air suspension KIA NIRO HYBRID EV 2022 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2022, Model line: NIRO HYBRID EV, Model: KIA NIRO HYBRID EV 2022Pages: 684, PDF Size: 9.67 MB

Page 537 of 684

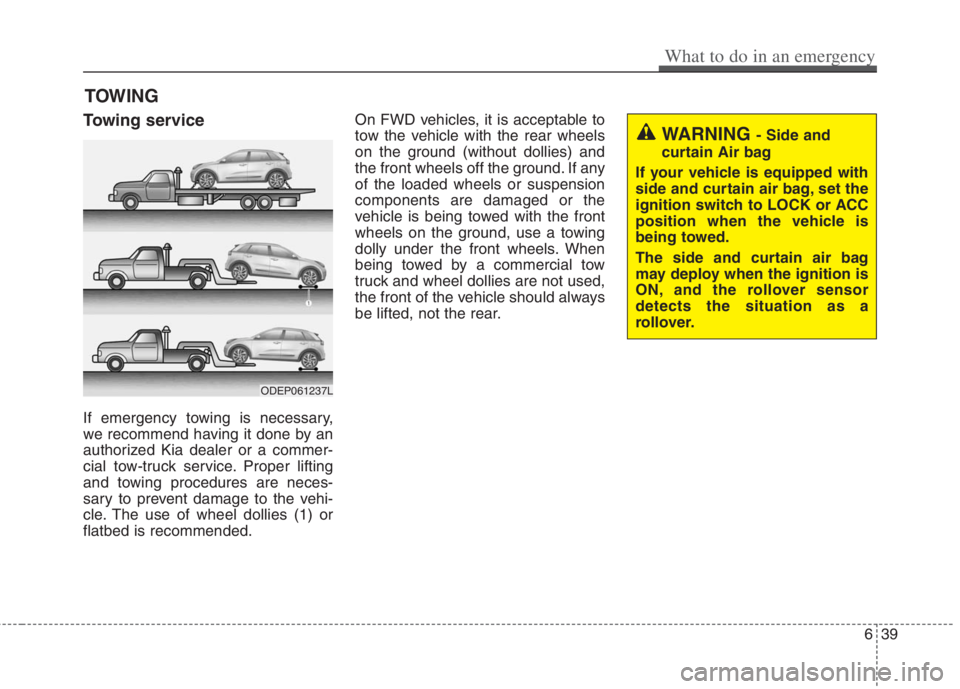

TOWING

Towing service

If emergency towing is necessary,

we recommend having it done by an

authorized Kia dealer or a commer-

cial tow-truck service. Proper lifting

and towing procedures are neces-

sary to prevent damage to the vehi-

cle. The use of wheel dollies (1) or

flatbed is recommended.On FWD vehicles, it is acceptable to

tow the vehicle with the rear wheels

on the ground (without dollies) and

the front wheels off the ground. If any

of the loaded wheels or suspension

components are damaged or the

vehicle is being towed with the front

wheels on the ground, use a towing

dolly under the front wheels. When

being towed by a commercial tow

truck and wheel dollies are not used,

the front of the vehicle should always

be lifted, not the rear.

WARNING - Side and

curtain Air bag

If your vehicle is equipped with

side and curtain air bag, set the

ignition switch to LOCK or ACC

position when the vehicle is

being towed.

The side and curtain air bag

may deploy when the ignition is

ON, and the rollover sensor

detects the situation as a

rollover.

