stop start KIA OPTIMA PHEV 2017 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2017, Model line: OPTIMA PHEV, Model: KIA OPTIMA PHEV 2017Pages: 604, PDF Size: 13.16 MB

Page 451 of 604

711

What to do in an emergency

✽

✽NOTICE

If the TPMS, Low Tire Pressure

indicator does not illuminate for 3

seconds when the ignition switch is

turned to the ON position or engine

is running, or if they remain illumi-

nated after coming on for approxi-

mately 3 seconds, take your vehicle

to your nearest authorized Kia deal-

er and have the system checked.

Low tire pressure

telltale

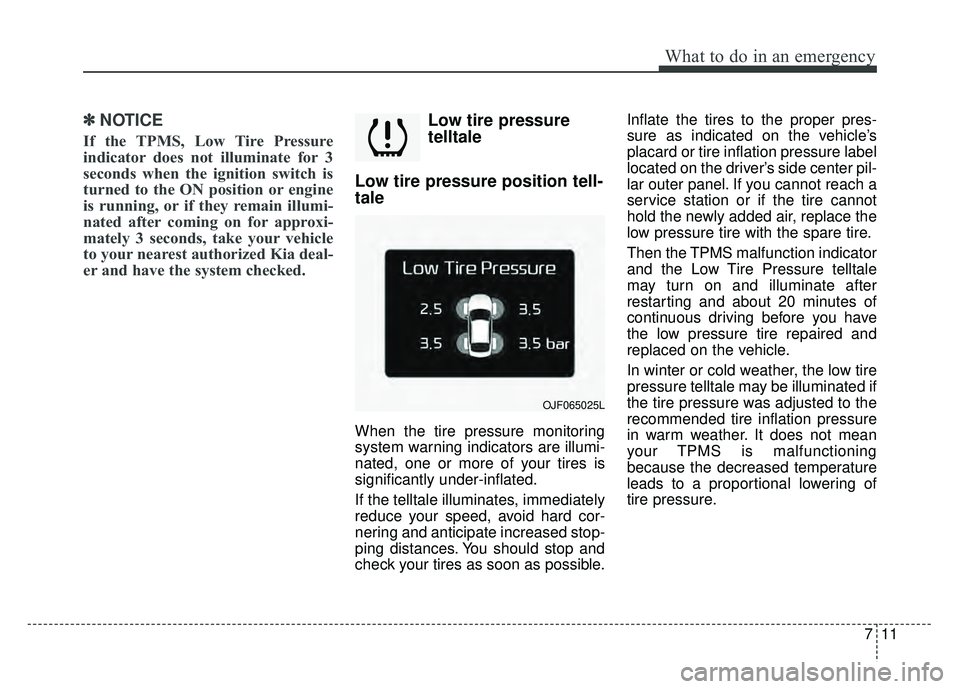

Low tire pressure position tell-

tale

When the tire pressure monitoring

system warning indicators are illumi-

nated, one or more of your tires is

significantly under-inflated.

If the telltale illuminates, immediately

reduce your speed, avoid hard cor-

nering and anticipate increased stop-

ping distances. You should stop and

check your tires as soon as possible. Inflate the tires to the proper pres-

sure as indicated on the vehicle’s

placard or tire inflation pressure label

located on the driver’s side center pil-

lar outer panel. If you cannot reach a

service station or if the tire cannot

hold the newly added air, replace the

low pressure tire with the spare tire.

Then the TPMS malfunction indicator

and the Low Tire Pressure telltale

may turn on and illuminate after

restarting and about 20 minutes of

continuous driving before you have

the low pressure tire repaired and

replaced on the vehicle.

In winter or cold weather, the low tire

pressure telltale may be illuminated if

the tire pressure was adjusted to the

recommended tire inflation pressure

in warm weather. It does not mean

your TPMS is malfunctioning

because the decreased temperature

leads to a proportional lowering of

tire pressure.

