oil KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 585 of 1575

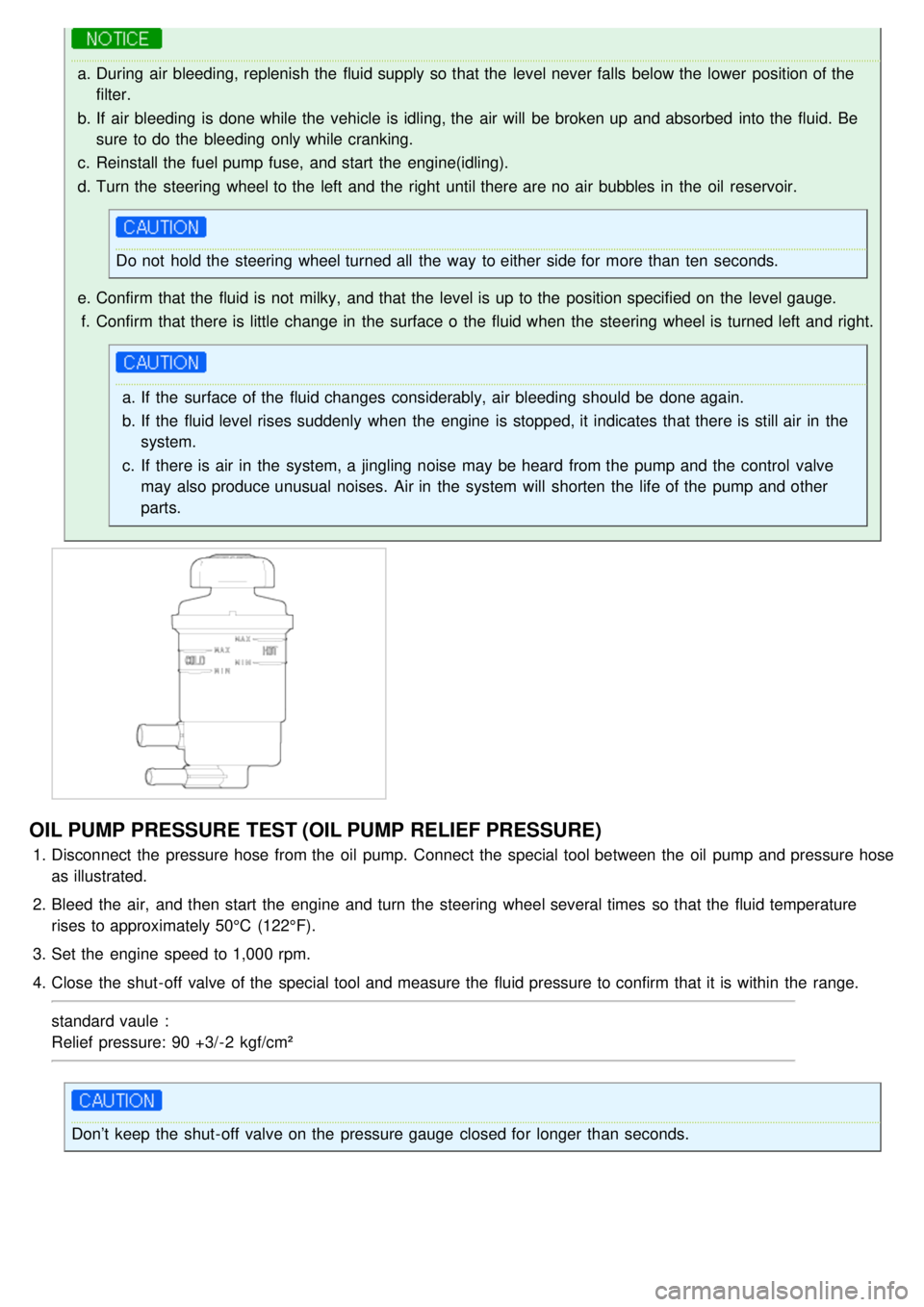

a.During air bleeding, replenish the fluid supply so that the level never falls below the lower position of the

filter.

b. If air bleeding is done while the vehicle is idling, the air will be broken up and absorbed into the fluid. Be

sure to do the bleeding only while cranking.

c. Reinstall the fuel pump fuse, and start the engine(idling).

d. Turn the steering wheel to the left and the right until there are no air bubbles in the oil reservoir.

