tire pressure KIA OPTIMA 2020 Features and Functions Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2020, Model line: OPTIMA, Model: KIA OPTIMA 2020Pages: 591, PDF Size: 14.1 MB

Page 438 of 591

619

What to do in an emergency

Position the wrench as shown in the

drawing and tighten the wheel nuts.

Be sure the socket is seated com-

pletely over the nut. Do not stand on

the wrench handle or use an exten-

sion pipe over the wrench handle. Go

around the wheel, tightening every

nut following the numerical sequence

shown in the image until they are all

tight. Double-check each nut for

tightness. After changing wheels,

have an authorized Kia dealer tight-

en the wheel nuts to their proper

torque as soon as possible.

Wheel nut tightening torque:

79~94 lbf·ft (11~13 kgf·m)If you have a tire gauge, remove the

valve cap and check the air pressure.

If the pressure is lower than recom-

mended, drive slowly to the nearest

service station and inflate to the cor-

rect pressure. If it is too high, adjust

it until it is correct. Always reinstall

the valve cap after checking or

adjusting the tire pressure. If the cap

is not replaced, dust and dirt may get

into the tire valve and air may leak

from the tire. If you lose a valve cap,

buy another and install it as soon as

possible.

After you have changed the wheels,

always secure the flat tire in its place

and return the jack and tools to their

proper storage locations.

Note that most lug nuts do not have

metric threads. Be sure to use

extreme care in checking for thread

style before installing aftermarket lug

nuts or wheels. If in doubt, consult an

authorized Kia dealer.

CAUTION- Reusing lug

nuts

Make certain during wheelremoval that the same nuts thatwere removed are reinstalled -or, if replaced, that nuts withmetric threads and the samechamfer configuration are used.Your vehicle has metric threadson the wheel studs and nuts.Installation of a non-metricthread nut on a metric stud willnot secure the wheel to the hubproperly and will damage thestud so that it must be replaced.

OJF065009

JFa PE USA 6.qxp 5/15/2019 3:18 PM Page 19

Page 439 of 591

What to do in an emergency

20

6

To prevent the jack, wheel lug nut

wrench and spare tire from rattling

while the vehicle is in motion, store

them properly.

Check the inflation pressures as

soon as possible after installing the

spare tire. Adjust it to the specified

pressure, if necessary. Refer to

“Tires and wheels” in section 8.

Important - use of compact spare

tire

Your vehicle is equipped with a com-

pact spare tire. This compact spare

tire takes up less space than a regu-

lar-size tire. This tire is smaller than a

conventional tire and is designed for

temporary use only.

You should drive carefully when the compact spare is in use. The

compact spare should be replaced

by the proper conventional tire and

rim at the first opportunity.

The operation of this vehicle is not recommended with more than one

compact spare tire in use at the

same time. The compact spare should be inflat-

ed to 60 psi (420 kPa).

✽ ✽

NOTICE

Check the inflation pressure after

installing the spare tire. Adjust it to

the specified pressure, as necessary.

WARNING- Spare tire

The compact spare tire is for

emergency use only. Do not

operate your vehicle on this

compact spare at speeds over

50 mph (80 km/h). The original

tire should be repaired or

replaced as soon as possible to

avoid failure of the spare possi-

bly leading to personal injury or

death.WARNING- Wheel studs

If the studs are damaged, they

may lose their ability to retain

the wheel. This could lead to the

loss of the wheel and a collision

resulting in serious injuries.

JFa PE USA 6.qxp 5/15/2019 3:18 PM Page 20

Page 443 of 591

What to do in an emergency

24

6

Introduction

With the Tire Mobility Kit (TMK) you

stay mobile even after experiencing a

tire puncture.

The system compressor and sealing

compound effectively seal most

punctures in a passenger car tire

caused by nails or similar objects and

reinflates the tire.

After you ensure that the tire is prop-

erly sealed, you can drive cautiously

on the tire at a max. speed of 50 mph

(80 km/h) in order to reach a vehicle

or tire dealer to have the tire replaced.

WARNING- Temporary fix

Have your tire repaired as soon

as possible. The tire may lose

air pres-sure at any time after

inflating with the Tire Mobility

Kit.WARNING- Tire wall

Do not use the Tire Mobility Kit

to repair large punctures or

damage to the tire sidewalls. In

these situations, the tire cannot

be sealed completely and airwill

leak from the tire. This can

result in tire failure.

