KIA CARNIVAL 2007 Workshop Manual

CARNIVAL 2007

KIA

KIA

https://www.carmanualsonline.info/img/2/57045/w960_57045-0.png

KIA CARNIVAL 2007 Workshop Manual

Trending: engine, Radio wiring c, SAe, headlights, key battery, open hood, CD changer

Page 451 of 1575

Page 452 of 1575

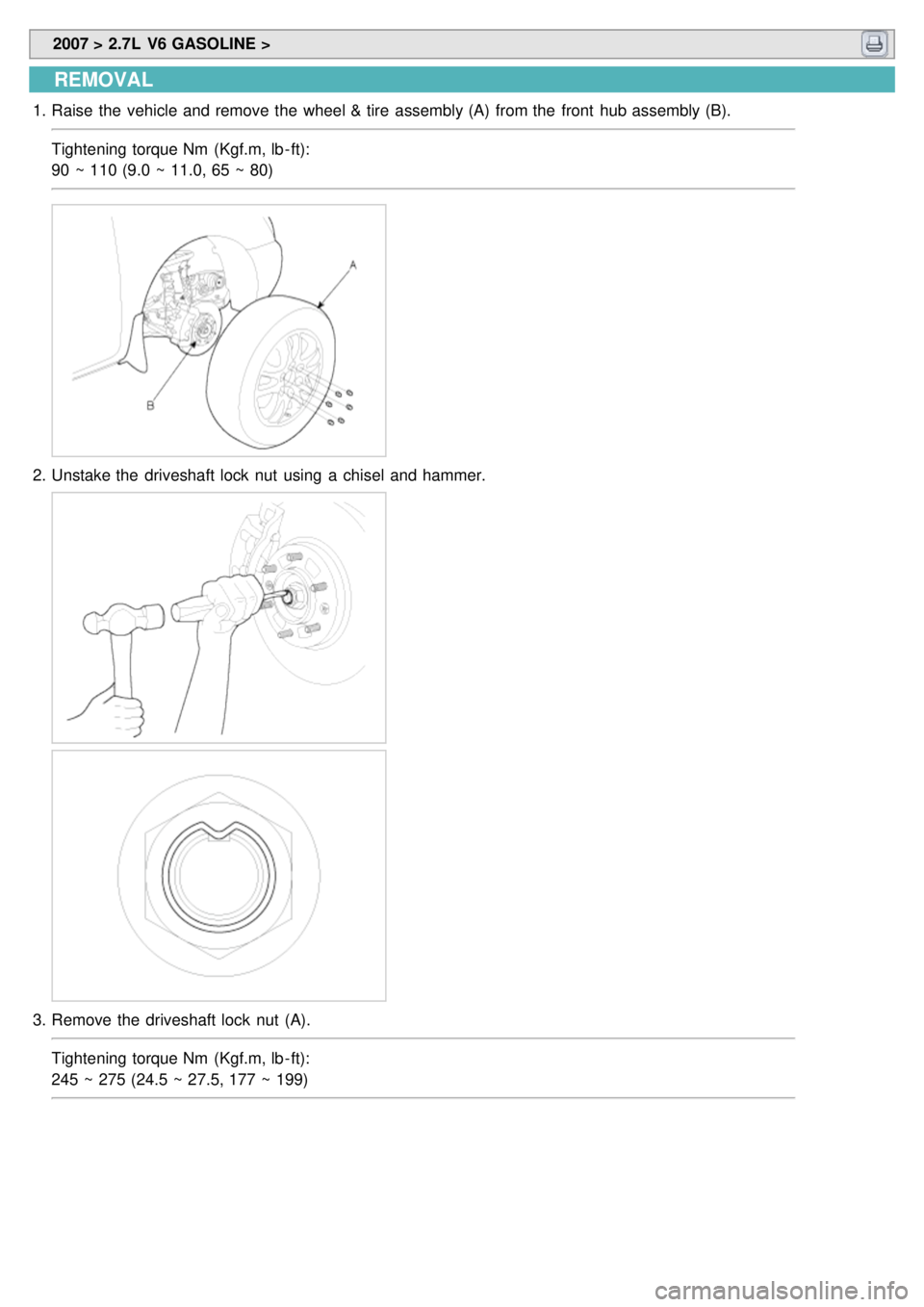

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Raise the vehicle and remove the wheel & tire assembly (A) from the front hub assembly (B).

