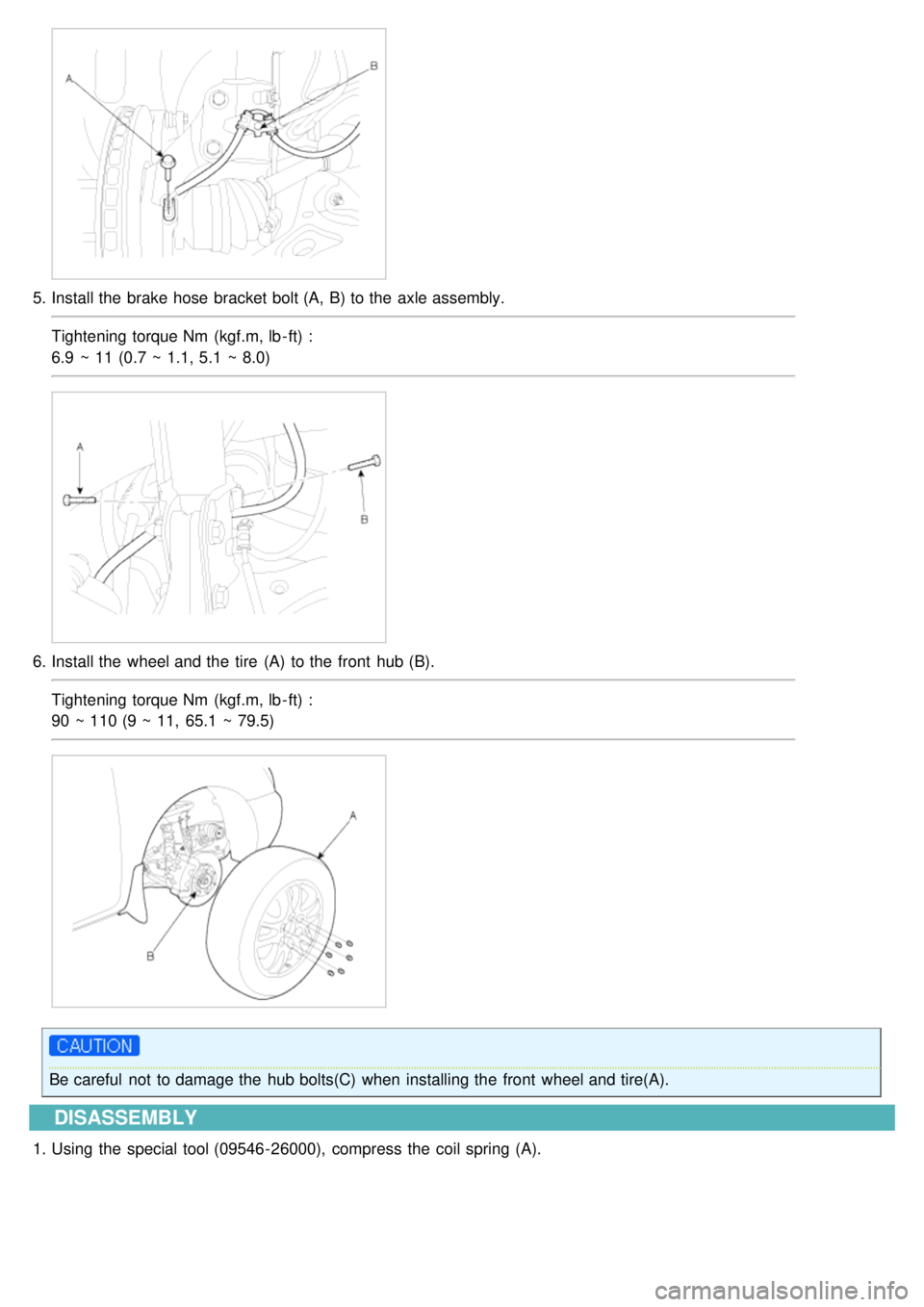

5.Install the brake hose bracket bolt (A, B) to the axle assembly.

