engine Lancia Flavia 2013 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2013, Model line: Flavia, Model: Lancia Flavia 2013Pages: 244, PDF Size: 2.87 MB

Page 186 of 244

PREPARATIONS FOR

JUMP-START

The battery in your vehicle is located

between the left front headlight as-

sembly and the left front wheel splash

shield. To allow jump-starting there

are remote battery posts located on

the left side of the engine compart-

ment.

WARNING!

Take care to avoid the radiatorcooling fan whenever the hood is

raised. It can start anytime the

ignition switch is ON. You can be

injured by moving fan blades.

Remove any metal jewelry such

as watch bands or bracelets that

might make an inadvertent elec-

trical contact. You could be seri-

ously injured.

Batteries contain sulfuric acid that can burn your skin or eyes

and generate hydrogen gas which

is flammable and explosive. Keep

open flames or sparks away from

the battery.

1. Set the parking brake, shift the

automatic transmission into PARK

and turn the ignition to LOCK.

2. Turn off the heater, radio, and all

unnecessary electrical accessories. 3. Remove the protective cover over

the remote positive

(+)battery post.

To remove the cover, press the locking

tab and pull upward on the cover.

4. If using another vehicle to jump-

start the battery, park the vehicle

within the jumper cables reach, set

the parking brake and make sure the

ignition is OFF.

WARNING!

Do not allow vehicles to touch each

other as this could establish a

ground connection and personal in-

jury could result.

Remote Battery Posts

1 — Remote Positive (+)Post

(covered with protective cap)

2 — Remote Negative (-)Post

Locking Tab

180

Page 187 of 244

JUMP-STARTING

PROCEDUREWARNING!

Failure to follow this procedure

could result in personal injury or

property damage due to battery ex-

plosion.CAUTION!

Failure to follow these procedures

could result in damage to the

charging system of the booster ve-

hicle or the discharged vehicle.

1. Connect the positive (+)end of the

jumper cable to the remote posi-

tive (+)post of the discharged vehicle.

2. Connect the opposite end of the

positive (+)jumper cable to the posi-

tive (+)post of the booster battery.

3. Connect the negative end (-)of the

jumper cable to the negative (-)post

of the booster battery. 4. Connect the opposite end of the

negative

(-)jumper cable to the re-

mote negative (-)post of the vehicle

with the discharged battery.

WARNING!

Do not connect the cable to the

negative post (-)of the discharged

battery. The resulting electrical

spark could cause the battery to

explode and could result in per-

sonal injury.

5. Start the engine in the vehicle that

has the booster battery, let the engine

idle a few minutes, and then start the

engine in the vehicle with the dis-

charged battery.

Once the engine is started, remove the

jumper cables in the reverse sequence:

6. Disconnect the negative (-)jumper

cable from the remote negative (-)

post of the vehicle with the discharged

battery. 7. Disconnect the negative end

(-)of

the jumper cable from the negative (-)

post of the booster battery.

8. Disconnect the opposite end of the

positive (+)jumper cable from the

positive (+)post of the booster bat-

tery.

9. Disconnect the positive (+)end of

the jumper cable from the remote

positive (+)post of the discharged ve-

hicle.

10. Reinstall the protective cover

over the remote positive (+)battery

post of the discharged vehicle.

If frequent jump-starting is required

to start your vehicle, you should have

the battery and charging system in-

spected at your authorized dealer.

181

Page 188 of 244

CAUTION!Accessories that can be plugged into

the vehicle power outlets draw power

from the vehicle’s battery, even when

not in use (i.e., cellular phones, etc.).

Eventually, if plugged in long

enough, the vehicle’s battery will dis-

charge sufficiently to degrade battery

life and/or prevent the engine from

starting.FREEING A STUCK

VEHICLE

If your vehicle becomes stuck in mud,

sand, or snow, it can often be moved

using a rocking motion. Turn the

steering wheel right and left to clear

the area around the front wheels.Then shift back and forth between

DRIVE and REVERSE, while gently

pressing the accelerator. Use the least

amount of accelerator pedal pressure

that will maintain the rocking motion,

without spinning the wheels, or racing

the engine.

CAUTION!

Racing the engine or spinning the

wheels may lead to transmission

overheating and failure. Allow the

engine to idle with the transmission

in NEUTRAL for at least one min-

ute after every five rocking-motion

cycles. This will minimize over-

heating and reduce the risk of

transmission failure during pro-

longed efforts to free a stuck ve-

hicle.NOTE:

Press the "ESC Off" switch,

to place the Electronic Stability

Control (ESC) system in "Partial Off"

mode, before rocking the vehicle.

