KIA Optima 2006 2.G Owner's Manual

Manufacturer: KIA, Model Year: 2006, Model line: Optima, Model: KIA Optima 2006 2.GPages: 225, PDF Size: 3.77 MB

Page 211 of 225

7-35

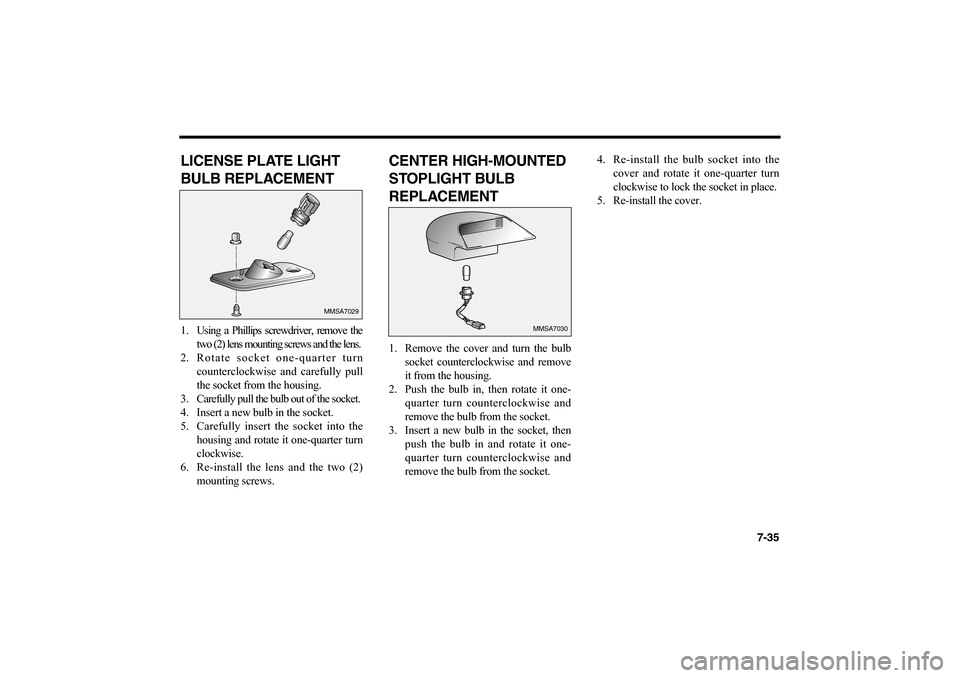

LICENSE PLATE LIGHT

BULB REPLACEMENT1. Using a Phillips screwdriver, remove the

two (2) lens mounting screws and the lens.

2. Rotate socket one-quarter turn

counterclockwise and carefully pull

the socket from the housing.

3. Carefully pull the bulb out of the socket.

4. Insert a new bulb in the socket.

5. Carefully insert the socket into the

housing and rotate it one-quarter turn

clockwise.

6. Re-install the lens and the two (2)

mounting screws.