Tightening torque Nm (Kgf.m, lb - ft):

90 ~ 110 (9.0 ~ 11.0, 65 ~ 80)

2.Unstake the driveshaft lock nut using a chisel and hammer.

3.Remove the driveshaft lock nut (A).

Tightening torque Nm (Kgf.m, lb - ft):

245 ~ 275 (24.5 ~ 27.5, 177 ~ 199)

Page 453 of 1575

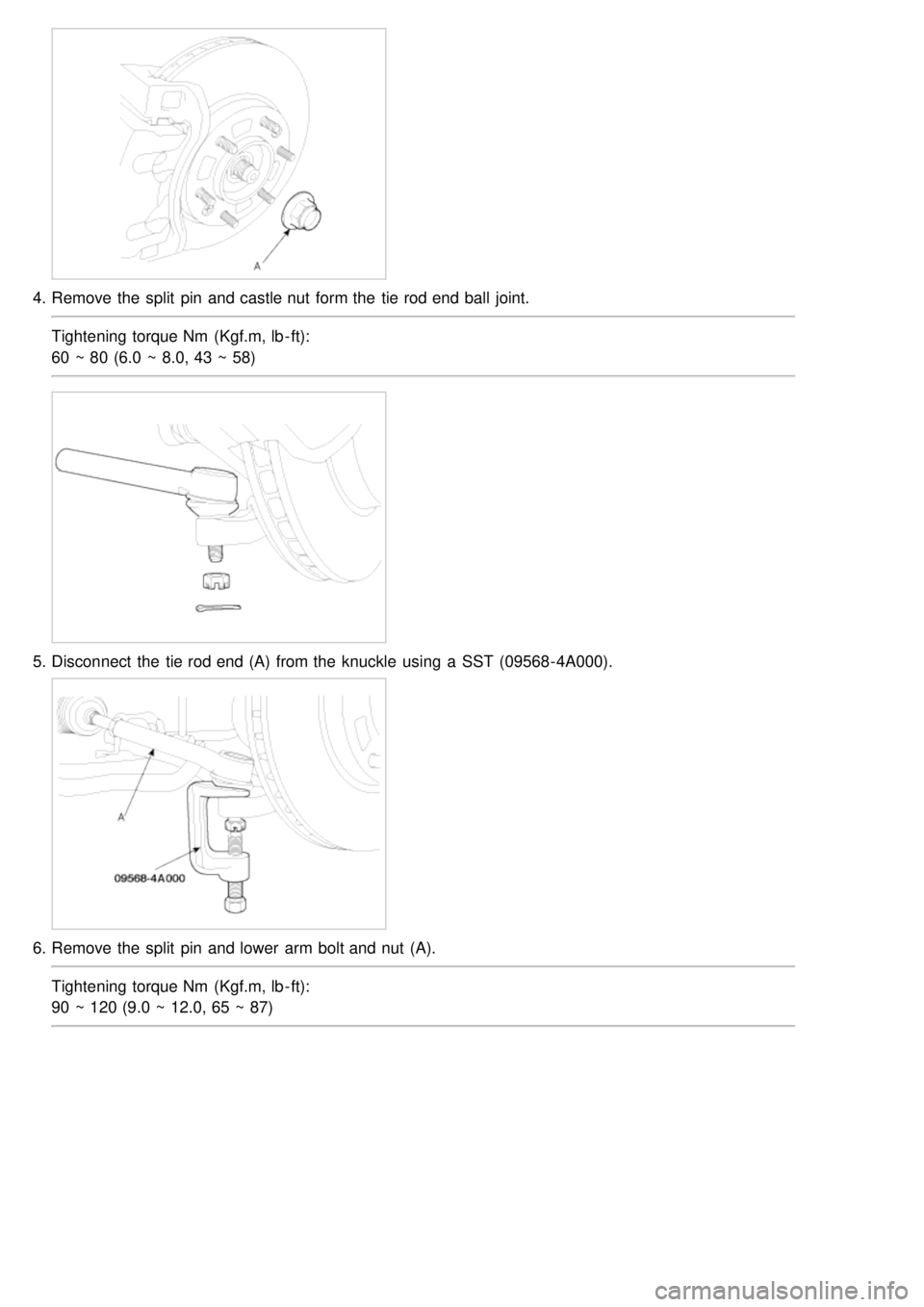

4.Remove the split pin and castle nut form the tie rod end ball joint.

