coolant KIA OPTIMA 2020 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2020, Model line: OPTIMA, Model: KIA OPTIMA 2020Pages: 589, PDF Size: 11.37 MB

Page 481 of 589

715

Maintenance

Vacuum crankcase ventilation

hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold.

Inspect the hose routing to assure

that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component which

might cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

Air cleaner filter

A Genuine Kia air cleaner filter is

recommended when the filter is

replaced.

Spark plugs

Make sure to install new spark plugs

of the correct heat range.

Cooling system

Check the cooling system compo-

nents, such as the radiator, coolant

reservoir, hoses and connections for

leakage and damage. Replace any

damaged parts.

Coolant (Engine / Inverter)

The coolant should be changed at

the intervals specified in the mainte-

nance schedule.

Page 483 of 589

717

Maintenance

Exhaust pipe and muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine

off, check for excessive free-play in

the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or

damage. Replace any damaged

parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.When checking engine oil, engine

coolant, brake fluid, and washer fluid,

always be sure to clean the area

around any filler plug, drain plug, or

dipstick before checking or draining

any lubricant or fluid. This is espe-

cially important in dusty or sandy

areas and when the vehicle is used

on unpaved roads. Cleaning the plug

and dipstick areas will prevent dirt

and grit from entering the engine and

other mechanisms that could be

damaged.

CHECKING FLUID LEVELS

Page 487 of 589

721

Maintenance

COOLANT

The high-pressure cooling system

has a reservoir filled with year round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant level at least once a year: at

the beginning of the winter season,

and before traveling to a colder cli-

mate.Checking the coolant level Turn the engine off and wait until itcools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back while the

pressure is released from the cool-

ing system.

When you are sure all the pressure

has been released, press down on

the cap, using a thick towel, and

continue turning counterclockwise

to remove it.

Even if the engine is not operating, do not remove the radiator cap or

the drain plug while the engine and

radiator are hot. Hot coolant and

steam may still blow out under

pressure, causing serious injury.

The engine coolant and/or inverter

coolant level is influenced by the

hybrid system temperature. Before

checking or refilling the engine

coolant and/or inverter coolant,

turn the hybrid vehicle off.

WARNING

Removing radiator

cap

Never attempt to remove the

radiator cap while the engine is

operating or hot. Doing so

might lead to cooling system

and engine damage and could

result in serious personal injury

from escaping hot coolant or

steam.

CAUTION - Radiator cap

Never attempt to remove theradiator cap while the engine isoperating or hot. Doing somight lead to cooling systemand engine damage.

Page 488 of 589

Maintenance

22

7

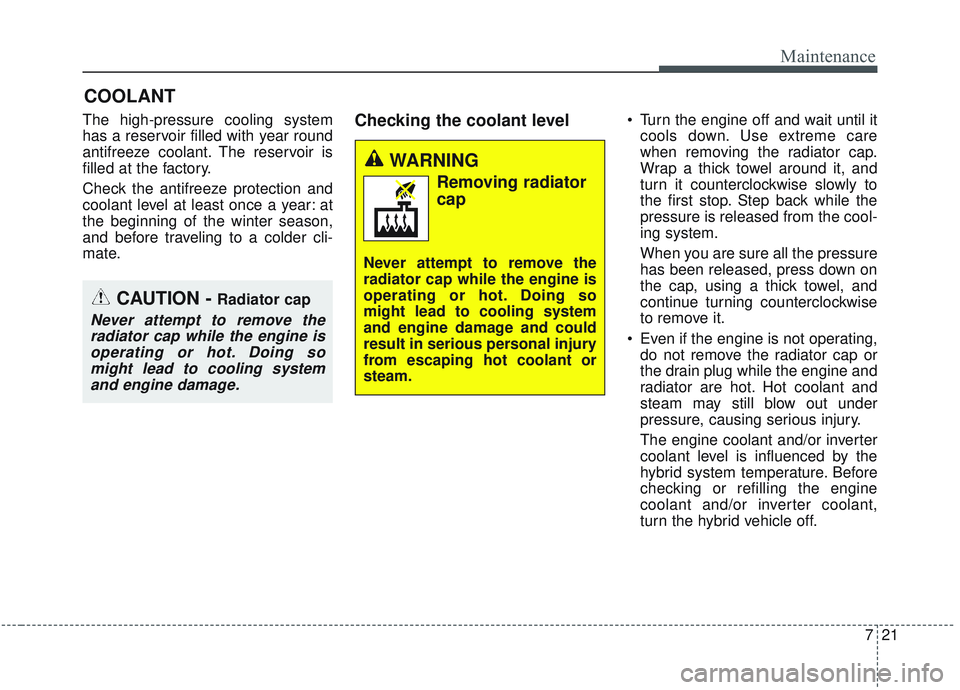

Engine coolant

Check the condition and connections

of all cooling system hoses and

heater hoses. Replace any swollen

or deteriorated hoses.