ODEP061237L

What to do in an emergency

39 6

Page 553 of 684

711

Maintenance

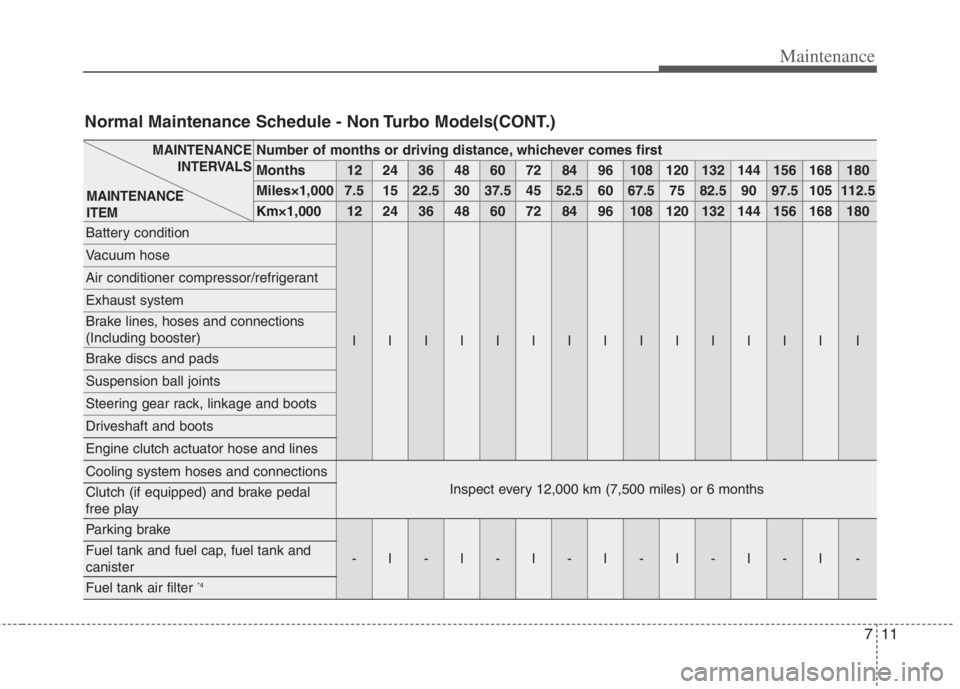

Number of months or driving distance, whichever comes first

Months1224364860728496108120132144156168180

Miles×1,0007.51522.530 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5

Km×1,00012 24 36 48 60 72 84 96 108 120 132 144 156 168 180

Battery condition

IIIIIIIIIIIIIII

Vacuum hose

Air conditioner compressor/refrigerant

Exhaust system

Brake lines, hoses and connections

(Including booster)

Brake discs and pads

Suspension ball joints

Steering gear rack, linkage and boots

Driveshaft and boots

Engine clutch actuator hose and lines

Cooling system hoses and connections

Inspect every 12,000 km (7,500 miles) or 6 monthsClutch (if equipped) and brake pedal

free play

Parking brake

-I-I-I-I-I-I-I-Fuel tank and fuel cap, fuel tank and

canister

Fuel tank air filter *4

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

Normal Maintenance Schedule - Non Turbo Models(CONT.)

