light KIA Magnetis 2006 2.G Manual PDF

[x] Cancel search | Manufacturer: KIA, Model Year: 2006, Model line: Magnetis, Model: KIA Magnetis 2006 2.GPages: 225, PDF Size: 3.77 MB

Page 177 of 225

MAINTENANCE

7-1

MAINTENANCEMaintenance Services . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Owner Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Engine Compartment . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

Engine Oil and Oil Filter . . . . . . . . . . . . . . . . . . . . . . . .7-12

Engine Cooling System . . . . . . . . . . . . . . . . . . . . . . . . .7-14

Brakes and Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-17

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

Power Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

Automatic Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19

Lubricants and Fluids . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-21

Wiper Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-23

Tires and Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-25

Bulb Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-32

Lubricant Specifications . . . . . . . . . . . . . . . . . . . . . . . .7-36

Exterior Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-38

Interior Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-40

Headlight Aiming Adjustment . . . . . . . . . . . . . . . . . . .7-42

7

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 1

Page 199 of 225

7-23

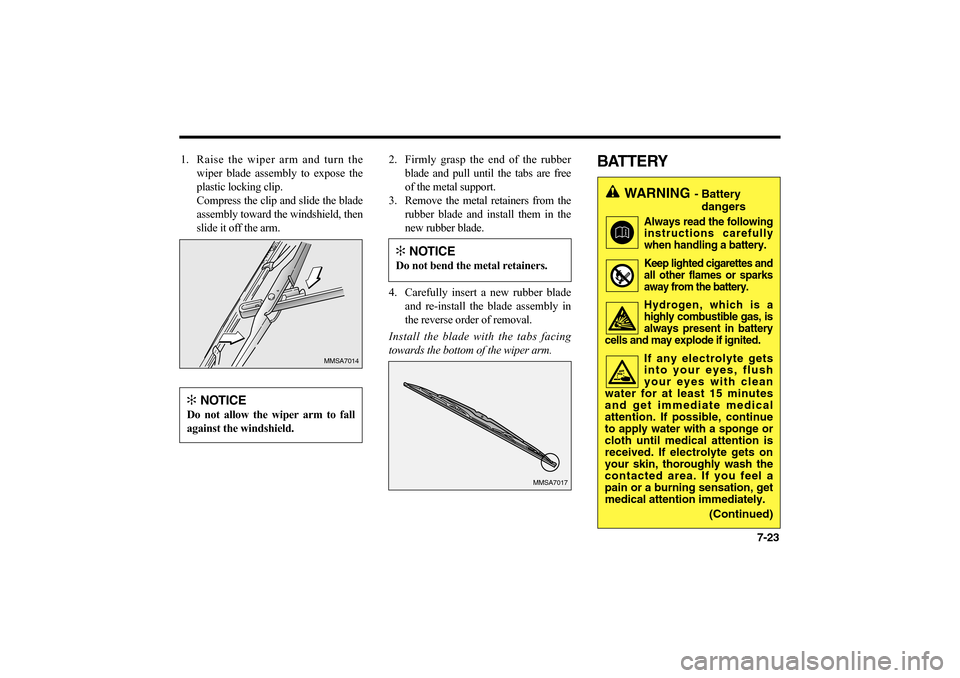

1. Raise the wiper arm and turn the

wiper blade assembly to expose the

plastic locking clip.

Compress the clip and slide the blade

assembly toward the windshield, then

slide it off the arm.2. Firmly grasp the end of the rubber

blade and pull until the tabs are free

of the metal support.

3. Remove the metal retainers from the

rubber blade and install them in the

new rubber blade.

4. Carefully insert a new rubber blade

and re-install the blade assembly in

the reverse order of removal.

Install the blade with the tabs facing

towards the bottom of the wiper arm.

BATTERY

MMSA7014

MMSA7017

✻

NOTICE

Do not allow the wiper arm to fall

against the windshield.

✻

NOTICE

Do not bend the metal retainers.

WARNING

- Battery

dangers

Always read the following

instructions carefully

when handling a battery.Keep lighted cigarettes and

all other flames or sparks

away from the battery.Hydrogen, which is a

highly combustible gas, is

always present in battery

cells and may explode if ignited.If any electrolyte gets

into your eyes, flush

your eyes with clean

water for at least 15 minutes

and get immediate medical

attention. If possible, continue

to apply water with a sponge or

cloth until medical attention is

received. If electrolyte gets on

your skin, thoroughly wash the

contacted area. If you feel a

pain or a burning sensation, get

medical attention immediately.

