engine Lancia Thema 2013 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2013, Model line: Thema, Model: Lancia Thema 2013Pages: 336, PDF Size: 3.87 MB

Page 247 of 336

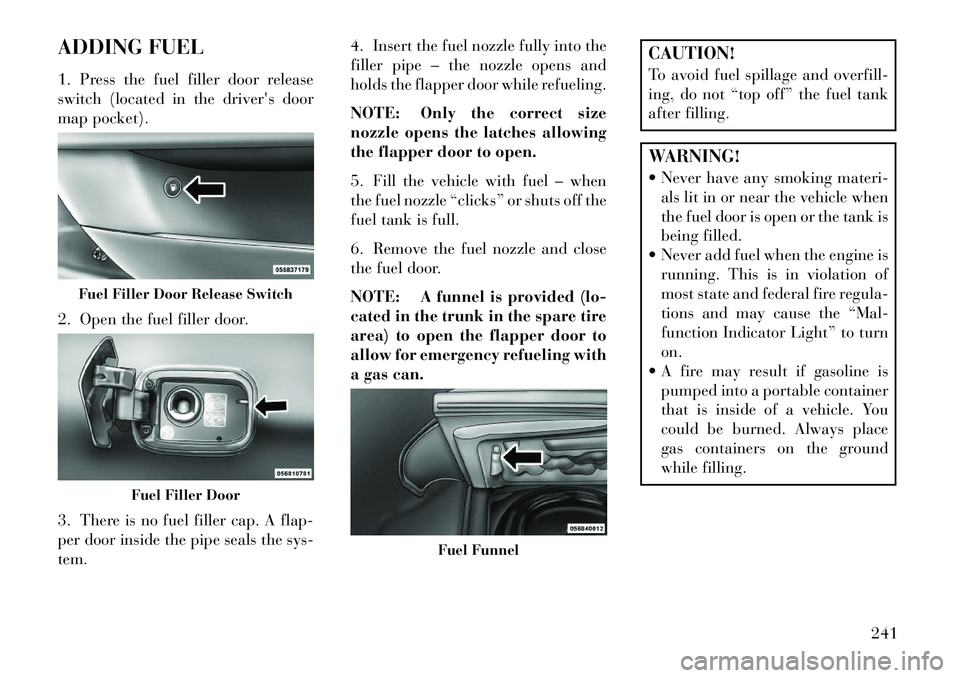

ADDING FUEL

1. Press the fuel filler door release

switch (located in the driver's door

map pocket).

2. Open the fuel filler door.

3. There is no fuel filler cap. A flap-

per door inside the pipe seals the sys-

tem.4. Insert the fuel nozzle fully into the

filler pipe – the nozzle opens and

holds the flapper door while refueling.

NOTE: Only the correct size

nozzle opens the latches allowing

the flapper door to open.

5. Fill the vehicle with fuel – when

the fuel nozzle “clicks” or shuts off the

fuel tank is full.

6. Remove the fuel nozzle and close

the fuel door.

NOTE: A funnel is provided (lo-

cated in the trunk in the spare tire

area) to open the flapper door to

allow for emergency refueling with

a gas can.

CAUTION!

To avoid fuel spillage and overfill-

ing, do not “top off” the fuel tank

after filling.WARNING!

Never have any smoking materi-

als lit in or near the vehicle when

the fuel door is open or the tank is

being filled.

Never add fuel when the engine is running. This is in violation of

most state and federal fire regula-

tions and may cause the “Mal-

function Indicator Light” to turn

on.

A fire may result if gasoline is

pumped into a portable container

that is inside of a vehicle. You

could be burned. Always place

gas containers on the ground

while filling.

Fuel Filler Door Release Switch

Fuel Filler Door

Fuel Funnel

241

Page 249 of 336

Refer to “Vehicle Loading/Vehicle

Certification Label” in “Starting and

Operating” for further information.WARNING!