Tightening torque Nm (kgf.m, lb - ft) :

6.9 ~ 11 (0.7 ~ 1.1, 5.1 ~ 8.0)

6.Install the wheel and the tire (A) to the front hub (B).

Tightening torque Nm (kgf.m, lb - ft) :

90 ~ 110 (9 ~ 11, 65.1 ~ 79.5)

Be careful not to damage the hub bolts(C) when installing the front wheel and tire(A).

DISASSEMBLY

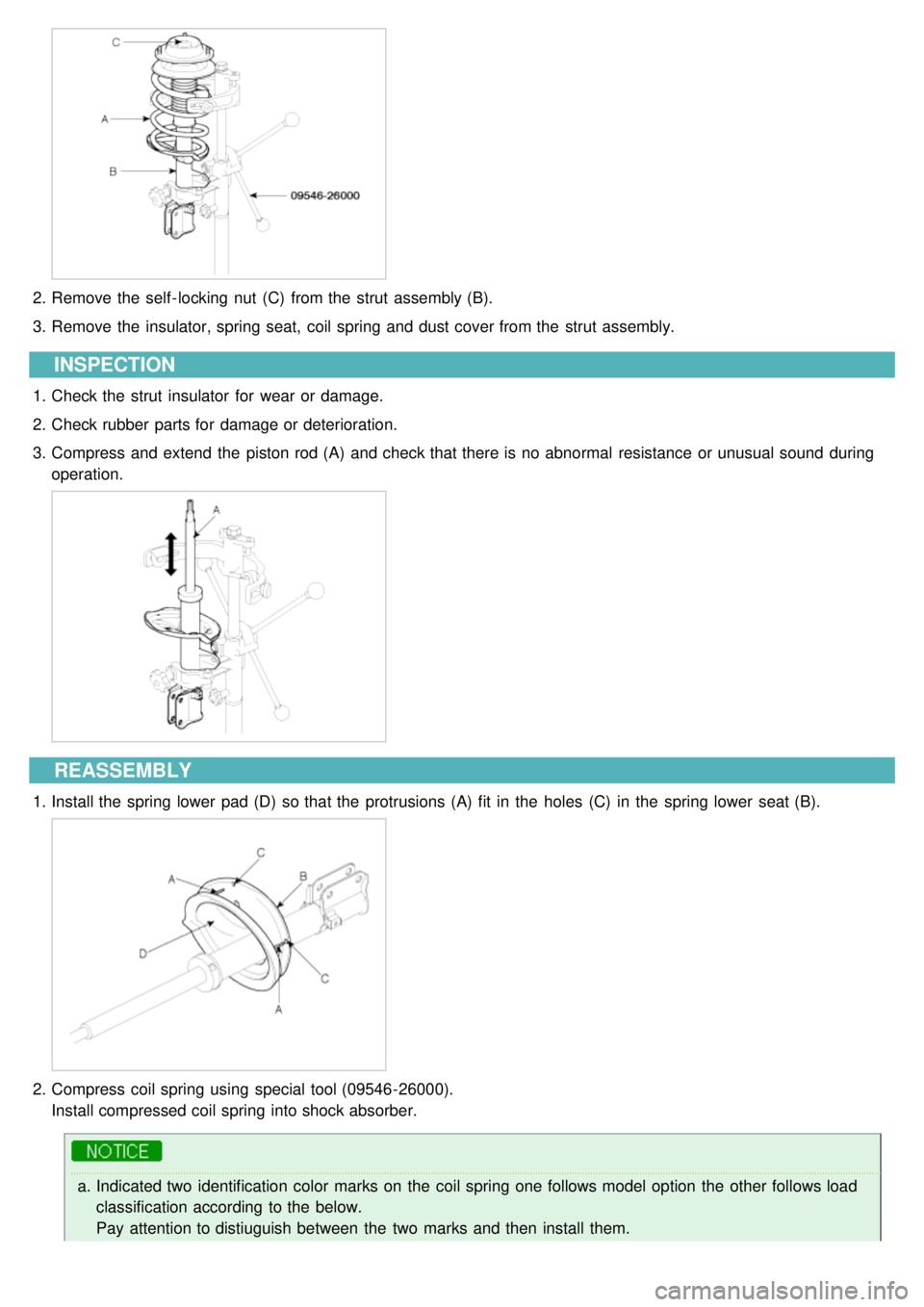

1.Using the special tool (09546- 26000), compress the coil spring (A).