Tightening torque Nm (Kgf.m, lb - ft):

60 ~ 80 (6.0 ~ 8.0, 43 ~ 58)

5.Disconnect the tie rod end (A) from the knuckle using a SST (09568- 4A000).

6.Remove the split pin and lower arm bolt and nut (A).

Tightening torque Nm (Kgf.m, lb - ft):

90 ~ 120 (9.0 ~ 12.0, 65 ~ 87)

Page 454 of 1575

7.Using a plastic hammer, disconnect the driveshaft (A) from the front hub assembly (B).

8.Removal of the driveshaft [RH].

a. [Gasoline 3.8 only]

Remove the heat protector (A).

b.Remove the inner shaft bearing bracket assembly mounting bolts (A).

Tightening torque Nm (Kgf.m, lb - ft):

Diesel: 43 ~ 63 (4.3 ~ 6.3, 31 ~ 46)

Page 455 of 1575

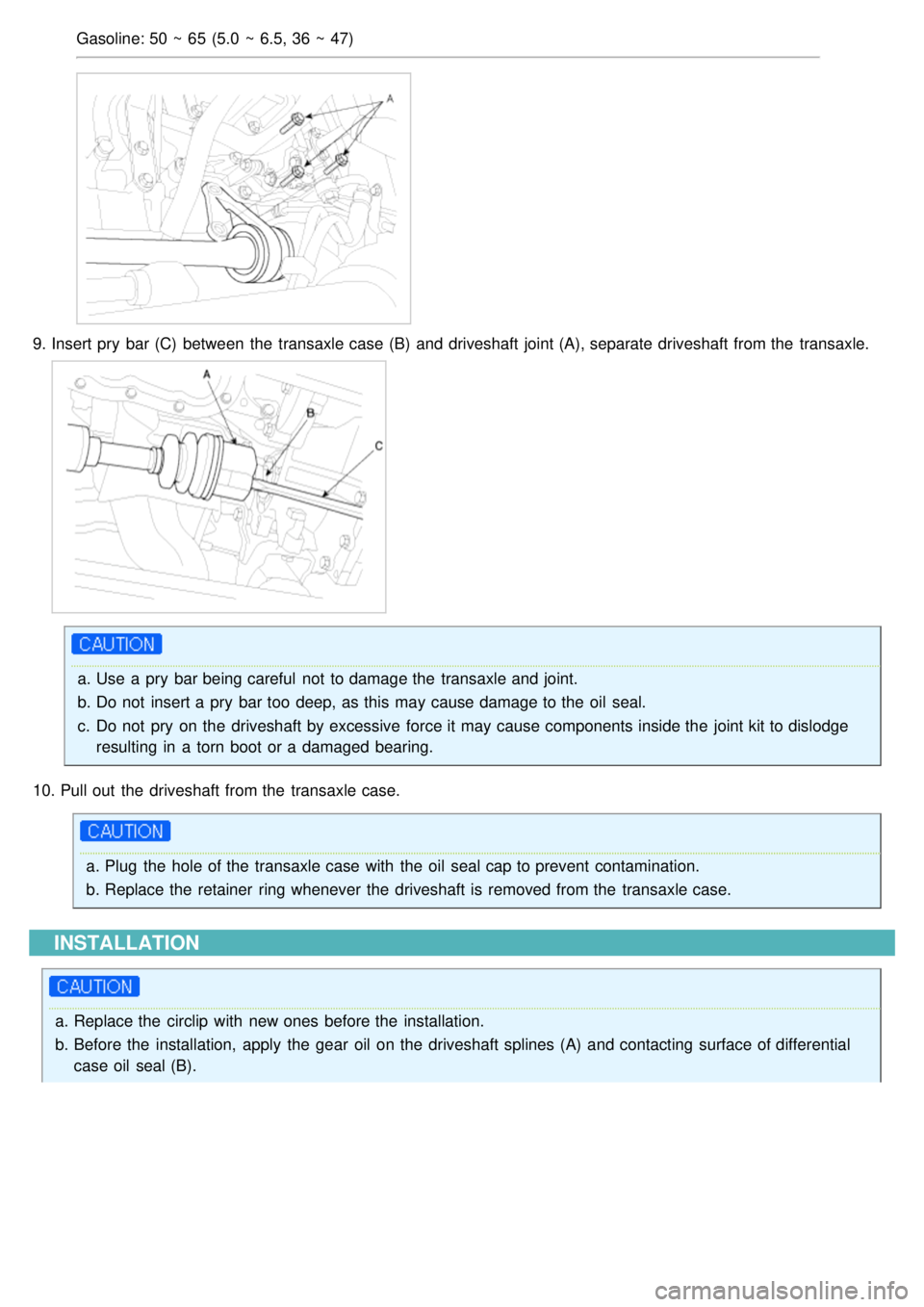

Gasoline: 50 ~ 65 (5.0 ~ 6.5, 36 ~ 47)

9.Insert pry bar (C) between the transaxle case (B) and driveshaft joint (A), separate driveshaft from the transaxle.

a.Use a pry bar being careful not to damage the transaxle and joint.

b. Do not insert a pry bar too deep, as this may cause damage to the oil seal.

c. Do not pry on the driveshaft by excessive force it may cause components inside the joint kit to dislodge

resulting in a torn boot or a damaged bearing.

10. Pull out the driveshaft from the transaxle case.

a.Plug the hole of the transaxle case with the oil seal cap to prevent contamination.

b. Replace the retainer ring whenever the driveshaft is removed from the transaxle case.

INSTALLATION

a.Replace the circlip with new ones before the installation.

b. Before the installation, apply the gear oil on the driveshaft splines (A) and contacting surface of differential

case oil seal (B).

Page 456 of 1575

1.Installation is reverse of the removal.

a.The driveshaft lock nut should be replaced with new ones.

b. After installation driveshaft lock nut, stake the lock nut using a chisel and hammer as shown in the

illustration below.

INSPECTION

1.Check the driveshaft boots for damage and deterioration.