Do not hold the steering wheel turned all the way to either side for more than ten seconds.

e. Confirm that the fluid is not milky, and that the level is up to the position specified on the level gauge.

f. Confirm that there is little change in the surface o the fluid when the steering wheel is turned left and right.

a. If the surface of the fluid changes considerably, air bleeding should be done again.

b. If the fluid level rises suddenly when the engine is stopped, it indicates that there is still air in the

system.

c. If there is air in the system, a jingling noise may be heard from the pump and the control valve

may also produce unusual noises. Air in the system will shorten the life of the pump and other

parts.

OIL PUMP PRESSURE TEST (OIL PUMP RELIEF PRESSURE)

1.Disconnect the pressure hose from the oil pump. Connect the special tool between the oil pump and pressure hose

as illustrated.

2. Bleed the air, and then start the engine and turn the steering wheel several times so that the fluid temperature

rises to approximately 50°C (122°F).

3. Set the engine speed to 1,000 rpm.

4. Close the shut- off valve of the special tool and measure the fluid pressure to confirm that it is within the range.

standard vaule :

Relief pressure: 90 +3/- 2 kgf/cm²

Don’t keep the shut- off valve on the pressure gauge closed for longer than seconds.

Page 587 of 1575

2007 > 2.7L V6 GASOLINE >

SPECIFICATIONS

Items Specifications

Steering column/ shaft Type

Tilt

Tilt stroke +7°/ - 11.7°

Steering gear Type

Rack & pinion

Rack stroke VRS On

148 mm (5.827 in)

VRS Off 156 mm (6.142 in)

Power steering pump Type

Vane

Diesel Relief pressure

90 kgf/cm²

Discharge 9.6 cc/rev

Gasoline Relief pressure

90 kgf/cm²

Discharge 10.5 cc/rev

SERVICE STANDARD

Items Specifications

Steering wheel free play 30 mm (1.12 in)

Steering angle VRS on

Inner

38.64°

Outer 31.78°

VRS off Inner

41.91°

Outer 33.54°

TIGHTENING TORQUE

Items NmKgf.m Lb- ft

Steering wheel lock nut 40 ~ 504.0 ~ 5.0 29 ~ 36

Steering column mounting bolts and nut 13 ~ 181.3 ~ 1.89.4 ~ 13.0

Bolt connecting steering column to universal

joint 15 ~ 20

1.5 ~ 2.010.8 ~ 14.5

Bolt connecting universal joint to steering gear 13 ~ 181.3 ~ 1.89.4 ~ 13.0

Steering column mounting bolts and nut 13 ~ 181.3 ~ 1.89.4 ~ 13.0

Tie rod end castle nut 35 ~ 453.5 ~ 4.5 25 ~ 33

Front lower arm ball joint assembly bolts 90 ~ 1209.0 ~ 12.0 65 ~ 87

Stabilizer link to strut assembly nut 100 ~ 12010.0 ~ 12.0 72 ~ 87

Rear roll stopper to sub- frame bolts 50 ~ 605.0 ~ 6.0 36 ~ 43

Pressure tube to valve body housing nut 12 ~ 181.2 ~ 1.8 9 ~ 13

Pressure tube to oil pump eye bolt 65 ~ 756.5 ~ 7.5 47 ~ 54

Return tube to valve body housing nut 12 ~ 181.2 ~ 1.8 9 ~ 13

Power steering gear box to sub- frame bots 90 ~ 1109.0 ~ 11.0 65 ~ 80

LUBRICANT

Item Lubricant Quantity

Power steering fluid PSF - 31.1 L

Page 599 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Remove the both front wheel & tire assemblies.