CAUTION

When repairing a flat tire with the Tire Mobility Kit (TMK),quickly remove the sealant onthe tire pressure sensor andwheel. When installing therepaired tire and wheel, tightenthe wheel nut to a torque valueof 24~28 ft.lb.

OJF068010

JFa PE USA 6.qxp 5/15/2019 3:18 PM Page 24

Page 444 of 591

625

What to do in an emergency

It is possible that some tires, espe-

cially with larger punctures or dam-

age to the sidewall, cannot be sealed

completely.

Air pressure loss in the tire may

adversely affect tire performance.

For this reason, you should avoid

abrupt steering or other driving

maneuvers, especially if the vehicle is

heavily loaded or if a trailer is in use.

The Tire Mobility Kit is not designed

or intended as a permanent tire

repair method and is to be used for

one tire only.

This instruction shows you step by

step how to temporarily seal the

puncture.

Read the section "Notes on the safe

use of the Tire Mobility Kit".Notes on the safe use of the

Tire Mobility Kit

Park your car at the side of theroad so that you can work with the

Tire Mobility Kit away from moving

traffic.

To be sure your vehicle will not move, even when you're on fairly

level ground, always set your park-

ing brake.

Only use the Tire Mobility Kit for sealing/inflation passenger car

tires. Only punctured areas located

within the tread region of the tire

can be sealed using the Tire

Mobility Kit.

Do not use on motorcycles, bicy- cles or any other type of tires.

When the tire and wheel are dam- aged, do not use Tire Mobility Kit

for your safety. Use of the Tire Mobility Kit may not

be effective for tire damage larger

than approximately 0.24 in (6 mm).

Please contact the nearest Kia

dealership if the tire cannot be

made roadworthy with the Tire

Mobility Kit.

Do not remove any foreign objects such as nails or screws that have

penetrated the tire.

Provided the car is outdoors, leave the engine running. Otherwise

operating the compressor may

eventually drain the car battery.

Never leave the Tire Mobility Kit unattended while it is being used.

Do not leave the compressor run- ning for more than 10 min. at a time

or it may overheat.

Do not use the Tire Mobility Kit if the ambient temperature is below -22°F

(-30°C).

JFa PE USA 6.qxp 5/15/2019 3:18 PM Page 25

Page 446 of 591

627

What to do in an emergency

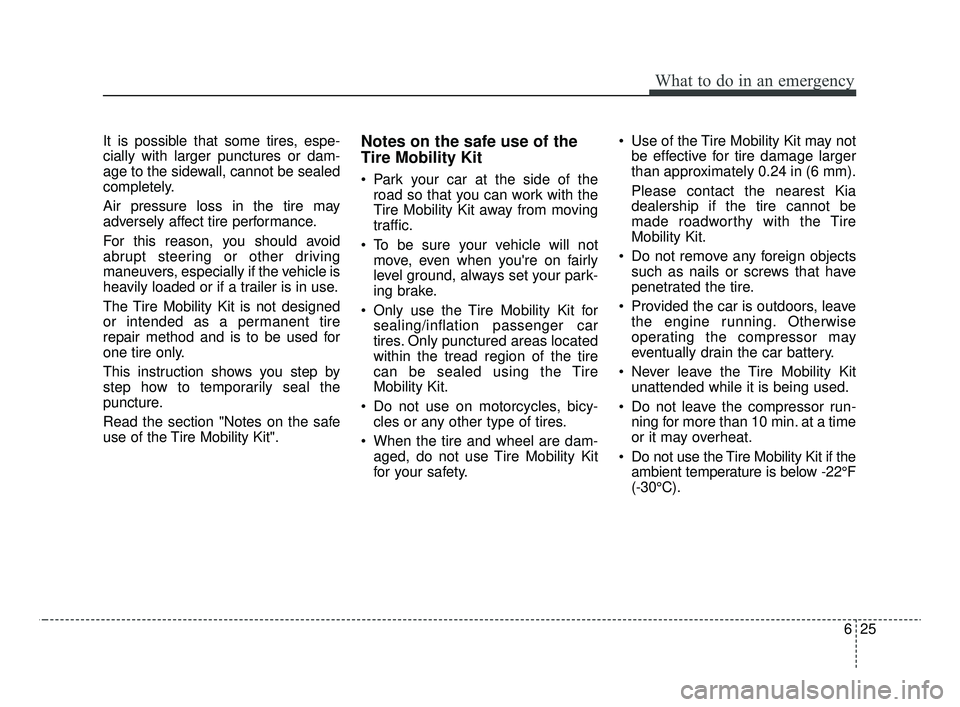

1. Speed restriction label

2. Sealant bottle and label withspeed restriction

3. Filling hose from sealant bottle to wheel 4. Connectors and cable for the

power outlet direct connection

5. Holder for the sealant bottle

6. Compressor

7. On/off switch 8. Pressure gauge for displaying the

tire inflation pressure

9. Button for reducing tire inflation pressure

Connectors and cable are stored in

the compressor housing.

