warning light KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 149 of 1575

2007 > 2.7L V6 GASOLINE >

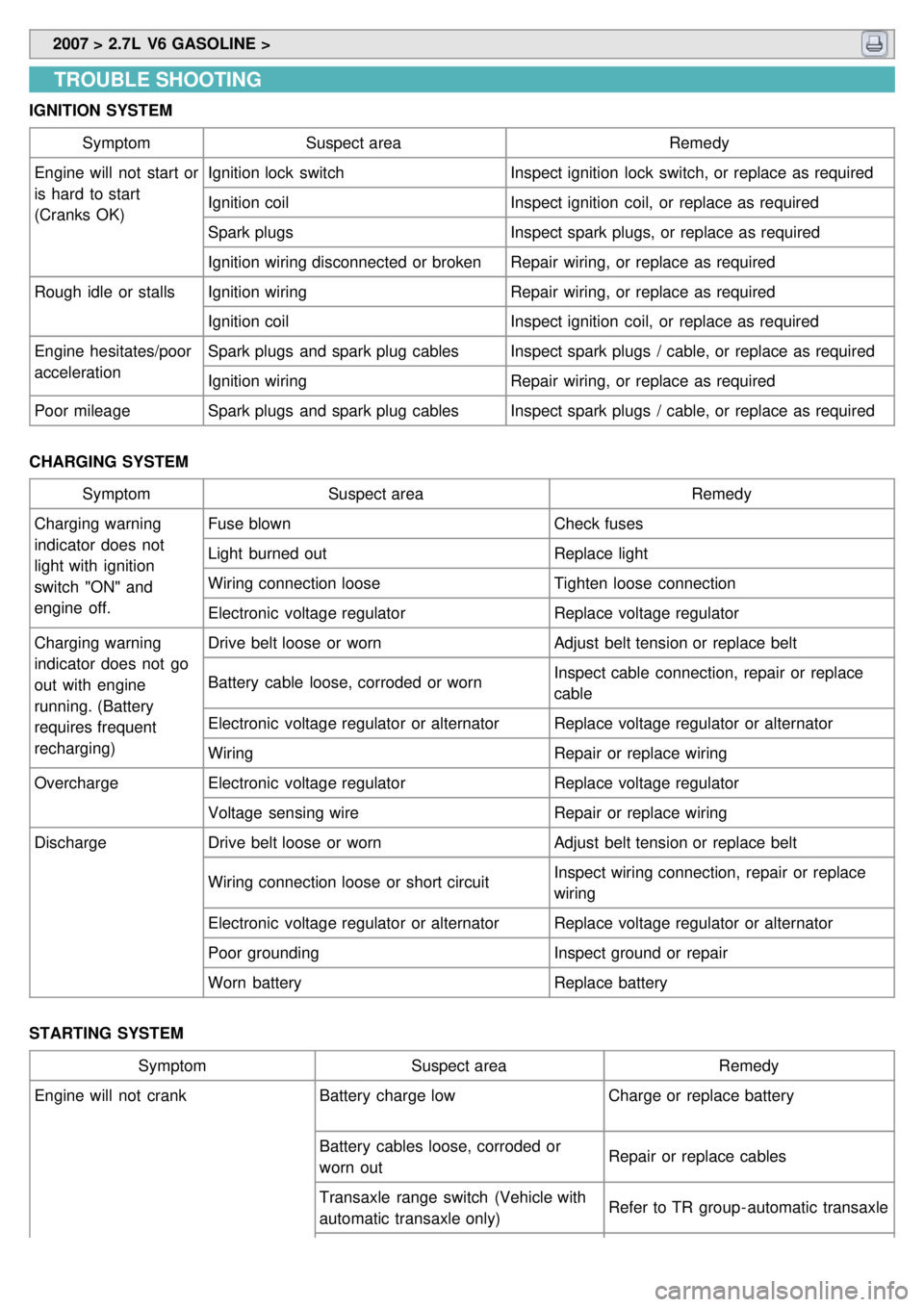

TROUBLE SHOOTING

IGNITION SYSTEM

Symptom Suspect area Remedy

Engine will not start or

is hard to start

(Cranks OK) Ignition lock switch

Inspect ignition lock switch, or replace as required

Ignition coil Inspect ignition coil, or replace as required

Spark plugs Inspect spark plugs, or replace as required

Ignition wiring disconnected or broken Repair wiring, or replace as required

Rough idle or stalls Ignition wiring Repair wiring, or replace as required

Ignition coil Inspect ignition coil, or replace as required

Engine hesitates/poor

acceleration Spark plugs and spark plug cables

Inspect spark plugs / cable, or replace as required

Ignition wiring Repair wiring, or replace as required

Poor mileage Spark plugs and spark plug cables Inspect spark plugs / cable, or replace as required

