KIA CARNIVAL 2007 Workshop Manual

CARNIVAL 2007

KIA

KIA

https://www.carmanualsonline.info/img/2/57045/w960_57045-0.png

KIA CARNIVAL 2007 Workshop Manual

Trending: air filter, fuel fill door release, dimensions, coolant level, radiator cap, Bulb, traction control

Page 421 of 1575

2007 > 2.7L V6 GASOLINE >

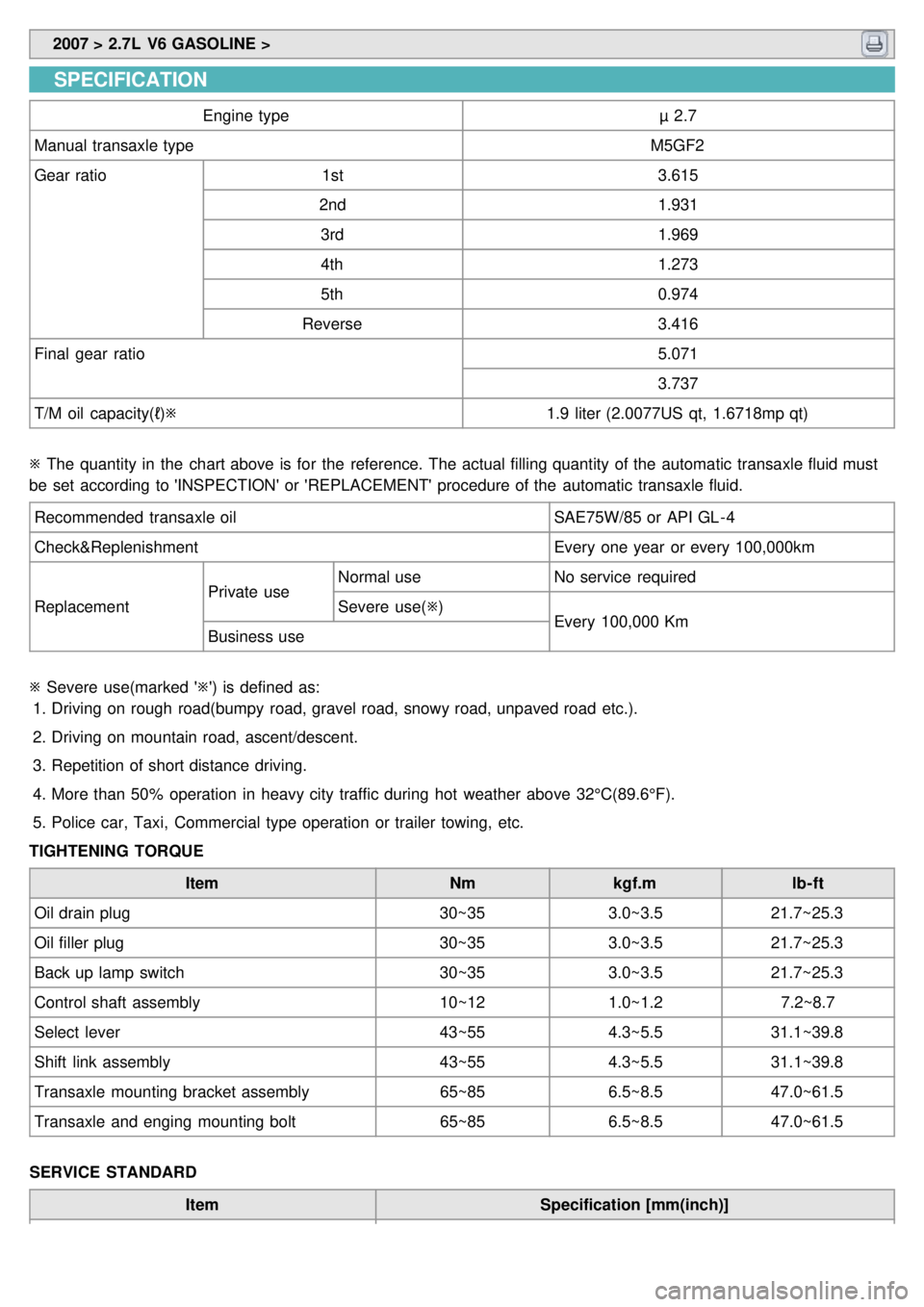

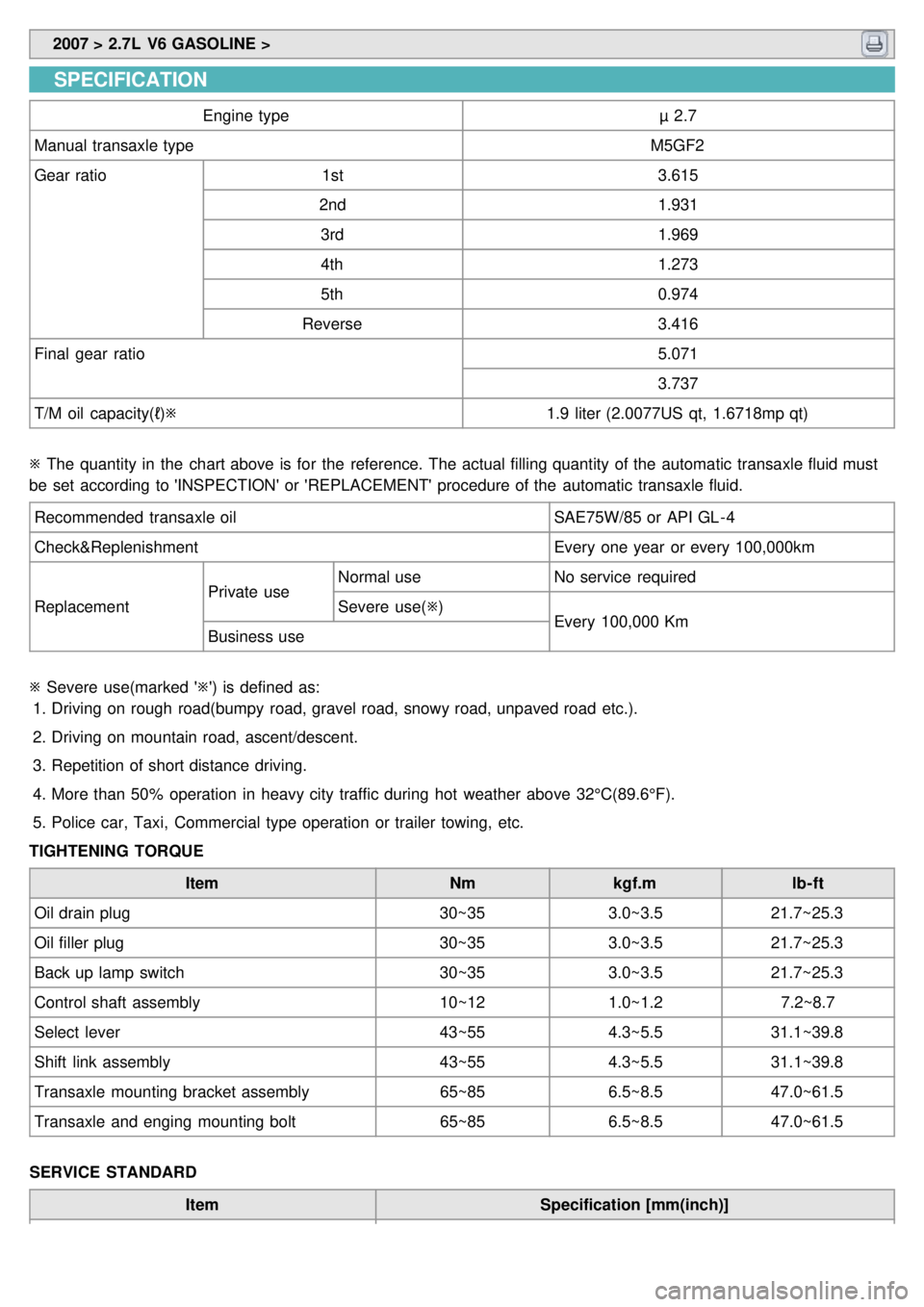

SPECIFICATION

Engine type µ 2.7

Manual transaxle type M5GF2

Gear ratio 1st 3.615

2nd 1.931

3rd 1.969

4th 1.273

5th 0.974

Reverse 3.416

Final gear ratio 5.071

3.737

T/M oil capacity(ℓ) ※ 1.9 liter (2.0077US qt, 1.6718mp qt)

※ The quantity in the chart above is for the reference. The actual filling quantity of the automatic transaxle fluid must

be set according to 'INSPECTION' or 'REPLACEMENT' procedure of the automatic transaxle fluid.

