KIA PICANTO 2006 Owners Manual

Manufacturer: KIA, Model Year: 2006, Model line: PICANTO, Model: KIA PICANTO 2006Pages: 281, PDF Size: 9.89 MB

Page 231 of 281

Maintenance

18

7

1 23456789

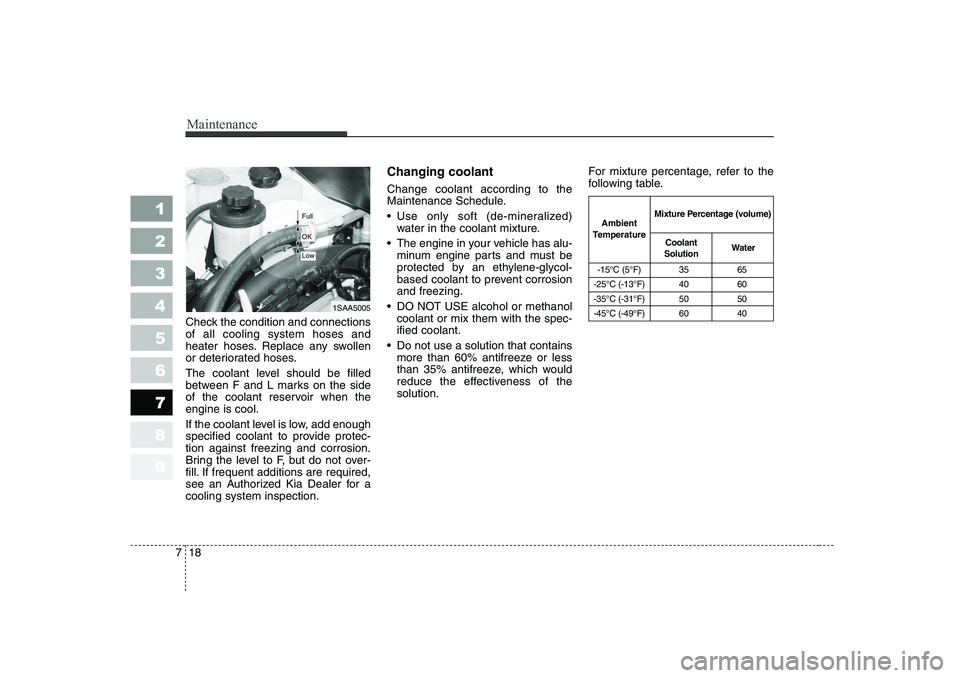

Check the condition and connections of all cooling system hoses and

heater hoses. Replace any swollen

or deteriorated hoses.

The coolant level should be filled

between F and L marks on the side

of the coolant reservoir when theengine is cool.

If the coolant level is low, add enough

specified coolant to provide protec-tion against freezing and corrosion.

Bring the level to F, but do not over-

fill. If frequent additions are required,

see an Authorized Kia Dealer for acooling system inspection. Changing coolant Change coolant according to the

Maintenance Schedule.

Use only soft (de-mineralized)

water in the coolant mixture.

The engine in your vehicle has alu- minum engine parts and must be

protected by an ethylene-glycol-

based coolant to prevent corrosionand freezing.

DO NOT USE alcohol or methanol coolant or mix them with the spec-ified coolant.

Do not use a solution that contains more than 60% antifreeze or less

than 35% antifreeze, which would

reduce the effectiveness of thesolution. For mixture percentage, refer to the

following table.

1SAA5005

-15°C (5°F) 35 65

-25°C (-13°F) 40 60

-35°C (-31°F) 50 50

-45°C (-49°F) 60 40

Ambient

Temperature Mixture Percentage (volume)

Coolant

Solution WaterFull

OK

Low

Page 232 of 281

719

Maintenance

1 23456789

1. Turn the radiator cap counter-clockwise to remove it.

2. Loosen the radiator drain plug and drain the coolant into a suitable

container.

3. With the plug loose, flush the sys- tem with running water.

4. Drain the system completely and retighten the drain plug. Add the

necessary amount of ethylene-gly-

col based coolant and water to

provide the required protection

against freezing and corrosion. In

extremely cold climates, add ethyl-ene-glycol based coolant in accor-

dance with the instructions of the

manufacturer. 5. Run the engine at idle with the

radiator cap off. Slowly add addi-

tional coolant as necessary.