(Continued)

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 23

Page 200 of 225

BATTERY MAINTENANCEFor best battery service:

• Keep the battery securely mounted.

• Keep the battery top clean and dry.

• Keep the terminals and connections

clean, tight, and coated with

petroleum jelly or terminal grease.

• Immediately rinse any spilled

electrolyte from the battery with a

solution of water and baking soda.

• If the vehicle is not going to be used

for an extended period of time,

disconnect the battery cables.

BATTERY RECHARGINGYour vehicle has a maintenance-free,

calcium-based battery.

• If the battery becomes discharged in

a short time (headlights or interior

lights were left on while the vehicle

was not in use), recharge it by slow

(trickle) charging for 10 hours.

• If the battery gradually discharges

because of high electric load while

the vehicle is being used, recharge it

at 20-30A for two hours.

MAINTENANCE

7-24

MMSA7034

(Continued)

Keep batteries out of the

reach of children

because batteries

contain highly corrosive

SULFURIC ACID. Do not allow

battery acid to contact your skin,

eyes, clothing or paint finish.

Wear eye protection

when charging or

working near a battery.

Always provide ventilation when

working in an enclosed space.

When lifting a plastic-cased

battery, excessive pressure

on the case may cause

battery acid to leak, resulting

in personal injury. Lift with a

battery carrier or with your

hands on opposite corners.

Never attempt to charge the

battery when the battery

cables are connected.

The electrical ignition system

works with high voltage. Never

touch these components with

the engine running or the

ignition switched on.

WARNING - Recharging

Battery

When recharging the battery,

observe the following

precautions:

The battery must be removed

from the vehicle and placed

in an area with good

ventilation.

Do not allow cigarettes,

sparks, or flame near the

battery.

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 24

Page 208 of 225

MAINTENANCE

7-32WHEEL REPLACEMENTWhen replacing the metal wheels for any

reason, make sure the new wheels are

equivalent to the original factory units in

diameter, rim width and offset.

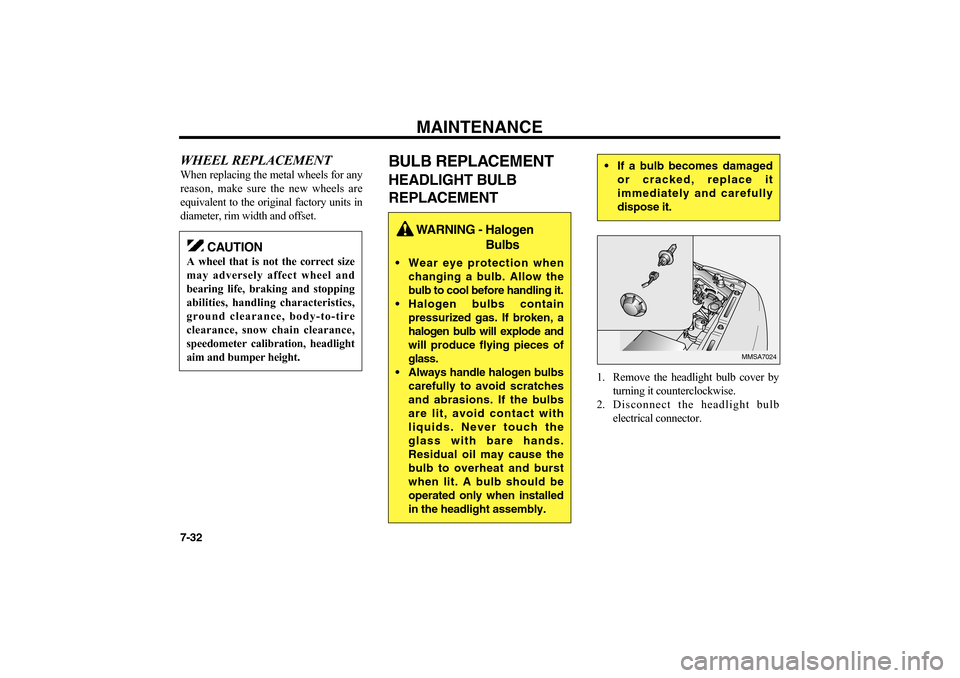

BULB REPLACEMENTHEADLIGHT BULB

REPLACEMENT

1. Remove the headlight bulb cover by

turning it counterclockwise.