CHARGING SYSTEM Symptom Suspect area Remedy

Charging warning

indicator does not

light with ignition

switch "ON" and

engine off. Fuse blown

Check fuses

Light burned out Replace light

Wiring connection loose Tighten loose connection

Electronic voltage regulator Replace voltage regulator

Charging warning

indicator does not go

out with engine

running. (Battery

requires frequent

recharging) Drive belt loose or worn

Adjust belt tension or replace belt

Battery cable loose, corroded or worn Inspect cable connection, repair or replace

cable

Electronic voltage regulator or alternator Replace voltage regulator or alternator

Wiring Repair or replace wiring

Overcharge Electronic voltage regulator Replace voltage regulator

Voltage sensing wire Repair or replace wiring

Discharge Drive belt loose or worn Adjust belt tension or replace belt

Wiring connection loose or short circuit Inspect wiring connection, repair or replace

wiring

Electronic voltage regulator or alternator Replace voltage regulator or alternator

Poor grounding Inspect ground or repair

Worn battery Replace battery

STARTING SYSTEM Symptom Suspect area Remedy

Engine will not crank Battery charge low Charge or replace battery

Battery cables loose, corroded or

worn out Repair or replace cables

Transaxle range switch (Vehicle with

automatic transaxle only) Refer to TR group - automatic transaxle

Page 160 of 1575

2007 > 2.7L V6 GASOLINE >

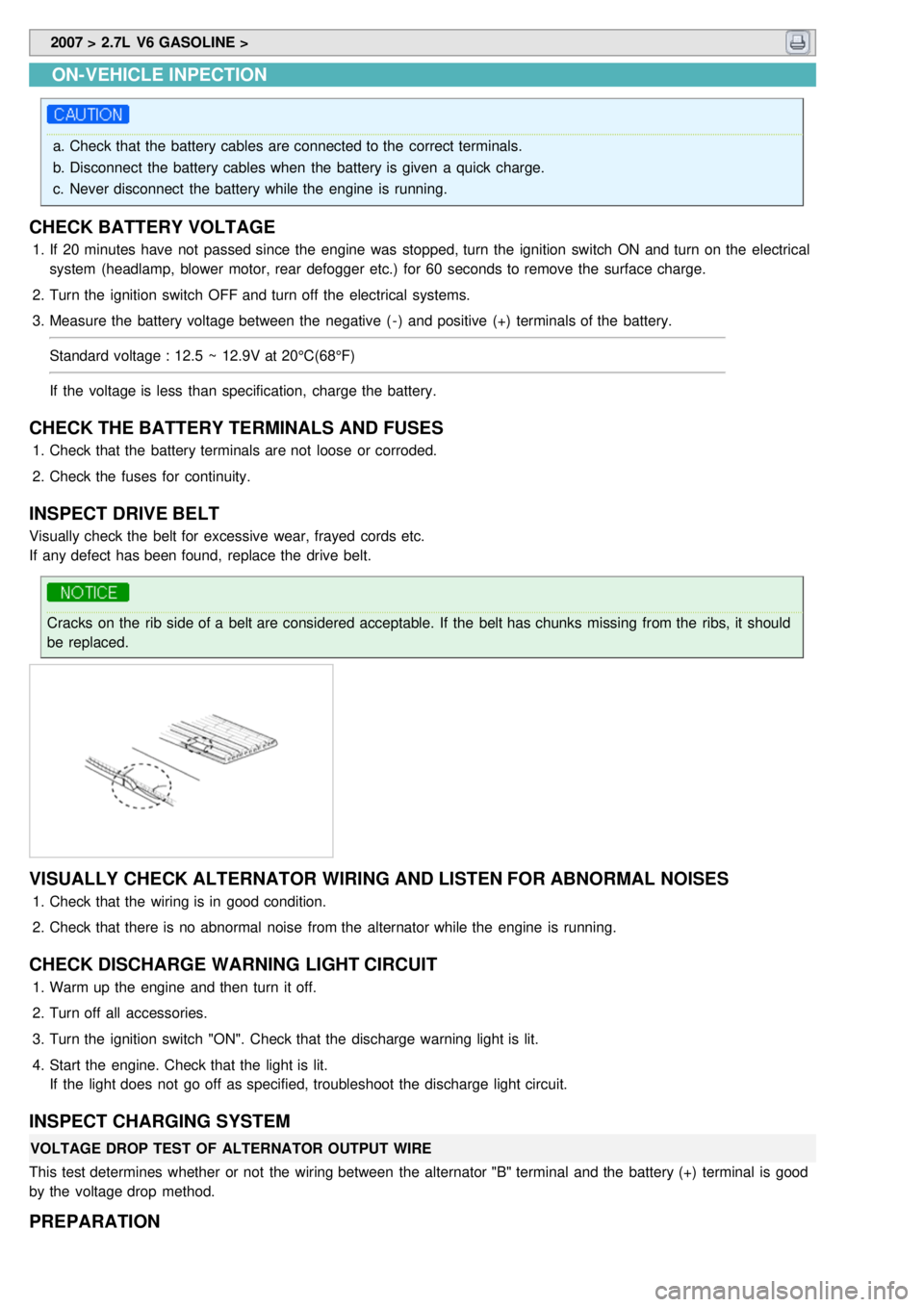

ON-VEHICLE INPECTION

a.Check that the battery cables are connected to the correct terminals.

b. Disconnect the battery cables when the battery is given a quick charge.

c. Never disconnect the battery while the engine is running.

CHECK BATTERY VOLTAGE

1.If 20 minutes have not passed since the engine was stopped, turn the ignition switch ON and turn on the electrical

system (headlamp, blower motor, rear defogger etc.) for 60 seconds to remove the surface charge.

2. Turn the ignition switch OFF and turn off the electrical systems.

3. Measure the battery voltage between the negative ( - ) and positive (+) terminals of the battery.

Standard voltage : 12.5 ~ 12.9V at 20°C(68°F)

If the voltage is less than specification, charge the battery.

CHECK THE BATTERY TERMINALS AND FUSES

1.Check that the battery terminals are not loose or corroded.

2. Check the fuses for continuity.

INSPECT DRIVE BELT