6. At this point, wait until the engine reaches normal operating temper-

ature. Depress the accelerator two

or three times; then add coolant asrequired. Be careful not to burn

yourself.

7. Reinstall the radiator cap. Inspect all connections for leaks and

recheck the coolant level in the

reservoir. Recheck again after a

few days and add coolant as nec-

essary.

1SAA50061SAA5007

WARNING

Do not remove the radiator cap when the engine and radiator

are hot. Scalding hot coolant

and steam may blow out under

pressure. This could cause seri-

ous injury.

Page 233 of 281

Maintenance

20

7

1 23456789

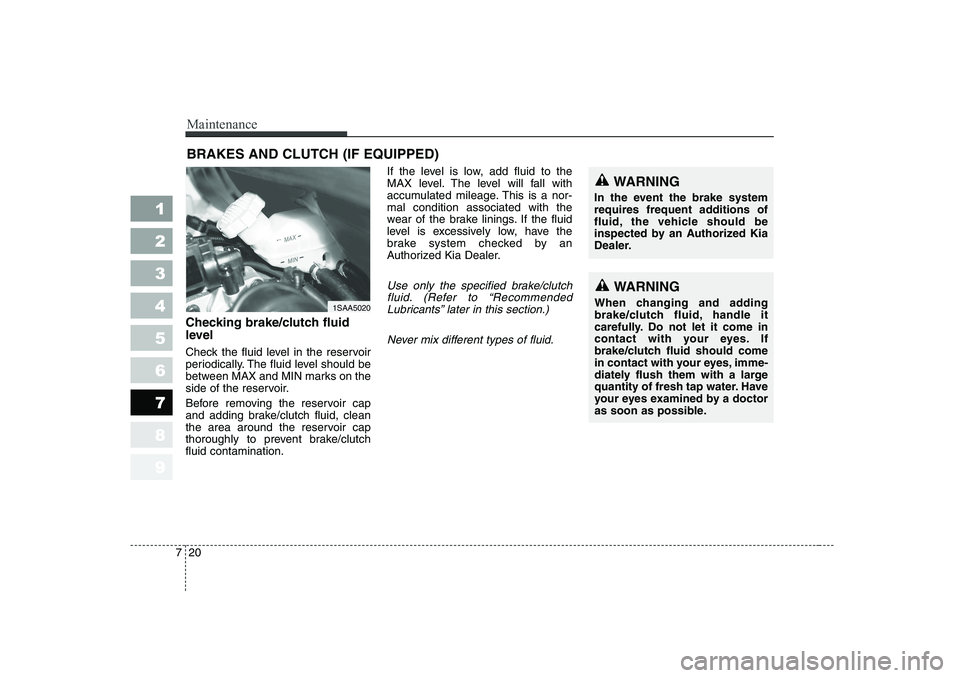

BRAKES AND CLUTCH (IF EQUIPPED)

Checking brake/clutch fluid

level

Check the fluid level in the reservoir

periodically. The fluid level should be

between MAX and MIN marks on the

side of the reservoir.

Before removing the reservoir cap

and adding brake/clutch fluid, clean

the area around the reservoir cap

thoroughly to prevent brake/clutchfluid contamination. If the level is low, add fluid to the

MAX level. The level will fall with

accumulated mileage. This is a nor-mal condition associated with the

wear of the brake linings. If the fluid

level is excessively low, have the

brake system checked by an

Authorized Kia Dealer.

Use only the specified brake/clutch

fluid. (Refer to “RecommendedLubricants” later in this section.)

Never mix different types of fluid.WARNING

When changing and adding

brake/clutch fluid, handle it

carefully. Do not let it come in

contact with your eyes. If

brake/clutch fluid should come

in contact with your eyes, imme-

diately flush them with a large

quantity of fresh tap water. Have

your eyes examined by a doctor

as soon as possible.

WARNING

In the event the brake system

requires frequent additions of

fluid, the vehicle should be

inspected by an Authorized Kia

Dealer.

