Maintenance

7

7-85

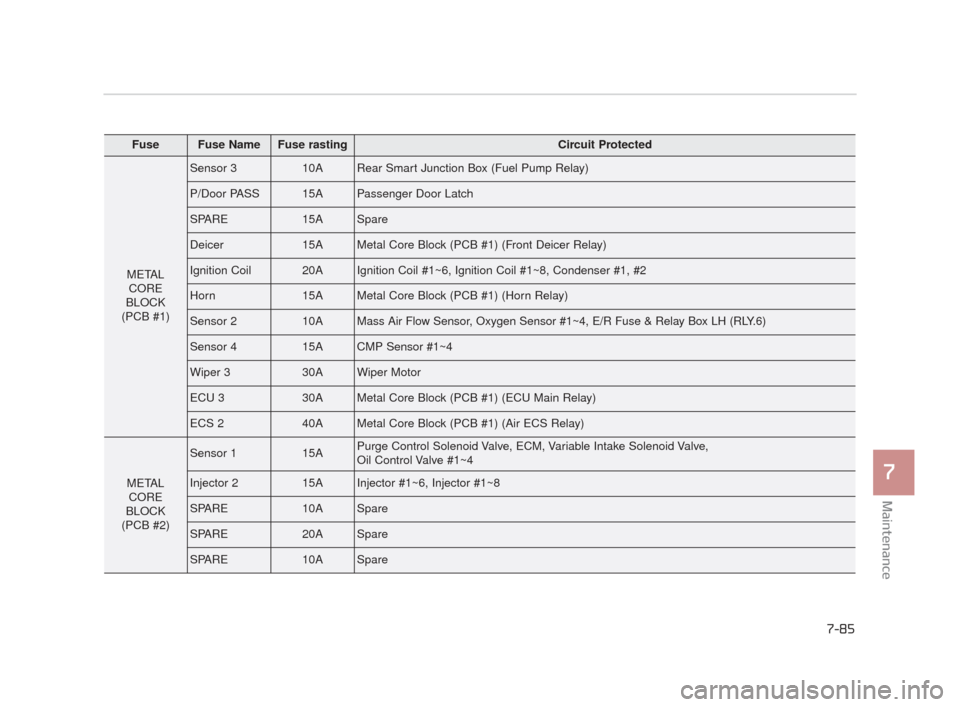

FuseFuse NameFuse rastingCircuit Protected

METALCORE

BLOCK

(PCB #1)

Sensor 310ARear Smart Junction Box (Fuel Pump Relay)

P/Door PASS15APassenger Door Latch

SPARE15ASpare

Deicer15AMetal Core Block (PCB #1) (Front Deicer Relay)

Ignition Coil20AIgnition Coil #1~6, Ignition Coil #1~8, Condenser #1, #2

Horn15AMetal Core Block (PCB #1) (Horn Relay)

Sensor 210AMass Air Flow Sensor, Oxygen Sensor #1~4, E/R Fuse & Relay Box LH (RLY.6)

Sensor 415ACMP Sensor #1~4

Wiper 330AWiper Motor

ECU 330AMetal Core Block (PCB #1) (ECU Main Relay)

ECS 240AMetal Core Block (PCB #1) (Air ECS Relay)

METAL CORE

BLOCK

(PCB #2)

