fuel Lancia Ypsilon 2002 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2002, Model line: Ypsilon, Model: Lancia Ypsilon 2002Pages: 191, PDF Size: 2.45 MB

Page 125 of 191

122

G

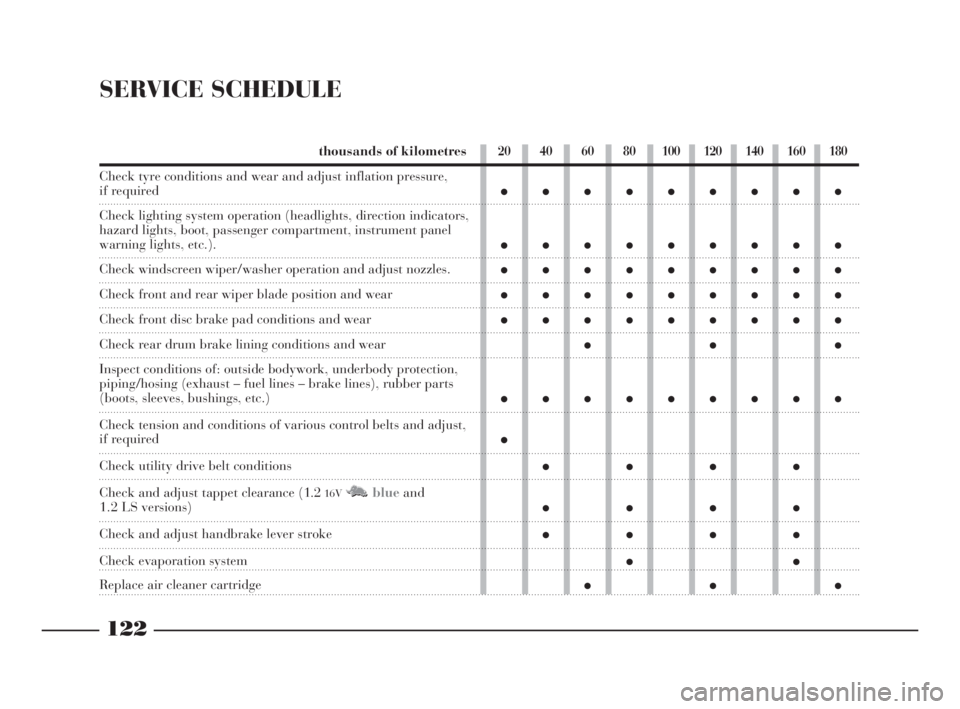

SERVICE SCHEDULE

thousands of kilometres

Check tyre conditions and wear and adjust inflation pressure,

if required

Check lighting system operation (headlights, direction indicators,

hazard lights, boot, passenger compartment, instrument panel

warning lights, etc.).

Check windscreen wiper/washer operation and adjust nozzles.

Check front and rear wiper blade position and wear

Check front disc brake pad conditions and wear

Check rear drum brake lining conditions and wear

Inspect conditions of: outside bodywork, underbody protection,

piping/hosing (exhaust – fuel lines – brake lines), rubber parts

(boots, sleeves, bushings, etc.)

Check tension and conditions of various control belts and adjust,

if required

Check utility drive belt conditions

Check and adjust tappet clearance (1.2

16VM Nblueand1.2 LS versions)

Check and adjust handbrake lever stroke

Check evaporation system

Replace air cleaner cartridge

20 40 60 80 100 120 140 160 180

●●●●●●●●●

●●●●●●●●●

●●●●●●●●●

●●●●●●●●●

●●●●●●●●●

●●●

●●●●●●●●●

●

●●●●

●●●●

●●●●

●●

●●●

4C120-143 ING 11-03-2008 12:01 Pagina 122

Page 127 of 191

124

G

ADDITIONAL

CHECKS

Every 1000 kilometres or before

long trips, check and top up as neces-

sary:

– coolant level

– brake fluid level

– power steering fluid level

– windscreen washer liquid level

– tyre pressure and condition.

Every 3,000 kmcheck and top up

as necessary: engine oil level.

You are recommended to use

FL Groupproducts designed and pro-

duced specially for Lancia cars (see

the “Capacities” table in the “Tech-

nical specifications” section).

ANNUAL

INSPECTION

SCHEDULE

The following annual inspection

schedule is recommended for cars

travelling less than 20,000 km a year

(e.g. approximately 10,000 km). The

schedule includes the following oper-

ations:

– Check tyre condition and wear and

adjust pressure, if required (including

spare wheel).

– Check operation of lights (head-

lights, direction indicators, hazard

lights, boot light, passenger compart-

ment ceiling light, glove compartment

light, instrument panel lights, etc.).

– Check windscreen wiper/washer

and adjust nozzles.

– Check position/wear of wind-

screen/rear window wiper blades.

– Check front brake pad conditions

and wear.– Inspect conditions of. engine, gear-

box, transmission, piping (exhaust -

fuel feed - brakes), rubber parts (boots

- sleeves - bushings - etc.), brake and

fuel line hoses.

– Check battery charge status.

– Check conditions of various con-

trol belts.

– Check and top up fluid levels (en-

gine coolant, brakes, windscreen

washer, battery, etc.).

– Change engine oil.

– Replace engine oil filter.

– Replace pollen filter (where fitted).