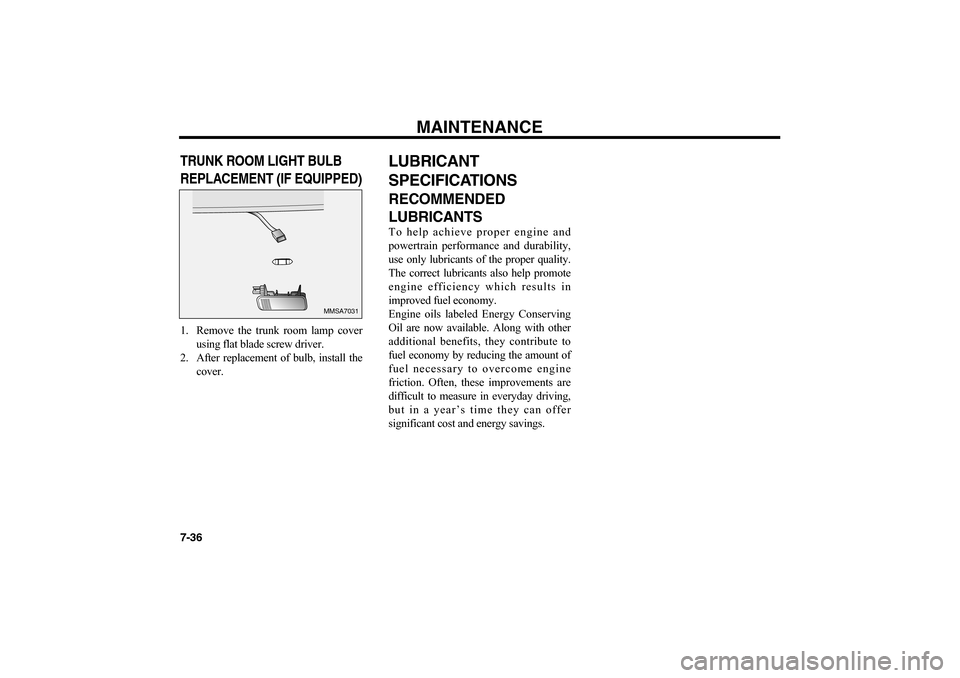

CENTER HIGH-MOUNTED

STOPLIGHT BULB

REPLACEMENT1. Remove the cover and turn the bulb

socket counterclockwise and remove

it from the housing.

2. Push the bulb in, then rotate it one-

quarter turn counterclockwise and

remove the bulb from the socket.

3. Insert a new bulb in the socket, then

push the bulb in and rotate it one-

quarter turn counterclockwise and

remove the bulb from the socket.4. Re-install the bulb socket into the

cover and rotate it one-quarter turn

clockwise to lock the socket in place.

5. Re-install the cover.

MMSA7029

MMSA7030

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 35

Page 212 of 225

MAINTENANCE

7-36TRUNK ROOM LIGHT BULB

REPLACEMENT (IF EQUIPPED)1. Remove the trunk room lamp cover

using flat blade screw driver.

2. After replacement of bulb, install the

cover.

LUBRICANT

SPECIFICATIONSRECOMMENDED

LUBRICANTSTo help achieve proper engine and

powertrain performance and durability,

use only lubricants of the proper quality.

The correct lubricants also help promote

engine efficiency which results in

improved fuel economy.

Engine oils labeled Energy Conserving

Oil are now available. Along with other

additional benefits, they contribute to

fuel economy by reducing the amount of

fuel necessary to overcome engine

friction. Often, these improvements are

difficult to measure in everyday driving,

but in a year’s time they can offer

significant cost and energy savings.

