steering KIA CARNIVAL 2007 Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 529 of 1575

Tightening torque Nm (kgf.m, lb - ft) :

13 ~ 18 (1.3 ~ 1.8, 9.4 ~ 13.0)

After installation, if neccessary, adjust the alignment of the steering wheel and front tires

INSPECTION

1.Check the bushing for wear and deterioration.

2. Check the stabilizer bar for bending or breakage.

3. Check the ball joint for rotating torque.

(1) If there is a crack in the dust cover, replace it and add grease.

(2) Move the stabilizer link ball joint stud several times in a circular motion.

(3) Mount the self - locking nut on the ball joint, and then measure the ball joint rotating torque.

Standard value :

0.5 ~ 2.5 Nm (5 ~ 25 kgf., 0.36 ~ 1.81 lb - ft)

Measure torque using the special tool(09532- 11600) and torque wrench at the range of 0.5 - 2 rpm after

moving the ball joint stud 10 times at room temperature.

(4)If the rotating torque exceeds the upper limit of standard value, replace the upper arm assembly.

(5) Even if the rotating torque is below the lower limit of the standard value, the ball joint may be reused unless it

has drag and excessive play.

Page 569 of 1575

![KIA CARNIVAL 2007 Owners Guide 2007 > 2.7L V6 GASOLINE >

TIRE WEAR

1.Measure the tread depth of the tires.

Tread depth [limit] : 1.6 mm (0.063 in)

2. If the remaining tread(A) depth is less than the limit, replace the KIA CARNIVAL 2007 Owners Guide 2007 > 2.7L V6 GASOLINE >

TIRE WEAR

1.Measure the tread depth of the tires.

Tread depth [limit] : 1.6 mm (0.063 in)

2. If the remaining tread(A) depth is less than the limit, replace the](/img/2/57045/w960_57045-568.png)

2007 > 2.7L V6 GASOLINE >

TIRE WEAR

1.Measure the tread depth of the tires.

Tread depth [limit] : 1.6 mm (0.063 in)

2. If the remaining tread(A) depth is less than the limit, replace the tire.

When the tread depth of the tires is less than 1.6 mm (0.063 in), the wear indicators(B) will appear.

TIRE ROTATION

Rotate the tires in the pattern illustrated.

CHECKING FOR PULL AND WANDER

If the steering pulls to one side, rotate the tires according to the following wheel rotation procedure.

1. Rotate the front right and front left tires, and perform a road test in order to confirm vehicle stability.

Page 570 of 1575

2.If the steering pulls to the opposite side, rotate the front and rear tires, and perform a road test again.

3.If the steering continues to pull to one side, rotate the front right and left tires again, and perform a road test.

4.If the steering continues to pull to the opposite side, replace the front wheels with new ones.

Page 572 of 1575

2007 > 2.7L V6 GASOLINE >

WHEEL ALIGNMENT

When using commercially available computerized four wheel alignment equipment (caster, camber, toe) to inspect the

front wheel alignment, always position the car on a level surface with the front wheels facing straight ahead.

Prior to inspection, make sure that the front suspension and steering system are in normal operating condition and

that the wheels and tires face straight ahead and the tires are inflated to the specified pressure.