✽ ✽ NOTICE

The sealant container and insert

hose (3) cannot be reused.

ODE067044

Components of the Tire Mobility Kit (TMK)

WARNING - Sealant

Keep out of reach of children.

Avoid contact with eyes.

Do not swallow.

WARNING - Expired sealant

Do not use the Tire sealant after

the sealant has expired (i.e.

after the expiration date on the

sealant container). This can

increase the risk of tire failure.

JFa PE USA 6.qxp 5/15/2019 3:18 PM Page 27

Page 447 of 591

What to do in an emergency

28

6

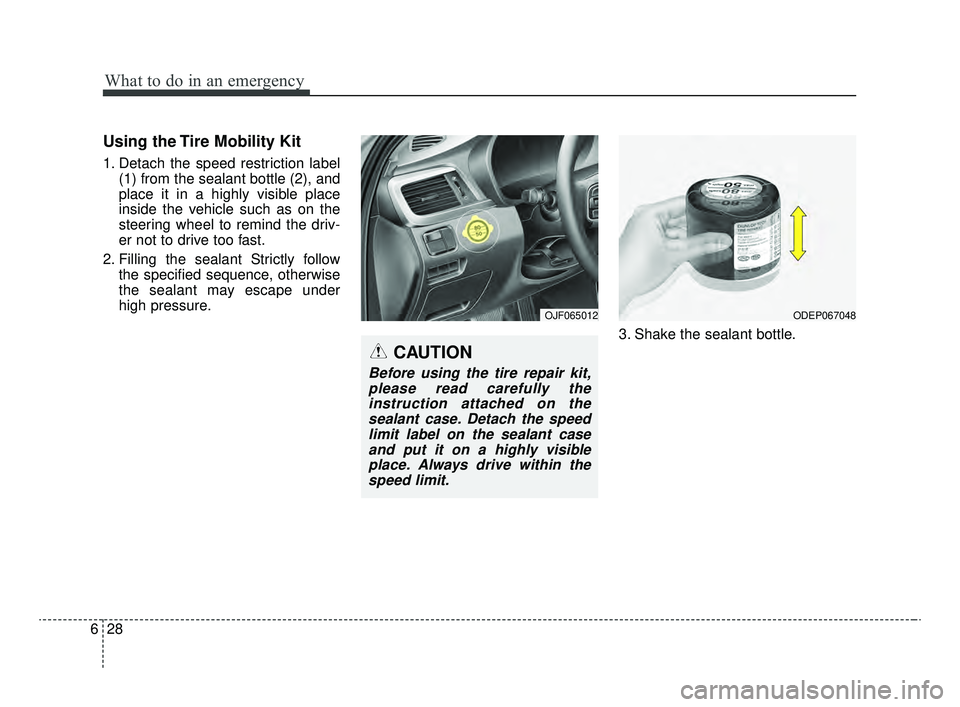

Using the Tire Mobility Kit

1. Detach the speed restriction label

(1) from the sealant bottle (2), and

place it in a highly visible place

inside the vehicle such as on the

steering wheel to remind the driv-

er not to drive too fast.

2. Filling the sealant Strictly follow the specified sequence, otherwise

the sealant may escape under

high pressure.

3. Shake the sealant bottle.

OJF065012ODEP067048

CAUTION

Before using the tire repair kit,please read carefully theinstruction attached on thesealant case. Detach the speedlimit label on the sealant caseand put it on a highly visibleplace. Always drive within thespeed limit.