Recommended transaxle oil SAE75W/85 or API GL - 4

Check&Replenishment Every one year or every 100,000km

Replacement Private useNormal use

No service required

Severe use( ※)

Every 100,000 Km

Business use

※ Severe use(marked '※') is defined as:

1. Driving on rough road(bumpy road, gravel road, snowy road, unpaved road etc.).

2. Driving on mountain road, ascent/descent.

3. Repetition of short distance driving.

4. More than 50% operation in heavy city traffic during hot weather above 32°C(89.6°F).

5. Police car, Taxi, Commercial type operation or trailer towing, etc.

TIGHTENING TORQUE

Item Nmkgf.m lb- ft

Oil drain plug 30~353.0~3.521.7~25.3

Oil filler plug 30~353.0~3.521.7~25.3

Back up lamp switch 30~353.0~3.521.7~25.3

Control shaft assembly 10~121.0~1.2 7.2~8.7

Select lever 43~554.3~5.531.1~39.8

Shift link assembly 43~554.3~5.531.1~39.8

Transaxle mounting bracket assembly 65~856.5~8.547.0~61.5

Transaxle and enging mounting bolt 65~856.5~8.547.0~61.5

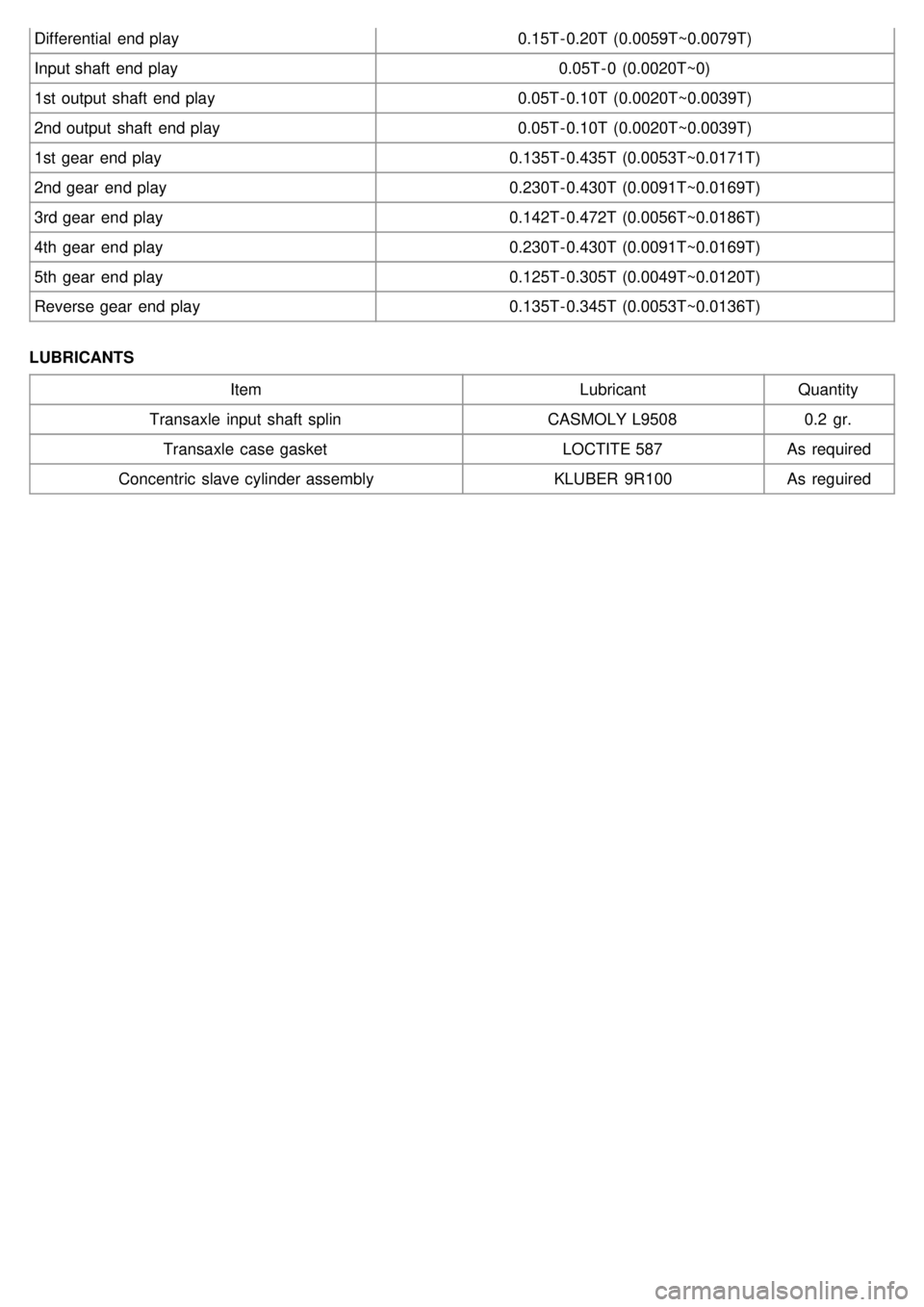

SERVICE STANDARD Item Specification [mm(inch)]

Page 422 of 1575

Differential end play0.15T - 0.20T (0.0059T~0.0079T)

Input shaft end play 0.05T - 0 (0.0020T~0)

1st output shaft end play 0.05T - 0.10T (0.0020T~0.0039T)

2nd output shaft end play 0.05T - 0.10T (0.0020T~0.0039T)

1st gear end play 0.135T- 0.435T (0.0053T~0.0171T)

2nd gear end play 0.230T- 0.430T (0.0091T~0.0169T)

