oil KIA CARNIVAL 2007 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 17 of 1575

Valve stem to valve

guide clearanceIntake

0.020 ~ 0.050mm(0.0008 ~ 0.0020in.) 0.10mm(0.0039in.)

or less

Exhaust 0.035 ~ 0.065mm(0.0014 ~ 0.0026in.) 0.13mm(0.0051in.)

or less

Valve guide

Inner diameter Intake 6.000 ~ 6.015mm(2.2362 ~ 2.2368in.)

Exhaust 6.000 ~ 6.015mm(2.2362 ~ 2.2368in.)

Length Intake 45.8 ~ 46.2mm(1.8031 ~ 1.8189in.)

Exhaust 46.8 ~ 47.2mm(1.8425 ~ 1.8583in.)

Valve spring

Free length 46.8mm(1.8425in.)

Load Height: 35mm 180.5 ~ 199.5N(18.4 ~ 20.3Kgf, 40.6 ~ 44.8lb)

Height: 26.5mm 342 ~ 378N(34.9 ~ 38.6Kgf, 76.9 ~ 85.1lb)

Out of squareness 1.5° or less

MLA(Mechanical Lash Adjuster)

MLA outer diameter Intake 29.964 ~ 29.980mm(1.1797 ~ 1.1803in.)

Exhaust 29.964 ~ 29.980mm(1.1797 ~ 1.1803in.)

Cylinder head

tappet bore inner

diameter Intake

30.000 ~ 30.025mm(1.1811 ~ 1.1821in.)

Exhaust 30.000 ~ 30.025mm(1.1811 ~ 1.1821in.)

MLA to tappet bore

clearance Intake

0.020 ~ 0.061mm(0.0008 ~ 0.0024in.) 0.07mm(0.0027in.)

or less

Exhaust 0.020 ~ 0.061mm(0.0008 ~ 0.0024in.) 0.07mm(0.0027in.)

or less

Valve clearance

Intake 0.17 ~ 0.23mm (0.0067 ~ 0.0090in.) 0.10 ~ 0.30mm

(0.0039 ~

0.0118in.)

Exhaust 0.27 ~ 0.33mm (0.0106 ~ 0.0129in.) 0.20 ~ 0.40mm

(0.0078 ~

0.0157in.)

Cylinder block

Cylinder bore 96.00 ~ 96.03mm (3.7795 ~ 3.7807in.)

Flatness of gasket surface Less than 0.05mm (0.0019in.)

[Less than 0.02mm (0.0008in.) / 150x150]

Piston

Piston outer diameter 95.96 ~ 95.99mm(3.7779 ~ 3.7791in.)

Piston to cylinder clearance 0.03 ~ 0.05mm(0.0012 ~ 0.0020in.)

Ring groove width No. 1 ring groove 1.22 ~ 1.24mm (0.0480 ~ 0.0488in.)

No. 2 ring groove 1.22 ~ 1.24mm (0.0480 ~ 0.0488in.)

Oil ring groove 2.01 ~ 2.03mm (0.0791 ~ 0.0799in.)

Piston O.S. 0.25mm(0.0098in.)

Piston ring

Side clearance No. 1 ring 0.04 ~ 0.08mm(0.0016 ~ 0.0031in.) 0.1mm(0.0039in.)

