Lancia Flavia 2012 Owner handbook (in English)

Manufacturer: LANCIA, Model Year: 2012, Model line: Flavia, Model: Lancia Flavia 2012Pages: 233, PDF Size: 2.61 MB

Page 181 of 233

CAUTION!

Failure to follow these procedures

could result in damage to the charg-

ing system of the booster vehicle or

the discharged vehicle.

1. Connect the positive (+)end of the

jumper cable to the remote positive

(+) post of the discharged vehicle.

2. Connect the opposite end of the

positive (+)jumper cable to the posi-

tive (+)post of the booster battery.

3. Connect the negative end (-)of the

jumper cable to the negative (-)post

of the booster battery.

4. Connect the opposite end of the

negative (-)jumper cable to the re-

mote negative (-)post of the vehicle

with the discharged battery.WARNING!

Do not connect the cable to the nega-

tive post (-)of the discharged bat-

tery. The resulting electrical spark

could cause the battery to explode

and could result in personal injury.

5. Start the engine in the vehicle that

has the booster battery, let the engine idle a few minutes, and then start the

engine in the vehicle with the dis-

charged battery.

Once the engine is started, remove the

jumper cables in the reverse sequence:

6. Disconnect the negative

(-)jumper

cable from the remote negative (-)

post of the vehicle with the discharged

battery.

7. Disconnect the negative end (-)of

the jumper cable from the negative (-)

post of the booster battery.

8. Disconnect the opposite end of the

positive (+)jumper cable from the

positive (+)post of the booster bat-

tery.

9. Disconnect the positive (+)end of

the jumper cable from the remote

positive (+)post of the discharged ve-

hicle.

10. Reinstall the protective cover

over the remote positive (+)battery

post of the discharged vehicle.

If frequent jump-starting is required

to start your vehicle you should have

the battery and charging system in-

spected at your authorized dealer.

CAUTION!

Accessories that can be plugged into

the vehicle power outlets draw

power from the vehicle’s battery,

even when not in use (i.e., cellular

phones, etc.). Eventually, if plugged

in long enough, the vehicle’s battery

will discharge sufficiently to degrade

battery life and/or prevent the en-

gine from starting.

FREEING A STUCK

VEHICLE

If your vehicle becomes stuck in mud,

sand, or snow, it can often be moved

by a rocking motion. Turn your steer-

ing wheel right and left to clear the

area around the front wheels. Then

shift back and forth between DRIVE

and REVERSE. Using minimal accel-

erator pedal pressure to maintain the

rocking motion, without spinning the

wheels, is most effective.

174

Page 182 of 233

CAUTION!

Racing the engine or spinning the

wheels may lead to transmission

overheating and failure. Allow the

engine to idle with the shift lever in

NEUTRAL for at least one minute

after every five rocking-motion

cycles. This will minimize overheat-

ing and reduce the risk of transmis-

sion failure during prolonged efforts

to free a stuck vehicle.

NOTE:

If your vehicle is equipped with

Electronic Stability Control (ESC),

turn the system to Partial OFF be-

fore attempting to “rock” the ve-

hicle. Refer to “Electronic Brake

Control” in “Starting And Operat-

ing” for further information.CAUTION!

When “rocking” a stuck vehicle by moving between DRIVE and

REVERSE, do not spin the wheels

faster than 24 km/h, or drivetrain

damage may result.

(Continued)

CAUTION!(Continued)

Revving the engine or spinning

the wheels too fast may lead to

transmission overheating and

failure. It can also damage the

tires. Do not spin the wheels above

48 km/h while in gear (no trans-

mission shifting occurring).WARNING!

Fast spinning tires can be danger-

ous. Forces generated by excessive

wheel speeds may cause damage, or

even failure, of the axle and tires. A

tire could explode and injure some-

one. Do not spin your vehicle's

wheels faster than 48 km/h or for

longer than 30 seconds continuously

without stopping when you are stuck

and do not let anyone near a spin-

ning wheel, no matter what the

speed.

SHIFT LEVER

OVERRIDE

If a malfunction occurs and the shift

lever cannot be moved out of the

PARK position, you can use the fol- lowing procedure to temporarily

move the shift lever:

1. Firmly apply the parking brake.

2. Remove the cupholder liner.

3. Turn the ignition to the ON/RUN

position without starting the engine.