3rd gear end play 0.142T- 0.472T (0.0056T~0.0186T)

4th gear end play 0.230T- 0.430T (0.0091T~0.0169T)

5th gear end play 0.125T- 0.305T (0.0049T~0.0120T)

Reverse gear end play 0.135T- 0.345T (0.0053T~0.0136T)

LUBRICANTS Item LubricantQuantity

Transaxle input shaft splin CASMOLY L95080.2 gr.

Transaxle case gasket LOCTITE 587As required

Concentric slave cylinder assembly KLUBER 9R100As reguired

Page 423 of 1575

Page 424 of 1575

2007 > 2.7L V6 GASOLINE >

SERVICE ADJUSTMENT PROCEDURE

Transmission oil inspection and replacement

1. After parking the vehicle on a plain, stop the engine.

2. After removing the oil filler plug and washer, inspect the manual transaxle fluid condition and quantity.

3. If the manual transaxle fluid is contaminated, drain it out by removing the oil drain plug.

4. Tighten the new oil drain plug and feed manual transaxle fluid to a proper level.

TORQUE:

29.4~34.4 Nm(3.0~3.5kgf.m, 21.7~25.3lb - ft)

Oil type: SAE75W/85

Oil quantity:

1.9 liter(2.0077 US qt, 1.6718 lmp qt)

5. Retighten the oil filler plug with a new washer.

TORQUE:

29.4~34.4 Nm(3.0~3.5kgf.m, 21.7~25.3lb - ft)

Back up lamp switch inspection

1.Disconnect the back up lamp switch connector(B).

2.Inspect the continuity of the switch. When the shift lever is located in reverse range, it should be applied an electric

current.

3. Replace the back up lamp switch, if necessary.

TORQUE:

29.4~34.4 Nm(3.0~3.5kgf.m, 21.7~25.3lb - ft)