Refer to “Electronic Brake Control”

in “Starting And Operating” for fur-

ther information. Once the vehicle

has been freed, press the "ESC Off"

switch again to restore "ESC On"

mode.

CAUTION!

When “rocking” a stuck vehicle by shifting between DRIVE and

REVERSE, do not spin the

wheels faster than 24 km/h, or

drivetrain damage may result.

Revving the engine or spinning

the wheels too fast may lead to

transmission overheating and

failure. It can also damage the

tires. Do not spin the wheels

above 48 km/h while in gear (no

transmission shifting occurring).

182

Page 189 of 244

WARNING!

Fast spinning tires can be danger-

ous. Forces generated by excessive

wheel speeds may cause damage, or

even failure, of the axle and tires. A

tire could explode and injure some-

one. Do not spin your vehicle's

wheels faster than 48 km/h or for

longer than 30 seconds continu-

ously without stopping when you

are stuck and do not let anyone

near a spinning wheel, no matter

what the speed.SHIFT LEVER

OVERRIDE

If a malfunction occurs and the shift

lever cannot be moved out of the

PARK position, you can use the fol-

lowing procedure to temporarily

move the shift lever:

1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Remove the rubber cupholder

liner. Squeeze one side of the liner's

center to expose its edge and facilitate

removal.

4. Turn the ignition to the ACC or

ON/RUN position, but do not start the

engine.

5. Press and maintain firm pressure

on the brake pedal. 6. Insert a screwdriver or similar tool

into the access hole (at the front of the

cupholder) and push and hold the

override release lever forward.

7. Move the shift lever into the NEU-

TRAL position.

8. The vehicle may then be started in

NEUTRAL.

9. Reinstall the cupholder liner.

Shift Lever Override

183

Page 193 of 244

7

MAINTAINING YOUR VEHICLE

ENGINE COMPARTMENT — 2.4L . . . . . . . . . . . .189

ONBOARD DIAGNOSTIC SYSTEM — OBD II . . .190

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . .190

MAINTENANCE PROCEDURES . . . . . . . . . . . . . .190 ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . .191

ENGINE OIL FILTER . . . . . . . . . . . . . . . . . . . .192

ENGINE AIR CLEANER FILTER . . . . . . . . . . .192

MAINTENANCE-FREE BATTERY . . . . . . . . . .193

AIR CONDITIONER MAINTENANCE . . . . . . . .194

A/C AIR FILTER . . . . . . . . . . . . . . . . . . . . . . .194

BODY LUBRICATION . . . . . . . . . . . . . . . . . . .195

WINDSHIELD WIPER BLADES . . . . . . . . . . .196

ADDING WASHER FLUID . . . . . . . . . . . . . . . .196

EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . .196

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . .198

BRAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . .201

AUTOMATIC TRANSMISSION . . . . . . . . . . . . .202

APPEARANCE CARE AND PROTECTIONFROM CORROSION . . . . . . . . . . . . . . . . . . . . .204

CLEANING CENTER CONSOLE CUPHOLDERS . . . . . . . . . . . . . . . . . . . . . . . .206

187

Page 194 of 244

CONVERTIBLE TOP CARE . . . . . . . . . . . . . . . .206

WEATHER STRIP CARE – SOFT ANDHARD TOP . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