Page 555 of 684

713

Maintenance

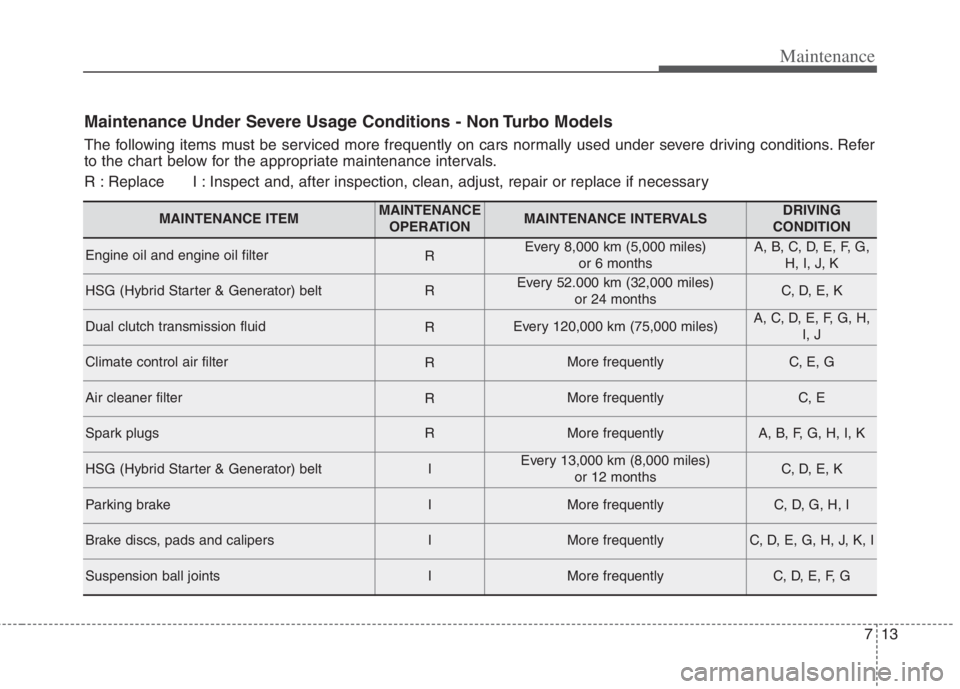

Maintenance Under Severe Usage Conditions - Non Turbo Models

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer

to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

MAINTENANCE ITEMMAINTENANCE

OPERATIONMAINTENANCE INTERVALSDRIVING

CONDITION

Engine oil and engine oil filterREvery 8,000 km (5,000 miles)

or 6 monthsA, B, C, D, E, F, G,

H, I, J, K

HSG (Hybrid Starter & Generator) beltREvery 52.000 km (32,000 miles)

or 24 monthsC, D, E, K

Dual clutch transmission fluidREvery 120,000 km (75,000 miles)A, C, D, E, F, G, H,

I, J

Climate control air filterRMore frequentlyC, E, G

Air cleaner filterRMore frequentlyC, E

Spark plugsRMore frequentlyA, B, F, G, H, I, K

HSG (Hybrid Starter & Generator) beltIEvery 13,000 km (8,000 miles)

or 12 monthsC, D, E, K

Parking brakeIMore frequentlyC, D, G, H, I

Brake discs, pads and calipersIMore frequentlyC, D, E, G, H, J, K, I

Suspension ball jointsIMore frequentlyC, D, E, F, G

Page 560 of 684

Maintenance

18 7

Exhaust pipe and muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine

off, check for excessive free-play in

the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or

damage. Replace any damaged

parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.When checking engine oil, engine

coolant, brake fluid, and washer fluid,

always be sure to clean the area

around any filler plug, drain plug, or

dipstick before checking or draining

any lubricant or fluid. This is espe-

cially important in dusty or sandy

areas and when the vehicle is used

on unpaved roads. Cleaning the plug

and dipstick areas will prevent dirt

and grit from entering the engine and

other mechanisms that could be

damaged.

CHECKING FLUID LEVELS

Page 650 of 684

Maintenance

108 7

Bright-metal maintenance

To remove road tar and insects,

use a tar remover, not a scraper or

other sharp object.

To protect the surfaces of bright-

metal parts from corrosion, apply a

coating of wax or chrome preser-

vative and rub to a high luster.

During winter weather or in coastal

areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

Underbody maintenance

Road salt and other corrosive chemi-

cals are used in cold weather states to

melt snow and prevent ice accumula-

tion. If these chemicals are not regu-

larly removed, they will corrode the

vehicle underbody and over time dam-

age fuel lines, the fuel tank retention

system, the vehicle suspension, the

exhaust system, and even the body

frame.

Wash the undercarriage of your

vehicle regularly during the winter

and whenever your vehicle has

been exposed to such salts or

chemicals.

Do a thorough washing of the

undercarriage at the end of the

winter.

Use professional service techni-

cians or governmental inspection

stations to annually inspect for cor-

rosion. Immediately seek an inspection of

your vehicle if you become visually

aware of corrosion flaking or scal-

ing or if you become aware of a

change in vehicle performance,

such as soft or spongey brakes,

fluids leaking, impairment of direc-

tional control, suspension noises

or rattling metal straps.