2. Drain the power steering fluid.

3. Remove the bolt (A) connecting steering column to universal joint.

Tightening torque Nm (kgf.m, lb - ft):

13 ~ 18 (1.3 ~ 1.8, 9.4 ~ 13.0)

4.Disconnect the pressure tube (A) from the power steering oil pump by loosening eye bolt.

Tightening torque Nm (kgf.m, lb - ft):

65 ~ 75 (6.5 ~ 7.5, 47 ~ 54)

[Diesel]

[Gasoline]

5.Disconnect the return hose (A)

Page 607 of 1575

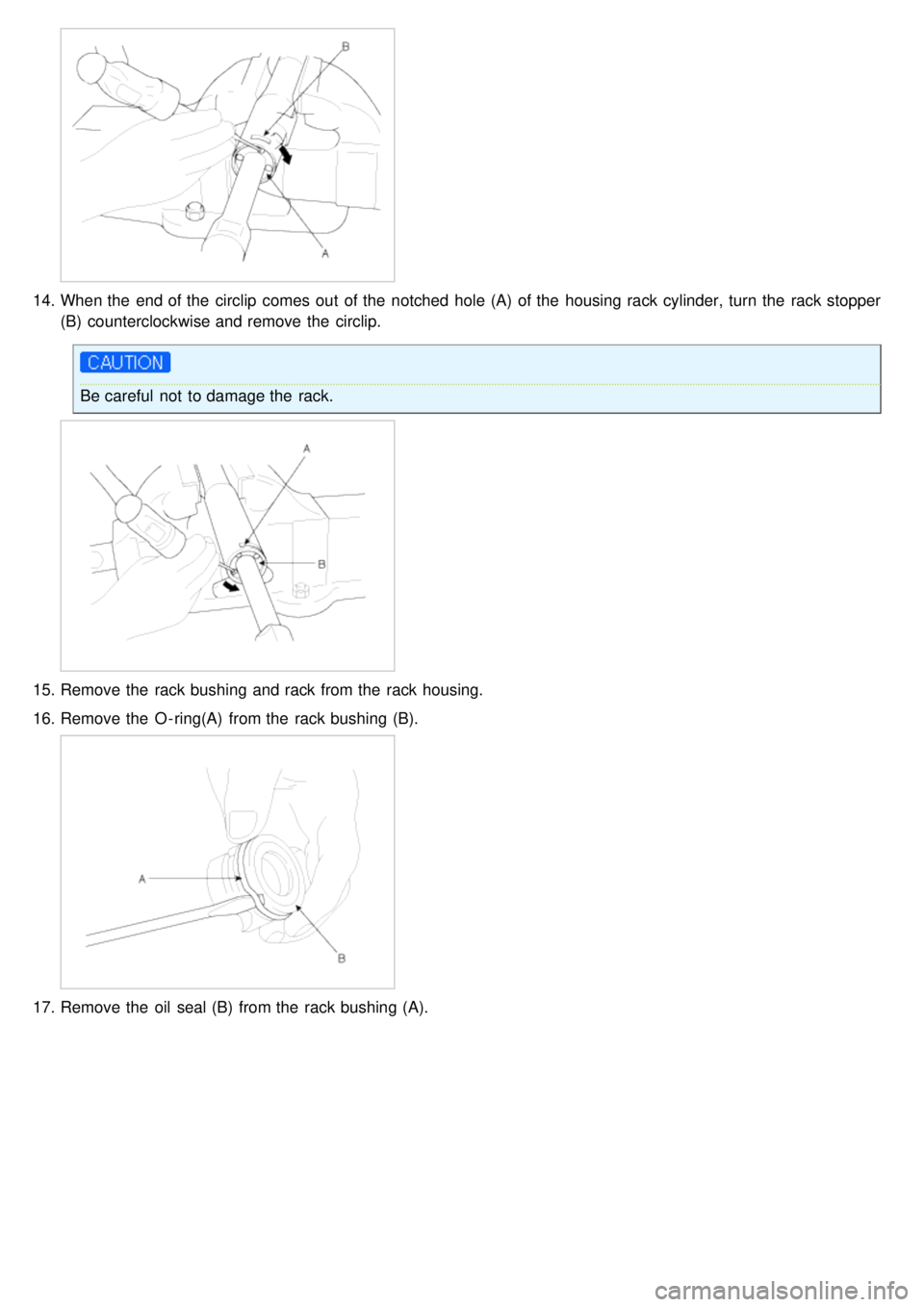

14.When the end of the circlip comes out of the notched hole (A) of the housing rack cylinder, turn the rack stopper