4. Press and maintain firm pressure

on the brake pedal.

5. Insert a screwdriver or similar tool

into the hole at the front of the cup-

holder and push and hold the override

lever forward.

6. Move the shift lever into the NEU-

TRAL position.

7. The vehicle may then be started in

NEUTRAL.

8. Reinstall the cupholder liner.

Shift Lever Override

175

Page 183 of 233

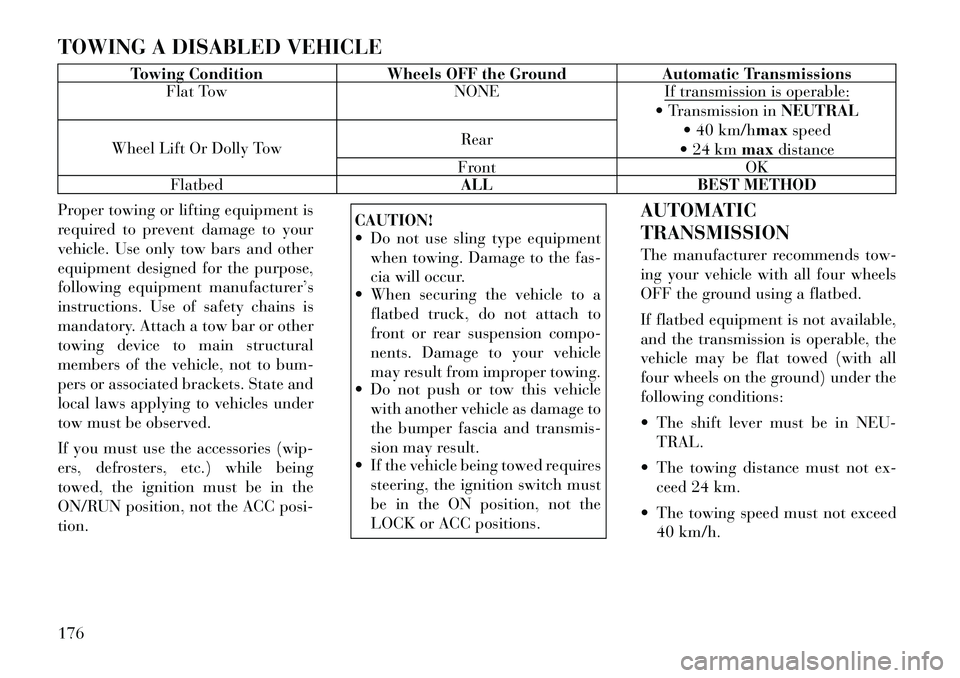

TOWING A DISABLED VEHICLE

Towing ConditionWheels OFF the Ground Automatic Transmissions

Flat Tow NONEIf transmission is operable:

Transmission inNEUTRAL

40 km/hmax speed

24 km maxdistance

Wheel Lift Or Dolly Tow Rear

Front OK

Flatbed ALLBEST METHOD

Proper towing or lifting equipment is

required to prevent damage to your

vehicle. Use only tow bars and other

equipment designed for the purpose,

following equipment manufacturer’s

instructions. Use of safety chains is

mandatory. Attach a tow bar or other

towing device to main structural

members of the vehicle, not to bum-

pers or associated brackets. State and

local laws applying to vehicles under

tow must be observed.

If you must use the accessories (wip-

ers, defrosters, etc.) while being

towed, the ignition must be in the

ON/RUN position, not the ACC posi-

tion.

CAUTION!

Do not use sling type equipment when towing. Damage to the fas-

cia will occur.

When securing the vehicle to a

flatbed truck, do not attach to

front or rear suspension compo-

nents. Damage to your vehicle

may result from improper towing.

Do not push or tow this vehicle

with another vehicle as damage to

the bumper fascia and transmis-

sion may result.

If the vehicle being towed requires

steering, the ignition switch must

be in the ON position, not the

LOCK or ACC positions. AUTOMATIC

TRANSMISSION

The manufacturer recommends tow-

ing your vehicle with all four wheels

OFF the ground using a flatbed.

If flatbed equipment is not available,

and the transmission is operable, the

vehicle may be flat towed (with all

four wheels on the ground) under the

following conditions:

The shift lever must be in NEU-

TRAL.

The towing distance must not ex- ceed 24 km.