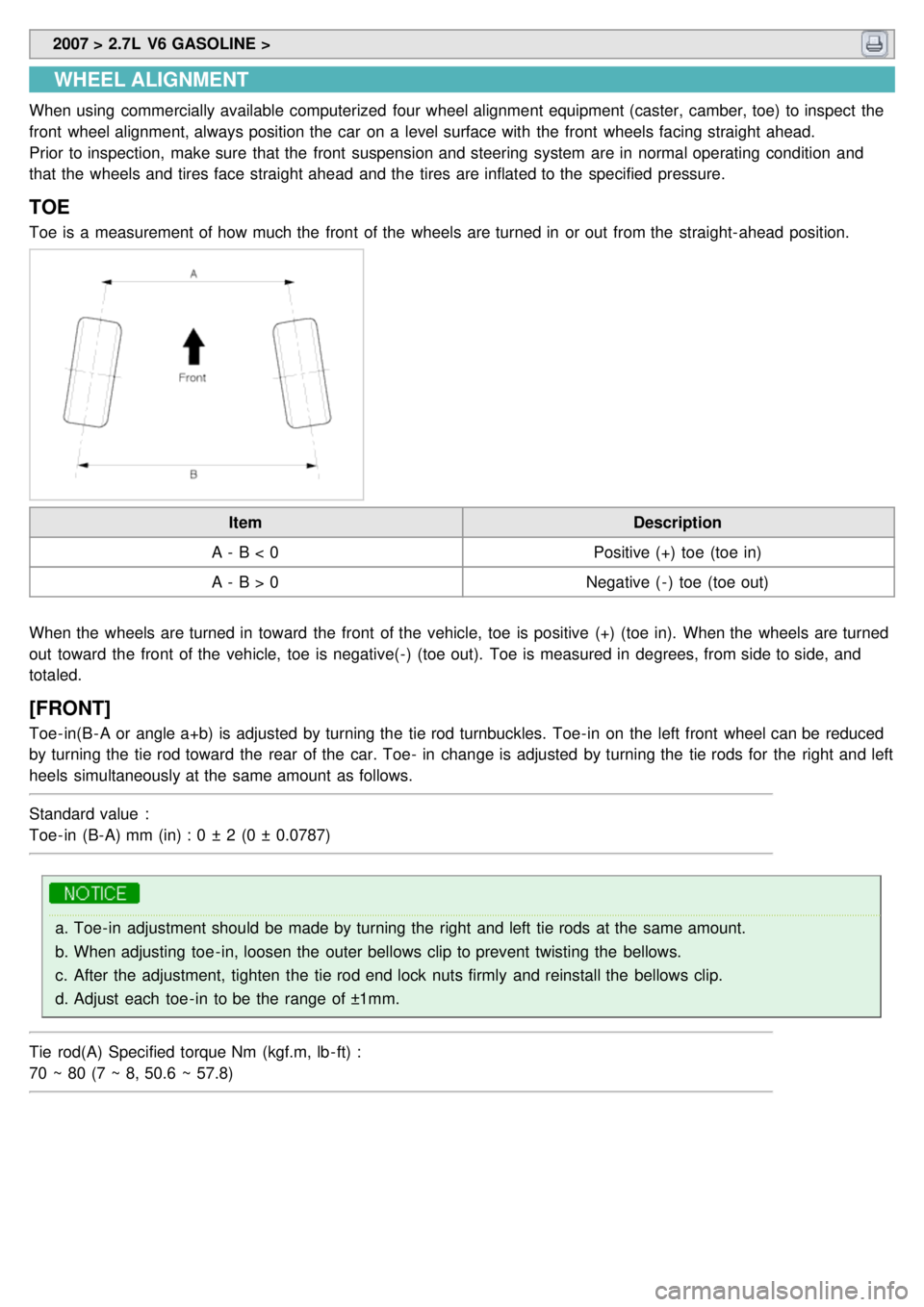

TOE

Toe is a measurement of how much the front of the wheels are turned in or out from the straight- ahead position.

Item Description

A - B < 0 Positive (+) toe (toe in)

A - B > 0 Negative ( - ) toe (toe out)

When the wheels are turned in toward the front of the vehicle, toe is positive (+) (toe in). When the wheels are turned

out toward the front of the vehicle, toe is negative(- ) (toe out). Toe is measured in degrees, from side to side, and

totaled.

[FRONT]

Toe- in(B - A or angle a+b) is adjusted by turning the tie rod turnbuckles. Toe- in on the left front wheel can be reduced

by turning the tie rod toward the rear of the car. Toe- in change is adjusted by turning the tie rods for the right and left

heels simultaneously at the same amount as follows.

Standard value :

Toe- in (B- A) mm (in) : 0 ± 2 (0 ± 0.0787)

a. Toe- in adjustment should be made by turning the right and left tie rods at the same amount.

b. When adjusting toe - in, loosen the outer bellows clip to prevent twisting the bellows.

c. After the adjustment, tighten the tie rod end lock nuts firmly and reinstall the bellows clip.

d. Adjust each toe - in to be the range of ±1mm.

Tie rod(A) Specified torque Nm (kgf.m, lb - ft) :

70 ~ 80 (7 ~ 8, 50.6 ~ 57.8)

Page 577 of 1575

CHAPTER 10:

Steering System

Page 579 of 1575

2007 > 2.7L V6 GASOLINE >

SPECIAL TOOLS

Tool (Number and Name) IllustrationUse

09222 - 32100

Valve stem oil seal installer

Installation of the oil pump oil seal

09555 - 21000

Bar

Removal and installation of the oil

seal

(Use with 09573 - 33100, 09573 -

33000,09573- 21000)

09561 - 11001

Steering wheel puller

Removal of steering wheel

09568 - 4A000

Tie rod end puller

Separation of the tie rod end bail

joint

09572 - 21000

Oil pressure gauge

Measurement of the oil pressure

(Use with 09572 - 22100, 09572 -

21200)

09572 - 21200

Oil pressure gauge adapter

Measurement of the oil pressure

(Use with 09572 - 21000, 09572 -

22100)

09572 - 22100 Measurement of the oil pressure

Page 581 of 1575

2007 > 2.7L V6 GASOLINE >

TROUBLESHOOTING

Symptom Probable cause Remedy

Excessive play in

steering Loose yoke plug

Retighten

Loose steering gear mounting bolts Retighten

Loose or worn tie rod end Retighten or replace as necessary

Steering wheel

operation is not

smooth (Insufficient

power assist) V- belt slippage

Readjust

Damaged V- belt Replace

Low fluid level Replenish

Air in the fluid Bleed air

Twisted or damaged hoses Correct the routing or replace

Insufficient oil pump pressure Repair or replace the oil pump

Sticky flow control valve Replace

Excessive internal oil pump leakage Replace the damaged parts

Excessive oil leaks from rack and pinion in

gear box Replace the damaged parts

Distorted or damaged gear box or valve body

seals Replace

Steering wheel does

not return properly Excessive turning resistance of tierod end

Replace

Yoke plug excessively tight Adjust

Tie rod and/or ball joint cannot turn smoothly Replace

Loose mounting of gear box mounting bracket

Worn steering shaft joint and/or Retighten

Worn steering shaft joint and/or body

grommet Correct or replace

Distorted rack Replace

Damaged pinion bearing Replace

Twisted or damaged hoses Reposition or replace

Damaged oil pressure control valve Replace

Damaged oil pump input shaft bearing Replace

Noise Hissing Noise in Steering Gear

There is some noise with all power steering systems. One of the most common is a hissing