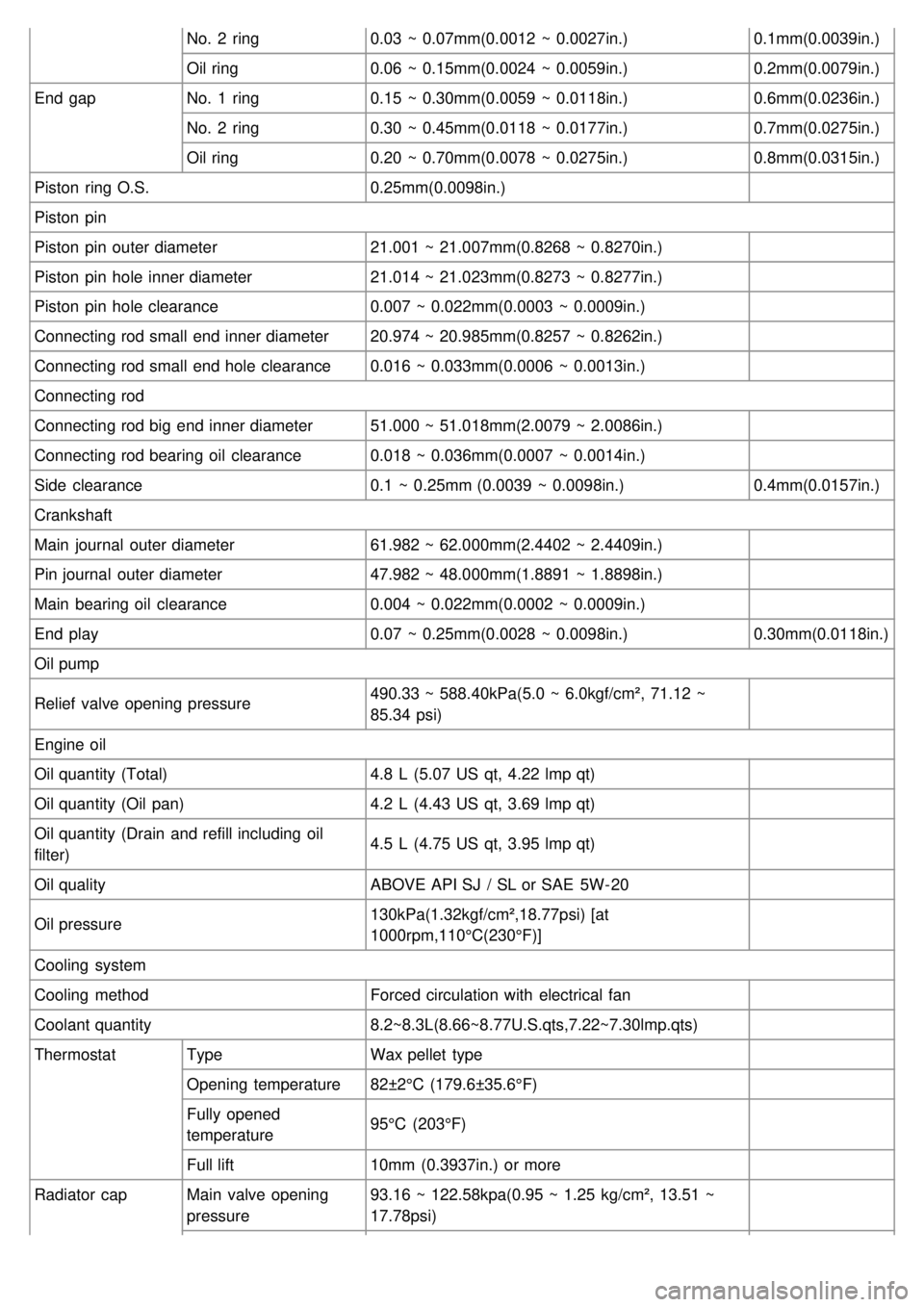

Page 18 of 1575

No. 2 ring0.03 ~ 0.07mm(0.0012 ~ 0.0027in.) 0.1mm(0.0039in.)

Oil ring 0.06 ~ 0.15mm(0.0024 ~ 0.0059in.) 0.2mm(0.0079in.)

End gap No. 1 ring 0.15 ~ 0.30mm(0.0059 ~ 0.0118in.) 0.6mm(0.0236in.)

No. 2 ring 0.30 ~ 0.45mm(0.0118 ~ 0.0177in.) 0.7mm(0.0275in.)

Oil ring 0.20 ~ 0.70mm(0.0078 ~ 0.0275in.) 0.8mm(0.0315in.)

Piston ring O.S. 0.25mm(0.0098in.)

Piston pin

Piston pin outer diameter 21.001 ~ 21.007mm(0.8268 ~ 0.8270in.)

Piston pin hole inner diameter 21.014 ~ 21.023mm(0.8273 ~ 0.8277in.)

Piston pin hole clearance 0.007 ~ 0.022mm(0.0003 ~ 0.0009in.)

Connecting rod small end inner diameter 20.974 ~ 20.985mm(0.8257 ~ 0.8262in.)

Connecting rod small end hole clearance 0.016 ~ 0.033mm(0.0006 ~ 0.0013in.)

Connecting rod

Connecting rod big end inner diameter 51.000 ~ 51.018mm(2.0079 ~ 2.0086in.)

Connecting rod bearing oil clearance 0.018 ~ 0.036mm(0.0007 ~ 0.0014in.)

Side clearance 0.1 ~ 0.25mm (0.0039 ~ 0.0098in.) 0.4mm(0.0157in.)