OJF065025L

Page 461 of 604

721

What to do in an emergency

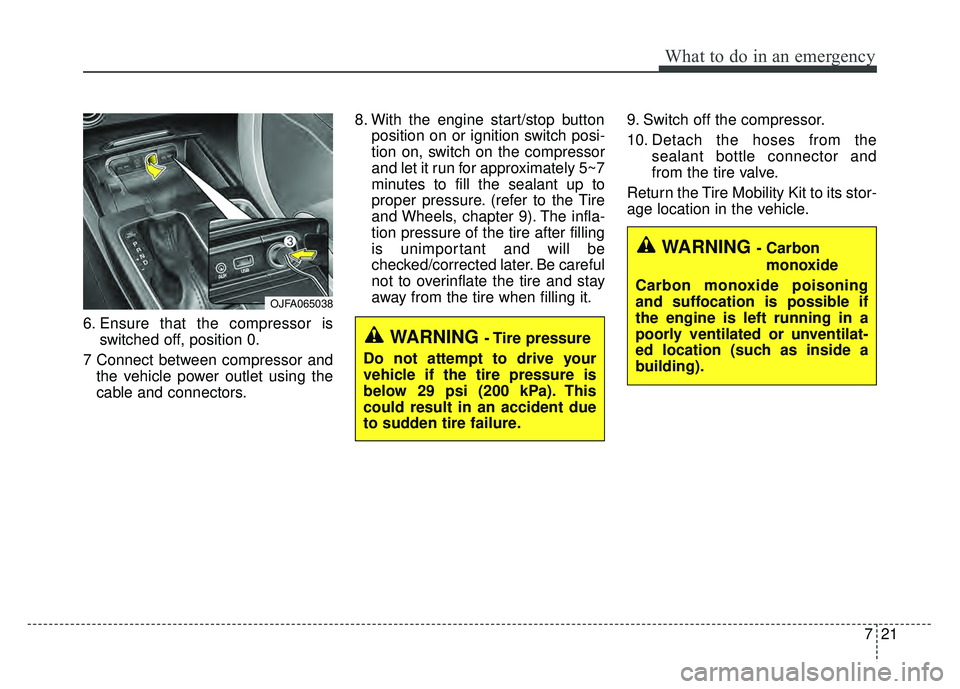

6. Ensure that the compressor isswitched off, position 0.

7 Connect between compressor and the vehicle power outlet using the

cable and connectors. 8. With the engine start/stop button

position on or ignition switch posi-

tion on, switch on the compressor

and let it run for approximately 5~7

minutes to fill the sealant up to

proper pressure. (refer to the Tire

and Wheels, chapter 9). The infla-

tion pressure of the tire after filling

is unimportant and will be

checked/corrected later. Be careful

not to overinflate the tire and stay

away from the tire when filling it. 9. Switch off the compressor.

10. Detach the hoses from the

sealant bottle connector and

from the tire valve.

Return the Tire Mobility Kit to its stor-

age location in the vehicle.

OJFA065038

WARNING - Carbon monoxide

Carbon monoxide poisoning

and suffocation is possible if

the engine is left running in a

poorly ventilated or unventilat-

ed location (such as inside a

building).

WARNING - Tire pressure

Do not attempt to drive your

vehicle if the tire pressure is

below 29 psi (200 kPa). This

could result in an accident due

to sudden tire failure.