Visually check the belt for excessive wear, frayed cords etc.

If any defect has been found, replace the drive belt.

Cracks on the rib side of a belt are considered acceptable. If the belt has chunks missing from the ribs, it should

be replaced.

VISUALLY CHECK ALTERNATOR WIRING AND LISTEN FOR ABNORMAL NOISES

1.Check that the wiring is in good condition.

2. Check that there is no abnormal noise from the alternator while the engine is running.

CHECK DISCHARGE WARNING LIGHT CIRCUIT

1.Warm up the engine and then turn it off.

2. Turn off all accessories.

3. Turn the ignition switch "ON". Check that the discharge warning light is lit.

4. Start the engine. Check that the light is lit.

If the light does not go off as specified, troubleshoot the discharge light circuit.

INSPECT CHARGING SYSTEM

VOLTAGE DROP TEST OF ALTERNATOR OUTPUT WIRE

This test determines whether or not the wiring between the alternator "B" terminal and the battery (+) terminal is good

by the voltage drop method.

PREPARATION

Page 816 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

The primary purpose of the SRSCM (Supplemental Restraints System Control Module) is to discriminate between an

event that warrants restraint system deployment and an event that does not. The SRSCM must decide whether to

deploy the restraint system or not. After determining that pretensioners and/or airbag deployment is required, the

SRSCM must supply sufficient power to the pretensioners and airbag igniters to initiate deployment. The SRSCM

determines that an impact may require deployment of the pretensioners and airbags from data obtained from impact

sensors and other components in conjunction with a safing function. The SRSCM will not be ready to detect a crash or

to activate the restraint system devices until the signals in the SRSCM circuitry stabilize. It is possible that the SRSCM

could activate the safety restraint devices in approximately 2 seconds but is guaranteed to fully function after prove-

out is completed. The SRSCM must perform a diagnostic routine and light a system readiness indicator at key - on. The

system must perform a continuous diagnostic routine and provide fault annunciation through a warning lamp indicator

in the event of fault detection. A serial diagnostic communication interface will be used to facilitate servicing of the

restraint control system.