The coolant level should be filled

between F and L marks on the side

of the coolant reservoir when the

engine is cool.

If the coolant level is low, add enough

specified coolant to provide protec-

tion against freezing and corrosion.

Bring the level to F, but do not over-

fill. If frequent additions are required,

see an authorized Kia dealer for a

cooling system inspection.

Inverter coolant

The coolant level should be filled

between MAX and MIN marks on the

side of the coolant reservoir when

the engine is cool.

If the coolant level is low, add enough

specified coolant to provide protec-

tion against freezing and corrosion.

Bring the level to MAX, but do not

overfill. If frequent additions are

required, see an authorized Kia deal-

er for a cooling system inspection.

OJF075006OJFH075186L

WARNING- Cooling fan

Use caution when

working near the

blade of the cooling

fan. The electric

motor (cooling fan) is

controlled by engine coolant

temperature, refrigerant pres-

sure and vehicle speed. it may

sometimes operate even when

the engine is not running.

Page 489 of 589

723

Maintenance

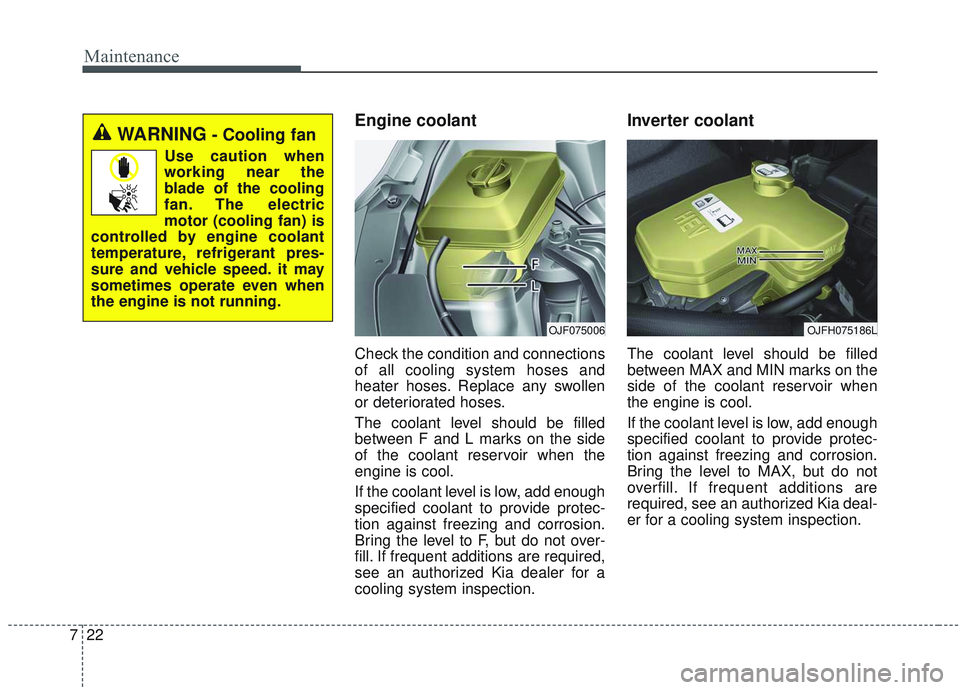

Recommended coolant

When adding coolant, use onlydeionized water or soft water for

your vehicle and never mix hard

water in the coolant filled at the fac-

tory. An improper coolant mixture

can result in serious malfunction or

engine damage.

The engine in your vehicle has alu- minum engine parts and must be

protected by an ethylene-glycol

with phosphate based coolant to

prevent corrosion and freezing.

DO NOT USE alcohol or methanol coolant or mix them with the spec-

ified coolant.