It is important that you do not ex-

ceed the maximum front or rear

GAWR. A dangerous driving condi-

tion can result if either rating is

exceeded. You could lose control of

the vehicle and have a collision.

Tongue Weight (TW)

The tongue weight is the downward

force exerted on the hitch ball by the

trailer. In most cases, it should not be

less than 7% or more than 10% of the

trailer load. Tongue weight must not

exceed the lesser of either the hitch

certification rating, or the trailer

tongue chassis rating. It should never

be less than 4% of the trailer load, and

not less than 25 kg. You must consider

tongue load as part of the load on your

vehicle and its GAWR. Frontal Area

The frontal area is the maximum

height multiplied by the maximum

width of the front of a trailer.

Trailer Sway Control

The trailer sway control can be a me-

chanical telescoping link that can be

installed between the hitch receiver

and the trailer tongue that typically

provides adjustable friction associ-

ated with the telescoping motion to

dampen any unwanted trailer sway-

ing motions while traveling.

If equipped, the electronic Trailer

Sway Control (TSC) recognizes a

swaying trailer and automatically ap-

plies individual wheel brakes and/or

reduces engine power to attempt to

eliminate the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the

trailer tongue weight, just as if it were

luggage located at a hitch ball or some

other connecting point of the vehicle.

These kinds of hitches are the mostpopular on the market today and they

are commonly used to tow small- and

medium-sized trailers.

Weight-Distributing Hitch

A weight-distributing system works

by applying leverage through spring

(load) bars. They are typically used

for heavier loads to distribute trailer

tongue weight to the tow vehicle's

front axle and the trailer axle(s).

When used in accordance with the

manufacturer's directions, it provides

for a more level ride, offering more

consistent steering and brake control

thereby enhancing towing safety. The

addition of a friction / hydraulic sway

control also dampens sway caused by

traffic and crosswinds and contrib-

utes positively to tow vehicle and

trailer stability. Trailer sway control

and a weight distributing (load equal-

izing) hitch are recommended for

heavier Tongue Weights (TW) and

may be required depending on vehicle

and trailer configuration / loading to

comply with Gross Axle Weight Rat-

ing (GAWR) requirements.

243

Page 251 of 336

TRAILER TOWING WEIGHTS (MAXIMUM TRAILER WEIGHT RATINGS)

The following chart provides the maximum trailer weight ratings towable for your given drivetrain.

Engine/TransmissionFrontal AreaMax. GTW

(Gross Trailer Wt.) Max. Tongue Wt.

(See Note)

3.6L Automatic 2.04 sq m 1 725 kg86 kg

3.0L Diesel Automatic 2.97 sq m 1 996 kg100 kg

Refer to local laws for maximum trailer towing speeds

NOTE: The trailer tongue weight must be considered as part of the combined weight of occupants and cargo,

and it should never exceed the weight referenced on the “Tire and Loading Information” placard. Refer to

“Tire Safety Information” in “Starting and Operating” for further information.

TRAILER AND TONGUE

WEIGHT

Always load a trailer with 60% to

65% of the weight in the front of the

trailer. This places 5% of the Gross

Trailer Weight (GTW) on the tow

hitch of your vehicle. Loads balanced

over the wheels or heavier in the rear

can cause the trailer to sway severely

side to side which will cause loss of

control of the vehicle and trailer. Fail-

ure to load trailers heavier in front is

the cause of many trailer collisions.

Never exceed the maximum tongue

weight stamped on your bumper or

trailer hitch. Consider the following items when

computing the weight on the rear axle

of the vehicle:

The tongue weight of the trailer.

The weight of any other type of

cargo or equipment put in or on

your vehicle. The weight of the driver and all

passengers.

NOTE: Remember that every-

thing put into or on the trailer adds

to the load on your vehicle. Also,

additional factory-installed op-

tions or dealer-installed options

must be considered as part of the

total load on your vehicle. Refer to

the “Tire and Loading Informa-

tion” placard for the maximum

combined weight of occupants and

cargo for your vehicle.