Page 926 of 1575

18Voltage for hybrid ECU 1 A500 mA 60200

5,10,17,19 signal wheel speed sensor FL,

FR, RL,RR

6 mA

16 mA 250200 to

ground 1.5M to bat

16,9,6,8 Voltage supply for the active

wheel speed sensor FL,FR,

RL, RR 6 mA

16 mA 250200 to

ground 1.5M to bat

14,24 wheel speed sensor output

(FR, RL) 20 mA

10 mA 250200

11 Diagnostic wire K 6 mA3 mA 250200

22 ABS - warning lamp actuation 30 mA5 mA 250200

12 EBD- warning lamp actuation 30 mA5 mA 250200

20 brake light switch 10 mA5 mA 250200

15 CAN Low 30 mA20 mA 250200

26 CAN High 30 mA20 mA 250200

ABS HECU CONNECTOR Connector terminal SpecificationCondition

Number Description

1 Ground for recirculation pump Current range: Min.10A

Max.20~39A Always

4 Ground for solenoid valves and

ECU Current range: Min.2.5A

Max.5~15A Always

2 Voltage supply for pump motor

Battery voltageAlways

3 Voltage supply for solenoid valves

16 Voltage supply for the active

wheel speed sensor FL,FR, RL, RR Battery voltage

IG ON

9

6

8

5

signal wheel speed sensor FL, FR, RL,RR Voltage(High) : 0.89~1.26 V

Voltage (Low) : 0.44~0.63 V On driving

10

17

19

11

Diagnostic wire K Voltage (High)

≥ 0.8 * IG ON

Voltage (Low) ≤ 0.2 * IG ON On SCAN TOOL

communication

18 Voltage for hybrid ECU Battery voltageKEY ON/OFF

20 Brake light switch Voltage (High)

≥ 0.8 * IG ON

Voltage (Low) ≤ 0.3 * IG ON BRAKE ON/OFF

SENSOR OUTPUT ON SCAN TOOL(ABS) Description AbbreviationUnitRemarks

1 Vehicle speed sensor VEH. SPDKm/h

2 Battery voltage BATT. VOLV

3 FL Wheel speed sensor FL WHEELKm/h

Page 937 of 1575

c.Stop lamp switch circuit.

d. Check the hydraulic circuit for leakage.

Communication with Scan tool is not possible.

(Communication with any system is not possible) a.

Power source circuit

b. Diagnosis line

Communication with Scan tool is not possible.

(Communication with ABS only is not possible) a.

Power source circuit

b. Diagnosis line

c. HECU

When ignition key is turned ON (engine OFF), the ABS

warning lamp does not light up. a.

ABS warning lamp circuit

b. HECU

Even after the engine is started, the ABS warning lamp

remains ON. a.

ABS warning lamp circuit

b. HECU

During ABS operation, the brake pedal may vibrate or may not be able to be depressed. Such phenomena are

due to intermittent changes in hydraulic pressure inside the brake line to prevent the wheels from locking and is

not an abnormality.

DETECTING CONDITION

Trouble Symptoms Possible Cause

Brake operation varies depending on driving conditions and road

surface conditions, so diagnosis can be difficult.However if a normal

DTC is displayed, check the following probable cause. When the

problem is still occurring, replace the ABS control module. a.

Inoperative power source circuit

b. Inoperative wheel speed sensor circuit

c. Inoperative hydraulic circuit for leakage

d. Inoperative HECU

INSPECTION PROCEDURES

DTC INSPECTION

1. Connect the Scan Tool with the data link connector and turn the ignition switch ON.

2. Verify that the system is operating to specifications.

Is the system operating to specifications ?

▶ Check the power source circuit.

▶ Erase the DTC and recheck using Scan Tool.

CHECK THE POWER SOURCE CIRCUIT.

1. Disconnect the connector from the ABS control module.

2. Turn the ignition switch ON, measure the voltage between terminal 18 of the ABS control module harness side

connector and body ground.