Page 513 of 1575

2.Remove the self - locking nut (C) from the strut assembly (B).

3. Remove the insulator, spring seat, coil spring and dust cover from the strut assembly.

INSPECTION

1.Check the strut insulator for wear or damage.

2. Check rubber parts for damage or deterioration.

3. Compress and extend the piston rod (A) and check that there is no abnormal resistance or unusual sound during

operation.

REASSEMBLY

1.Install the spring lower pad (D) so that the protrusions (A) fit in the holes (C) in the spring lower seat (B).

2.Compress coil spring using special tool (09546- 26000).

Install compressed coil spring into shock absorber.

a.Indicated two identification color marks on the coil spring one follows model option the other follows load

classification according to the below.

Pay attention to distiuguish between the two marks and then install them.

Page 514 of 1575

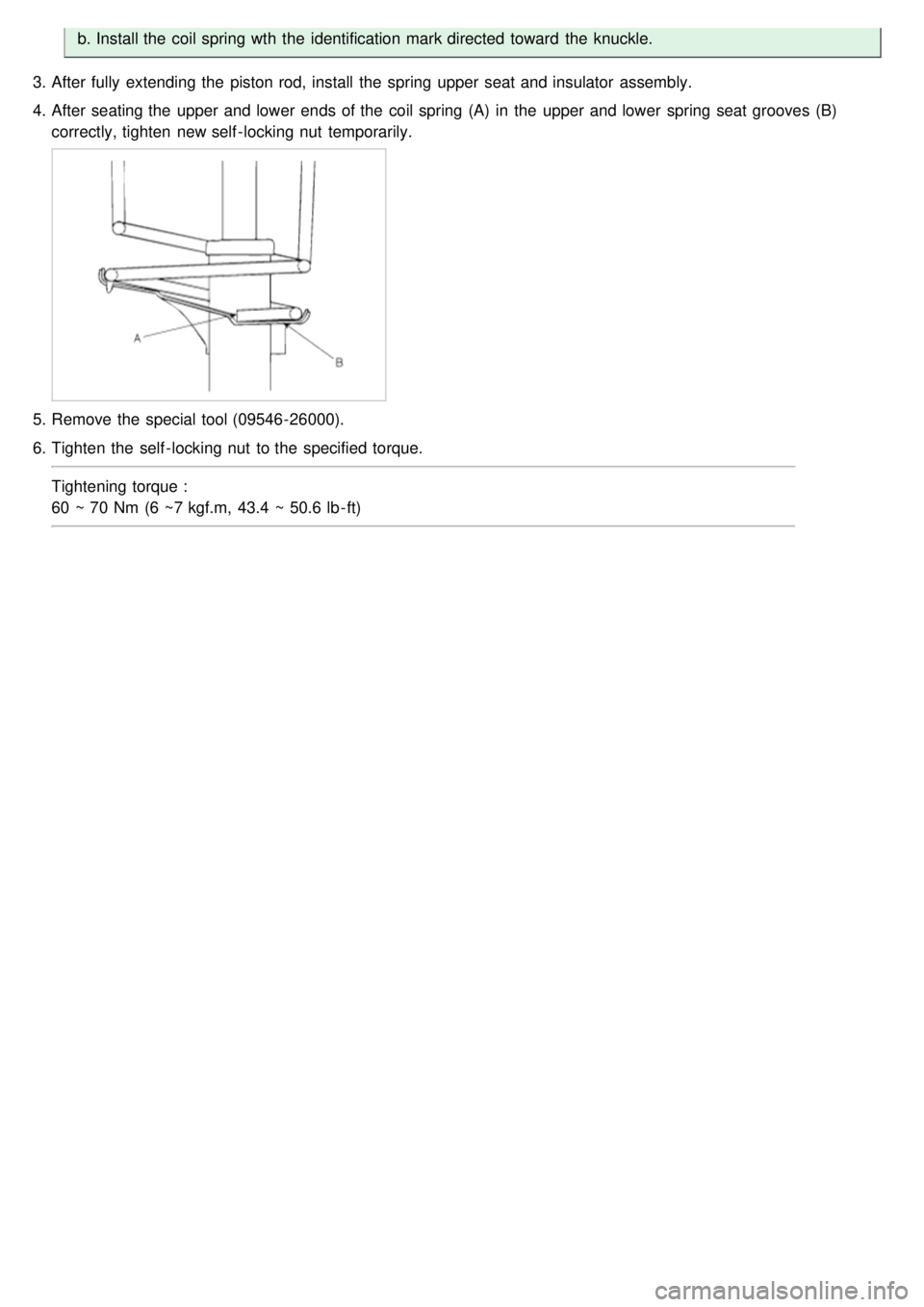

b.Install the coil spring wth the identification mark directed toward the knuckle.

3. After fully extending the piston rod, install the spring upper seat and insulator assembly.

4. After seating the upper and lower ends of the coil spring (A) in the upper and lower spring seat grooves (B)

correctly, tighten new self - locking nut temporarily.

5.Remove the special tool (09546- 26000).

6. Tighten the self - locking nut to the specified torque.

Tightening torque :

60 ~ 70 Nm (6 ~7 kgf.m, 43.4 ~ 50.6 lb - ft)