Do not use a solution that contains more than 60% antifreeze or less

than 35% antifreeze. This would

reduce the effectiveness of the

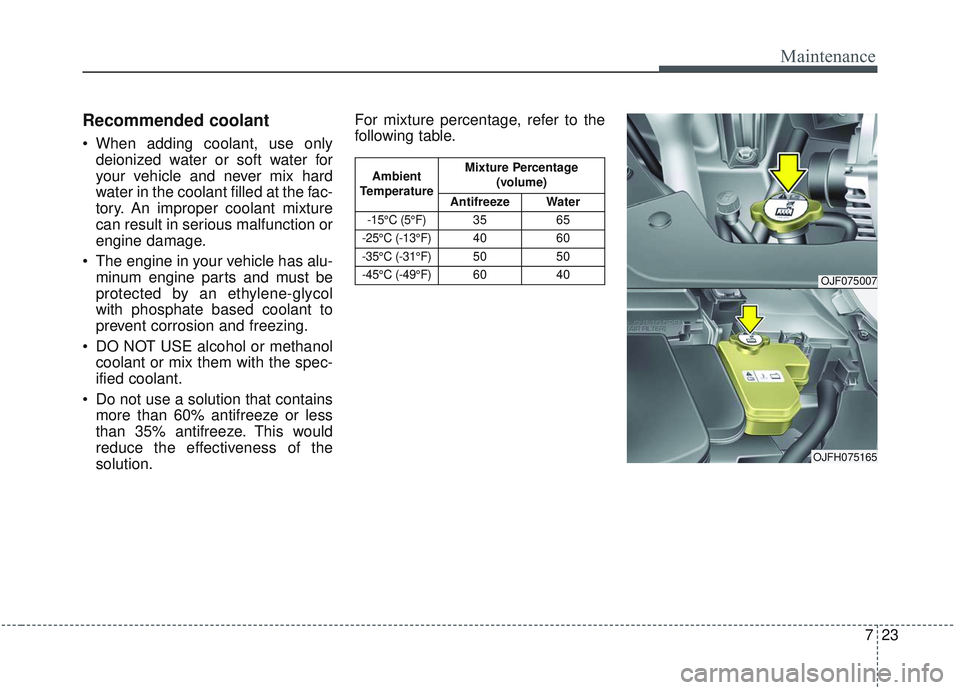

solution. For mixture percentage, refer to the

following table.

Ambient

Temperature Mixture Percentage

(volume)

Antifreeze Water

-15°C (5°F)35 65

-25°C (-13°F)4060

-35°C (-31°F)5050

-45°C (-49°F)6040OJF075007

OJFH075165

Page 490 of 589

Maintenance

24

7

Changing the coolant

Have the coolant changed by an

authorized Kia dealer according to

the Maintenance Schedule at the

beginning of this chapter.

CAUTION

Put a thick cloth or fabric

around the radiator cap beforerefilling the coolant in order toprevent the coolant from over-flowing into engine parts suchas the generator.

WARNING

Radiator cap

Do not remove the radiator cap

when the engine and radiator

are hot. Scalding hot coolant

and steam may blow out under

pressure which may result in

serious injury.