Specification: approximately B+

Is the voltage within specification?

▶ Check the ground circuit.

▶ Check the harness or connector between the fuse (10A) in the engine compartment junction block and the ABS

control module. Repair if necessary.

Page 942 of 1575

DETECTING CONDITIONTrouble Symptoms Possible Cause

When current flows in the HECU the ABS warning lamp turns from

ON to OFF as the initial check.Therefore if the lamp does not light up,

the cause may be an open in the lamp power supply circuit, a blown

bulb, an open in the both circuits between the ABS warning lamp and

the HECU, and the inoperative HECU. a.

Inoperative ABS warning lamp bulb

b. Blown No.2 fuse (10A) in the engine

compartment junction block

c. Inoperative ABS warning lamp module

d. Inoperative HECU

INSPECTION PROCEDURES

PROBLEM VERIFICATION

Disconnect the connector from the ABS control module and turn the ignition switch ON.

Does the ABS warning lamp light up?

▶ It is normal. Recheck the ABS control module.

▶ Check the power source for the ABS warning lamp.

CHECK THE POWER SOURCE FOR THE ABS WARNING LAMP

1. Disconnect the instrument cluster connector and turn the ignition switch ON.

2. Measure the voltage between terminal 8 of the cluster harness side connector and body ground.

Specification: approximately B+

Is voltage within specification?

▶ Repair bulb or instrument cluster assembly.

▶ Check for blown fuse.