2. Check the ball joints for wear and damage.

3. Check the splines for wear and damage.

4. Check the dynamic damper for cracks and wear.

Page 457 of 1575

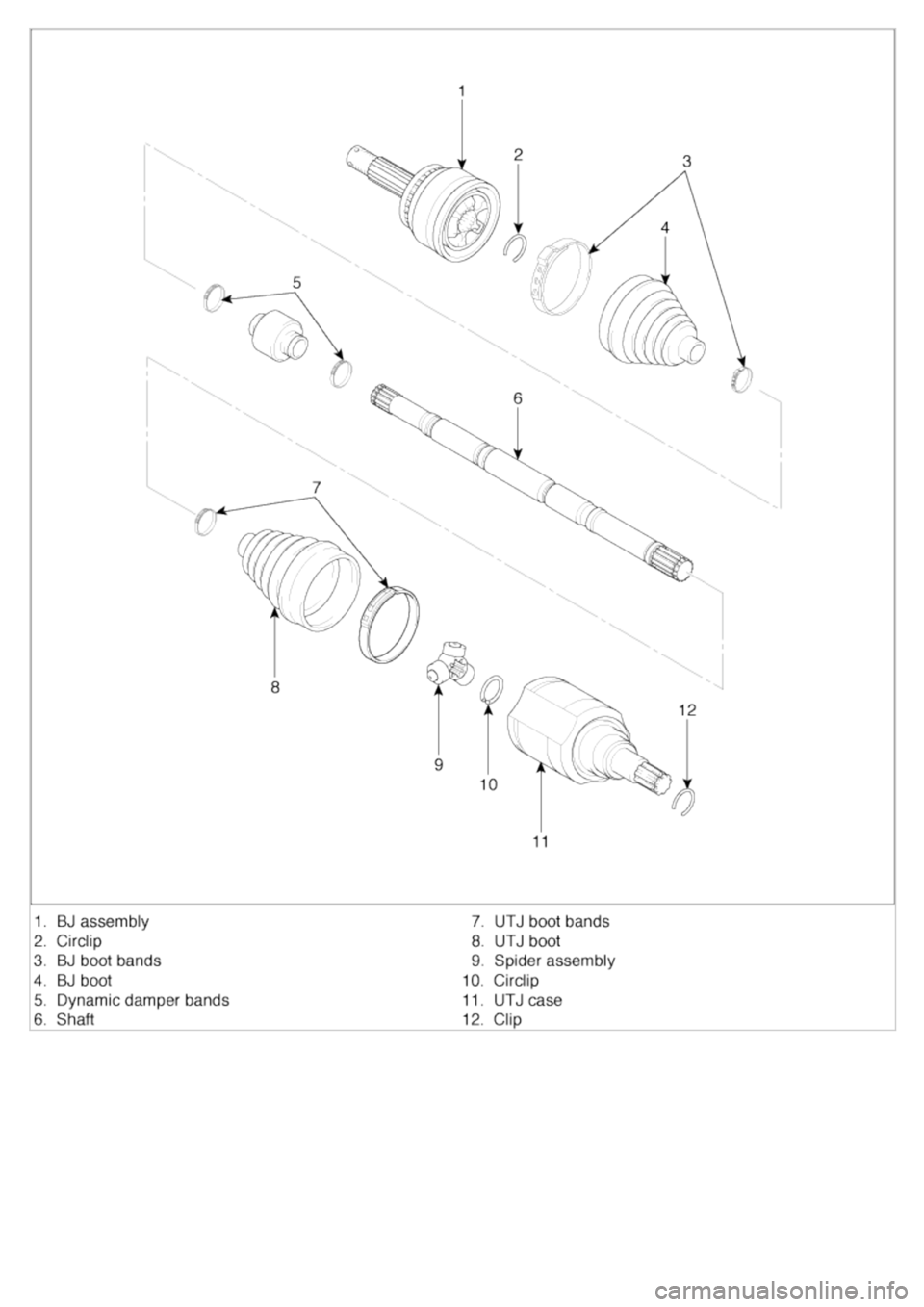

INSPECTION

1.Check the drive shaft spline for wear or damage.

2. Check that there is no water or foreign material in the BJ.

3. Check the spider assembly for roller rotation, wear or corrosion.

4. Check the groove inside the UTJ case for wear or corrosion.

5. Check the dynamic damper for damage or cracks.

DISASSEMBLY

a.Do not disassemble the BJ assembly.

b. The Driveshaft joint uses special grease. Do not subtitute with another type of grease.

c. The Boot band should be replaced with a new one.

1. Remove the TSJ boot band and pull the boot from TSJ outer race.

Be careful not to damage it.

Page 458 of 1575

2.Remove the circlip using a screwdriver.

3.Remove the driveshaft from TSJ outer race.

4.Remove the snap ring and disassemble the spider assembly from the shaft.

5. Clean the spider assembly.

6. Remove the BJ boot band and removal of the TSJ boot and the BJ boot.

If the boot is reused, wrap a tape around the driveshaft splines to protect the boot.