Page 425 of 1575

2007 > 2.7L V6 GASOLINE >

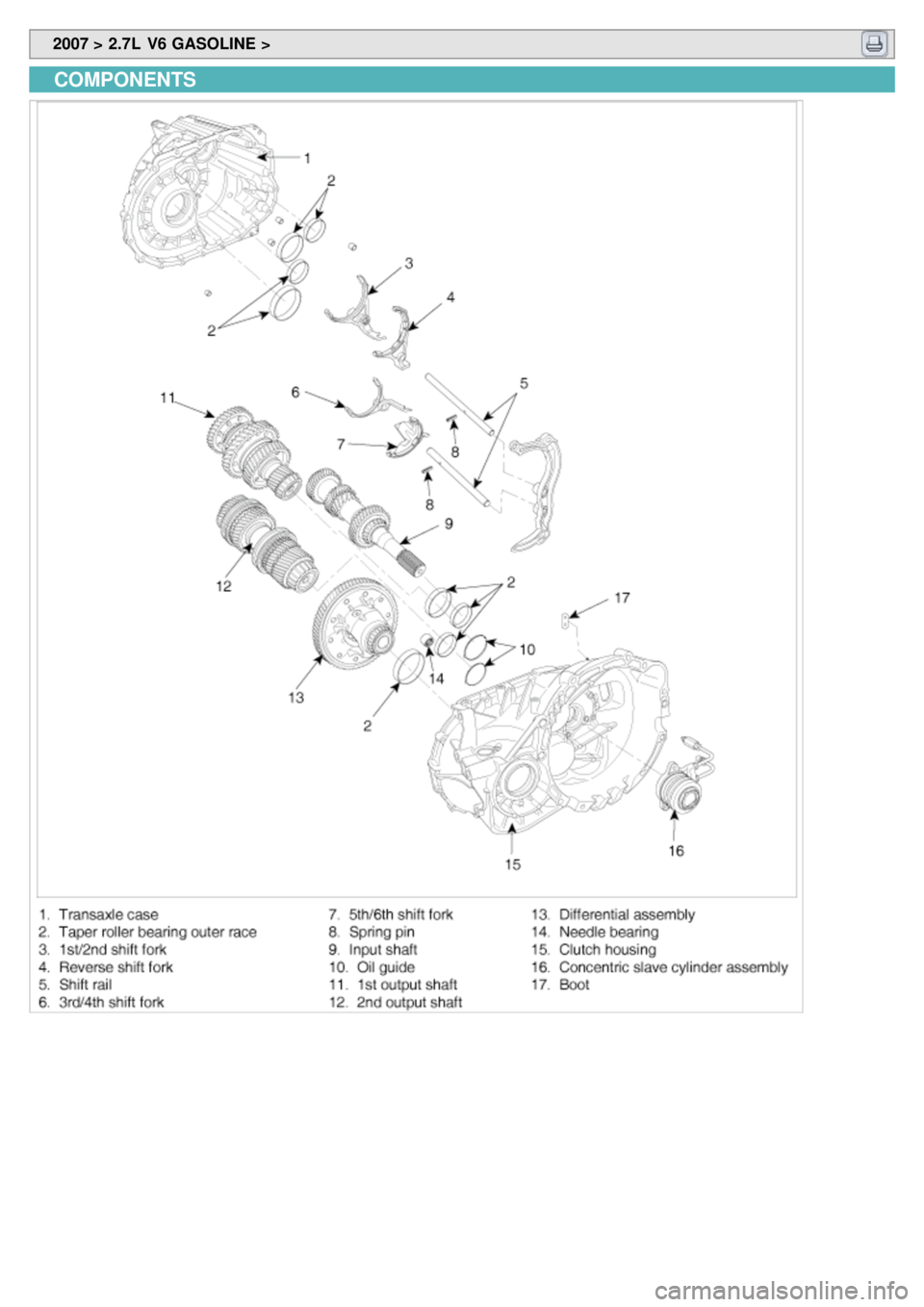

COMPONENTS

Page 426 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

a.Use a cover not to damage the vehicle surface.

b. Disconnect connectors carefully not to be damaged.

a.Mark wires or hoses for identification not to be confused.