Crankshaft

Main journal outer diameter 61.982 ~ 62.000mm(2.4402 ~ 2.4409in.)

Pin journal outer diameter 47.982 ~ 48.000mm(1.8891 ~ 1.8898in.)

Main bearing oil clearance 0.004 ~ 0.022mm(0.0002 ~ 0.0009in.)

End play 0.07 ~ 0.25mm(0.0028 ~ 0.0098in.) 0.30mm(0.0118in.)

Oil pump

Relief valve opening pressure 490.33 ~ 588.40kPa(5.0 ~ 6.0kgf/cm², 71.12 ~

85.34 psi)

Engine oil

Oil quantity (Total) 4.8 L (5.07 US qt, 4.22 lmp qt)

Oil quantity (Oil pan) 4.2 L (4.43 US qt, 3.69 lmp qt)

Oil quantity (Drain and refill including oil

filter) 4.5 L (4.75 US qt, 3.95 lmp qt)

Oil quality ABOVE API SJ / SL or SAE 5W- 20

Oil pressure 130kPa(1.32kgf/cm²,18.77psi) [at

1000rpm,110°C(230°F)]

Cooling system

Cooling method Forced circulation with electrical fan

Coolant quantity 8.2~8.3L(8.66~8.77U.S.qts,7.22~7.30lmp.qts)

Thermostat Type Wax pellet type

Opening temperature 82±2°C (179.6±35.6°F)

Fully opened

temperature 95°C (203°F)

Full lift 10mm (0.3937in.) or more

Radiator cap Main valve opening

pressure 93.16 ~ 122.58kpa(0.95 ~ 1.25 kg/cm², 13.51 ~

17.78psi)

Page 19 of 1575

Vacuum valve opening

pressure0.98 ~ 4.90 kpa(0.01 ~ 0.05 kg/cm², 0.14 ~ 0.71

psi)