Page 459 of 1575

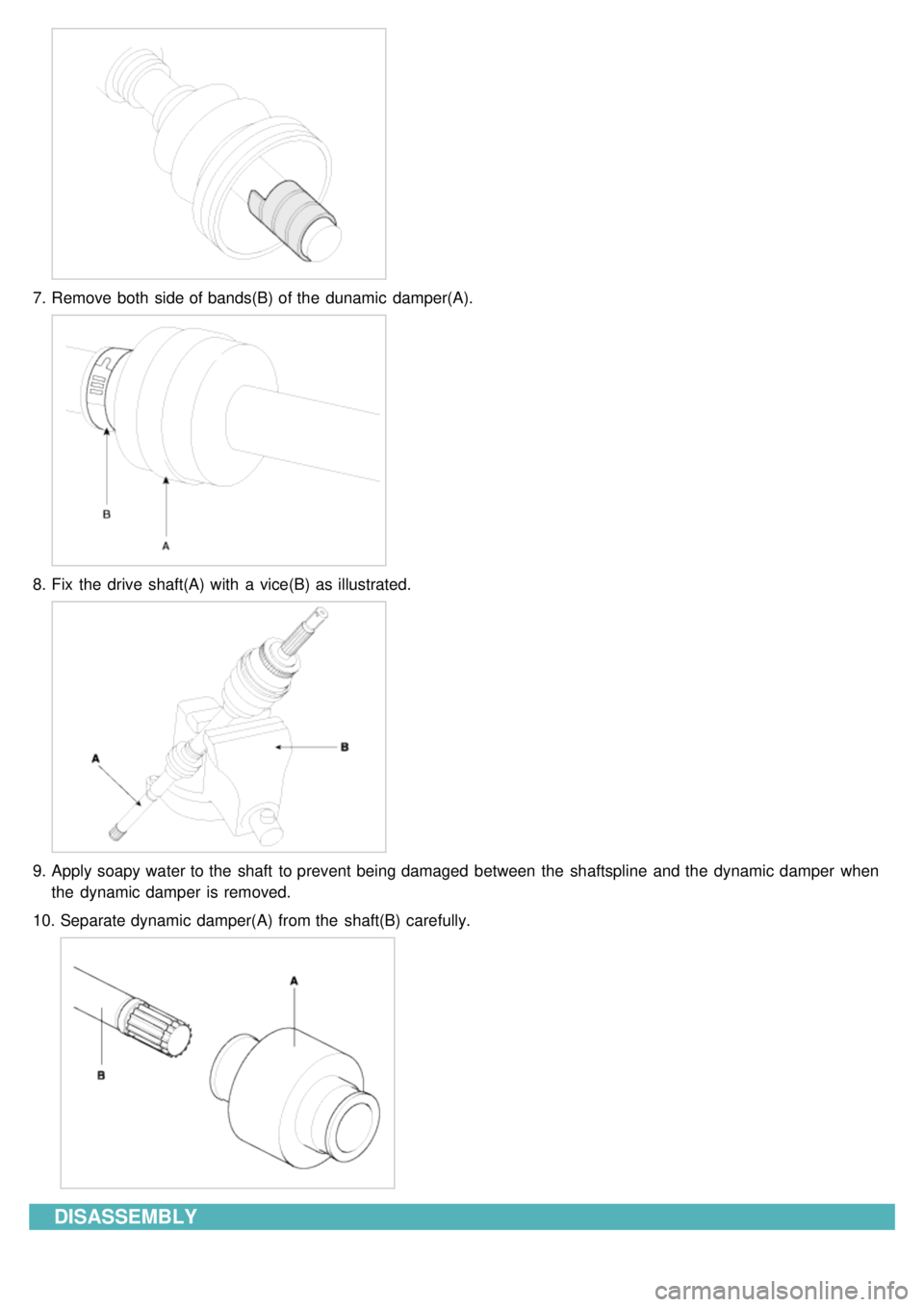

7.Remove both side of bands(B) of the dunamic damper(A).

8.Fix the drive shaft(A) with a vice(B) as illustrated.

9.Apply soapy water to the shaft to prevent being damaged between the shaftspline and the dynamic damper when

the dynamic damper is removed.

10. Separate dynamic damper(A) from the shaft(B) carefully.

DISASSEMBLY

Page 460 of 1575

a.Do not disassemble the BJ assembly.

b. Special grease must be applied to the drive shaft joint. Do not substitute with another type of grease.

c. The boot band should be replaced with a new one.

1. Remove the clip (B) from drive shaft splines (A) of the transaxle side.

2.Remove both boot bands from the transaxle side UTJ case.

3.Pull out the boot from the transaxle side joint(UTJ).

4. When separating the joint and boot (A), remove the grease from the UTJ case (B).

a.Be careful not to damage the boot.

b. According to ullustration below, put alignment marks across spider roller assembly (A), UTJ case (B), and

shaft splines (C) to aid in reassembly.

Trending: check transmission fluid, heating, oil type, timing belt, brake light, headlamp, trip computer

![KIA CARNIVAL 2007 Workshop Manual 7.Using a plastic hammer, disconnect the driveshaft (A) from the front hub assembly (B).

8.Removal of the driveshaft [RH].

a. [Gasoline 3.8 only]

Remove the heat protector (A).

b.Remove KIA CARNIVAL 2007 Workshop Manual 7.Using a plastic hammer, disconnect the driveshaft (A) from the front hub assembly (B).

8.Removal of the driveshaft [RH].

a. [Gasoline 3.8 only]

Remove the heat protector (A).

b.Remove](/img/2/57045/w960_57045-453.png)