MMSA7031

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 36

Page 213 of 225

7-37

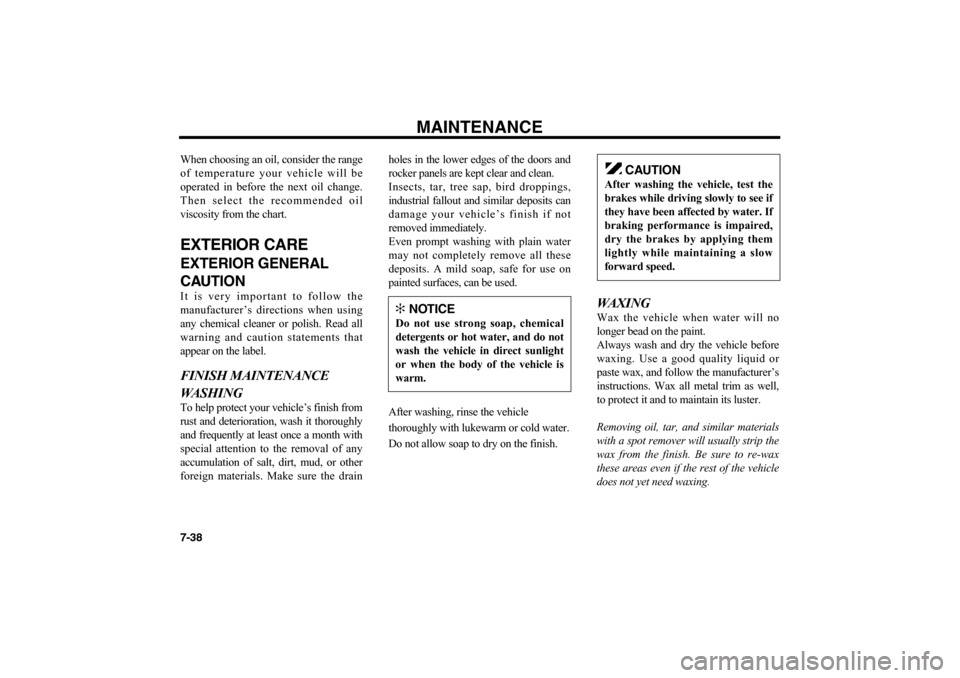

RECOMMENDED SAE

VISCOSITY NUMBEREngine oil viscosity (thickness) has an

effect on fuel economy and cold weather

operation (starting and oil flow). Lower

viscosity engine oils can provide better fuel

economy and cold weather performance,

however, higher viscosity engine oils are

required for satisfactory lubrication in hot

weather. Using oils of any viscosity other

than those recommended could result in

engine damage.

These lubricants and fluids are recommended for use in your vehicle.*1)

Refer to the recommended SAE viscosity numbers on the this page.

* Recommended for the Canadian climate.

Lubricant Classification

Engine oil* API Service SJ, SL or above,

ILSAC GF-3 or above

Manual transaxle oil* API Service GL-4 (SAE 75W-85)

Automatic trasaxle fluid SK ATF SP-III or Diamond ATF SP-III

Power steering fluid PSF-IV

Brake/clutch fluid SAEJ1703 or FMVSS116 DOT-3 DOT-4

✻

NOTICE

Always be sure to clean the area

around any filler plug, drain plug,

or dipstick before checking or

draining any lubricant. This is

especially important in dusty or

sandy areas and when the vehicle is

used on unpaved roads. Cleaning

the plug and dipstick areas will

prevent dirt and grit from entering

the engine and other mechanisms

that could be damaged.

Temperature Range for SAE Viscosity Numbers

Temperature

Gasoline

Engine Oil°C

(°F)

-30 -20 -10 0 10 20 30 40 50

-10 0 20 40 60 80 100 120

10W-30

5W-20, 5W-30

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 37

Page 214 of 225

MAINTENANCE

7-38When choosing an oil, consider the range

of temperature your vehicle will be

operated in before the next oil change.

Then select the recommended oil

viscosity from the chart.EXTERIOR CAREEXTERIOR GENERAL

CAUTIONIt is very important to follow the

manufacturer’s directions when using

any chemical cleaner or polish. Read all

warning and caution statements that

appear on the label.FINISH MAINTENANCE

WASHINGTo help protect your vehicle’s finish from

rust and deterioration, wash it thoroughly

and frequently at least once a month with

special attention to the removal of any

accumulation of salt, dirt, mud, or other

foreign materials. Make sure the drainholes in the lower edges of the doors and

rocker panels are kept clear and clean.

Insects, tar, tree sap, bird droppings,

industrial fallout and similar deposits can

damage your vehicle’s finish if not

removed immediately.

Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, can be used.

After washing, rinse the vehicle

thoroughly with lukewarm or cold water.

Do not allow soap to dry on the finish.

WAXINGWax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim as well,

to protect it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.

✻

NOTICE

Do not use strong soap, chemical

detergents or hot water, and do not

wash the vehicle in direct sunlight

or when the body of the vehicle is

warm.

CAUTION

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow

forward speed.

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 38

Page 215 of 225

7-39

FINISH DAMAGE REPAIRDeep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly

rust and may develop into a major repair

expense.

BRIGHT-METAL MAINTENANCE• To remove road tar and insects, use a

tar remover, not a scraper or other

sharp object.