Page 579 of 1575

2007 > 2.7L V6 GASOLINE >

SPECIAL TOOLS

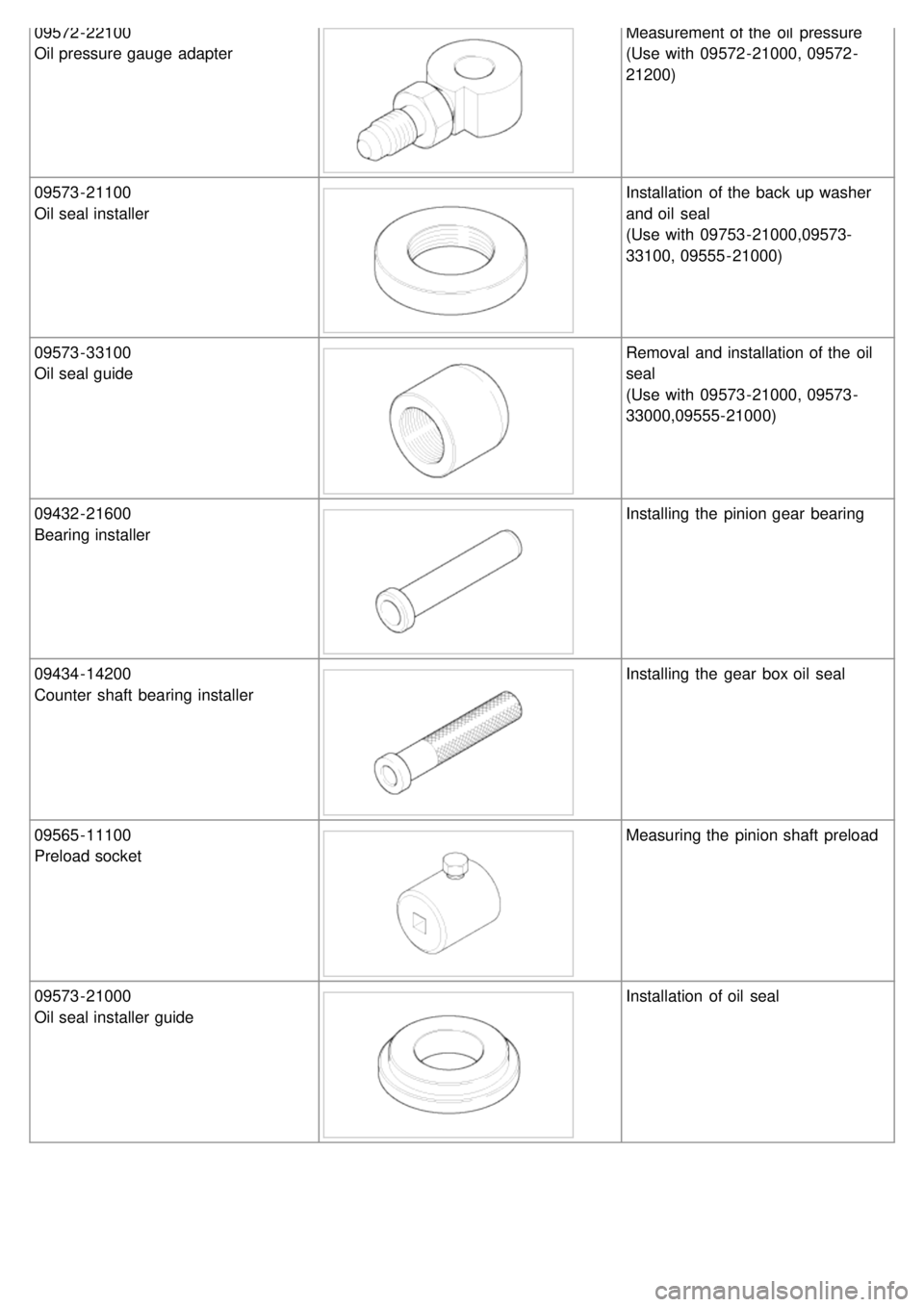

Tool (Number and Name) IllustrationUse

09222 - 32100

Valve stem oil seal installer

Installation of the oil pump oil seal

09555 - 21000

Bar

Removal and installation of the oil

seal

(Use with 09573 - 33100, 09573 -

33000,09573- 21000)

09561 - 11001

Steering wheel puller

Removal of steering wheel

09568 - 4A000

Tie rod end puller

Separation of the tie rod end bail

joint

09572 - 21000

Oil pressure gauge

Measurement of the oil pressure

(Use with 09572 - 22100, 09572 -

21200)

09572 - 21200

Oil pressure gauge adapter

Measurement of the oil pressure

(Use with 09572 - 21000, 09572 -

22100)

09572 - 22100 Measurement of the oil pressure

Page 580 of 1575

09572 - 22100

Oil pressure gauge adapterMeasurement of the oil pressure

(Use with 09572 - 21000, 09572 -

21200)

09573 - 21100

Oil seal installer

Installation of the back up washer

and oil seal

(Use with 09753 - 21000,09573-

33100, 09555 - 21000)

09573 - 33100

Oil seal guide

Removal and installation of the oil

seal

(Use with 09573 - 21000, 09573 -

33000,09555- 21000)