2. Disconnect the headlight bulb

electrical connector.

MMSA7024

CAUTION

A wheel that is not the correct size

may adversely affect wheel and

bearing life, braking and stopping

abilities, handling characteristics,

ground clearance, body-to-tire

clearance, snow chain clearance,

speedometer calibration, headlight

aim and bumper height.

WARNING - Halogen

Bulbs

Wear eye protection when

changing a bulb. Allow the

bulb to cool before handling it.

Halogen bulbs contain

pressurized gas. If broken, a

halogen bulb will explode and

will produce flying pieces of

glass.

Always handle halogen bulbs

carefully to avoid scratches

and abrasions. If the bulbs

are lit, avoid contact with

liquids. Never touch the

glass with bare hands.

Residual oil may cause the

bulb to overheat and burst

when lit. A bulb should be

operated only when installed

in the headlight assembly.

If a bulb becomes damaged

or cracked, replace it

immediately and carefully

dispose it.

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 32

Page 209 of 225

7-33

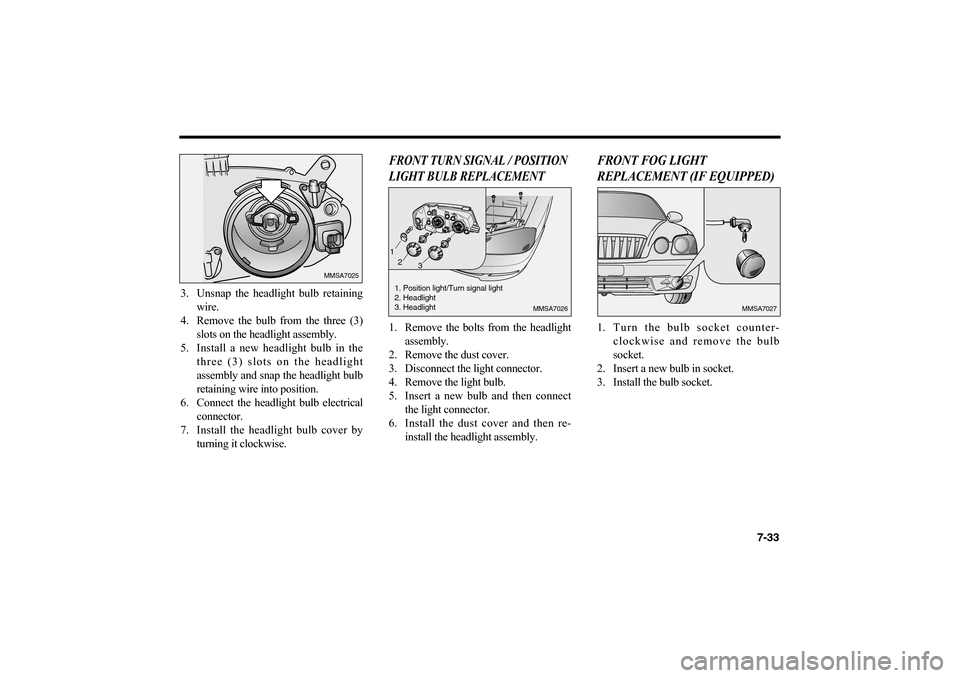

3. Unsnap the headlight bulb retaining

wire.

4. Remove the bulb from the three (3)

slots on the headlight assembly.

5. Install a new headlight bulb in the

three (3) slots on the headlight

assembly and snap the headlight bulb

retaining wire into position.

6. Connect the headlight bulb electrical

connector.

7. Install the headlight bulb cover by

turning it clockwise.

FRONT TURN SIGNAL / POSITION

LIGHT BULB REPLACEMENT1. Remove the bolts from the headlight

assembly.

2. Remove the dust cover.

3. Disconnect the light connector.

4. Remove the light bulb.

5. Insert a new bulb and then connect

the light connector.

6. Install the dust cover and then re-

install the headlight assembly.