INTEGRATED POWER MODULE . . . . . . . . . .208

VEHICLE STORAGE . . . . . . . . . . . . . . . . . . . . . .212

REPLACEMENT BULBS . . . . . . . . . . . . . . . . . . .212

BULB REPLACEMENT . . . . . . . . . . . . . . . . . . . .213

HEADLAMP . . . . . . . . . . . . . . . . . . . . . . . . . .213

FRONT TURN SIGNAL . . . . . . . . . . . . . . . . . .214

FRONT FOG LAMP . . . . . . . . . . . . . . . . . . . . .214

REAR TURN SIGNAL LAMPS . . . . . . . . . . . . .214

BACKUP LAMP . . . . . . . . . . . . . . . . . . . . . . . .215

LICENSE PLATE LAMP . . . . . . . . . . . . . . . . . .215

FLUID CAPACITIES . . . . . . . . . . . . . . . . . . . . . . .216

FLUIDS, LUBRICANTS AND GENUINE PARTS . .216

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .216

CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .217

188

Page 195 of 244

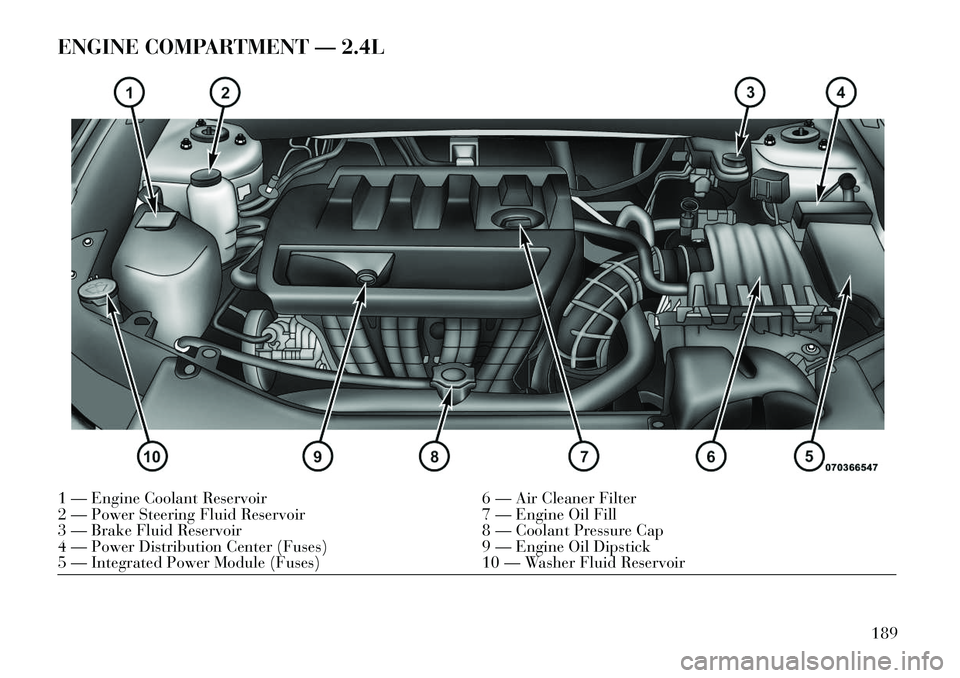

ENGINE COMPARTMENT — 2.4L1 — Engine Coolant Reservoir6 — Air Cleaner Filter

2 — Power Steering Fluid Reservoir 7 — Engine Oil Fill

3 — Brake Fluid Reservoir 8 — Coolant Pressure Cap

4 — Power Distribution Center (Fuses) 9 — Engine Oil Dipstick

5 — Integrated Power Module (Fuses) 10 — Washer Fluid Reservoir

189

Page 196 of 244

ONBOARD DIAGNOSTIC

SYSTEM — OBD II

Your vehicle is equipped with a so-

phisticated onboard diagnostic sys-

tem called OBD II. This system moni-

tors the performance of the emissions,

engine, and automatic transmission

control systems. When these systems

are operating properly, your vehicle

will provide excellent performance

and fuel economy, as well as engine

emissions well within current govern-

ment regulations.If any of these systems require service,

the OBD II system will turn on the “Mal-

function Indicator Light.” It will also

store diagnostic codes and other infor-

mation to assist your service technician

in making repairs. Although your ve-

hicle will usually be drivable and not

need towing, see your dealer for service

as soon as possible.

CAUTION!

Prolonged driving with the “Mal-function Indicator Light” on

could cause further damage to the

emission control system. It could

also affect fuel economy and

driveability. The vehicle must be

serviced before any emissions

tests can be performed.

If the “Malfunction Indicator Light” is flashing while the en-

gine is running, severe catalytic

converter damage and power loss

will soon occur. Immediate ser-

vice is required.

REPLACEMENT PARTS

Use of genuine parts for normal/

scheduled maintenance and repairs is

highly recommended to ensure the de-

signed performance. Damage or fail-

ures caused by the use of parts which

are not quality-equivalent to genuine

parts for maintenance and repairs will

not be covered by the manufacturer’s

warranty. MAINTENANCE

PROCEDURES

The pages that follow contain the

re-

quired maintenance services deter-

mined by the engineers who designed

your vehicle.

Besides those maintenance items

specified in the fixed maintenance

schedule, there are other components

which may require servicing or re-

placement in the future.

CAUTION!

Failure to properly maintain your

vehicle or perform repairs and ser-

vice when necessary could result in

more costly repairs, damage to

other components or negatively im-

pact vehicle performance. Immedi-

ately have potential malfunctions

examined by an authorized dealer-

ship or qualified repair center.