JFa PE USA 6.qxp 5/15/2019 3:18 PM Page 28

Page 449 of 591

What to do in an emergency

30

6

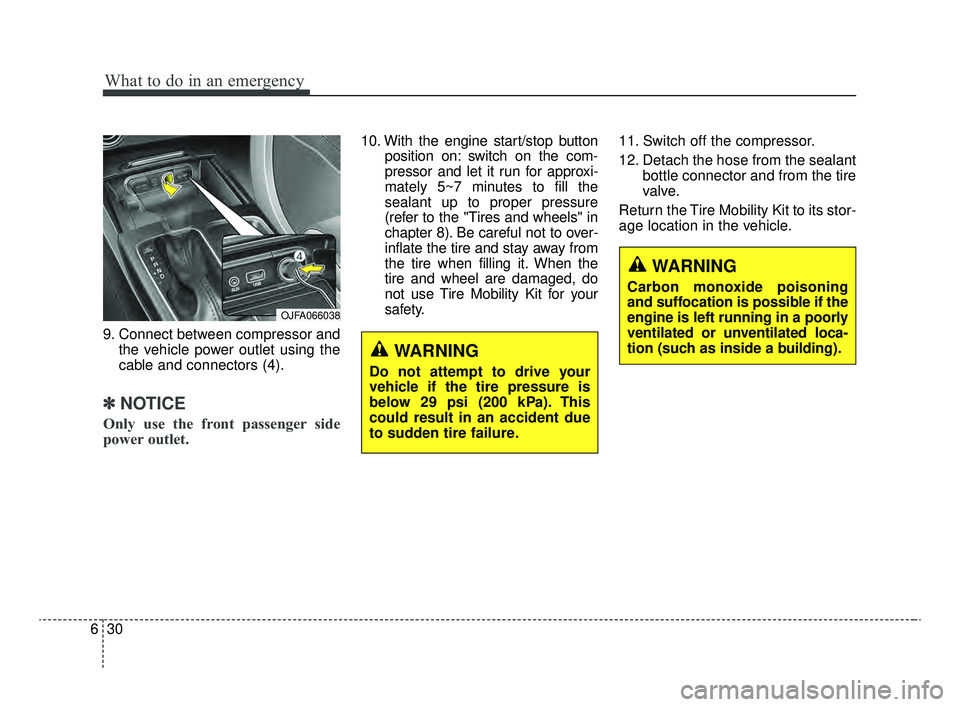

9. Connect between compressor and

the vehicle power outlet using the

cable and connectors (4).

✽ ✽NOTICE

Only use the front passenger side

power outlet.

10. With the engine start/stop button

position on: switch on the com-

pressor and let it run for approxi-

mately 5~7 minutes to fill the

sealant up to proper pressure

(refer to the "Tires and wheels" in

chapter 8). Be careful not to over-

inflate the tire and stay away from

the tire when filling it. When the

tire and wheel are damaged, do

not use Tire Mobility Kit for your

safety. 11. Switch off the compressor.

12. Detach the hose from the sealant

bottle connector and from the tire

valve.

Return the Tire Mobility Kit to its stor-

age location in the vehicle.

OJFA066038

WARNING

Do not attempt to drive your

vehicle if the tire pressure is

below 29 psi (200 kPa). This

could result in an accident due

to sudden tire failure.

WARNING

Carbon monoxide poisoning

and suffocation is possible if the

engine is left running in a poorly

ventilated or unventilated loca-

tion (such as inside a building).

JFa PE USA 6.qxp 5/15/2019 3:18 PM Page 30

Page 450 of 591

631

What to do in an emergency

Distributing the sealant

13. Immediately drive approximately4~6 miles (7~10 km or, about 10

min) to evenly distribute the

sealant in the tire.

When you use the Tire Mobility Kit,

the tire pressure sensors and wheel

may be stained by sealant. Therefore,

remove the tire pressure sensors and

wheel stained by sealant and have

your vehicle inspected by an author-

ized Kia dealer.

Checking the tire inflation

pressure

1.After driving approximately 4~6 miles (7~10 km or about 10 min-

utes), stop at a suitable location.

2.Connect the filling hose (3) of the compressor (clip mounted side)

directly and then connect the filling

hose (3) (opposite side) to the tire

valve.

3.Connect between compressor and the vehicle power outlet using the

cable and connectors.

4.Adjust the tire inflation pressure to 29 psi (200 kPa). With the ignition

switched on, proceed as follows.

- To increase the inflation pres-sure: Switch on the compressor,

position I. To check the current

inflation pressure setting, briefly

switch off the compressor. - To reduce the inflation pres-

sure: Press the button (9) on the

compressor.