• To protect the surfaces of bright-

metal parts from corrosion, apply a

coating of wax or chrome

preservative and rub to a high luster.

• During winter weather or in coastal

areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

UNDERBODY

MAINTENANCECorrosive materials used for ice and

snow removal or dust control may

collect on the underbody. If these

materials are not removed, accelerated

rusting can occur on underbody parts,

such as the fuel lines, frame, floor pan

and exhaust system, even though they

have been treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month and especially

at the end of each winter. Pay special

attention to these areas because it is

difficult to see all the mud and dirt. The

lower edges of doors, rocker panels, and

frame members have drain holes that

should not be allowed to clog with dirt;

trapped water in these areas can cause

rusting. It will do more harm than good

to wet down the road grime without

removing it.

✻

NOTICE

• Wiping dust or dirt off the body

with a dry cloth will scratch the

inish.

• Do not use steel wool, abrasive

cleaners, or strong detergents

containing highly alkaline or

caustic agents on chrome-plated

or anodized aluminum parts.

This may result in damage to the

protective coating and cause

discoloration or paint

deterioration.

✻

NOTICE

If your vehicle is damaged and

requires any metal repair or

replacement, be sure the body shop

applies anti-corrosion materials to

the parts repaired or replaced.

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 39

Page 216 of 225

MAINTENANCE

7-40ALUMINUM WHEEL

MAINTENANCEThe aluminum wheels are coated with a

clear protective finish.

• Do not use any abrasive cleaner,

polishing compound, solvent, or wire

brushes on aluminum wheels. They

may scratch or damage the finish.

• Use only a mild soap or neutral

detergent, and rinse thoroughly with

water. Also, be sure to clean the

wheels after driving on salted roads.

This helps prevent corrosion.

• Avoid washing the wheels with high-

speed car wash brushes.

INTERIOR CAREINTERIOR GENERAL

PRECAUTIONSPrevent caustic solutions such as

perfume and cosmetic oil from

contacting the dashboard; they may

cause damage or discoloration. If they do

contact the dashboard, wipe them off

immediately.UPHOLSTERY AND

INTERIOR TRIM CLEANINGVINYLFirst, remove dust and loose dirt from

vinyl with a whisk broom or vacuum

cleaner. Then, clean vinyl surfaces with a

vinyl cleaner.

FABRICFirst, remove dust and loose dirt from

fabric with a whisk broom or vacuum

cleaner. Then, clean with a mild soap

solution recommended for upholstery or

carpets. Remove fresh spots immediately

with a fabric spot cleaner. If a fresh spot

do not receive immediate attention, the

fabric may be stained and its color can be

affected. Also, its fire-resistant properties

may be reduced if the material is not

properly maintained.

CAUTION

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water.

CAUTION

Using anything but recommended

cleaners and procedures may affect

the fabric’s appearance and fire-

resistant properties.

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 40

Page 217 of 225

7-41

LAP/SHOULDER BELT

WEBBING CLEANINGClean the belt webbing with any mild

soap solution recommended for cleaning

upholstery or carpet. Follow the

instructions provided with the soap. Do

not bleach or re-dye the webbing

because this may weaken it.INTERIOR WINDOW

GLASS CLEANINGIf the interior glass surfaces of the

vehicle become fogged (that is, covered

with an oily, greasy or waxy film), they

should be cleaned with glass cleaner.

Follow the directions on the glass cleaner

container.

✻

NOTICE

Do not scrape or scratch the inside

of the rear window. This could

damage the rear window defroster

grid.