245

Page 252 of 336

TOWING REQUIREMENTS

To promote proper break-in of your

new vehicle drivetrain components

the following guidelines are recom-

mended:CAUTION!

Do not tow a trailer at all duringthe first 805 km the new vehicle is

driven. The engine, axle or other

parts could be damaged.

Then, during the first 805 km

that a trailer is towed, do not

drive over 80 km/h and do not

make starts at full throttle. This

helps the engine and other parts

of the vehicle wear in at the

heavier loads.WARNING!

Improper towing can lead to an in-

jury collision. Follow these guide-

lines to make your trailer towing as

safe as possible:

(Continued)

WARNING!(Continued)

Make certain that the load is se- cured in the trailer and it will not

shift during travel. When traile-

ring cargo that is not fully se-

cured, dynamic load shifts can

occur that may be difficult for the

driver to control. You could lose

control of your vehicle and have a

collision.

When hauling cargo or towing a trailer, do not overload your ve-

hicle or trailer. Overloading can

cause a loss of control, poor per-

formance, or damage to brakes,

axle, engine, transmission, steer-

ing, suspension, chassis structure,

or tires.

Safety chains must always be used

between your vehicle and trailer.

Always connect the chains to the

frame or hook retainers of the ve-

hicle hitch. Cross the chains under

the trailer tongue and allow

enough slack for turning corners.

(Continued)

WARNING! (Continued)

Vehicles with trailers should not be parked on a grade. When

parking, apply the parking brake

on the tow vehicle. Put the tow

vehicle automatic transmission in

PARK. Always, block or "chock"

the trailer wheels.

GCWR must not be exceeded.

Total weight must be distrib-

uted between the tow vehicle

and the trailer such that the

following four ratings are not

exceeded:

1. Max loading as defined on the

“Tire and Loading Information”

placard.

2. GTW

3. GAWR

4.

Tongue weight rating for the

trailer hitch utilized. (This re-

quirement may limit the ability to

always achieve the 10% to 15%

range of tongue weight as a per-

centage of total trailer weight.)

246

Page 255 of 336

Pin

Number Function Wire

Color

5 Right Rear Position,

Side Marker

Lights, and

Rear Regis-

tration Plate

Illumination

Device. b Brown

6 Stoplights Red

7 Left Rear Position,

Side Marker

Lights, and

Rear Regis-

tration Plate

Illumination

Device. b Black

8 Reverse lights Red/ Black

9

Permanent

Power Supply

(+12V)

Brown/

White

10

Power Supply

Controlled

by Ignition

Switch (+12V)

Red

Pin

Number Function Wire

Color

11 a Return for Contact

(Pin) 10 White

12 Reserve for Future Allo-

cation Red/

Blue

13 a Return for Contact

(Pin) 9 White

Note: The allocation pin 12 has

been changed from “Coding for

coupled Trailer” to “Reserve for

Future Allocation.”

a The three return circuits shall not

be connected electrically in the

trailer.

b The rear position registration

plate illumination device shall be

connected such that no light of the

device has a common connection

with both pins 5 and 7. TOWING TIPS

Before setting out on a trip, practice

turning, stopping, and backing up the

trailer in an area located away from

heavy traffic.

Automatic Transmission

The DRIVE range can be selected

when towing. The transmission con-

trols include an adaptive drive strat-

egy to avoid frequent shifting when

towing. However, if frequent shifting

does occur while in DRIVE, use

the AutoStick® shift control (for

versions/markets, where provided) to

manually select a lower gear.

NOTE: Selecting a lower gear

while operating the vehicle under

heavy loading conditions will im-

prove performance and extend

transmission life by reducing ex-

cessive shifting and heat buildup.

This action will also provide better

engine braking.

249

Page 256 of 336

If you REGULARLY tow a trailer for

more than 45 minutes of continuous

operation, then change the automatic

transmission fluid and filter as speci-

fied for “police, taxi, fleet, or frequent

trailer towing.” Refer to the “Mainte-

nance Schedule” for the proper main-

tenance intervals.