The towing speed must not exceed 40 km/h.

176

Page 184 of 233

If the transmission is not operable,

or the vehicle must be towed faster

than 40 km/h or farther than

24 km, it must be towed with the

front wheels OFF the ground (us-

ing a flatbed truck, towing dolly, or

wheel lift equipment with the front

wheels raised).CAUTION!

Towing faster than 40 km/h or far-

ther than 24 km with front wheels

on the ground can cause severe dam-

age to the transmission. Such dam-

age is not covered by the New Ve-

hicle Limited Warranty.WITHOUT THE IGNITION

KEY

Special care must be taken when the

vehicle is towed with the ignition in

the LOCK position. Flatbed towing is

the preferred towing method. How-

ever, if a flatbed towing vehicle is not

available, wheel lift towing equip-

ment may be used. Rear towing (with

the front wheels on the ground) is not

allowed, as transmission damage will

occur. If rear towing is the only alter-

native, the front wheels must be

placed on a towing dolly. Proper tow-

ing equipment is necessary to prevent

damage to the vehicle.

CAUTION!

Failure to follow these towing meth-

ods can cause severe damage to the

transmission. Such damage is not

covered by the New Vehicle Limited

Warranty.

177

Page 185 of 233

178

Page 186 of 233

7

MAINTAINING YOUR VEHICLE

ENGINE COMPARTMENT — 2.4L . . . . . . . . . . . 181

ONBOARD DIAGNOSTIC SYSTEM — OBD II . . . 182

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . 182

MAINTENANCE PROCEDURES . . . . . . . . . . . . . 182 ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . 183

ENGINE OIL FILTER . . . . . . . . . . . . . . . . . . . 184

ENGINE AIR CLEANER FILTER . . . . . . . . . . 184

MAINTENANCE-FREE BATTERY . . . . . . . . . 185

AIR CONDITIONER MAINTENANCE . . . . . . . 186

A/C AIR FILTER . . . . . . . . . . . . . . . . . . . . . . 186

BODY LUBRICATION . . . . . . . . . . . . . . . . . . . 187

WINDSHIELD WIPER BLADES . . . . . . . . . . . 188

ADDING WASHER FLUID . . . . . . . . . . . . . . . 188

EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . 189

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . 190

BRAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . 193

AUTOMATIC TRANSMISSION . . . . . . . . . . . . 194

APPEARANCE CARE AND PROTECTIONFROM CORROSION . . . . . . . . . . . . . . . . . . . . 196

CLEANING CENTER CONSOLE CUPHOLDERS . . . . . . . . . . . . . . . . . . . . . . . . 198

179

Page 187 of 233

CONVERTIBLE TOP CARE . . . . . . . . . . . . . . 198

WEATHER STRIP CARE – SOFT AND HARDTOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 INTEGRATED POWER MODULE . . . . . . . . . . 200

VEHICLE STORAGE . . . . . . . . . . . . . . . . . . . . . 203

REPLACEMENT BULBS . . . . . . . . . . . . . . . . . . 203

BULB REPLACEMENT . . . . . . . . . . . . . . . . . . . 203 HEADLAMP . . . . . . . . . . . . . . . . . . . . . . . . . . 203

FRONT TURN SIGNAL . . . . . . . . . . . . . . . . . . 204

FRONT FOG LAMP . . . . . . . . . . . . . . . . . . . . 204

REAR TURN SIGNAL LAMPS . . . . . . . . . . . . 205

BACKUP LAMP . . . . . . . . . . . . . . . . . . . . . . . 205

LICENSE PLATE LAMP . . . . . . . . . . . . . . . . . 205

FLUID CAPACITIES . . . . . . . . . . . . . . . . . . . . . . 206

FLUIDS, LUBRICANTS, AND GENUINE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

180

Page 188 of 233

ENGINE COMPARTMENT — 2.4L1 — Engine Coolant Reservoir6 — Air Cleaner Filter

2 — Power Steering Fluid Reservoir 7 — Engine Oil Fill

3 — Brake Fluid Reservoir 8 — Coolant Pressure Cap

4 — Power Distribution Center (Fuses) 9 — Engine Oil Dipstick

5 — Integrated Power Module (Fuses) 10 — Washer Fluid Reservoir

181

Page 189 of 233

ONBOARD DIAGNOSTIC

SYSTEM — OBD II

Your vehicle is equipped with a so-

phisticated onboard diagnostic sys-

tem called OBD II. This system moni-

tors the performance of the emissions,

engine, and automatic transmission

control systems. When these systems

are operating properly, your vehicle

will provide excellent performance

and fuel economy, as well as engine

emissions well within current govern-

ment regulations.