Page 492 of 589

Maintenance

26

7

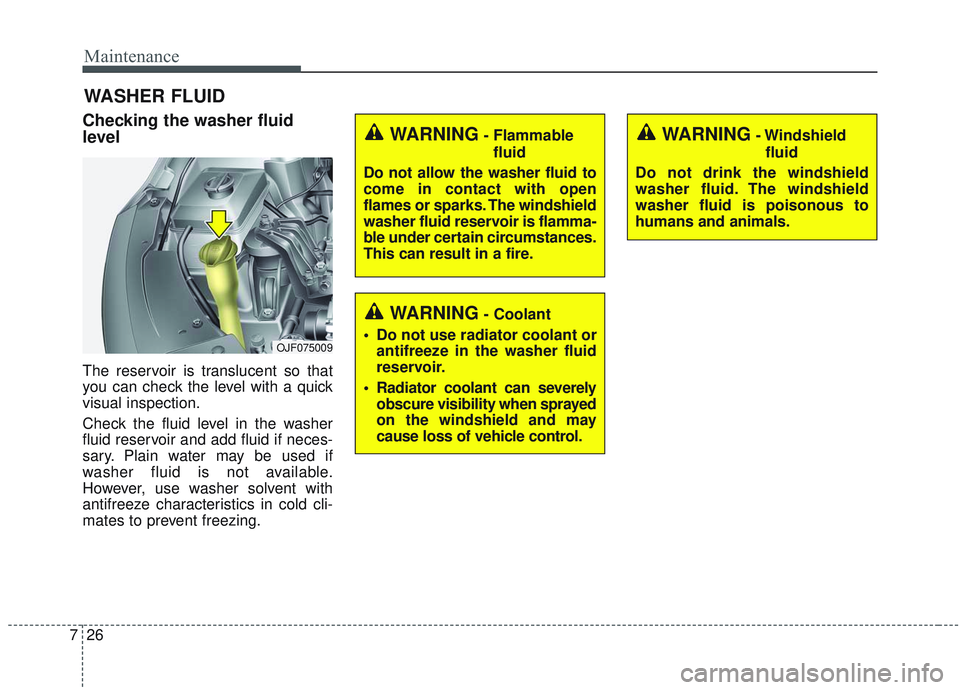

WASHER FLUID

Checking the washer fluid

level

The reservoir is translucent so that

you can check the level with a quick

visual inspection.

Check the fluid level in the washer

fluid reservoir and add fluid if neces-

sary. Plain water may be used if

washer fluid is not available.

However, use washer solvent with

antifreeze characteristics in cold cli-

mates to prevent freezing.

WARNING- Flammable

fluid

Do not allow the washer fluid to

come in contact with open

flames or sparks. The windshield

washer fluid reservoir is flamma-

ble under certain circumstances.

This can result in a fire.WARNING- Windshield fluid

Do not drink the windshield

washer fluid. The windshield

washer fluid is poisonous to

humans and animals.

WARNING- Coolant

Do not use radiator coolant or antifreeze in the washer fluid

reservoir.

Radiator coolant can severely obscure visibility when sprayed

on the windshield and may

cause loss of vehicle control.

OJF075009

Page 514 of 589

Maintenance

48

7

Temperature -A, B & C

The temperature grades are A (the

highest), B and C representing the

tire’s resistance to the generation of

heat and its ability to dissipate heat

when tested under controlled condi-

tions on a specified indoor laboratory

test wheel.

Sustained high temperature can

cause the material of the tire to

degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure. Grades B and A

represent higher levels of perform-

ance on the laboratory test wheel

than the minimum required by law. Tire terminology and definitions

Air Pressure:

The amount of air

inside the tire pressing outward on

the tire. Air pressure is expressed in

kilopascal (kPa) or pounds per

square inch (psi).

Accessory Weight: This means the

combined weight of optional acces-

sories. Some examples of optional

accessories are, automatic transmis-

sion, power seats, and air condition-

ing.

Aspect Ratio: The relationship of a

tire's height to its width.

Belt: A rubber coated layer of cords

that is located between the plies and

the tread. Cords may be made from

steel or other reinforcing materials.

Bead: The tire bead contains steel

wires wrapped by steel cords that

hold the tire onto the rim.

Bias Ply Tire: A pneumatic tire in

which the plies are laid at alternate

angles less than 90 degrees to the

centerline of the tread. Cold Tire Pressure:

The amount of

air pressure in a tire, measured in

kilopascals (kPa) or pounds per

square inch (psi) before a tire has

built up heat from driving.

Curb Weight: This means the weight

of a motor vehicle with standard and

optional equipment including the

maximum capacity of fuel, oil and

coolant, but without passengers and

cargo.

DOT Markings: The DOT code

includes the Tire Identification

Number (TIN), an alphanumeric des-

ignator which can also identify the

tire manufacturer, production plant,

brand and date of production.

Page 566 of 589

Maintenance

100

7

Canister

Fuel vapors generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in

the canister are drawn into the surge

tank through the purge control sole-

noid valve.

Purge Control Solenoid Valve

(PCSV)

The purge control solenoid valve is

controlled by the Engine Control

Module (ECM); when the engine

coolant temperature is low during

idling, the PCSV closes so that evap-

orated fuel is not taken into the

engine. After the engine warms up

during ordinary driving, the PCSV

opens to introduce evaporated fuel to

the engine.

3. Exhaust emission control system

The Exhaust Emission Control

System is a highly effective system

which controls exhaust emissions

while maintaining good vehicle per-

formance.

Engine exhaust gas precautions

(carbon monoxide)

Carbon monoxide can be present with other exhaust fumes.