Electronic Speed Control

Do not use in hilly terrain or withheavy loads.

When using the speed control, if you experience speed drops greater

than 16 km/h, disengage until you

can get back to cruising speed.

Use speed control in flat terrain and with light loads to maximize fuel

efficiency.

AutoStick® (for versions/markets,

where provided)

– When using the AutoStick® shift control, select the highest gear that

allows for adequate performance

and avoids frequent downshifts. For example, choose “4” if the de-

sired speed can be maintained.

Choose “3” or “2” if needed to

maintain the desired speed.

– To prevent excess heat generation, avoid continuous driving at high

RPM. Reduce vehicle speed as nec-

essary to avoid extended driving at

high RPM. Return to a higher gear

or vehicle speed when grade and

road conditions allow.

Cooling System

To reduce potential for engine and

transmission overheating, take the

following actions:

City Driving

When stopped for short periods of

time, shift the transmission into NEU-

TRAL and increase engine idle speed.

Highway Driving

Reduce speed.

Air Conditioning

Turn off temporarily. TRAILER HITCH

ATTACHING POINTS

Your vehicle will require extra equip-

ment to tow a trailer safely and effi-

ciently. The trailer tow hitch must be

attached to your vehicle using the

provided attaching points on the ve-

hicle's frame. Refer to the following

chart to determine the accurate at-

taching points. Other equipment,

such as trailer sway controls and

braking equipment, trailer equalizing

(leveling) equipment and low profile

mirrors, may also be required or

strongly recommended.

250

Page 259 of 336

6

WHAT TO DO IN EMERGENCIES

HAZARD WARNING FLASHERS . . . . . . . . . . . . .254

IF YOUR ENGINE OVERHEATS . . . . . . . . . . . . . .254

TIREFIT KIT (for versions/markets, where provided) . . . . . . . . . . . . . . . . . . . . . . . . . .255

TIREFIT STORAGE . . . . . . . . . . . . . . . . . . . . .255

TIREFIT KIT COMPONENTS AND OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . .255

TIREFIT USAGE PRECAUTIONS . . . . . . . . . . .256

SEALING A TIRE WITH TIREFIT. . . . . . . . . . .257

JUMP-STARTING PROCEDURES . . . . . . . . . . . . .260

PREPARATIONS FOR JUMP-START . . . . . . . . .261

JUMP-STARTING PROCEDURE . . . . . . . . . . . .261

FREEING A STUCK VEHICLE . . . . . . . . . . . . . . .262

TOW EYES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .263

SHIFT LEVER OVERRIDE — 5 SPEED TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . .263

MANUAL PARK RELEASE — 8 SPEED TRANSMISSION (3.6L Engine) . . . . . . . . . . . . . . .264

TOWING A DISABLED VEHICLE . . . . . . . . . . . .266 Without The Ignition Key . . . . . . . . . . . . . . . . .267

253

Page 260 of 336

HAZARD WARNING

FLASHERS

The Hazard Warning flasher switch is

located in the center of the instrument

panel between the center air outlets.Press the switch to turn on the

Hazard Warning flashers.

When the switch is activated, all di-

rectional turn signals will flash on and

off to warn oncoming traffic of an

emergency. Press the switch a second

time to turn off the Hazard Warning

flashers.

This is an emergency warning system

and it should not be used when the

vehicle is in motion. Use it when your

vehicle is disabled and it is creating a

safety hazard for other motorists.

When you must leave the vehicle to

seek assistance, the Hazard Warning

flashers will continue to operate even

though the ignition is placed in the

OFF position.

NOTE: With extended use the

Hazard Warning flashers may

wear down your battery. IF YOUR ENGINE

OVERHEATS

In any of the following situations, you

can reduce the potential for overheat-

ing by taking the appropriate action.

On the highways — slow down.