1SAA5020

Page 234 of 281

721

Maintenance

1 23456789

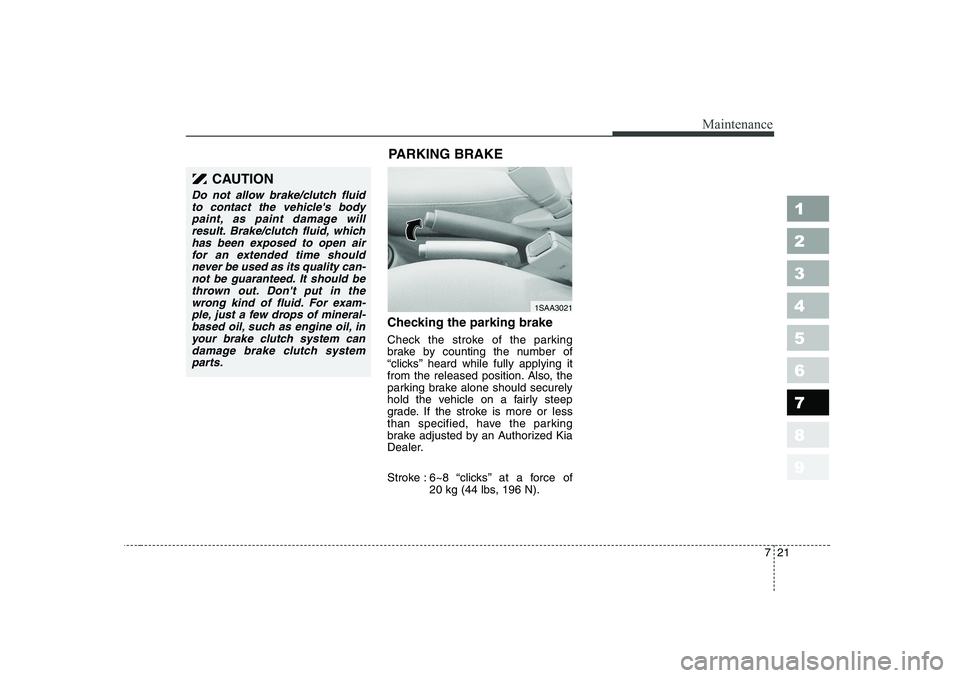

Checking the parking brake

Check the stroke of the parking

brake by counting the number of

“clicks’’ heard while fully applying it

from the released position. Also, the

parking brake alone should securely

hold the vehicle on a fairly steep

grade. If the stroke is more or less

than specified, have the parking

brake adjusted by an Authorized Kia

Dealer.

Stroke : 6~8 “clicks’’ at a force of 20 kg (44 lbs, 196 N).

1SAA3021

PARKING BRAKE

CAUTION

Do not allow brake/clutch fluid

to contact the vehicle's body paint, as paint damage willresult. Brake/clutch fluid, whichhas been exposed to open air for an extended time shouldnever be used as its quality can-not be guaranteed. It should be thrown out. Don't put in thewrong kind of fluid. For exam-ple, just a few drops of mineral- based oil, such as engine oil, inyour brake clutch system candamage brake clutch systemparts.