(B) counterclockwise and remove the circlip.

Be careful not to damage the rack.

15.Remove the rack bushing and rack from the rack housing.

16. Remove the O - ring(A) from the rack bushing (B).

17.Remove the oil seal (B) from the rack bushing (A).

Page 608 of 1575

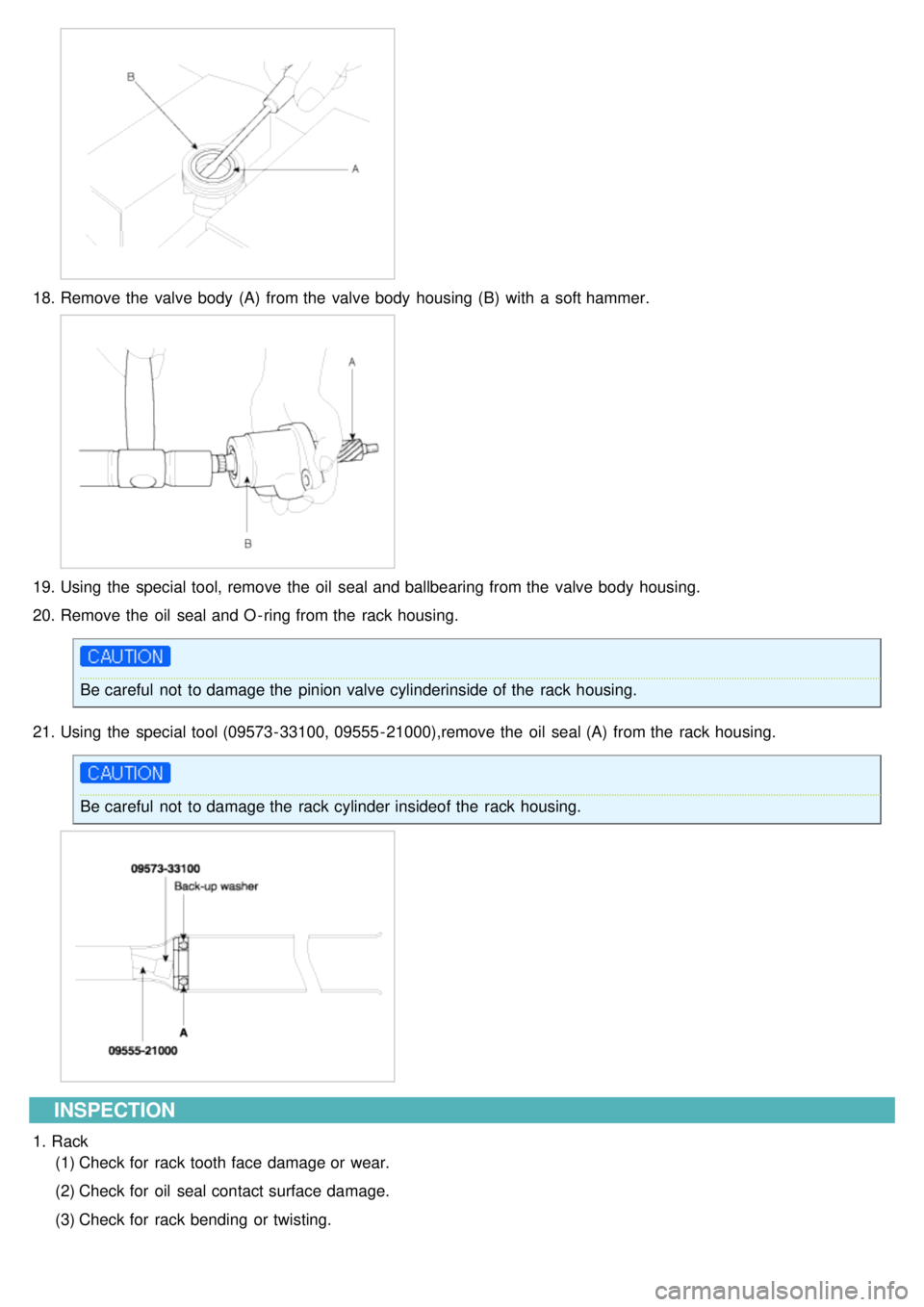

18.Remove the valve body (A) from the valve body housing (B) with a soft hammer.

19.Using the special tool, remove the oil seal and ballbearing from the valve body housing.

20. Remove the oil seal and O - ring from the rack housing.

Be careful not to damage the pinion valve cylinderinside of the rack housing.

21. Using the special tool (09573- 33100, 09555 - 21000),remove the oil seal (A) from the rack housing.

Be careful not to damage the rack cylinder insideof the rack housing.

INSPECTION

1.Rack

(1) Check for rack tooth face damage or wear.

(2) Check for oil seal contact surface damage.

(3) Check for rack bending or twisting.

Page 609 of 1575

(4)Check for oil seal ring damage or wear.

(5) Check for oil seal damage or wear.

2.Pinion valve

(1) Check for pinion gear tooth face damage or wear.

(2) Check for oil seal contact surface damage.

(3) Check for seal ring damage or wear.

(4) Check for oil seal damage or wear.

3.Bearing

(1) Check for seizure or abnormal noise during abearing rotation.

(2) Check for excessive play.

(3) Check for missing needle bearing rollers.

4. Others

(1) Check for damage of the rack housing cylinder bore.

(2) Check for boot damage, cracking or aging.

REASSEMBLY

1.Apply the specified fluid to the entire surface of the rack oil seal.