Page 943 of 1575

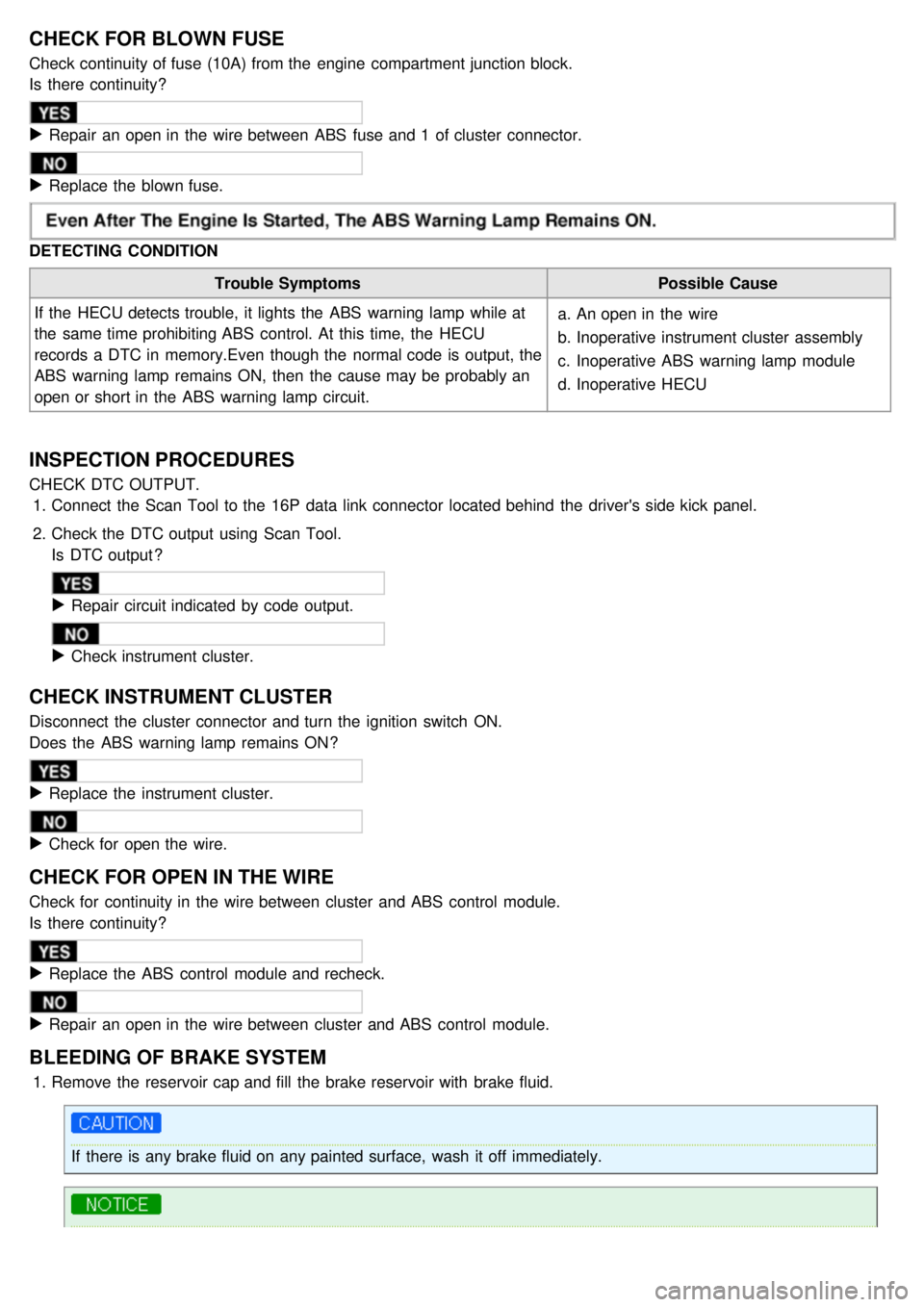

CHECK FOR BLOWN FUSE

Check continuity of fuse (10A) from the engine compartment junction block.

Is there continuity?

▶ Repair an open in the wire between ABS fuse and 1 of cluster connector.

▶ Replace the blown fuse.

DETECTING CONDITION

Trouble Symptoms Possible Cause

If the HECU detects trouble, it lights the ABS warning lamp while at

the same time prohibiting ABS control. At this time, the HECU

records a DTC in memory.Even though the normal code is output, the

ABS warning lamp remains ON, then the cause may be probably an

open or short in the ABS warning lamp circuit. a.

An open in the wire

b. Inoperative instrument cluster assembly

c. Inoperative ABS warning lamp module

d. Inoperative HECU

INSPECTION PROCEDURES

CHECK DTC OUTPUT.

1. Connect the Scan Tool to the 16P data link connector located behind the driver's side kick panel.

2. Check the DTC output using Scan Tool.

Is DTC output ?

▶ Repair circuit indicated by code output.

▶ Check instrument cluster.

CHECK INSTRUMENT CLUSTER

Disconnect the cluster connector and turn the ignition switch ON.

Does the ABS warning lamp remains ON?

▶ Replace the instrument cluster.

▶ Check for open the wire.

CHECK FOR OPEN IN THE WIRE

Check for continuity in the wire between cluster and ABS control module.

Is there continuity?

▶ Replace the ABS control module and recheck.

▶ Repair an open in the wire between cluster and ABS control module.

BLEEDING OF BRAKE SYSTEM

1. Remove the reservoir cap and fill the brake reservoir with brake fluid.

If there is any brake fluid on any painted surface, wash it off immediately.