Sensor 115APurge Control Solenoid Valve, ECM, Variable Intake Solenoid Valve,

Oil Control Valve #1~4

Injector 215AInjector #1~6, Injector #1~8

SPARE10ASpare

SPARE20ASpare

SPARE10ASpare

KH CAN (ENG) 7:2015 3/26/2015 6:42 AM Page 85

Maintenance

7

7-89

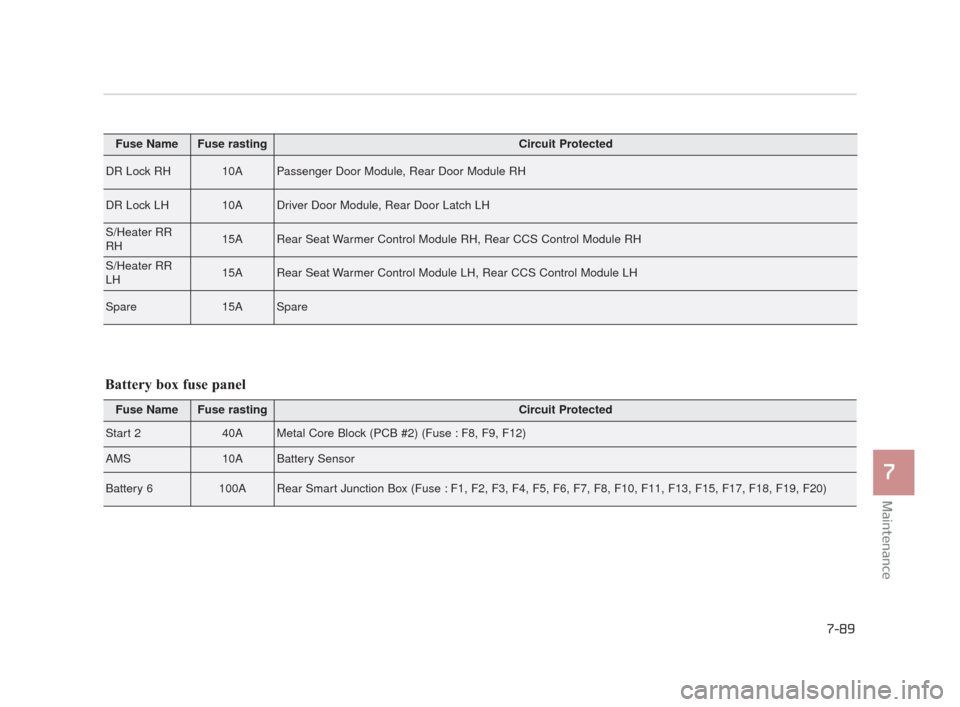

Fuse NameFuse rastingCircuit Protected

DR Lock RH10APassenger Door Module, Rear Door Module RH

DR Lock LH10ADriver Door Module, Rear Door Latch LH

S/Heater RR

RH15ARear Seat Warmer Control Module RH, Rear CCS Control Module RH

S/Heater RR

LH15ARear Seat Warmer Control Module LH, Rear CCS Control Module LH

Spare15ASpare

Fuse NameFuse rastingCircuit Protected

Start 240AMetal Core Block (PCB #2) (Fuse : F8, F9, F12)

AMS10ABattery Sensor

Battery 6100ARear Smart Junction Box (Fuse : F1, F2, F3, F4, F5, F6, F7, F8, F10, F11, F13, F15, F17, F18, F19, F20)\

Battery box fuse panel

KH CAN (ENG) 7:2015 3/26/2015 6:42 AM Page 89

Maintenance

7

7-97

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired, dry

the brakes by applying them lightly

while maintaining a slow forward

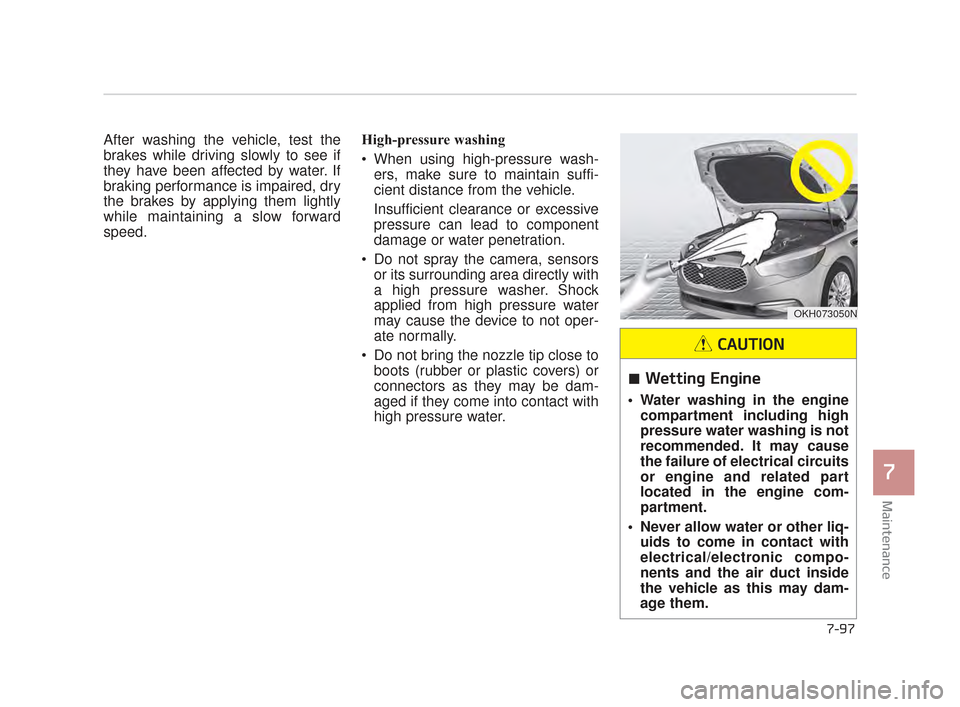

speed.High-pressure washing

When using high-pressure wash-

ers, make sure to maintain suffi-

cient distance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component

damage or water penetration.

Do not spray the camera, sensors or its surrounding area directly with

a high pressure washer. Shock

applied from high pressure water

may cause the device to not oper-

ate normally.

Do not bring the nozzle tip close to boots (rubber or plastic covers) or

connectors as they may be dam-

aged if they come into contact with

high pressure water.

OKH073050N

Wetting Engine

Water washing in the enginecompartment including high

pressure water washing is not

recommended. It may cause

the failure of electrical circuits

or engine and related part

located in the engine com-

partment.

Never allow water or other liq- uids to come in contact with

electrical/electronic compo-

nents and the air duct inside

the vehicle as this may dam-

age them.

CAUTION

KH CAN (ENG) 7:2015 3/26/2015 6:42 AM Page 97