FRONT FOG LIGHT

REPLACEMENT (IF EQUIPPED)1. Turn the bulb socket counter-

clockwise and remove the bulb

socket.

2. Insert a new bulb in socket.

3. Install the bulb socket.

MMSA7025

MMSA7026

1. Position light/Turn signal light

2. Headlight

3. Headlight

MMSA7027

1

2

3

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 33

Page 210 of 225

MAINTENANCE

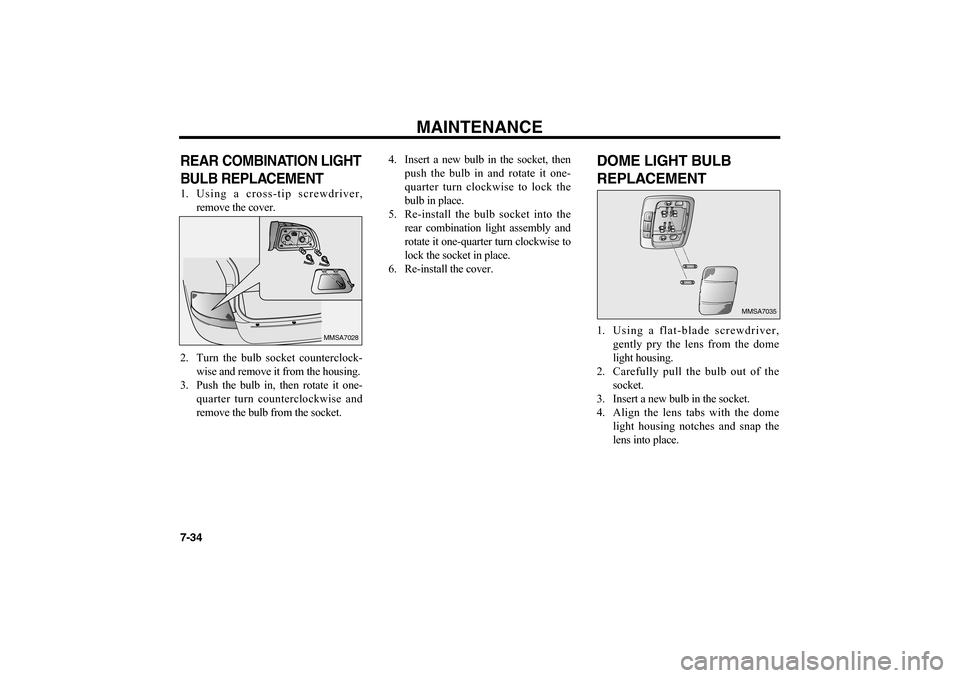

7-34REAR COMBINATION LIGHT

BULB REPLACEMENT 1. Using a cross-tip screwdriver,

remove the cover.

2. Turn the bulb socket counterclock-

wise and remove it from the housing.

3. Push the bulb in, then rotate it one-

quarter turn counterclockwise and

remove the bulb from the socket.4. Insert a new bulb in the socket, then

push the bulb in and rotate it one-

quarter turn clockwise to lock the

bulb in place.

5. Re-install the bulb socket into the

rear combination light assembly and

rotate it one-quarter turn clockwise to

lock the socket in place.

6. Re-install the cover.

DOME LIGHT BULB

REPLACEMENT1. Using a flat-blade screwdriver,

gently pry the lens from the dome

light housing.

2. Carefully pull the bulb out of the

socket.

3. Insert a new bulb in the socket.

4. Align the lens tabs with the dome

light housing notches and snap the

lens into place.