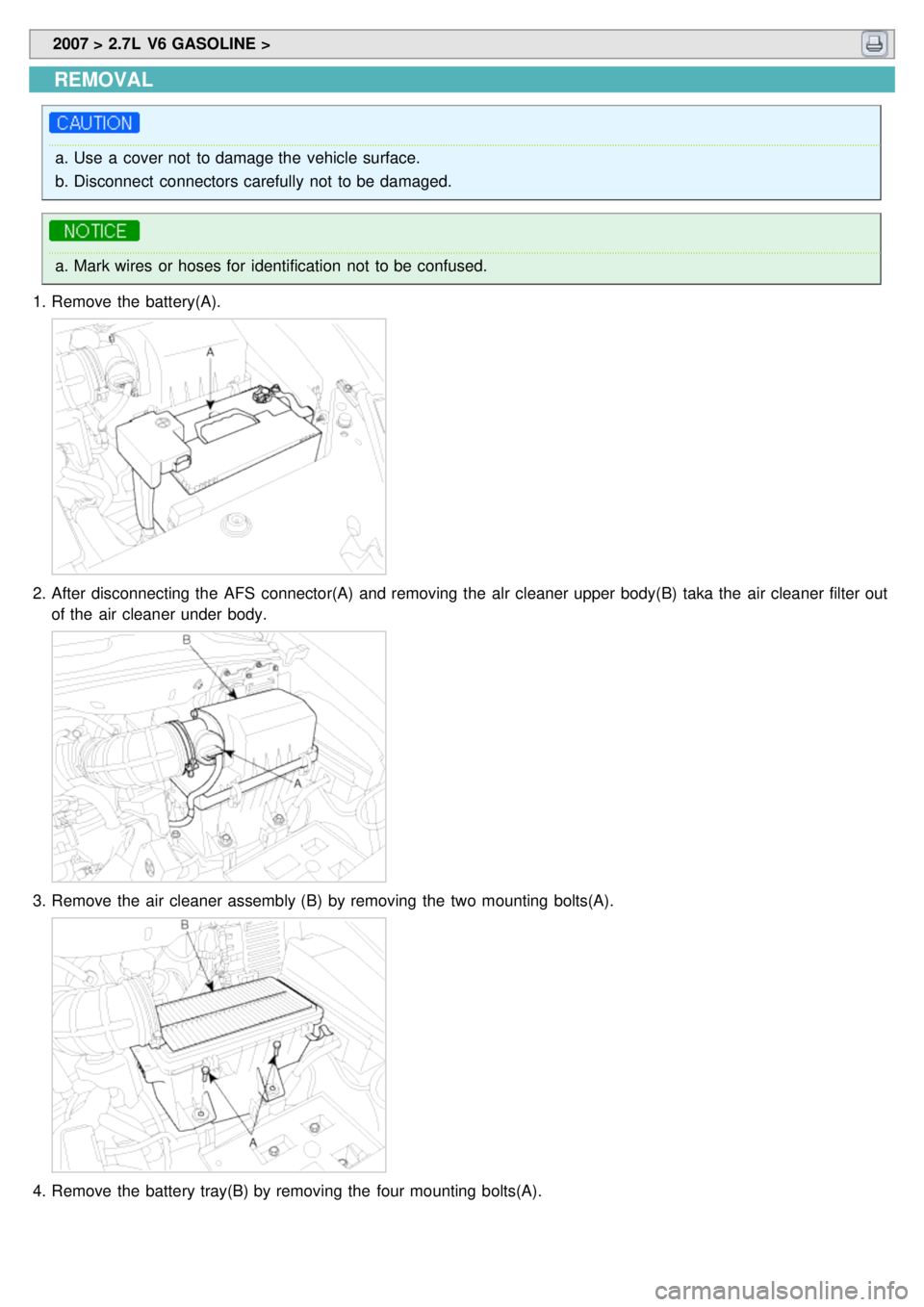

1. Remove the battery(A).

2.After disconnecting the AFS connector(A) and removing the alr cleaner upper body(B) taka the air cleaner filter out

of the air cleaner under body.

3.Remove the air cleaner assembly (B) by removing the two mounting bolts(A).

4.Remove the battery tray(B) by removing the four mounting bolts(A).

Page 427 of 1575

5.Disconnect the vehicle speed sensor connector (A) and the back up lamp switch(B).

6.Disconnect the shift cable assembly(A) after remaing the clips(B) and pins(C).

7.Remove the wire harness bracket(A).