Recommended fluid : PSF - 3

2. Install the backup washer and oil seal (A) to the specified position in the rack housing.

Page 610 of 1575

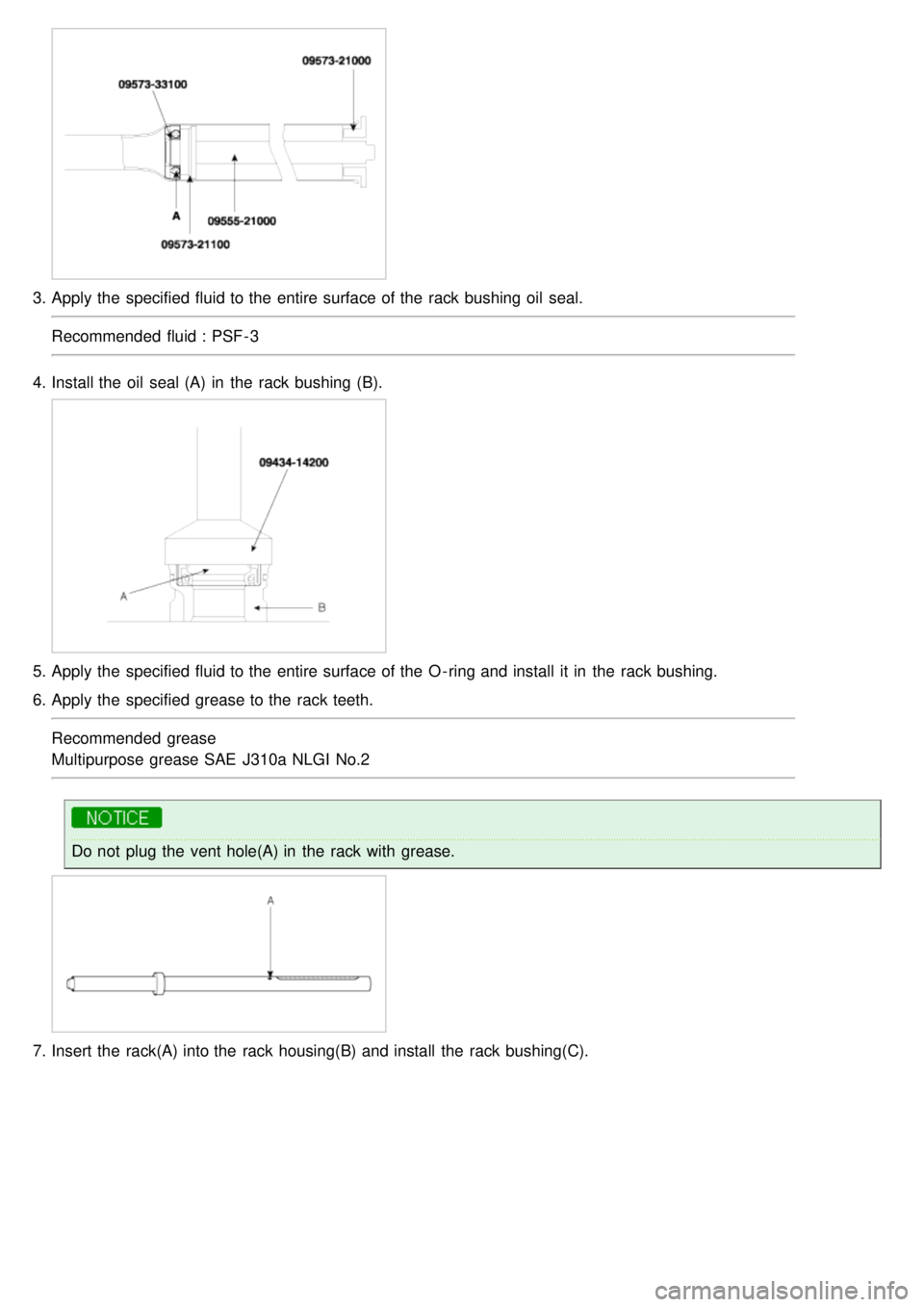

3.Apply the specified fluid to the entire surface of the rack bushing oil seal.

Recommended fluid : PSF - 3

4. Install the oil seal (A) in the rack bushing (B).

5.Apply the specified fluid to the entire surface of the O - ring and install it in the rack bushing.

6. Apply the specified grease to the rack teeth.

Recommended grease

Multipurpose grease SAE J310a NLGI No.2

Do not plug the vent hole(A) in the rack with grease.

7.Insert the rack(A) into the rack housing(B) and install the rack bushing(C).