Engine coolant temperature sensor

Type Thermister type

Resistance 20°C (68°F) 2.31 ~ 2.59 kΩ

80°C(176°F) 0.3222 kΩ

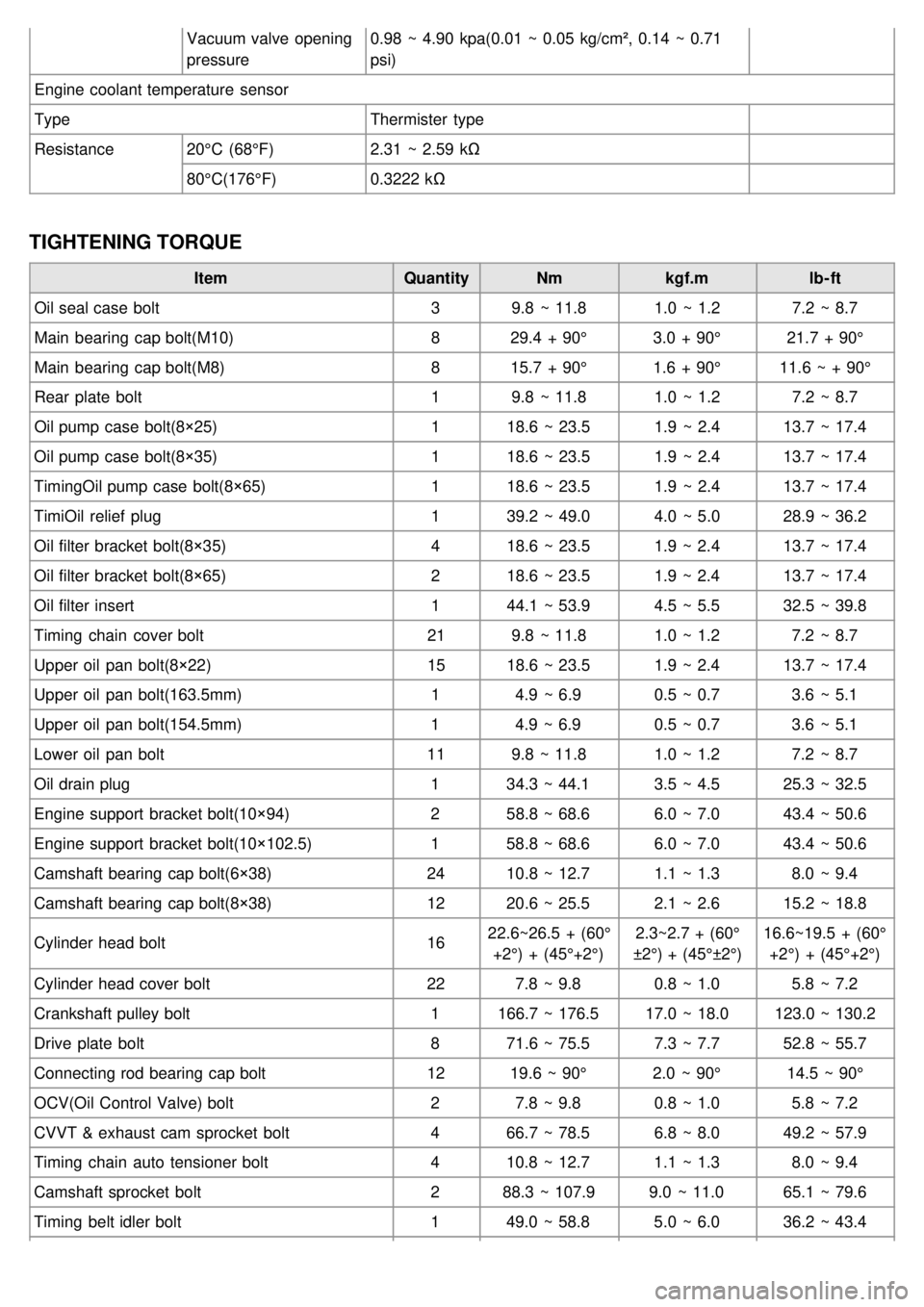

TIGHTENING TORQUE

Item QuantityNmkgf.m lb- ft

Oil seal case bolt 39.8 ~ 11.8 1.0 ~ 1.27.2 ~ 8.7

Main bearing cap bolt(M10) 829.4 + 90° 3.0 + 90°21.7 + 90°

Main bearing cap bolt(M8) 815.7 + 90° 1.6 + 90°11.6 ~ + 90°

Rear plate bolt 19.8 ~ 11.8 1.0 ~ 1.27.2 ~ 8.7

Oil pump case bolt(8×25) 118.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

Oil pump case bolt(8×35) 118.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

TimingOil pump case bolt(8×65) 118.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

TimiOil relief plug 139.2 ~ 49.0 4.0 ~ 5.028.9 ~ 36.2

Oil filter bracket bolt(8×35) 418.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

Oil filter bracket bolt(8×65) 218.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

Oil filter insert 144.1 ~ 53.9 4.5 ~ 5.532.5 ~ 39.8

Timing chain cover bolt 219.8 ~ 11.8 1.0 ~ 1.27.2 ~ 8.7

Upper oil pan bolt(8×22) 1518.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

Upper oil pan bolt(163.5mm) 14.9 ~ 6.9 0.5 ~ 0.73.6 ~ 5.1

Upper oil pan bolt(154.5mm) 14.9 ~ 6.9 0.5 ~ 0.73.6 ~ 5.1

Lower oil pan bolt 119.8 ~ 11.8 1.0 ~ 1.27.2 ~ 8.7

Oil drain plug 134.3 ~ 44.1 3.5 ~ 4.525.3 ~ 32.5

Engine support bracket bolt(10×94) 258.8 ~ 68.6 6.0 ~ 7.043.4 ~ 50.6

Engine support bracket bolt(10×102.5) 158.8 ~ 68.6 6.0 ~ 7.043.4 ~ 50.6

Camshaft bearing cap bolt(6×38) 2410.8 ~ 12.7 1.1 ~ 1.38.0 ~ 9.4

Camshaft bearing cap bolt(8×38) 1220.6 ~ 25.5 2.1 ~ 2.615.2 ~ 18.8

Cylinder head bolt 1622.6~26.5 + (60°

+2°) + (45°+2°) 2.3~2.7 + (60°

±2°) + (45°±2°) 16.6~19.5 + (60°

+2°) + (45°+2°)