(Continued)

190

Page 197 of 244

CAUTION!(Continued)

Car maintenance should be done

at a LANCIA Dealership. For rou-

tine and minor maintenance op-

erations you wish to carry out

yourself, we do recommend you

have the proper equipment, genu-

ine LANCIA spare parts and the

necessary fluids; do not however

carry out these operations if you

have no experience. Your vehicle has been built with improved fluids that protect the

performance and durability of

your vehicle and also allow ex-

tended maintenance intervals. Do

not use chemical flushes in these

components as the chemicals can

damage your engine, transmis-

sion, power steering or air condi-

tioning. Such damage is not cov-

ered by the New Vehicle Limited

Warranty. If a flush is needed be-

cause of component malfunction,

use only the specified fluid for the

flushing procedure. ENGINE OIL

Checking Oil Level

To assure proper engine lubrication of

your vehicle's engine, the engine oil

must be maintained at the correct

level. The best time to check the en-

gine oil level is about five minutes

after a fully warmed engine is shut off.

Do not check oil level before starting

the engine after it has sat overnight.

Checking engine oil level when the

engine is cold will give you an incor-

rect reading.

Checking the oil while the vehicle is

on level ground and only when the

engine is hot, will improve the accu-

racy of the oil level readings. Maintain

the oil level between the range mark-

ings on the dipstick. Either the range

markings consist of a crosshatch zone

marked SAFE or a crosshatch zone

marked with MIN at the low end of

the range and MAX at the high end of

the range. Adding 1.0 Liter of oil

when the reading is at the low end of

the range marking will raise the oil

level to the high end of the range

marking.

CAUTION!

Do not overfill the engine. Over-

filling the engine will cause oil

aeration, which can lead to loss of

oil pressure and an increase in oil

temperature. This could damage

your engine. Also, be sure the oil

fill cap is replaced and tightened

after adding oil.

Car maintenance should be done

at a LANCIA Dealership. For rou-

tine and minor maintenance op-

erations you wish to carry out

yourself, we do recommend you

have the proper equipment, genu-

ine LANCIA spare parts and the

necessary fluids; do not however

carry out these operations if you

have no experience.

Change Engine Oil

Refer to the “Maintenance Schedule”

for the proper maintenance intervals.

191

Page 198 of 244

Engine Oil Selection

SAE Grade 5W-20 SELENIA K

POWER fully synthetic engine oil that

meets FIAT Qualification 9.55535

API SN, ILSAC GF-5 or equivalent.

The engine oil filler cap also shows the

recommended engine oil viscosity for

your vehicle. For information on en-

gine oil filler cap location, refer to

“Engine Compartment” in “Main-

taining Your Vehicle” for further in-

formation.

Synthetic Engine Oils

You may use synthetic engine oils pro-

vided the recommended oil quality

requirements are met, and the recom-

mended maintenance intervals for oil

and filter changes are followed.

Materials Added To Engine Oil

Do not add any supplemental materi-

als, other than leak detection dyes, to

the engine oil. Engine oil is an engi-

neered product and its performance

may be impaired by supplemental

additives.Disposing Of Used Engine Oil And

Oil Filters

Care should be taken in disposing of

used engine oil and oil filters from

your vehicle. Used oil and oil filters,

indiscriminately discarded, can pres-

ent a problem to the environment.

Contact your authorized dealer, ser-

vice station or governmental agency

for advice on how and where used oil

and oil filters can be safely discarded

in your area.

ENGINE OIL FILTER

The engine oil filter should be re-

placed with a new filter at every en-

gine oil change.

Engine Oil Filter Selection

The manufacturer's engines have a

full-flow type disposable oil filter. Use

a filter of this type for replacement.

The quality of replacement filters var-

ies considerably. Only high-quality

filters should be used to assure most

efficient service. LANCIA engine oil

filters are high-quality oil filters and

are recommended.ENGINE AIR CLEANER

FILTER

Refer to the “Maintenance Schedule”

for the proper maintenance intervals.

WARNING!

The air induction system (air

cleaner, hoses, etc.) can provide a

measure of protection in the case of

engine backfire. Do not remove the

air induction system (air cleaner,

hoses, etc.) unless such removal is

necessary for repair or mainte-

nance. Make sure that no one is

near the engine compartment be-

fore starting the vehicle with the air

induction system (air cleaner,

hoses, etc.) removed. Failure to do

so can result in serious personal

injury.

Engine Air Cleaner Filter

Selection

The quality of replacement engine air

cleaner filters varies considerably.

Only high quality filters should be

used to assure most efficient service.

192