Page 488 of 604

819

Maintenance

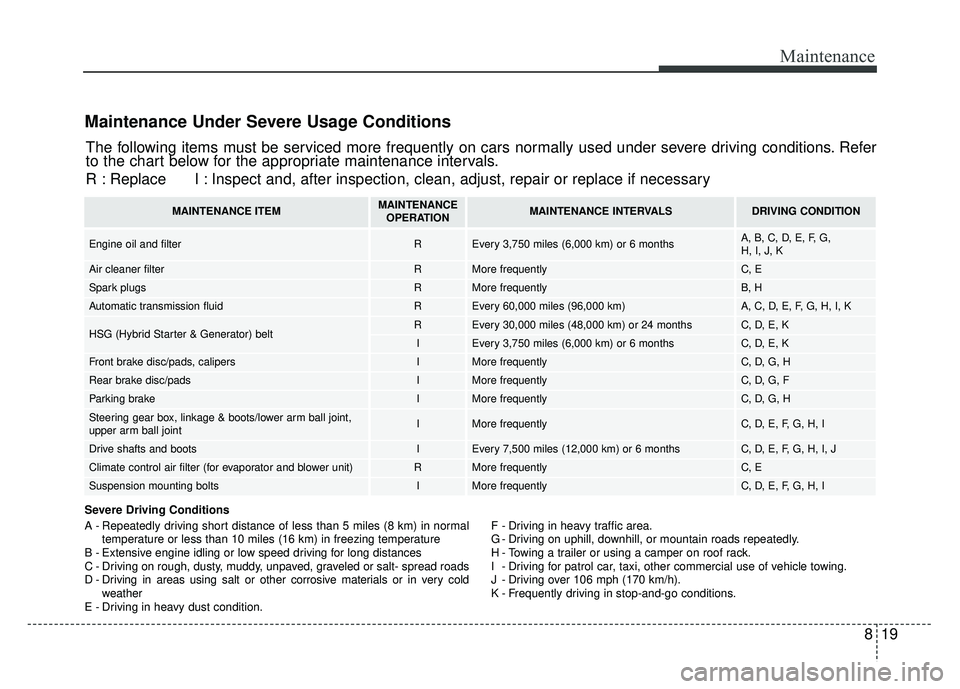

Maintenance Under Severe Usage Conditions

Severe Driving Conditions

A - Repeatedly driving short distance of less than 5 miles (8 km) in normaltemperature or less than 10 miles (16 km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

E - Driving in heavy dust condition. F - Driving in heavy traffic area.

G - Driving on uphill, downhill, or mountain roads repeatedly.

H - Towing a trailer or using a camper on roof rack.

I - Driving for patrol car, taxi, other commercial use of vehicle towing.

J - Driving over 106 mph (170 km/h).

K - Frequently driving in stop-and-go conditions.

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer

to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if neces\

sary

MAINTENANCE ITEMMAINTENANCE

OPERATIONMAINTENANCE INTERVALSDRIVING CONDITION

Engine oil and filter REvery 3,750 miles (6,000 km) or 6 monthsA, B, C, D, E, F, G,

H, I, J, K

Air cleaner filterRMore frequentlyC, E

Spark plugsRMore frequentlyB, H

Automatic transmission fluidREvery 60,000 miles (96,000 km)A, C, D, E, F, G, H, I, K

HSG (Hybrid Starter & Generator) beltREvery 30,000 miles (48,000 km) or 24 monthsC, D, E, K

IEvery 3,750 miles (6,000 km) or 6 monthsC, D, E, K

Front brake disc/pads, calipersIMore frequentlyC, D, G, H

Rear brake disc/padsIMore frequentlyC, D, G, F

Parking brakeIMore frequentlyC, D, G, H

Steering gear box, linkage & boots/lower arm ball joint,

upper arm ball jointIMore frequentlyC, D, E, F, G, H, I

Drive shafts and bootsIEvery 7,500 miles (12,000 km) or 6 monthsC, D, E, F, G, H, I, J

Climate control air filter (for evaporator and blower unit)RMore frequentlyC, E

Suspension mounting boltsIMore frequentlyC, D, E, F, G, H, I

Page 492 of 604

823

Maintenance

Brake fluid

Check the brake fluid level in the

brake fluid reservoir. The level should

be between “MIN” and “MAX” marks

on the side of the reservoir. Use only

hydraulic brake fluid conforming to

DOT 3 or DOT 4 specification.

Parking brake

Inspect the parking brake system

including the parking brake pedal

and cables.

Brake discs, pads, calipers

and rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

Exhaust pipe and muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine

off, check for excessive free-play in

the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or

damage. Replace any damaged

parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.