Cylinder head cover bolt 227.8 ~ 9.8 0.8 ~ 1.05.8 ~ 7.2

Crankshaft pulley bolt 1166.7 ~ 176.5 17.0 ~ 18.0123.0 ~ 130.2

Drive plate bolt 871.6 ~ 75.5 7.3 ~ 7.752.8 ~ 55.7

Connecting rod bearing cap bolt 1219.6 ~ 90° 2.0 ~ 90°14.5 ~ 90°

OCV(Oil Control Valve) bolt 27.8 ~ 9.8 0.8 ~ 1.05.8 ~ 7.2

CVVT & exhaust cam sprocket bolt 466.7 ~ 78.5 6.8 ~ 8.049.2 ~ 57.9

Timing chain auto tensioner bolt 410.8 ~ 12.7 1.1 ~ 1.38.0 ~ 9.4

Camshaft sprocket bolt 288.3 ~ 107.9 9.0 ~ 11.065.1 ~ 79.6

Timing belt idler bolt 149.0 ~ 58.8 5.0 ~ 6.036.2 ~ 43.4

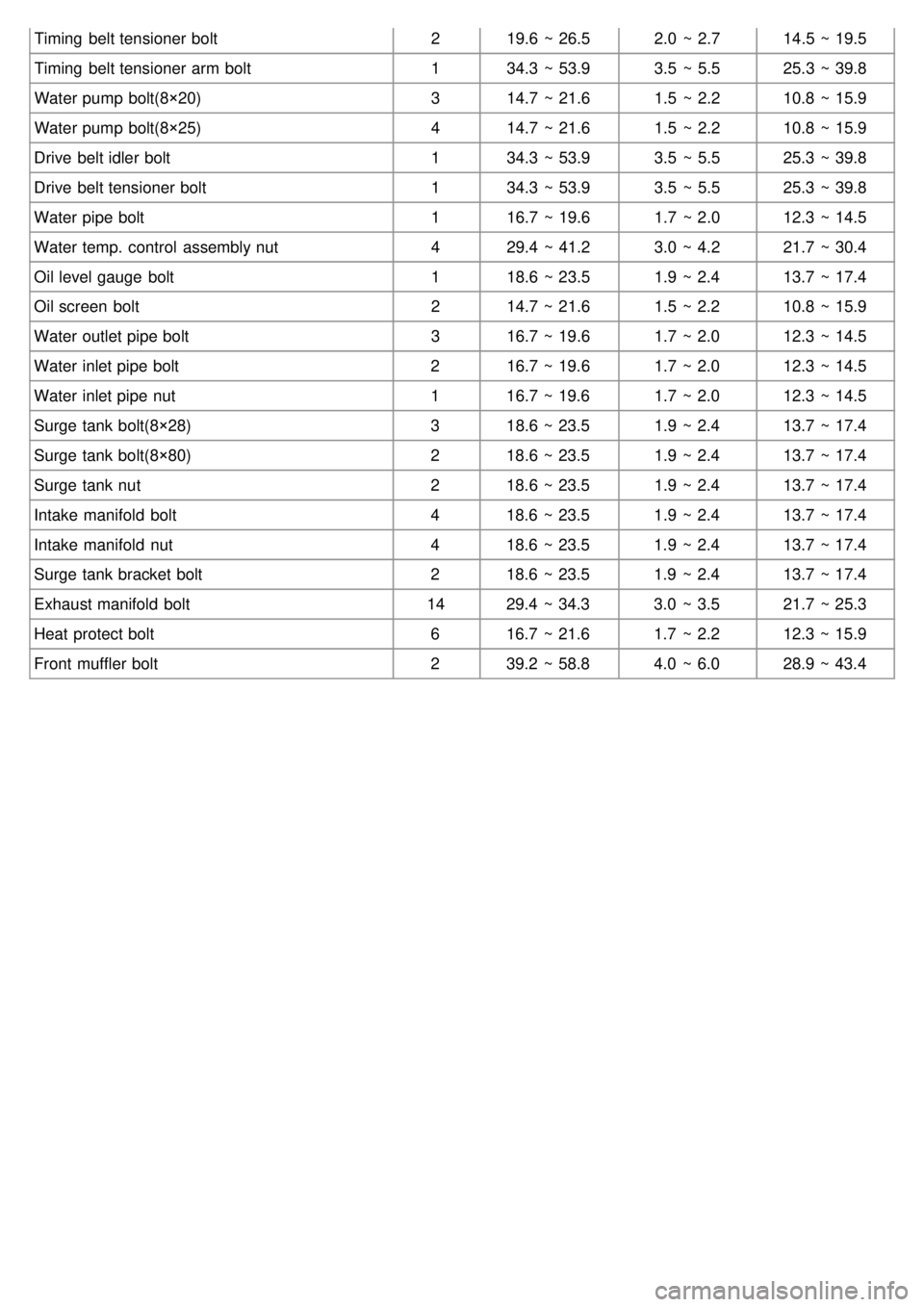

Page 20 of 1575

Timing belt tensioner bolt219.6 ~ 26.5 2.0 ~ 2.714.5 ~ 19.5

Timing belt tensioner arm bolt 134.3 ~ 53.9 3.5 ~ 5.525.3 ~ 39.8

Water pump bolt(8×20) 314.7 ~ 21.6 1.5 ~ 2.210.8 ~ 15.9

Water pump bolt(8×25) 414.7 ~ 21.6 1.5 ~ 2.210.8 ~ 15.9

Drive belt idler bolt 134.3 ~ 53.9 3.5 ~ 5.525.3 ~ 39.8

Drive belt tensioner bolt 134.3 ~ 53.9 3.5 ~ 5.525.3 ~ 39.8