Page 611 of 1575

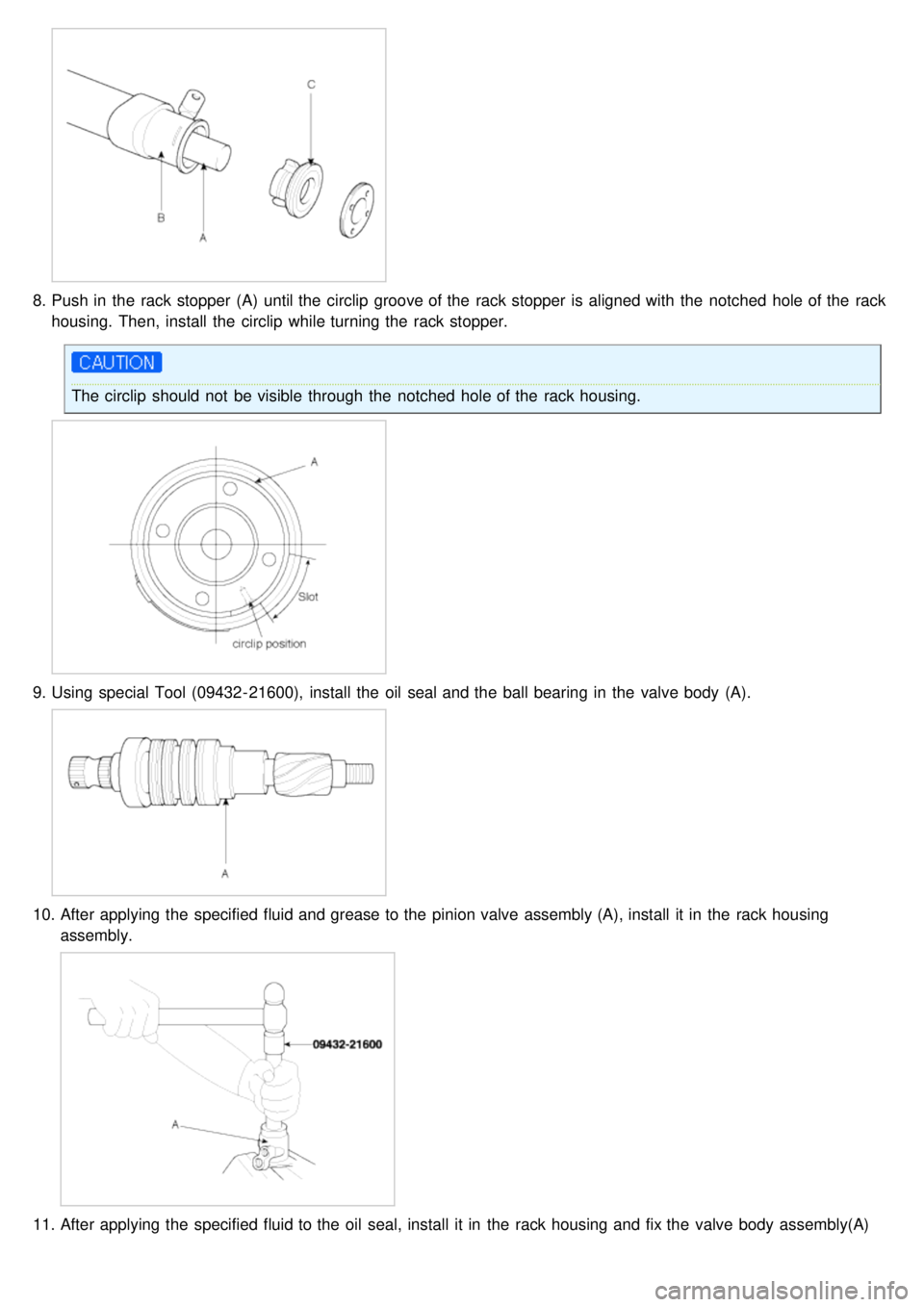

8.Push in the rack stopper (A) until the circlip groove of the rack stopper is aligned with the notched hole of the rack

housing. Then, install the circlip while turning the rack stopper.

The circlip should not be visible through the notched hole of the rack housing.

9.Using special Tool (09432- 21600), install the oil seal and the ball bearing in the valve body (A).

10. After applying the specified fluid and grease to the pinion valve assembly (A), install it in the rack housing

assembly.

11.After applying the specified fluid to the oil seal, install it in the rack housing and fix the valve body assembly(A)

and O - ring in the gear box(B).

Page 618 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Drain the power steering fluid.

2. Disconnect the pressure tube (A) and suction tube (B) from the power steering oil pump.

Tightening torque Nm (kgf.m, lb - ft):

55 ~ 65 (4.5 ~ 5.5, 40 ~ 47)

[Diesel]

[Gasoline]

3.Disconnect the pressure tube (A) and return tube from the valve body housing.

Tightening torque Nm (kgf.m, lb - ft):

12 ~ 18 (1.2 ~ 1.8, 9 ~ 13)

4.Remove the brackets of the pressure tube and hose from the sub- frame.