Page 495 of 604

Maintenance

26

8

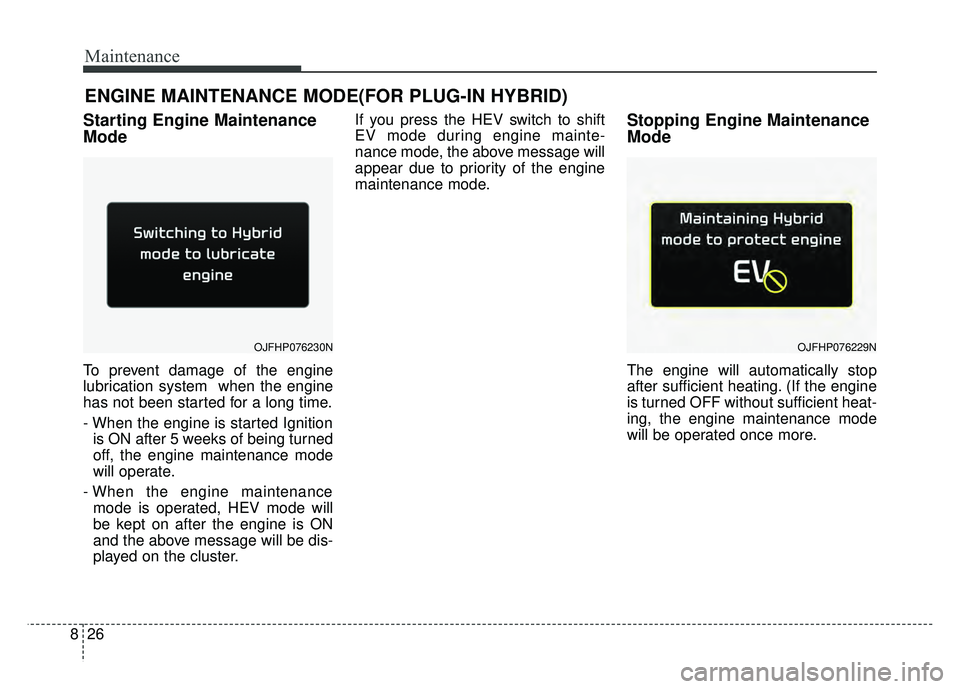

ENGINE MAINTENANCE MODE(FOR PLUG-IN HYBRID)

Starting Engine Maintenance

Mode

To prevent damage of the engine

lubrication system when the engine

has not been started for a long time.

- When the engine is started Ignition

is ON after 5 weeks of being turned

off, the engine maintenance mode

will operate.

- When the engine maintenance mode is operated, HEV mode will

be kept on after the engine is ON

and the above message will be dis-

played on the cluster. If you press the HEV switch to shift

EV mode during engine mainte-

nance mode, the above message will

appear due to priority of the engine

maintenance mode.

Stopping Engine Maintenance

Mode

The engine will automatically stop

after sufficient heating. (If the engine

is turned OFF without sufficient heat-

ing, the engine maintenance mode

will be operated once more.

OJFHP076230NOJFHP076229N

Page 509 of 604

Maintenance

40

8

4. Return the wiper arm on the wind-

shield.

5. Turn the engine start/stop button to the ON position and wiper arms

will return to the normal operating

position.

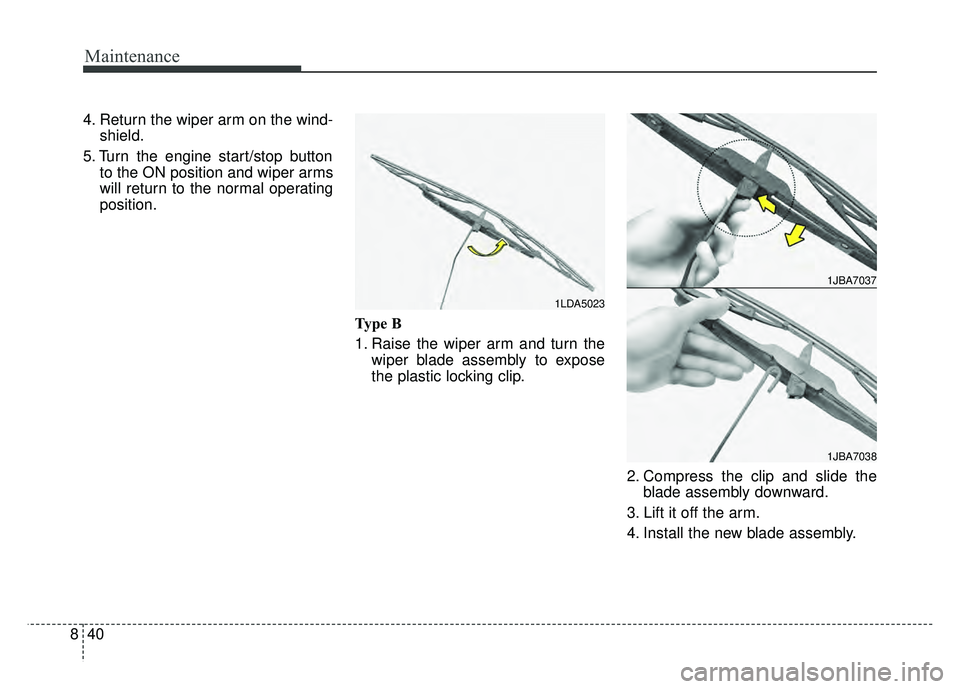

Type B

1. Raise the wiper arm and turn thewiper blade assembly to expose

the plastic locking clip.