Water pipe bolt 116.7 ~ 19.6 1.7 ~ 2.012.3 ~ 14.5

Water temp. control assembly nut 429.4 ~ 41.2 3.0 ~ 4.221.7 ~ 30.4

Oil level gauge bolt 118.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

Oil screen bolt 214.7 ~ 21.6 1.5 ~ 2.210.8 ~ 15.9

Water outlet pipe bolt 316.7 ~ 19.6 1.7 ~ 2.012.3 ~ 14.5

Water inlet pipe bolt 216.7 ~ 19.6 1.7 ~ 2.012.3 ~ 14.5

Water inlet pipe nut 116.7 ~ 19.6 1.7 ~ 2.012.3 ~ 14.5

Surge tank bolt(8×28) 318.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

Surge tank bolt(8×80) 218.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

Surge tank nut 218.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

Intake manifold bolt 418.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

Intake manifold nut 418.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

Surge tank bracket bolt 218.6 ~ 23.5 1.9 ~ 2.413.7 ~ 17.4

Exhaust manifold bolt 1429.4 ~ 34.3 3.0 ~ 3.521.7 ~ 25.3

Heat protect bolt 616.7 ~ 21.6 1.7 ~ 2.212.3 ~ 15.9

Front muffler bolt 239.2 ~ 58.8 4.0 ~ 6.028.9 ~ 43.4

Page 24 of 1575

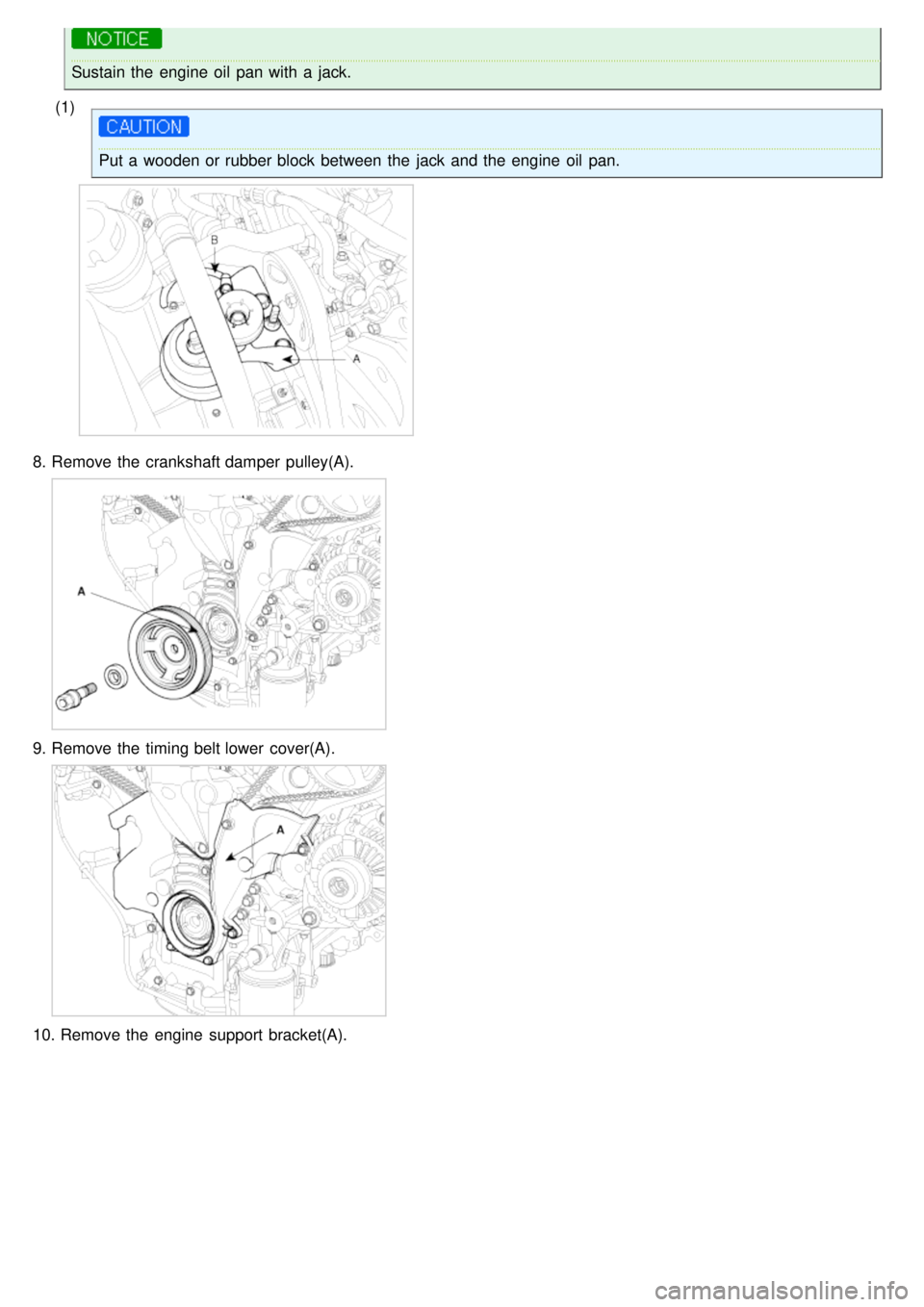

Sustain the engine oil pan with a jack.

(1)

Put a wooden or rubber block between the jack and the engine oil pan.

8. Remove the crankshaft damper pulley(A).

9.Remove the timing belt lower cover(A).

10. Remove the engine support bracket(A).

Page 31 of 1575

3.Replace the tensioner and the idler if grease is leaked from bearings.

TIMING BELT

1.Check the belt for oil or dust deposits.

Replace, if necessary.

Small deposits should be wiped away with a dry cloth or paper. Do not clean with solvent.

2. When the engine is overhauled or belt tension adjusted, check the belt carefully. If any of the following flaws are

evident, replace the belt.

a.Do not bend, twist or turn the timing belt inside out.

b. Do not allow the timing belt to come into contact with oil, water and steam.