Page 946 of 1575

DTCDESCRIPTION WARNING LAMP

REMARK

ABS EBDESC

C1101 BATTERY VOLTAGE HIGH ООО

C1102 BATTERY VOLTAGE LOW ОО

C1200 FL WHEEL SPEED SENSOR- OPEN/SHORT ОО

C1201 FL WHEEL SENSOR- RANGE/ PERFORMANCE ОО

C1202 FL WHEEL WHEEL SPEED SENSOR- NO SIGNAL ОО

C1203 FR WHEEL SPEED SENSOR- OPEN/SHORT ОО

C1204 FR WHEEL SENSOR- RANGE/ PERFORMANCE ОО

C1205 FR WHEEL SPEED SENSOR- NO SIGNAL ОО

C1206 RL WHEEL SPEED SENSOR- OPEN/SHORT ОО

C1207 RL WHEEL SENSOR- RANGE/ PERFORMANCE ОО

C1208 RL WHEEL SPEED SENSOR- NO SIGNAL ОО

C1209 RR WHEEL SPEED SENSOR- OPEN/SHORT ОО

C1210 RR WHEEL SENSOR- RANGE/ PERFORMANCE ОО

C1211 RR WHEEL SPEED SENSOR- NO SIGNAL ОО

C1213 WHEEL SPEED FREQUENCY ERROR ОО

C1235 PRESSURE SENSOR- ELECTRICAL ОESP

C1237 PRESSURE SENSOR- SIGNAL FAULT ОESP

C1260 STEERING ANGLE SENSOR- SIGNAL ОESP

C1261 STEERING ANGLE SENSOR NOT CALIBRATED ОESP

C1282 YAW RATE & LATERAL G SENSOR- ELECTRICAL ОESP

C1283 YAW RATE & LATERAL G SENSOR- SIGNAL ОESP

C1503 ESP SWITCH ERROR ОESP

C1513 BRAKE LIGHT SWITCH MALFUNCTION О

C1604 ECU HARDWARE ERROR ООО

C1605 CAN CONTROL HARDWARE ERROR ОESP

C1611 CAN TIME OUT- PCM(ECM) ОESP

C1612 CAN TIME OUT- PCM(TCM) ОESP

C1616 CAN BUS OFF ОESP

C1623 CAN TIMEOUT STEERING ANGLE SENSOR ОESP

C1625 CAN TIME OUT- ESP ОESP

C1626 IMPLAUSIBLE CONTROL ООESP

C1702 VARIANT CODING ООО ESP

C2112 VALVE RELAY MALFUNCTION ООО

C2308 FL INLET VALVE MALFUNCTION ООО

C2312 FL OUTLET VALVE MALFUNCTION ООО

C2316 FR INLET VALVE MALFUNCTION ООО

C2320 FR OUTLET VALVE MALFUNCTION ООО

C2324 RL INLET VALVE MALFUNCTION ООО

C2328 RL OUTLET VALVE MALFUNCTION ООО

Page 961 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

The EBD system (Electronic Brake force Distribution) as a sub- system of the ABS system is to control the effective

adhesion utilization by the rear wheels.

It further utilizes the efficiency of highly developed ABS equipment by controlling the slip of the rear wheels in the

partial braking range.

The brake force is moved even closer to the optimum and controlled electronically, thus dispensing with the need for

the proportioning valve.

The proportioning valve, because of a mechanical device, has limitations to achieve an ideal brake force distribution

tothe rear wheels as well as to carry out the flexible brake force distribution proportioning to the vehicle load or weight

increasing. And in the event of malfunctioning, driver cannot notice whether it fails or not.

EBD controlled by the ABS Control Module, calculates the slip ratio of each wheel at all times and controls the brake

pressure of the rear wheels not to exceed that of the front wheels.

If the EBD fails, the EBD warning lamp (Parking brake lamp) lights up.

ADVANTAGES

a.Function improvement of the base - brake system.

b. Compensation for the different friction coefficients.

c. Elimination of the proportioning valve.

d. Failure recognition by the warning lamp.