In city traffic — while stopped,

place the transmission in NEU-

TRAL, but do not increase the en-

gine idle speed.

NOTE: There are steps that you

can take to slow down an impend-

ing overheat condition:

If your air conditioner (A/C) is on, turn it off. The A/C system

adds heat to the engine cooling

system and turning the A/C off

can help remove this heat.

You can also turn the tempera- ture control to maximum heat,

the mode control to floor and the

blower control to high. This al-

lows the heater core to act as a

supplement to the radiator and

aids in removing heat from the

engine cooling system.

CAUTION!

Driving with a hot cooling system

could damage your vehicle. If the

temperature gauge reads “H,” pull

over and stop the vehicle. Idle the

vehicle with the air conditioner

turned off until the pointer drops

back into the normal range. If the

pointer remains on the “H,” turn

the engine off immediately and call

for service.WARNING!You or others can be badly burned

by hot engine coolant (antifreeze) or

steam from your radiator. If you see

or hear steam coming from under

the hood, do not open the hood until

the radiator has had time to cool.

Never try to open a cooling system

pressure cap when the radiator or

coolant bottle is hot.

254

Page 264 of 336

4. Remove the cap from the valve

stem and then screw the fitting at the

end of the Sealant Hose (6) onto the

valve stem.

5. Uncoil the Power Plug (8) and in-

sert the plug into the vehicle’s 12 Volt

power outlet.

NOTE: Do not remove foreign ob-

jects (e.g., screws or nails) from the

tire.

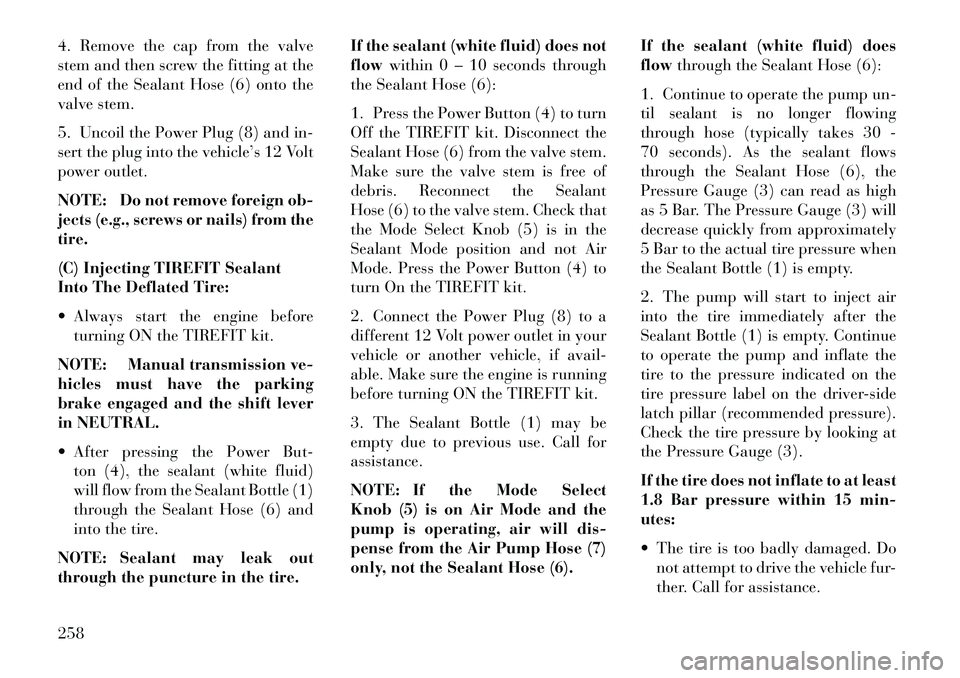

(C) Injecting TIREFIT Sealant

Into The Deflated Tire:

Always start the engine beforeturning ON the TIREFIT kit.

NOTE: Manual transmission ve-

hicles must have the parking

brake engaged and the shift lever

in NEUTRAL.