If any of these systems require service,

the OBD II system will turn on the

“Malfunction Indicator Light.” It will

also store diagnostic codes and other

information to assist your service

technician in making repairs. Al-

though your vehicle will usually be

drivable and not need towing, see

your dealer for service as soon as pos-

sible.

CAUTION!

Prolonged driving with the “Mal-function Indicator Light” on

could cause further damage to the

emission control system. It could

also affect fuel economy and

driveability. The vehicle must be

serviced before any emissions

tests can be performed.

If the “Malfunction Indicator

Light” is flashing while the engine

is running, severe catalytic con-

verter damage and power loss will

soon occur. Immediate service is

required.

REPLACEMENT PARTS

Use of genuine parts for normal/

scheduled maintenance and repairs is

highly recommended to ensure the de-

signed performance.

Damage or failures caused by the use

of parts which are not quality-

equivalent to genuine parts for main-

tenance and repairs will not be cov-

ered by the manufacturer’s warranty. MAINTENANCE

PROCEDURES

The pages that follow contain the

re-

quired maintenance services deter-

mined by the engineers who designed

your vehicle.

Besides those maintenance items

specified in the fixed maintenance

schedule, there are other components

which may require servicing or re-

placement in the future.

CAUTION!

Failure to properly maintain your vehicle or perform repairs and

service when necessary could re-

sult in more costly repairs, dam-

age to other components or nega-

tively impact vehicle

performance. Immediately have

potential malfunctions examined

by an authorized dealership or

qualified repair center.

(Continued)

182

Page 190 of 233

CAUTION!(Continued)

Car maintenance should be done

at a LANCIA Dealership. For rou-

tine and minor maintenance op-

erations you wish to carry out

yourself, we do recommend you

have the proper equipment, genu-

ine LANCIA spare parts and the

necessary fluids; do not however

carry out these operations if you

have no experience.

Your vehicle has been built with

improved fluids that protect the

performance and durability of

your vehicle and also allow ex-

tended maintenance intervals. Do

not use chemical flushes in these

components as the chemicals can

damage your engine, transmis-

sion, power steering or air condi-

tioning. Such damage is not cov-

ered by the New Vehicle Limited

Warranty. If a flush is needed be-

cause of component malfunction,

use only the specified fluid for the

flushing procedure. ENGINE OIL

Checking Oil Level

To assure proper engine lubrication of

your

vehicle's engine, the engine oil

must be maintained at the correct

level. The best time to check the en-

gine oil level is about five minutes

after a fully warmed engine is shut off.

Do not check oil level before starting

the engine after it has sat overnight.

Checking engine oil level when the

engine is cold will give you an incor-

rect reading.

Checking the oil while the vehicle is

on level ground and only when the

engine is hot, will improve the accu-

racy of the oil level readings. Maintain

the oil level between the range mark-

ings on the dipstick. Either the range

markings consist of a crosshatch zone

marked SAFE or a crosshatch zone

marked with MIN at the low end of

the range and MAX at the high end of

the range. Adding 1.0 Liter of oil

when the reading is at the low end of

the range marking will raise the oil

level to the high end of the range

marking.

CAUTION!

Do not overfill the engine. Over- filling the engine will cause oil

aeration, which can lead to loss of

oil pressure and an increase in oil

temperature. This could damage

your engine. Also, be sure the oil

fill cap is replaced and tightened

after adding oil.

Car maintenance should be done

at a LANCIA Dealership. For rou-

tine and minor maintenance op-

erations you wish to carry out

yourself, we do recommend you

have the proper equipment, genu-

ine LANCIA spare parts and the

necessary fluids; do not however

carry out these operations if you

have no experience.

Change Engine Oil

Refer to the “Maintenance Schedule”

for the proper maintenance intervals.

Engine Oil Selection

SAE Grade 5W-20 SELENIA K

POWER fully synthetic engine oil that

meets FIAT Qualification 9.55535

API SN, ILSAC GF-5 or equivalent.

183