Page 235 of 281

Maintenance

22

7

1 23456789

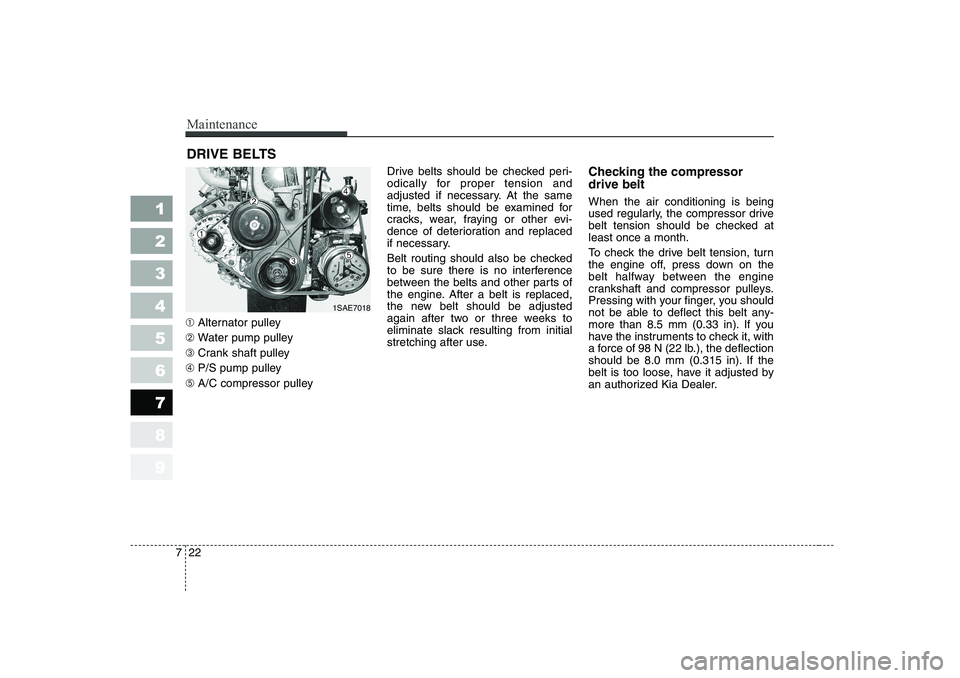

DRIVE BELTS

➀ Alternator pulley

➁ Water pump pulley

➂ Crank shaft pulley

➃ P/S pump pulley

➄ A/C compressor pulley Drive belts should be checked peri-

odically for proper tension and

adjusted if necessary. At the same

time, belts should be examined for

cracks, wear, fraying or other evi-

dence of deterioration and replaced

if necessary.

Belt routing should also be checked

to be sure there is no interference

between the belts and other parts of

the engine. After a belt is replaced,

the new belt should be adjusted

again after two or three weeks to

eliminate slack resulting from initial

stretching after use.

Checking the compressor drive belt When the air conditioning is being

used regularly, the compressor drive

belt tension should be checked atleast once a month.

To check the drive belt tension, turn

the engine off, press down on the

belt halfway between the engine

crankshaft and compressor pulleys.

Pressing with your finger, you should

not be able to deflect this belt any-

more than 8.5 mm (0.33 in). If you

have the instruments to check it, with

a force of 98 N (22 lb.), the deflection

should be 8.0 mm (0.315 in). If the

belt is too loose, have it adjusted by

an authorized Kia Dealer.

1SAE7018

➀

➁

➂

➃

➄

Page 236 of 281

723

Maintenance

1 23456789

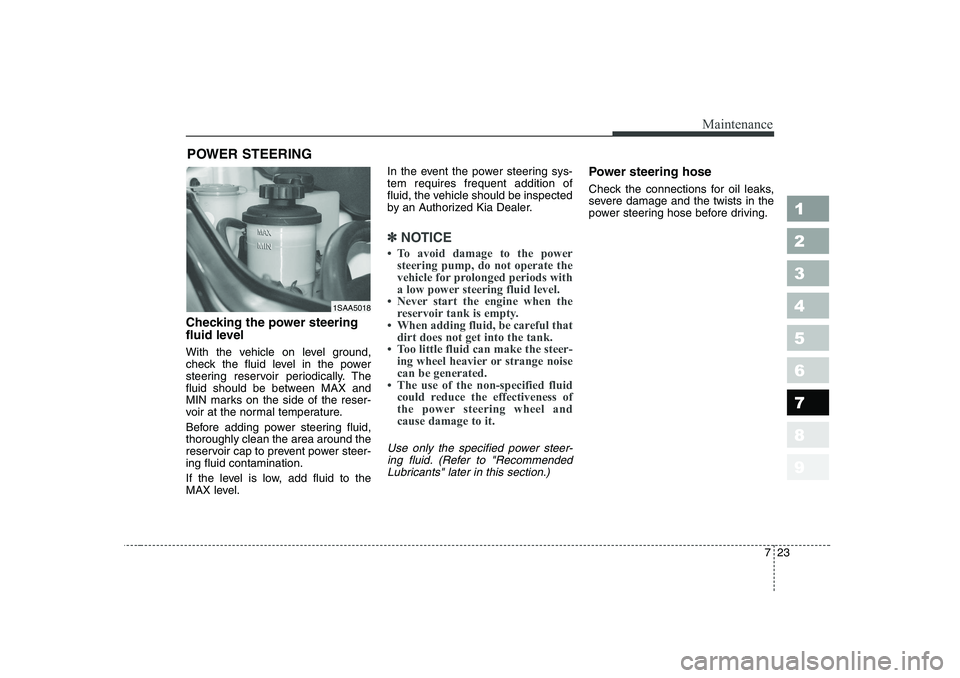

POWER STEERING

Checking the power steering

fluid level

With the vehicle on level ground,

check the fluid level in the power

steering reservoir periodically. The

fluid should be between MAX and

MIN marks on the side of the reser-

voir at the normal temperature.

Before adding power steering fluid, thoroughly clean the area around the

reservoir cap to prevent power steer-ing fluid contamination.