Page 428 of 1575

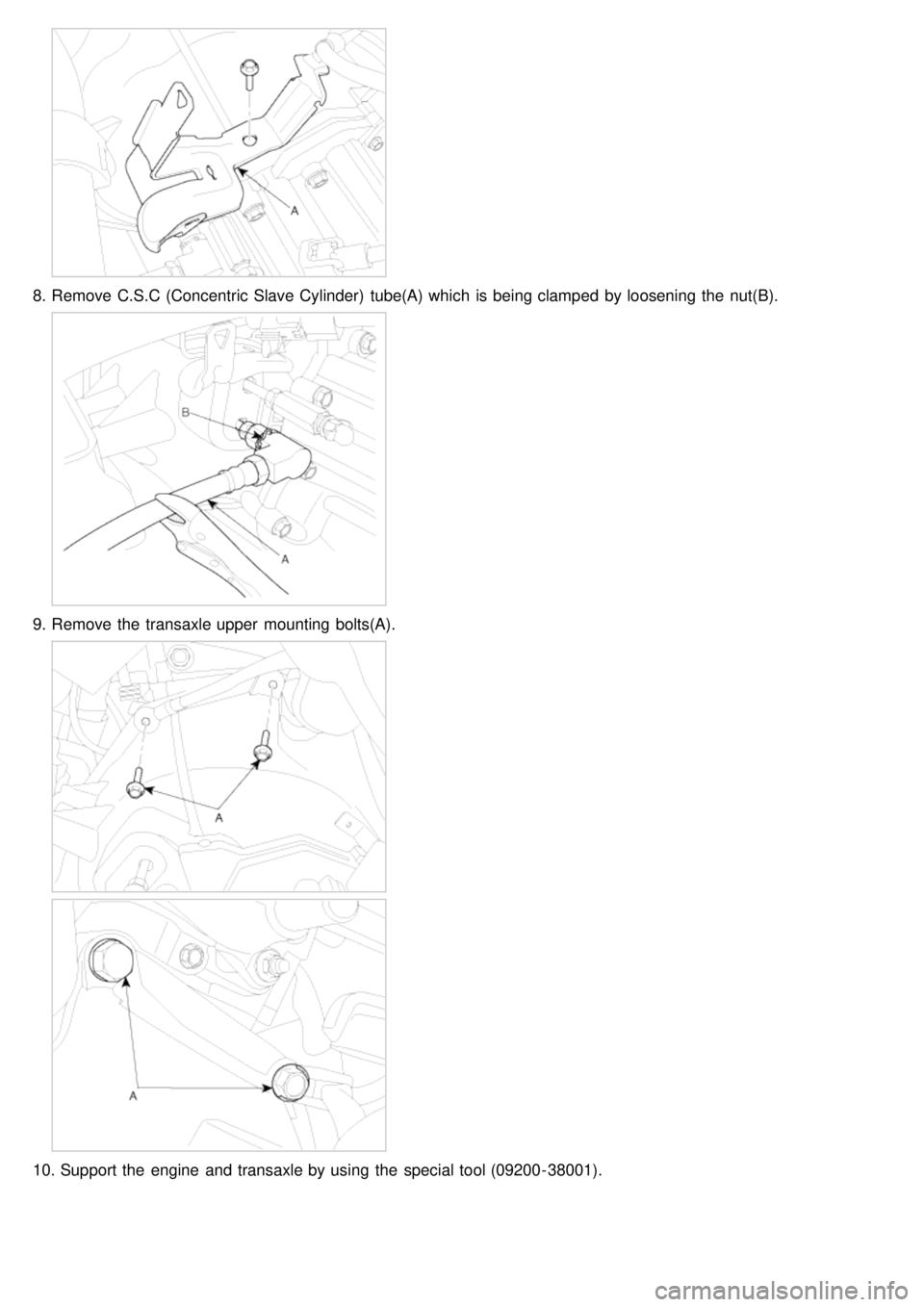

8.Remove C.S.C (Concentric Slave Cylinder) tube(A) which is being clamped by loosening the nut(B).

9.Remove the transaxle upper mounting bolts(A).