CAUTION - Tire pressure

sensor

When you use the Tire MobilityKit including sealant notapproved by Kia, the tire pres-sure sensors may be damagedby sealant. The sealant on thetire pressure sensor and wheelshould be removed when youreplace the tire with a new oneand inspect the tire pressuresensors at an authorized dealer.

WARNING

Do not let the compressor run

for more than 10 minutes, other-

wise the device will overheat

and may be damaged.

JFa PE USA 6.qxp 5/15/2019 3:18 PM Page 31

Page 451 of 591

What to do in an emergency

32

6

Technical Data

System voltage: DC 12 V

Working voltage: DC 10 - 15 V

Amperage rating: max. 15 A ± 1A (at

DC 12V operation)

Suitable for use at temperatures: -22 ~ +158°F (-30 ~ +70°C)

Max. working pressure: 87 psi (6 bar)

Size

Compressor: 6.3 x 5.9 x 2.2 in. (161 x 150 x 55.8 mm)

Sealant bottle: 4.1 x 3.3 ø in. (104 x 85 ø mm)

Compressor weight: 1.77 lbs ± 0.07 lbs (805g ± 30g)

Sealant volume: 18.3 cu. in. (300 ml) ❈

Sealant and spare parts can be

obtained and replaced at an

authorized vehicle or tire dealer.

Empty sealant bottles may be dis-

posed of at home. Liquid residue

from the sealant should be dis-

posed of by your vehicle or tire

dealer or in accordance with local

waste disposal regulations.

JFa PE USA 6.qxp 5/15/2019 3:18 PM Page 32

Page 455 of 591

Climate control air filter . . . . . . . . . . . . . . . . . . . . 7-36

• Filter inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Wiper blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

• Blade inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

• Blade replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-\

42

• For best battery service . . . . . . . . . . . . . . . . . . . . . . . 7-42

• Recharging the battery . . . . . . . . . . . . . . . . . . . . . . . . 7-43

• Reset items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44\

Tires and wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

• Tire care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

7-45

• Recommended cold tire inflation pressures . . . . . . . 7-45

• Tire pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

• Checking tire inflation pressure. . . . . . . . . . . . . . . . . 7-46

• Tire rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-47

• Wheel alignment and tire balance . . . . . . . . . . . . . . . 7-48

• Tire replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

• Wheel replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

• Tire traction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

• Tire maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

• Tire sidewall labeling . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

• All season tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-57

• Summer tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-57

• Snow tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-\

57

• Tire chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-58\

• Radial-ply tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-58

• Low aspect ratio tire . . . . . . . . . . . . . . . . . . . . . . . . . . 7-59

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

7-60

• Inner panel fuse replacement . . . . . . . . . . . . . . . . . . . 7-62

• Engine compartment fuse replacement. . . . . . . . . . . 7-64

• Fuse/relay panel description. . . . . . . . . . . . . . . . . . . . 7-66

Light bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-76

• Bulb replacement precaution . . . . . . . . . . . . . . . . . . . 7-76

• Light bulb position (Front). . . . . . . . . . . . . . . . . . . . . 7-78

• Light bulb position (Rear) . . . . . . . . . . . . . . . . . . . . . 7-79

• Light bulb position (Side) . . . . . . . . . . . . . . . . . . . . . . 7-80

• Headlamp (Low beam) bulb replacement

(Headlamp Type A) . . . . . . . . . . . . . . . . . . . . . . . . . . 7-80

• Headlamp (High beam) bulb replacement (Headlamp Type A) . . . . . . . . . . . . . . . . . . . . . . . . . . 7-81

• Front turn signal lamp bulb replacement (Headlamp Type A) . . . . . . . . . . . . . . . . . . . . . . . . . . 7-82

• Headlamp (Low/High beam) (LED type) bulb replacement (Headlamp Type B) . . . . . . . . . . 7-82

• Position lamp / Day time running lamp (LED type) replacement (Headlamp Type A, B) . . . . . . . . . . . . 7-83

• Front fog lamp bulb replacement . . . . . . . . . . . . . . . 7-83

• Side repeater lamp (LED type) bulb replacement . . 7-84

• Rear turn signal lamp bulb replacement . . . . . . . . . 7-84

• Stop and tail lamp bulb replacement . . . . . . . . . . . . 7-85

7

JFa PE USA 7.qxp 5/15/2019 3:12 PM Page 2