sound when the steering wheel is turned and the car is not moving. This noise will be most

evident when turning the wheel while the brakes are being applied. There is no relationship

between this noise and steering performance. Do not replace the valve unless the "hissing"

noise becomes extreme. A replaced valve will also make a slight noise, and is not always a

solution for the condition.

Rattling or chucking

noise in the rack and

pinion Interference with hoses from vehicle body

Reposition

Loose gear box bracket Retighten

Loose tie rod end and/or ball joint Retighten

Worn tie rod and/or ball joint Replace

Noise in the oil pump Low fluid level Replenish

Air in the fluid Bleed air

Loose pump mounting bolts Retighten

Page 582 of 1575

2007 > 2.7L V6 GASOLINE >

SERVICE ADJUSTMENT PROCEDURE

CHECKING STEERING WHEEL FREE PLAY

1. Start the engine and with the steering wheel in the straight ahead position.

2. Measure the play while turning the steering wheel to the left and right.

Standard value :

Steering wheel free play : 30 mm (1.1 in)

3.If the play exceeds the standard value, inspect the connection between the steering shaft and tie rod ends.

CHECKING STEERING ANGLE

1.Place the front wheel on a turning radius gauge and measure the steering angle.

Standard value

VRS on Inner

38.64 °

Outer 31.78 °

VRS off Inner

41.91 °

Outer 33.54 °

2. If the measured value is not within the standard value, adjust the toe and inspect again.

CHECKING THE TIE ROD END BALL JOINT STARTING TORQUE

1.Disconnect tie rod and knuckle with the special tool (09568- 4A000).

Page 583 of 1575

2.Shake the ball joint stud several times to check for looseness.

Tie rod end ball joint starting torque :

30 kg·cm or less

3.If the starting torque exceeds the upper limit of the standard value, replace the tie rod end.

4. Even if the starting torque is below the lower limit of the standard value, check the play of the ball joint and replace

if necessary.

CHECKING STEERING WHEEL RETURN

1.The force required to turn the steering wheel and the wheel return should be the same for both moderate and sharp

turns.

2. When the steering wheel is turned 90° and held for a couple of seconds while the vehicle is being driven at 20- 30

kph (12- 19 mph), the steering wheel should return at least 20° from its central position when it is released.

If the steering wheel is turned very quickly, steering may be momentarily difficult. This is not a malfunction

because the oil pump output will be somewhat decreased.

Page 584 of 1575

CHECKING POWER STEERING BELT TENSION

Refer to EM group(Timing system).

CHECKING POWER STEERING FLUID LEVEL

1.Position the vehicle on a level surface.

2. Start the engine. With the vehicle kept stationary, turn the steering wheel several times continuously to raise the

fluid temperature to 50- 60°C (122 - 140°F).

3. With the engine at idle, turn the steering wheel fully clockwise and counter- clockwise several times.

4. Make sure that there is no foaming or cloudiness in the reservoir fluid.

5. Stop the engine and check for any difference in fluid level between a stationary and a running engine.

a.If the fluid level varies 5 mm (0.2 in) or more, bleed the system again.

b. If the fluid level suddenly rises after stopping the engine, further bleeding is required.

c. Incomplete bleeding will produce a chattering sound in the pump and noise in the flow control valve, and

lead to decreased durability of the pump.

REPLACING POWER STEERING FLUID

1.Jack up the front wheels and support them with jackstands.

2. Disconnect the return hose from the oil reservoir and plug the oil reservoir.

3. Connect a vinyl hose to the disconnected return hose, and drain the oil into a container.

4. Remove the fuel pump fuse, then start the engine and wait for the engine to stall. Next, while operating the starting

motor intermittently, turn the steering wheel all the way to the left and then to the right several times to drain the

fluid.

5. Connect the return hoses, then fill the oil reservoir with the specified fluid.

6. Reinstall the fuel pump fuse.

7. Start the engine. Check for oil leakage.

8. Stop the engine.

9. Bleed the system.

Power steering fluid type : PSF - 3

Total quantity : Approx 1.1 liter

AIR BLEEDING

1.Remove the fuel pump fuse, then start the engine and wait for the engine to stall. Next, while operating the starting

motor intermittently (for 15 ~ 20 seconds), turn the steering wheel all the way to the left and then to the right five or

six times.