Comparison between Proportioning valve and EBD

Page 1211 of 1575

2007 > 2.7L V6 GASOLINE >

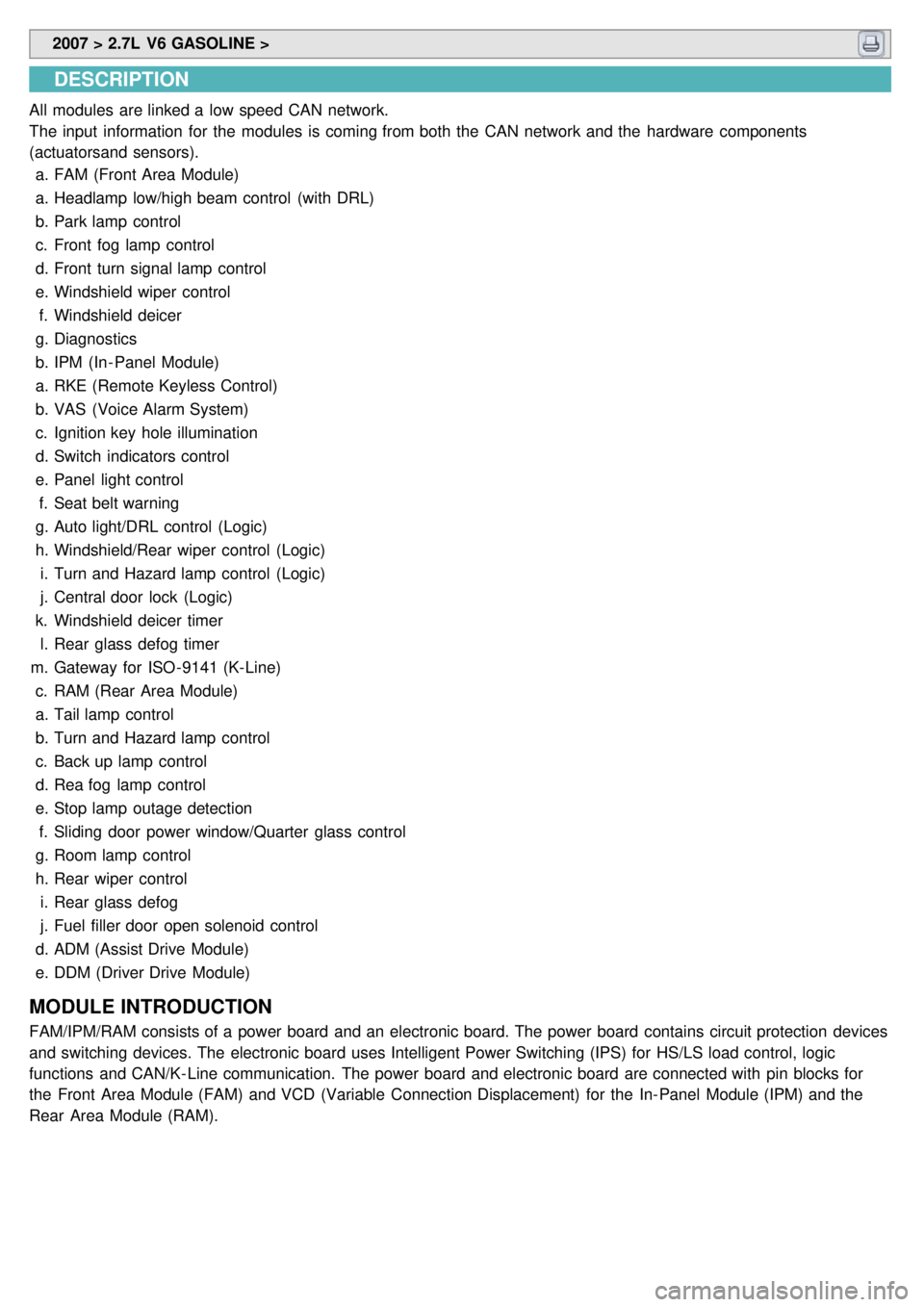

DESCRIPTION

All modules are linked a low speed CAN network.

The input information for the modules is coming from both the CAN network and the hardware components

(actuatorsand sensors).

a. FAM (Front Area Module)

a. Headlamp low/high beam control (with DRL)

b. Park lamp control

c. Front fog lamp control

d. Front turn signal lamp control

e. Windshield wiper control

f. Windshield deicer

g. Diagnostics

b. IPM (In - Panel Module)

a. RKE (Remote Keyless Control)

b. VAS (Voice Alarm System)

c. Ignition key hole illumination

d. Switch indicators control

e. Panel light control

f. Seat belt warning

g. Auto light/DRL control (Logic)

h. Windshield/Rear wiper control (Logic)

i. Turn and Hazard lamp control (Logic)

j. Central door lock (Logic)

k. Windshield deicer timer

l. Rear glass defog timer

m. Gateway for ISO- 9141 (K- Line)

c. RAM (Rear Area Module)

a. Tail lamp control

b. Turn and Hazard lamp control

c. Back up lamp control

d. Rea fog lamp control

e. Stop lamp outage detection

f. Sliding door power window/Quarter glass control

g. Room lamp control

h. Rear wiper control

i. Rear glass defog

j. Fuel filler door open solenoid control

d. ADM (Assist Drive Module)

e. DDM (Driver Drive Module)

MODULE INTRODUCTION

FAM/IPM/RAM consists of a power board and an electronic board. The power board contains circuit protection devices

and switching devices. The electronic board uses Intelligent Power Switching (IPS) for HS/LS load control, logic

functions and CAN/K- Line communication. The power board and electronic board are connected with pin blocks for

the Front Area Module (FAM) and VCD (Variable Connection Displacement) for the In- Panel Module (IPM) and the

Rear Area Module (RAM).