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 41

Page 218 of 225

MAINTENANCE

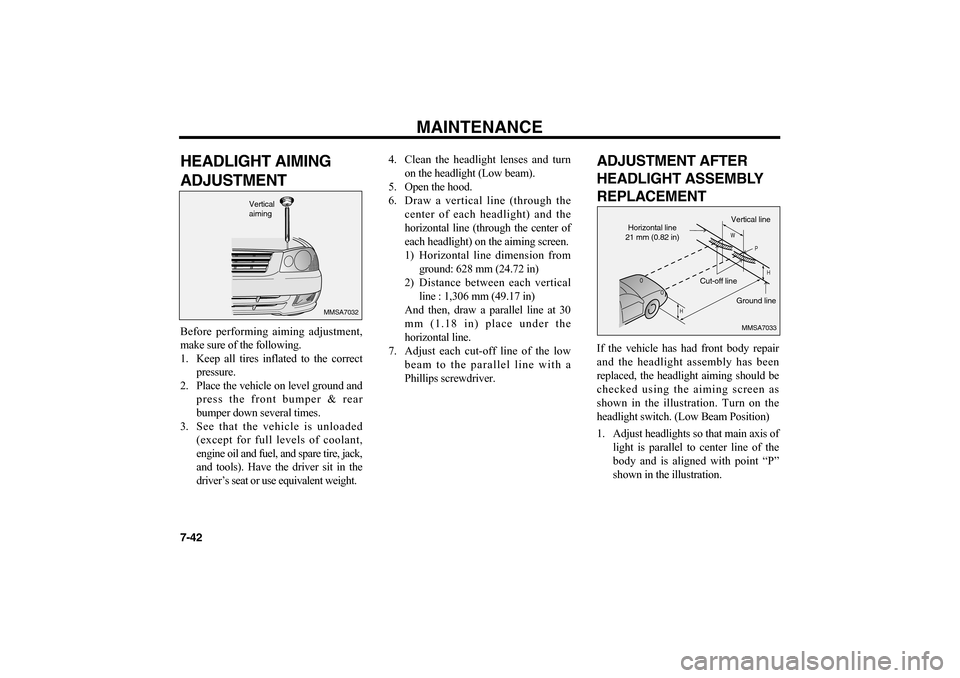

7-42HEADLIGHT AIMING

ADJUSTMENTBefore performing aiming adjustment,

make sure of the following.

1. Keep all tires inflated to the correct

pressure.

2. Place the vehicle on level ground and

press the front bumper & rear

bumper down several times.

3. See that the vehicle is unloaded

(except for full levels of coolant,

engine oil and fuel, and spare tire, jack,

and tools). Have the driver sit in the

driver’s seat or use equivalent weight.4. Clean the headlight lenses and turn

on the headlight (Low beam).

5. Open the hood.

6. Draw a vertical line (through the

center of each headlight) and the

horizontal line (through the center of

each headlight) on the aiming screen.

1) Horizontal line dimension from

ground: 628 mm (24.72 in)

2) Distance between each vertical

line : 1,306 mm (49.17 in)

And then, draw a parallel line at 30

mm (1.18 in) place under the

horizontal line.

7. Adjust each cut-off line of the low

beam to the parallel line with a

Phillips screwdriver.

ADJUSTMENT AFTER

HEADLIGHT ASSEMBLY

REPLACEMENTIf the vehicle has had front body repair

and the headlight assembly has been

replaced, the headlight aiming should be

checked using the aiming screen as

shown in the illustration. Turn on the

headlight switch. (Low Beam Position)

1. Adjust headlights so that main axis of

light is parallel to center line of the

body and is aligned with point “P”

shown in the illustration.

MMSA7032

Vertical

aiming

HH W

P

MMSA7033

Horizontal line

21 mm (0.82 in)

Cut-off line

Ground line Vertical line

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 42

Page 219 of 225

7-43

2. Dotted lines in the illustration show

center of headlights.

“H”;

Horizontal center line of headlights

from ground : 628 mm (24.72 in)

“W”;

Distance between each headlight

center: 1,306 mm (49.17 in)

“L”;

Distance between the headlights and

the wall that the lights are tested

against: 3,000 mm (118.11 in)

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 43

Page 220 of 225

8-1

SPECIFICATIONSSpecifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8

MS-CNA-Eng 8.QXD 7/25/2005 5:07 PM Page 1