2. Compress the clip and slide theblade assembly downward.

3. Lift it off the arm.

4. Install the new blade assembly.

1JBA7037

1JBA7038

1LDA5023

Page 510 of 604

841

Maintenance

5. Return the wiper arm on the wind-shield.

6. Turn the engine start/stop button to the ON position and wiper arms

will return to the normal operating

position.

Page 530 of 604

861

Maintenance

✽

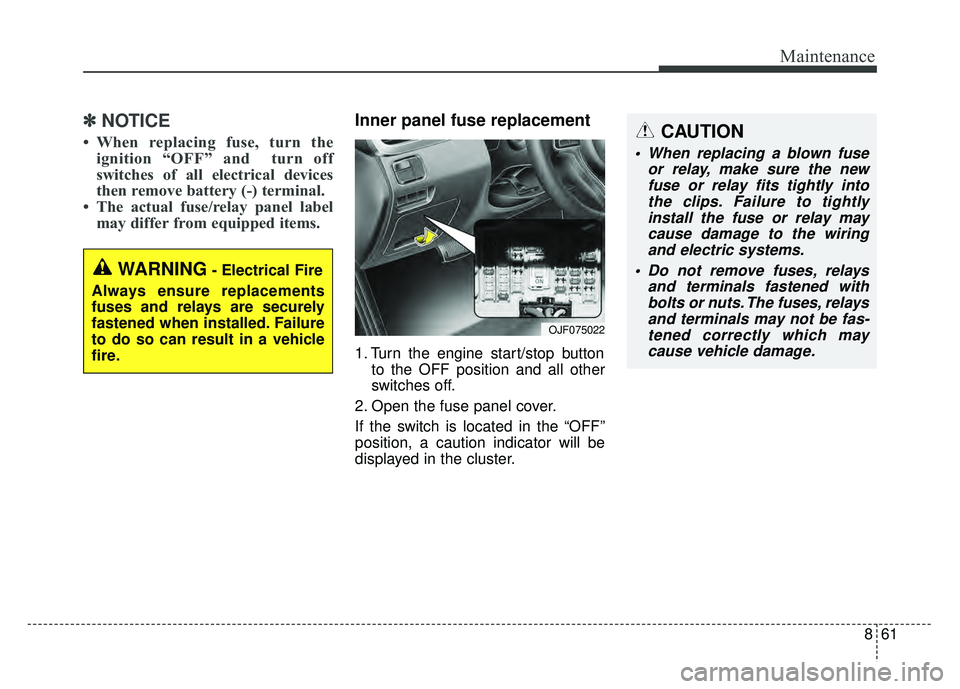

✽NOTICE

• When replacing fuse, turn the

ignition “OFF” and turn off

switches of all electrical devices

then remove battery (-) terminal.

• The actual fuse/relay panel label may differ from equipped items.

Inner panel fuse replacement

1. Turn the engine start/stop button

to the OFF position and all other

switches off.

2. Open the fuse panel cover.

If the switch is located in the “OFF”

position, a caution indicator will be

displayed in the cluster.

OJF075022

WARNING- Electrical Fire

Always ensure replacements

fuses and relays are securely

fastened when installed. Failure

to do so can result in a vehicle

fire.

CAUTION

When replacing a blown fuse or relay, make sure the newfuse or relay fits tightly intothe clips. Failure to tightlyinstall the fuse or relay maycause damage to the wiringand electric systems.

Do not remove fuses, relays and terminals fastened withbolts or nuts. The fuses, relaysand terminals may not be fas-tened correctly which maycause vehicle damage.

Page 532 of 604

863

Maintenance

Fuse switch

Always set the fuse switch to the ON

position before using the vehicle.

If you move the switch to the OFF

position, some items such as audio

and digital clock must be reset and

transmitter (or smart key) may not

work properly. When the switch is

Off, the caution indicator will be dis-

played on the instrument cluster.

Always place the fuse switch in the

ON position while driving the vehicle.

If the switch is located in the “OFF”

position, a caution indicator will be

displayed in the cluster.

Engine compartment fuse

replacement

1. Turn the engine start/stop buttonto the OFF position and all other

switches off.

2. Remove the fuse panel cover by pressing the tab and pulling the

cover up. When the blade type

fuse is disconnected, remove it by

using the clip designed for chang-

ing fuses located in the engine

compartment fuse box. Upon

removal, securely insert reserve

fuse of the same rating. 3. Check the removed fuse; replace it

if it is blown. To remove or insert

the fuse, use the fuse puller in the

engine compartment fuse panel.