09432 - 21600

Bearing installer

Installing the pinion gear bearing

09434 - 14200

Counter shaft bearing installer

Installing the gear box oil seal

09565 - 11100

Preload socket

Measuring the pinion shaft preload

09573 - 21000

Oil seal installer guide

Installation of oil seal

Page 581 of 1575

2007 > 2.7L V6 GASOLINE >

TROUBLESHOOTING

Symptom Probable cause Remedy

Excessive play in

steering Loose yoke plug

Retighten

Loose steering gear mounting bolts Retighten

Loose or worn tie rod end Retighten or replace as necessary

Steering wheel

operation is not

smooth (Insufficient

power assist) V- belt slippage

Readjust

Damaged V- belt Replace

Low fluid level Replenish

Air in the fluid Bleed air

Twisted or damaged hoses Correct the routing or replace

Insufficient oil pump pressure Repair or replace the oil pump

Sticky flow control valve Replace

Excessive internal oil pump leakage Replace the damaged parts

Excessive oil leaks from rack and pinion in

gear box Replace the damaged parts

Distorted or damaged gear box or valve body

seals Replace

Steering wheel does

not return properly Excessive turning resistance of tierod end

Replace

Yoke plug excessively tight Adjust

Tie rod and/or ball joint cannot turn smoothly Replace

Loose mounting of gear box mounting bracket

Worn steering shaft joint and/or Retighten

Worn steering shaft joint and/or body

grommet Correct or replace

Distorted rack Replace

Damaged pinion bearing Replace

Twisted or damaged hoses Reposition or replace

Damaged oil pressure control valve Replace

Damaged oil pump input shaft bearing Replace

Noise Hissing Noise in Steering Gear

There is some noise with all power steering systems. One of the most common is a hissing

sound when the steering wheel is turned and the car is not moving. This noise will be most

evident when turning the wheel while the brakes are being applied. There is no relationship

between this noise and steering performance. Do not replace the valve unless the "hissing"

noise becomes extreme. A replaced valve will also make a slight noise, and is not always a

solution for the condition.

Rattling or chucking

noise in the rack and

pinion Interference with hoses from vehicle body

Reposition

Loose gear box bracket Retighten

Loose tie rod end and/or ball joint Retighten

Worn tie rod and/or ball joint Replace

Noise in the oil pump Low fluid level Replenish

Air in the fluid Bleed air

Loose pump mounting bolts Retighten

Page 583 of 1575

2.Shake the ball joint stud several times to check for looseness.

Tie rod end ball joint starting torque :

30 kg·cm or less

3.If the starting torque exceeds the upper limit of the standard value, replace the tie rod end.

4. Even if the starting torque is below the lower limit of the standard value, check the play of the ball joint and replace

if necessary.

CHECKING STEERING WHEEL RETURN

1.The force required to turn the steering wheel and the wheel return should be the same for both moderate and sharp

turns.

2. When the steering wheel is turned 90° and held for a couple of seconds while the vehicle is being driven at 20- 30

kph (12- 19 mph), the steering wheel should return at least 20° from its central position when it is released.

If the steering wheel is turned very quickly, steering may be momentarily difficult. This is not a malfunction

because the oil pump output will be somewhat decreased.

Page 584 of 1575

CHECKING POWER STEERING BELT TENSION

Refer to EM group(Timing system).

CHECKING POWER STEERING FLUID LEVEL

1.Position the vehicle on a level surface.

2. Start the engine. With the vehicle kept stationary, turn the steering wheel several times continuously to raise the

fluid temperature to 50- 60°C (122 - 140°F).

3. With the engine at idle, turn the steering wheel fully clockwise and counter- clockwise several times.

4. Make sure that there is no foaming or cloudiness in the reservoir fluid.

5. Stop the engine and check for any difference in fluid level between a stationary and a running engine.

a.If the fluid level varies 5 mm (0.2 in) or more, bleed the system again.

b. If the fluid level suddenly rises after stopping the engine, further bleeding is required.

c. Incomplete bleeding will produce a chattering sound in the pump and noise in the flow control valve, and

lead to decreased durability of the pump.

REPLACING POWER STEERING FLUID

1.Jack up the front wheels and support them with jackstands.

2. Disconnect the return hose from the oil reservoir and plug the oil reservoir.

3. Connect a vinyl hose to the disconnected return hose, and drain the oil into a container.

4. Remove the fuel pump fuse, then start the engine and wait for the engine to stall. Next, while operating the starting

motor intermittently, turn the steering wheel all the way to the left and then to the right several times to drain the

fluid.

5. Connect the return hoses, then fill the oil reservoir with the specified fluid.

6. Reinstall the fuel pump fuse.

7. Start the engine. Check for oil leakage.

8. Stop the engine.

9. Bleed the system.

Power steering fluid type : PSF - 3

Total quantity : Approx 1.1 liter

AIR BLEEDING

1.Remove the fuel pump fuse, then start the engine and wait for the engine to stall. Next, while operating the starting

motor intermittently (for 15 ~ 20 seconds), turn the steering wheel all the way to the left and then to the right five or

six times.