Page 620 of 1575

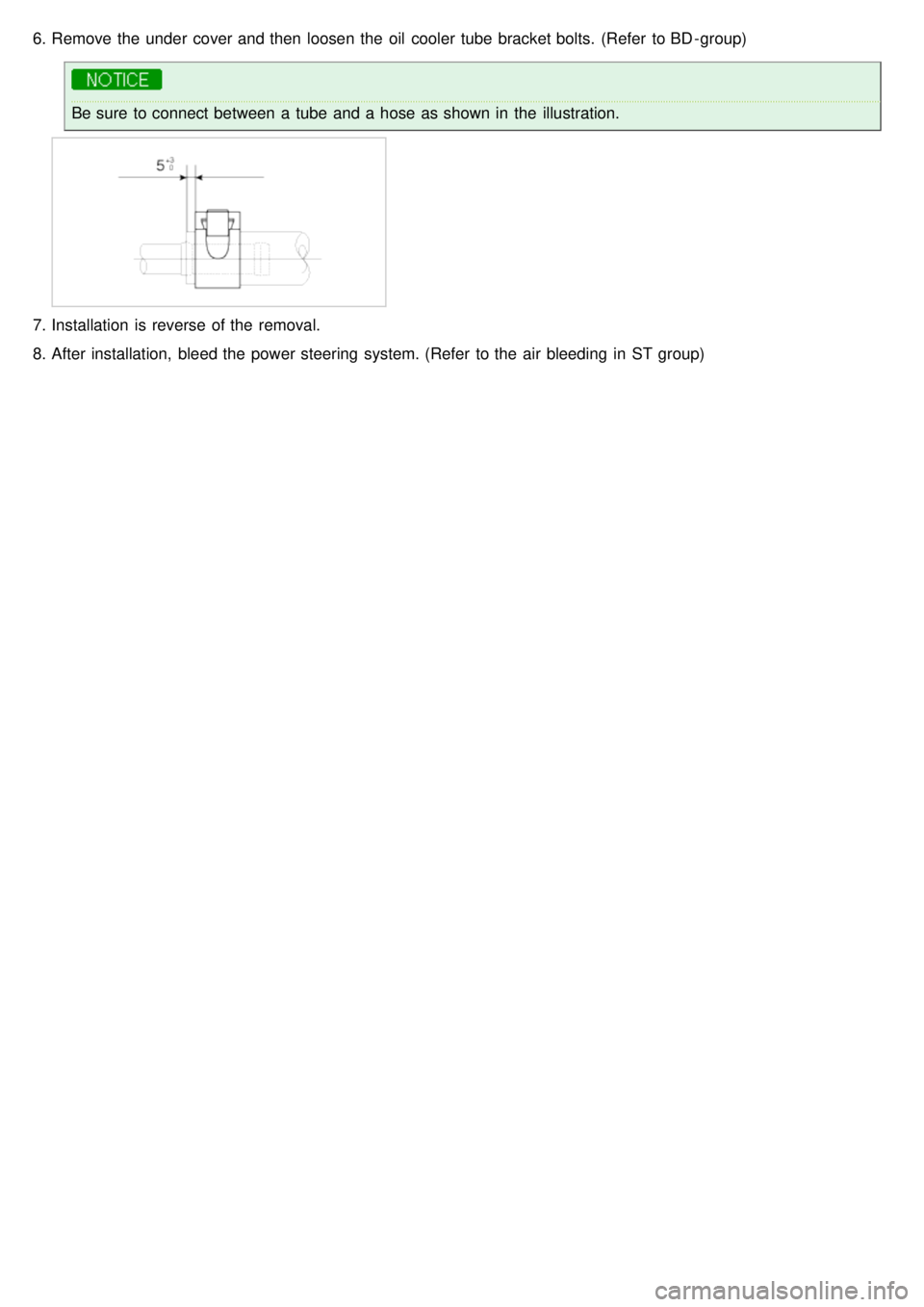

6.Remove the under cover and then loosen the oil cooler tube bracket bolts. (Refer to BD - group)

Be sure to connect between a tube and a hose as shown in the illustration.

7.Installation is reverse of the removal.

8. After installation, bleed the power steering system. (Refer to the air bleeding in ST group)