3. Inspect the idler for easy and smooth rotation and check for play or noise.

Page 36 of 1575

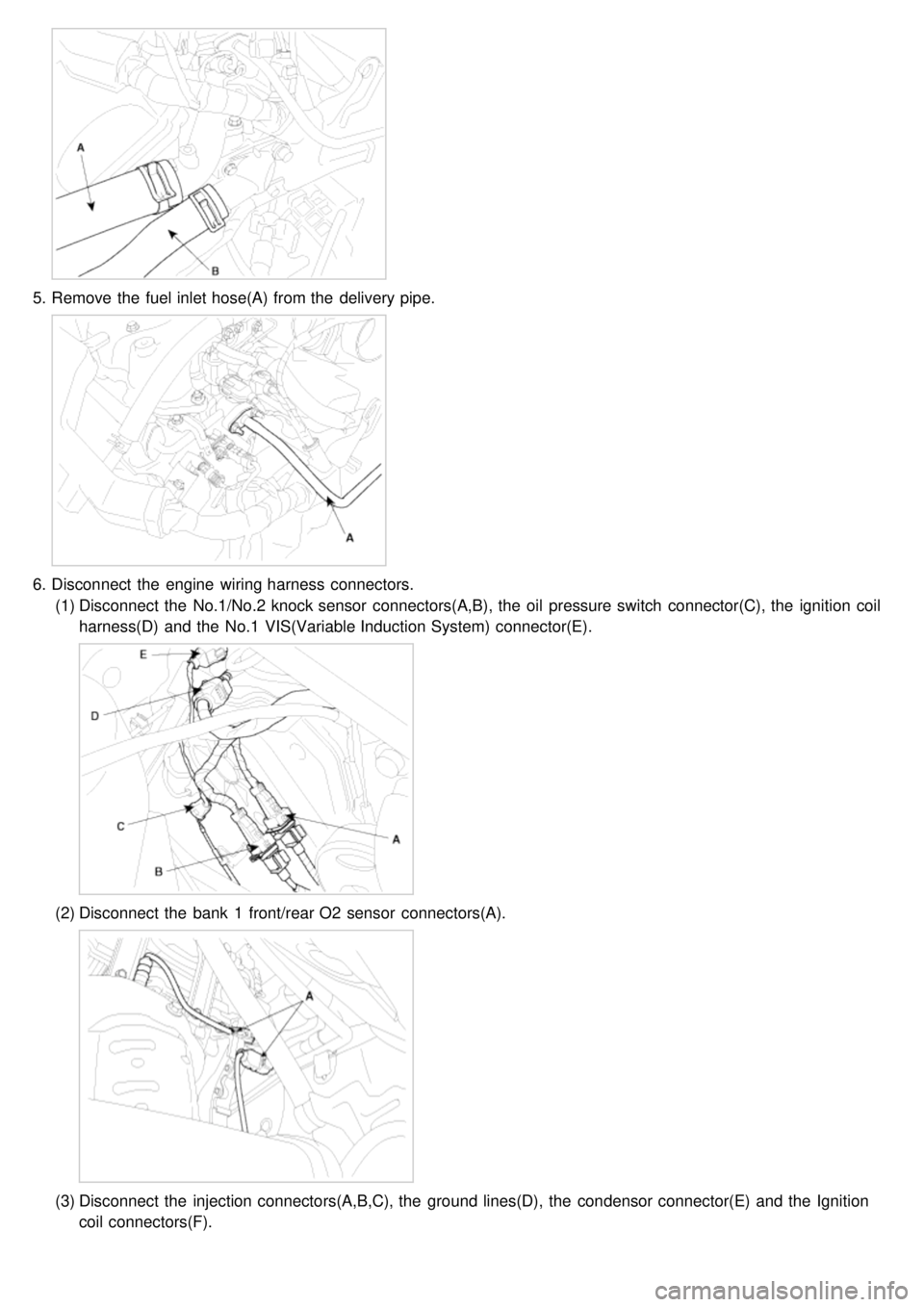

5.Remove the fuel inlet hose(A) from the delivery pipe.

6.Disconnect the engine wiring harness connectors.

(1) Disconnect the No.1/No.2 knock sensor connectors(A,B), the oil pressure switch connector(C), the ignition coil

harness(D) and the No.1 VIS(Variable Induction System) connector(E).

(2)Disconnect the bank 1 front/rear O2 sensor connectors(A).

(3)Disconnect the injection connectors(A,B,C), the ground lines(D), the condensor connector(E) and the Ignition

coil connectors(F).

Page 37 of 1575

(4)Disconnect the injection harness connector(A), the No.2 VIS(Variable Induction System) connector(B), the

No.1/No.2 OCV(Oil Control Valve) connectors(C,D) and the OTS(Oil Temperature Sensor) connector(E).

(5)Disconnect the MAPS(Manifold Absolute Pressure Sensor) connector(A), the ETC(Electronic Throttle Control)

connector(B) and the PCSV(Purge Control Solenoid Valve) connector(C).

(6)Disconnect the generator connector(A) and the air conditioning compressor connector(B).

Page 39 of 1575

8.Disconnect the brake vaccume hose(A).

9.Remove the heater hoses.

10. Remove the drive belt(A).

11.Remove the power steering pump.(Refer to 'ST' group).

12. Remove the exhaust manifold assembly.(Refer to 'Intake and exhause system').

13. Remove the intake manifold assembly.(Refer to 'Intake and exhause system').

14. Remove the timing belt.(Refer to 'Timing system').

15. Remove the ignition coils.

16. Remove the water temp. control assembly.

17. Remove the cylinder head cover(A).

Page 43 of 1575

Ensure the LH/RH classification of the cylinder head gasket when installing.

2. Tighten the cylinder head bolts with the plain washers in several steps as following order.

a.In assembling washers, the marked surface should face upward.

b. In installing the cylinder head bolts, apply engine oil on the thread of the bolts and the surface of the

washers.

Tightening torque

22.6~26.5Nm(2.3~2.7kgf.m, 16.6~19.5lb - ft) + (60° + 2°) + (45° + 2°)

Using the SST(09221- 4A000), tighten the bolts which need to be tightened with the angular tightening method.

3. Install the CVVT assembly and camshaft chain sprocket with the dowel pin in the CVVT installed to the intake

camshaft. Ensure that the pin will not be installed in the hole for oil feeding.