If the level is low, add fluid to the

MAX level. In the event the power steering sys-tem requires frequent addition of

fluid, the vehicle should be inspected

by an Authorized Kia Dealer.

✽✽

NOTICE

Page 237 of 281

Maintenance

24

7

1 23456789

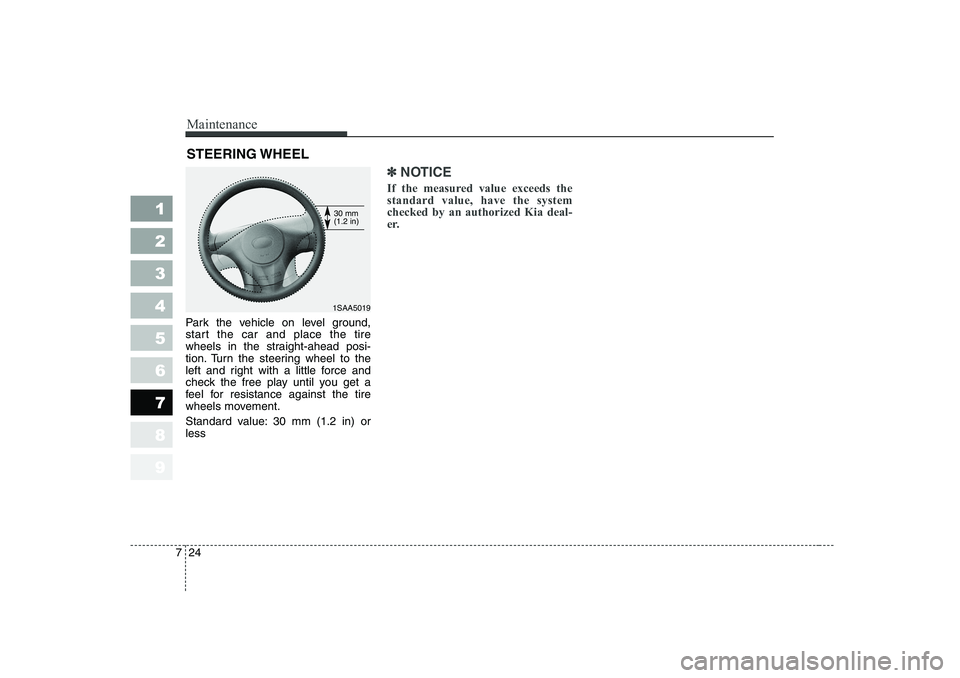

STEERING WHEEL

Park the vehicle on level ground,

start the car and place the tire

wheels in the straight-ahead posi-

tion. Turn the steering wheel to the

left and right with a little force and

check the free play until you get a

feel for resistance against the tire

wheels movement.

Standard value: 30 mm (1.2 in) or less

✽✽ NOTICE

If the measured value exceeds the standard value, have the systemchecked by an authorized Kia deal-

er.

1SAA5019

30 mm (1.2 in)