MMSA7028

O

F

FDOORON

MMSA7035

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 34

Page 211 of 225

7-35

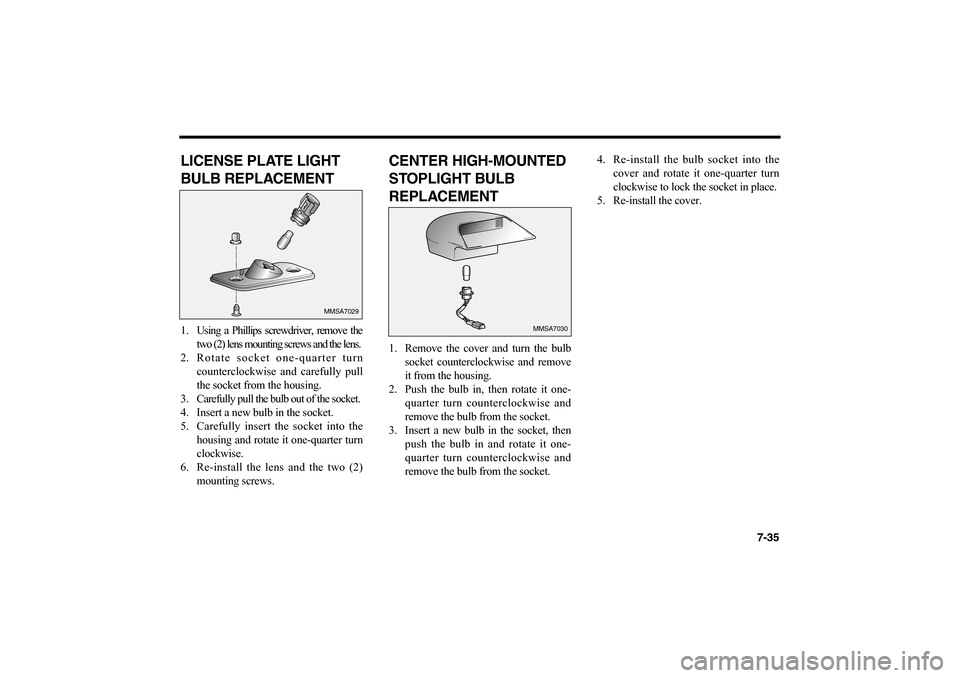

LICENSE PLATE LIGHT

BULB REPLACEMENT1. Using a Phillips screwdriver, remove the

two (2) lens mounting screws and the lens.

2. Rotate socket one-quarter turn

counterclockwise and carefully pull

the socket from the housing.

3. Carefully pull the bulb out of the socket.

4. Insert a new bulb in the socket.

5. Carefully insert the socket into the

housing and rotate it one-quarter turn

clockwise.

6. Re-install the lens and the two (2)

mounting screws.

CENTER HIGH-MOUNTED

STOPLIGHT BULB

REPLACEMENT1. Remove the cover and turn the bulb

socket counterclockwise and remove

it from the housing.

2. Push the bulb in, then rotate it one-

quarter turn counterclockwise and

remove the bulb from the socket.

3. Insert a new bulb in the socket, then

push the bulb in and rotate it one-

quarter turn counterclockwise and

remove the bulb from the socket.4. Re-install the bulb socket into the

cover and rotate it one-quarter turn

clockwise to lock the socket in place.

5. Re-install the cover.

MMSA7029

MMSA7030

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 35

Page 212 of 225

MAINTENANCE

7-36TRUNK ROOM LIGHT BULB

REPLACEMENT (IF EQUIPPED)1. Remove the trunk room lamp cover

using flat blade screw driver.

2. After replacement of bulb, install the

cover.

LUBRICANT

SPECIFICATIONSRECOMMENDED

LUBRICANTSTo help achieve proper engine and

powertrain performance and durability,

use only lubricants of the proper quality.

The correct lubricants also help promote

engine efficiency which results in

improved fuel economy.

Engine oils labeled Energy Conserving

Oil are now available. Along with other

additional benefits, they contribute to

fuel economy by reducing the amount of

fuel necessary to overcome engine

friction. Often, these improvements are

difficult to measure in everyday driving,

but in a year’s time they can offer

significant cost and energy savings.

MMSA7031

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 36

Page 214 of 225

MAINTENANCE

7-38When choosing an oil, consider the range

of temperature your vehicle will be

operated in before the next oil change.

Then select the recommended oil

viscosity from the chart.EXTERIOR CAREEXTERIOR GENERAL

CAUTIONIt is very important to follow the

manufacturer’s directions when using

any chemical cleaner or polish. Read all

warning and caution statements that

appear on the label.FINISH MAINTENANCE

WASHINGTo help protect your vehicle’s finish from

rust and deterioration, wash it thoroughly

and frequently at least once a month with

special attention to the removal of any

accumulation of salt, dirt, mud, or other

foreign materials. Make sure the drainholes in the lower edges of the doors and

rocker panels are kept clear and clean.

Insects, tar, tree sap, bird droppings,

industrial fallout and similar deposits can

damage your vehicle’s finish if not

removed immediately.

Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, can be used.

After washing, rinse the vehicle

thoroughly with lukewarm or cold water.

Do not allow soap to dry on the finish.

WAXINGWax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim as well,

to protect it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.

✻

NOTICE

Do not use strong soap, chemical

detergents or hot water, and do not

wash the vehicle in direct sunlight

or when the body of the vehicle is

warm.

CAUTION

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow

forward speed.

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 38

Page 218 of 225

MAINTENANCE

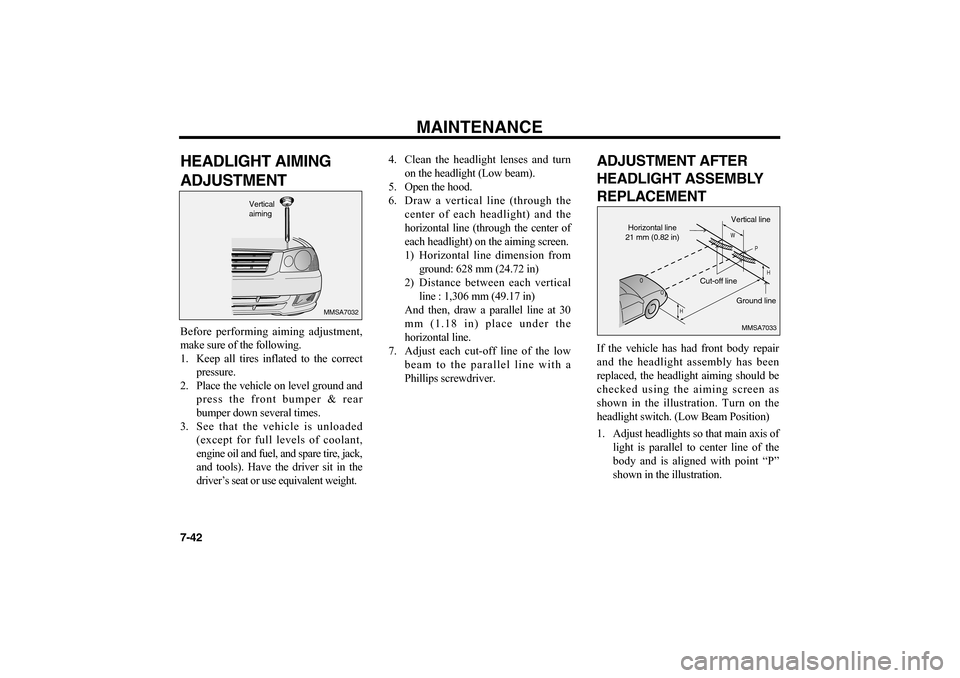

7-42HEADLIGHT AIMING

ADJUSTMENTBefore performing aiming adjustment,

make sure of the following.

1. Keep all tires inflated to the correct

pressure.

2. Place the vehicle on level ground and

press the front bumper & rear

bumper down several times.

3. See that the vehicle is unloaded

(except for full levels of coolant,

engine oil and fuel, and spare tire, jack,

and tools). Have the driver sit in the

driver’s seat or use equivalent weight.4. Clean the headlight lenses and turn

on the headlight (Low beam).

5. Open the hood.

6. Draw a vertical line (through the

center of each headlight) and the

horizontal line (through the center of

each headlight) on the aiming screen.

1) Horizontal line dimension from

ground: 628 mm (24.72 in)

2) Distance between each vertical

line : 1,306 mm (49.17 in)

And then, draw a parallel line at 30

mm (1.18 in) place under the

horizontal line.

7. Adjust each cut-off line of the low

beam to the parallel line with a

Phillips screwdriver.

ADJUSTMENT AFTER

HEADLIGHT ASSEMBLY

REPLACEMENTIf the vehicle has had front body repair

and the headlight assembly has been

replaced, the headlight aiming should be

checked using the aiming screen as

shown in the illustration. Turn on the

headlight switch. (Low Beam Position)

1. Adjust headlights so that main axis of

light is parallel to center line of the

body and is aligned with point “P”

shown in the illustration.

MMSA7032

Vertical

aiming

HH W

P

MMSA7033

Horizontal line

21 mm (0.82 in)

Cut-off line

Ground line Vertical line

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 42