Therefore, if you smell exhaust

fumes of any kind inside your vehi-

cle, have it inspected and repaired

immediately. If you ever suspect

exhaust fumes are coming into

your vehicle, drive it only with all

the windows fully open. Have your

vehicle checked and repaired

immediately.

WARNING - Exhaust

Engine exhaust gases contain

carbon monoxide (CO). Though

colorless and odorless, it is

dangerous and could be lethal if

inhaled. Follow the instructions

on this page to avoid CO poi-

soning.

Page 574 of 589

68

Specification & Consumer information

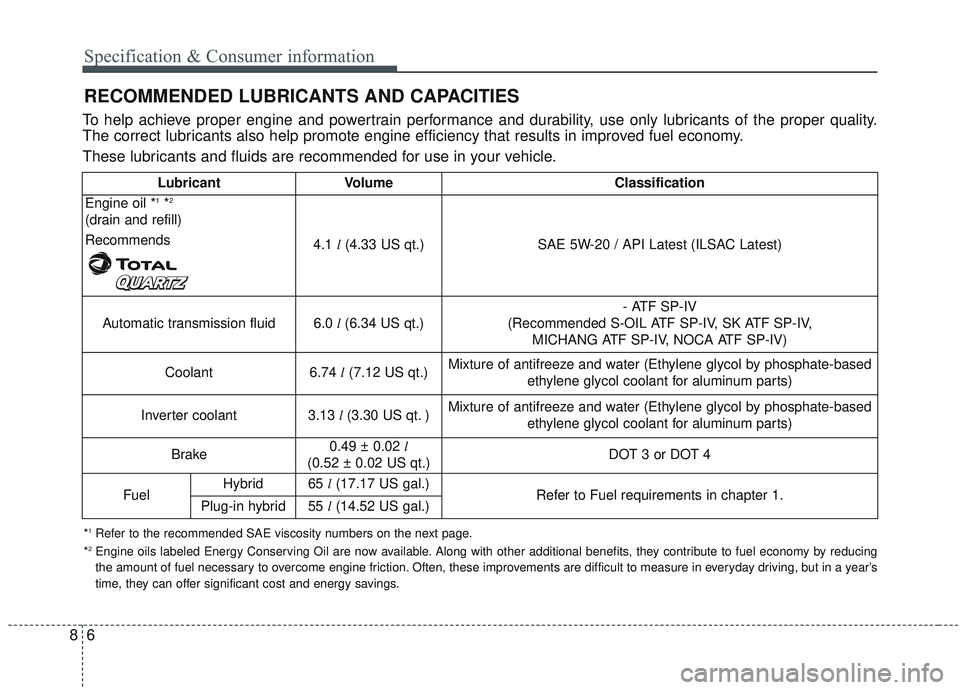

RECOMMENDED LUBRICANTS AND CAPACITIES

To help achieve proper engine and powertrain performance and durability, use only lubricants of the proper quality.

The correct lubricants also help promote engine efficiency that results in improved fuel economy.

These lubricants and fluids are recommended for use in your vehicle.

*1Refer to the recommended SAE viscosity numbers on the next page.

*2Engine oils labeled Energy Conserving Oil are now available. Along with other additional benefits, they contribute to fuel econo my by reducing

the amount of fuel necessary to overcome engine friction. Often, these improvements are difficult to measure in everyday driving, but in a year’s

time, they can offer significant cost and energy savings.

Lubricant VolumeClassification

Engine oil *1*2

(drain and refill)

Recommends

4.1 l(4.33 US qt.)SAE 5W-20 / API Latest (ILSAC Latest)

Automatic transmission fluid6.0 l (6.34 US qt.)

- ATF SP-IV

(Recommended S-OIL ATF SP-IV, SK ATF SP-IV, MICHANG ATF SP-IV, NOCA ATF SP-IV)

Coolant6.74 l(7.12 US qt.)Mixture of antifreeze and water (Ethylene glycol by phosphate-based

ethylene glycol coolant for aluminum parts)

Inverter coolant3.13 l (3.30 US qt. )Mixture of antifreeze and water (Ethylene glycol by phosphate-based

ethylene glycol coolant for aluminum parts)

Brake0.49 ± 0.02 l

(0.52 ± 0.02 US qt.)DOT 3 or DOT 4

FuelHybrid65 l(17.17 US gal.)Refer to Fuel requirements in chapter 1.Plug-in hybrid55 l(14.52 US gal.)