Page 238 of 281

725

Maintenance

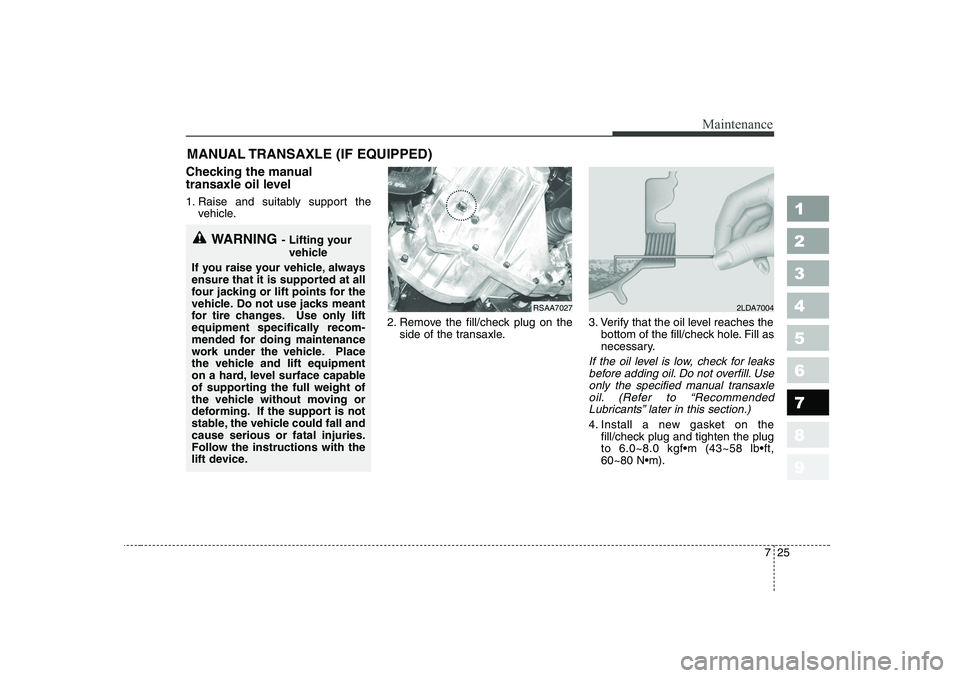

MANUAL TRANSAXLE (IF EQUIPPED)

Checking the manual

transaxle oil level

1. Raise and suitably support the vehicle.

2. Remove the fill/check plug on theside of the transaxle. 3. Verify that the oil level reaches the

bottom of the fill/check hole. Fill as

necessary.

If the oil level is low, check for leaks

before adding oil. Do not overfill. Useonly the specified manual transaxle oil. (Refer to “RecommendedLubricants” later in this section.)

4. Install a new gasket on the fill/check plug and tighten the plugto 6.0~8.0 kgfm (43~58 lbft,60~80 Nm).

1 23456789

WARNING - Lifting your

vehicle

If you raise your vehicle, always

ensure that it is supported at all

four jacking or lift points for the

vehicle. Do not use jacks meant

for tire changes. Use only lift

equipment specifically recom-

mended for doing maintenance

work under the vehicle. Place

the vehicle and lift equipment

on a hard, level surface capable

of supporting the full weight of

the vehicle without moving or

deforming. If the support is not

stable, the vehicle could fall andcause serious or fatal injuries.

Follow the instructions with the

lift device.

RSAA70272LDA7004

Page 239 of 281

Maintenance

26

7

1 23456789

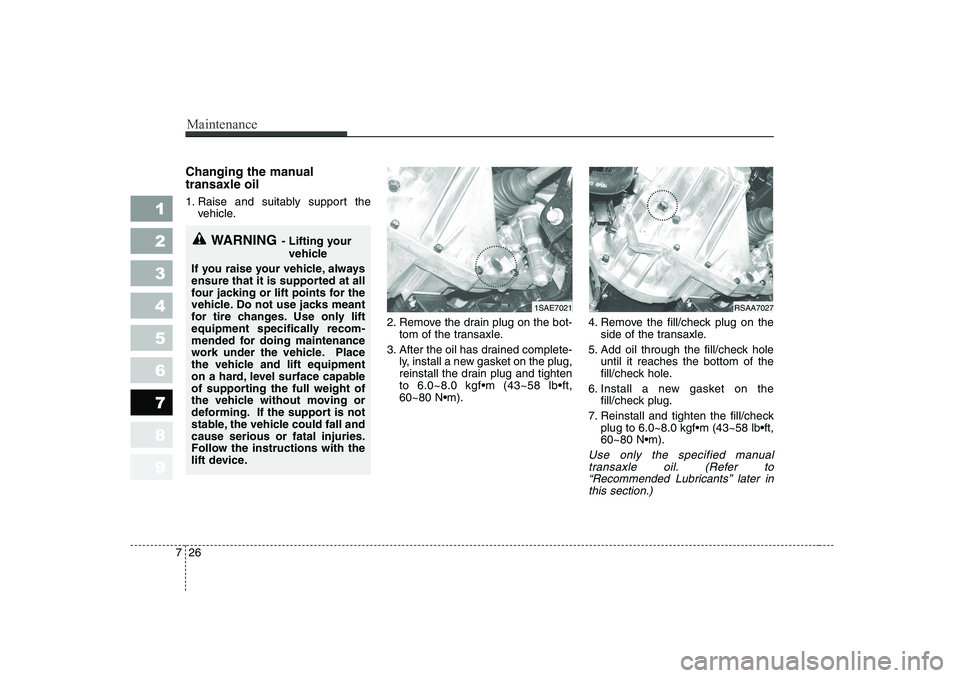

Changing the manual transaxle oil

1. Raise and suitably support the

vehicle.

2. Remove the drain plug on the bot-tom of the transaxle.

3. After the oil has drained complete- ly, install a new gasket on the plug,

reinstall the drain plug and tightento 6.0~8.0 kgfm (43~58 lbft,60~80 Nm). 4. Remove the fill/check plug on the

side of the transaxle.