4. Push in a new fuse of the same rating, and make sure it fits tightly

in the clips. If it fits loosely, consult

an authorized Kia dealer.

OJF075024

CAUTION

After checking the fuse panel inthe engine compartment,securely install the fuse panelcover through the audible click-ing sound.

If not, electrical failures mayoccur from water contact.

OJFH075025

Page 536 of 604

867

Maintenance

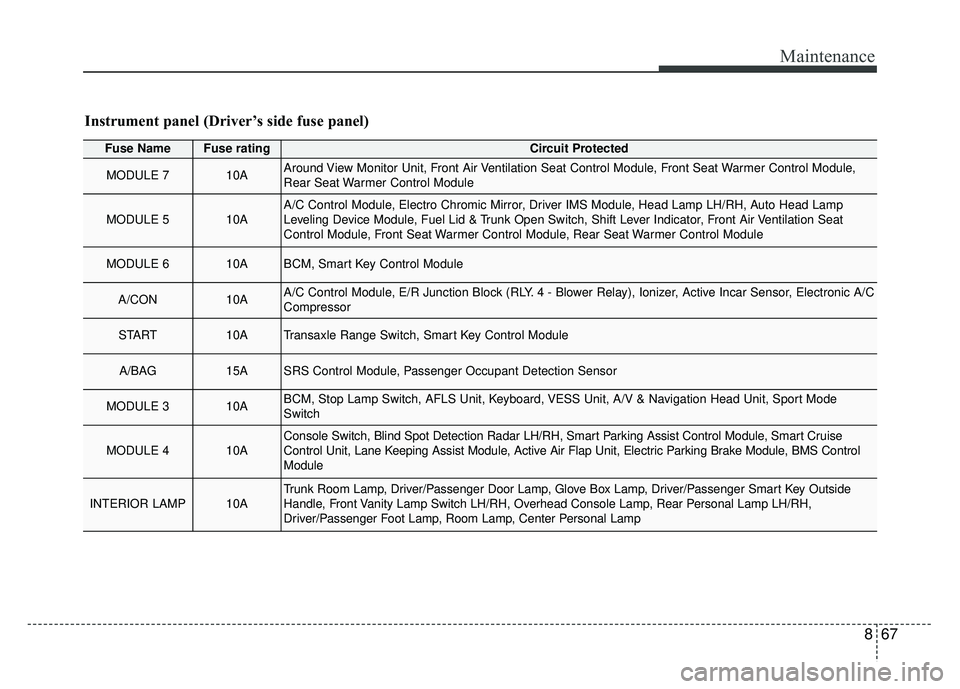

Instrument panel (Driver’s side fuse panel)

Fuse NameFuse ratingCircuit Protected

MODULE 710AAround View Monitor Unit, Front Air Ventilation Seat Control Module, Front Seat Warmer Control Module,

Rear Seat Warmer Control Module

MODULE 510AA/C Control Module, Electro Chromic Mirror, Driver IMS Module, Head Lamp LH/RH, Auto Head Lamp

Leveling Device Module, Fuel Lid & Trunk Open Switch, Shift Lever Indicator, Front Air Ventilation Seat

Control Module, Front Seat Warmer Control Module, Rear Seat Warmer Control Module

MODULE 610ABCM, Smart Key Control Module

A/CON10AA/C Control Module, E/R Junction Block (RLY. 4 - Blower Relay), Ionizer, Active Incar Sensor, Electronic A/C

Compressor

START10ATransaxle Range Switch, Smart Key Control Module

A/BAG15ASRS Control Module, Passenger Occupant Detection Sensor

MODULE 310ABCM, Stop Lamp Switch, AFLS Unit, Keyboard, VESS Unit, A/V & Navigation Head Unit, Sport Mode

Switch

MODULE 410AConsole Switch, Blind Spot Detection Radar LH/RH, Smart Parking Assist Control Module, Smart Cruise

Control Unit, Lane Keeping Assist Module, Active Air Flap Unit, Electric Parking Brake Module, BMS Control

Module

INTERIOR LAMP10ATrunk Room Lamp, Driver/Passenger Door Lamp, Glove Box Lamp, Driver/Passenger Smart Key Outside

Handle, Front Vanity Lamp Switch LH/RH, Overhead Console Lamp, Rear Personal Lamp LH/RH,

Driver/Passenger Foot Lamp, Room Lamp, Center Personal Lamp