10. Support the engine and transaxle by using the special tool (09200- 38001).

Page 429 of 1575

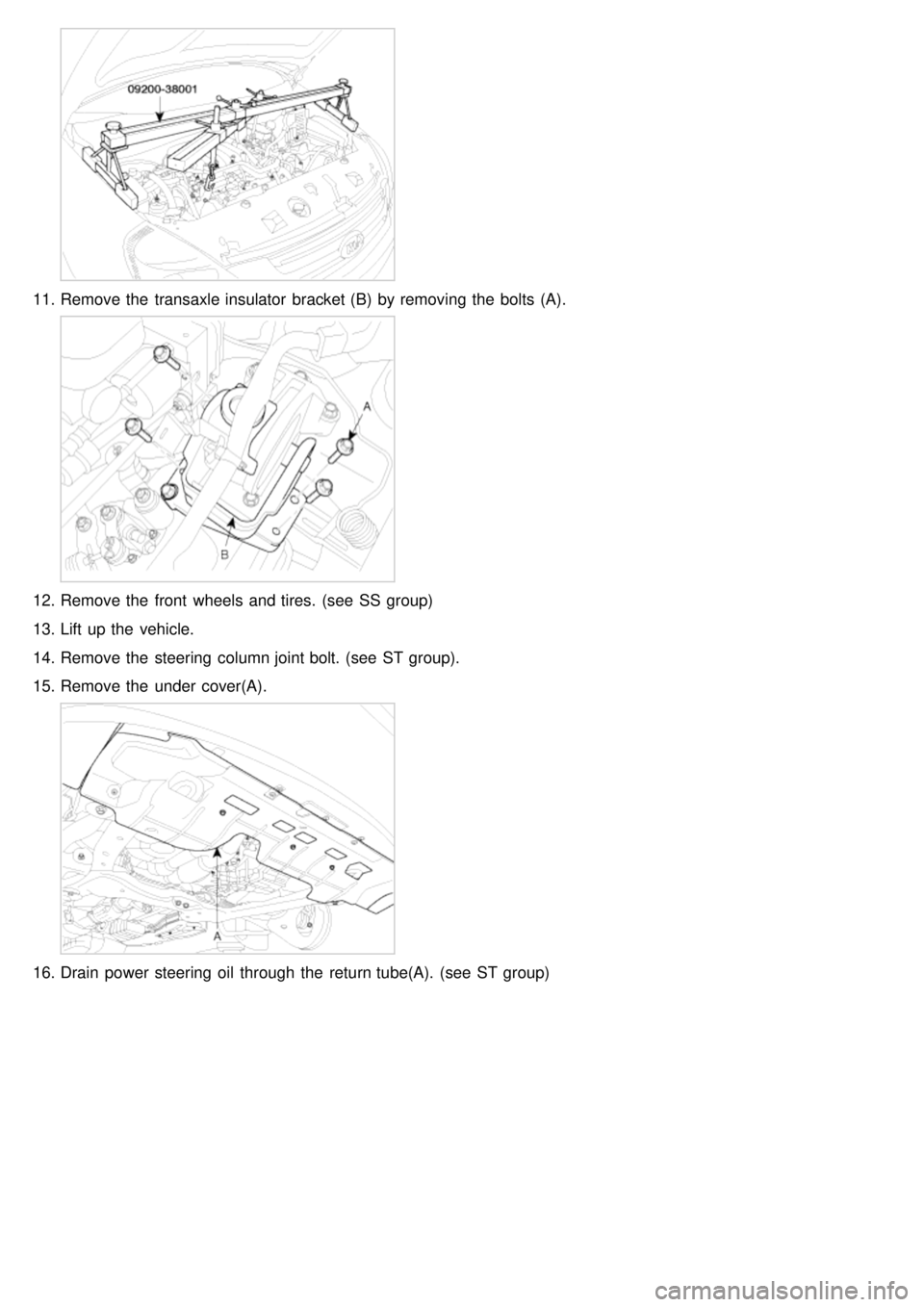

11.Remove the transaxle insulator bracket (B) by removing the bolts (A).

12.Remove the front wheels and tires. (see SS group)

13. Lift up the vehicle.

14. Remove the steering column joint bolt. (see ST group).

15. Remove the under cover(A).

16.Drain power steering oil through the return tube(A). (see ST group)

Page 430 of 1575

17.Disconnect the power steering pressure hose (A) from the power steering oil pump. (see ST group)

18.Drain the tranaxle fluid through the drain plug.

19. Remove the hanger(A).

20.Disconnect the lower arm, the tie rod end ball joint, the stabilizer bar link from the front knuckle. (see SS group)

21. Remove the roll stopper mounting bolt(A).

22.Remove the power steering return tube mounting bolt(A)

Trending: water pump position, clutch, trunk, fuel fill door release, fuse, fuel tank capacity, seat memory