5. Add oil through the fill/check hole until it reaches the bottom of the

fill/check hole.

6. Install a new gasket on the fill/check plug.

7. Reinstall and tighten the fill/check plug to 6.0~8.0 kgfm (43~58 lbft,60~80 Nm).

Use only the specified manual

transaxle oil. (Refer to“Recommended Lubricants’’ later inthis section.)

1SAE7021

WARNING - Lifting your

vehicle

If you raise your vehicle, always

ensure that it is supported at all

four jacking or lift points for the

vehicle. Do not use jacks meant

for tire changes. Use only lift

equipment specifically recom-

mended for doing maintenance

work under the vehicle. Place

the vehicle and lift equipment

on a hard, level surface capable

of supporting the full weight of

the vehicle without moving or

deforming. If the support is not

stable, the vehicle could fall andcause serious or fatal injuries.

Follow the instructions with the

lift device.

RSAA7027

Page 240 of 281

727

Maintenance

1 23456789

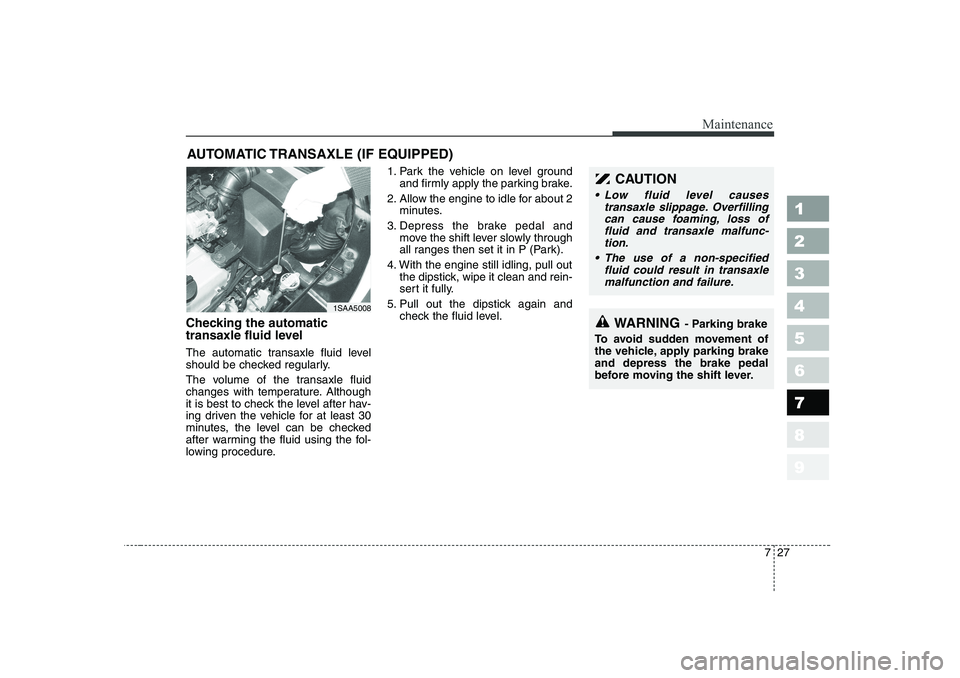

AUTOMATIC TRANSAXLE (IF EQUIPPED)

Checking the automatic

transaxle fluid level

The automatic transaxle fluid level

should be checked regularly.

The volume of the transaxle fluid

changes with temperature. Although

it is best to check the level after hav-

ing driven the vehicle for at least 30

minutes, the level can be checked

after warming the fluid using the fol-

lowing procedure. 1. Park the vehicle on level ground

and firmly apply the parking brake.

2. Allow the engine to idle for about 2 minutes.

3. Depress the brake pedal and move the shift lever slowly through

all ranges then set it in P (Park).

4. With the engine still idling, pull out the dipstick, wipe it clean and rein-

sert it fully.

5. Pull out the dipstick again and check the fluid level.

1SAA5008

CAUTION

Low fluid level causes

transaxle slippage. Overfillingcan cause foaming, loss offluid and transaxle malfunc-tion.

The use of a non-specified fluid could result in transaxlemalfunction and failure.

WARNING - Parking brake

To avoid sudden movement of

the vehicle, apply parking brakeand depress the brake pedal

before moving the shift lever.