After pressing the Power But- ton (4), the sealant (white fluid)

will flow from the Sealant Bottle (1)

through the Sealant Hose (6) and

into the tire.

NOTE: Sealant may leak out

through the puncture in the tire. If the sealant (white fluid) does not

flow

within 0 – 10 seconds through

the Sealant Hose (6):

1. Press the Power Button (4) to turn

Off the TIREFIT kit. Disconnect the

Sealant Hose (6) from the valve stem.

Make sure the valve stem is free of

debris. Reconnect the Sealant

Hose (6) to the valve stem. Check that

the Mode Select Knob (5) is in the

Sealant Mode position and not Air

Mode. Press the Power Button (4) to

turn On the TIREFIT kit.

2. Connect the Power Plug (8) to a

different 12 Volt power outlet in your

vehicle or another vehicle, if avail-

able. Make sure the engine is running

before turning ON the TIREFIT kit.

3. The Sealant Bottle (1) may be

empty due to previous use. Call for

assistance.

NOTE: If the Mode Select

Knob (5) is on Air Mode and the

pump is operating, air will dis-

pense from the Air Pump Hose (7)

only, not the Sealant Hose (6). If the sealant (white fluid) does

flow

through the Sealant Hose (6):

1. Continue to operate the pump un-

til sealant is no longer flowing

through hose (typically takes 30 -

70 seconds). As the sealant flows

through the Sealant Hose (6), the

Pressure Gauge (3) can read as high

as 5 Bar. The Pressure Gauge (3) will

decrease quickly from approximately

5 Bar to the actual tire pressure when

the Sealant Bottle (1) is empty.

2. The pump will start to inject air

into the tire immediately after the

Sealant Bottle (1) is empty. Continue

to operate the pump and inflate the

tire to the pressure indicated on the

tire pressure label on the driver-side

latch pillar (recommended pressure).

Check the tire pressure by looking at

the Pressure Gauge (3).

If the tire does not inflate to at least

1.8 Bar pressure within 15 min-

utes:

The tire is too badly damaged. Do not attempt to drive the vehicle fur-

ther. Call for assistance.

258

Page 267 of 336

PREPARATIONS FOR

JUMP-START

The battery is stored under an access

cover in the trunk. Remote battery

posts are located on the right side of

the engine compartment for jump-

starting.

NOTE: The remote battery posts

are viewed by standing on the right

side of the vehicle looking over the

fender.

WARNING!

Take care to avoid the radiatorcooling fan whenever the hood is

raised. It can start anytime the

ignition switch is ON. You can be

injured by moving fan blades.

Remove any metal jewelry such

as watch bands or bracelets that

might make an inadvertent elec-

trical contact. You could be seri-

ously injured.

Batteries contain sulfuric acid that can burn your skin or eyes

and generate hydrogen gas which

is flammable and explosive. Keep

open flames or sparks away from

the battery.

1. Set the parking brake, shift the

automatic transmission into PARK

and turn the ignition to LOCK.

2. Turn off the heater, radio, and all

unnecessary electrical accessories.

3. If using another vehicle to jump-

start the battery, park the vehicle

within the jumper cables reach, set

the parking brake and make sure the

ignition is OFF.

WARNING!

Do not allow vehicles to touch each

other as this could establish a

ground connection and personal

injury could result.

JUMP-STARTING

PROCEDUREWARNING!

Failure to follow this procedure

could result in personal injury or

property damage due to battery

explosion.CAUTION!

Failure to follow these procedures

could result in damage to the

charging system of the booster ve-

hicle or the discharged vehicle.

1. Connect the positive (+)end of the

jumper cable to the remote posi-

tive (+)post of the discharged vehicle.

2. Connect the opposite end of the

positive (+)jumper cable to the posi-

tive (+)post of the booster battery.

Remote Battery Post Locations

1 — Remote Positive (+)Post

2 — Remote Negative (-)Post

261