4C120-143 ING 11-03-2008 12:01 Pagina 124

Page 140 of 191

137

G

If you get a flat tyre, stop immedi-

ately and change it so as not to dam-

age the tyre, the wheel, the suspension

and the steering.

Tyres age even if they are not used

very much. Cracking of the tread rub-

ber and the side walls are a sign of

this ageing. In any case, if the tyres

have been fitted for more than six

years they should be examined by an

expert who can judge whether they

are still fit for use. Remember to

check the spare tyre particularly care-

fully too.

If a replacement is necessary, always

use new tyres and avoid using ones

the origin of which you are not certain

about.

Lancia Y uses tubeless tyres. Under

no circumstances should an inner

tube be used with these tyres.

If you replace a tyre it is a good idea

to change the inflation valve, too.To ensure the front and rear tyres all

wear evenly, you are advised to

change the tyres over every 10-15

thousand kilometres keeping them on

the same side of the car so as not to

reverse the direction of rotation.RUBBER TUBING

Follow the Service Schedule care-

fully in the case of the braking and

fuel supply systems rubber hoses.

Ozone, high temperatures and long

absence of liquid in the system can in

fact cause the hardening and crack-

ing of the pipes with possible loss of

fluid. A careful check is therefore es-

sential.

Do not change the tyres

over in criss-cross fashion

by moving a tyre from the

left hand side of the car to the right

and vice versa.

4C120-143 ING 11-03-2008 12:01 Pagina 137

Page 147 of 191

TECHNICAL SPECIFICATIONS

Motor and engineering enthusiasts as well as

those “in the trade” will probably start reading

from this point in the manual. This, in fact, is

where a section jam-packed with facts, figures,

formulae, measurements and tables begins. In a

sense, it is the Lancia Y’s identity card.

A document that introduces the car and explains

in technical jargon all the features that go together

to make it a model designed to give you superla-

tive driving satisfaction.VEHICLE IDENTIFICATION DATA ............... 145

ENGINE CODE - BODY VERSIONS............... 146

ENGINE......................................................... 147

TRANSMISSION............................................. 150

BRAKES......................................................... 151

SUSPENSION ................................................. 152

STEERING..................................................... 152

WHEELS........................................................ 153

WHEEL GEOMETRY ..................................... 155

ELECTRICAL SYSTEM ................................. 155

PERFORMANCE............................................ 156

WEIGHTS...................................................... 157

DIMENSIONS................................................. 158

CAPACITIES .................................................. 160

TYRE PRESSURE .......................................... 163

FLUIDS AND LUBRICANTS .......................... 164

FUEL CONSUMPTION -

CO

2EMISSIONS ............................................. 166

144

G

4C144-167 ING 11-03-2008 12:02 Pagina 144

Page 151 of 191

148

G

FUEL SUPPLY / IGNITION

1.2 versions

Integrated electronic injection and

ignition system: a single electronic

control unit controls both functions.

It processes both the time the injec-

tion lasts (for fuel metering) and the

spark advance angle.

– Type: ......................Multi-point.

– Method of measuring the amount

of aspirated air for petrol metering:

“Speed density” (*).

– “Closed loop”: information on

combustion for correct petrol meter-

ing achieved by means of two lambda

sensors (one upstream and the other

downstream with respect to the catal-

yser).– Electric petrol pump: in-tank.

– Injection pressure: ......... 3.5 bar.

– Air cleaner: dry-type with paper

filter element.

– Firing order: ................1-3-4-2.

– Engine idling speed: 750±50 rpm.

– Spark plugs:

Champion.................RC10YCC

NGK ........................... BKR5EZ1.216Vversions

Integrated electronic injection and

ignition system: a single electronic

control unit controls both functions.

It processes both the time the injec-

tion lasts (for fuel metering) and the

spark advance angle.

– Type: ......................Multi-point.

– Method of measuring the amount

of aspirated air for “Speed density”

petrol metering (*).

– “Closed loop”: information on

combustion for correct petrol meter-

ing achieved by means of two lambda

sensors (one upstream and the other

downstream with respect to the catal-

yser).

– Electric petrol pump: in-tank.

4C144-167 ING 11-03-2008 12:02 Pagina 148

Page 152 of 191

149

G

– Injection pressure: ......... 3.5 bar.

– Air cleaner: dry-type with paper

filter element.

– Firing order: ................1-3-4-2.

– Engine idling speed: 700±50 rpm.

– Spark plugs:

NGK ..........................DCPR8E-N

(*) Analytic method, by electronically process-

ing data from the engine rpm (speed) sensor

and from the air temperature and absolute pres-

sure sensors in the intake manifold (density).

LUBRICATION

Forced-fed with gear pump with

pressure relief valve incorporated.

Oil purification through full-flow

cartridge filter.

COOLING

Cooling system with radiator, cen-

trifugal pump and expansion tank.

“Fixed by-pass” thermostat(1.2 en-

gine)” on the secondary circuit for the

recirculation of water from the engine

to the radiator.

Electric fan for radiator cooling on

the radiator with switching on/off

controlled by thermostatic switch lo-

cated on the radiator. Modifications or repairs

to the fuel feed system that

are not carried out prop-

erly or do not take the system’s

technical specifications into ac-

count can cause malfunctions with

the risk of fire.

4C144-167 ING 11-03-2008 12:02 Pagina 149

Page 160 of 191

157

G

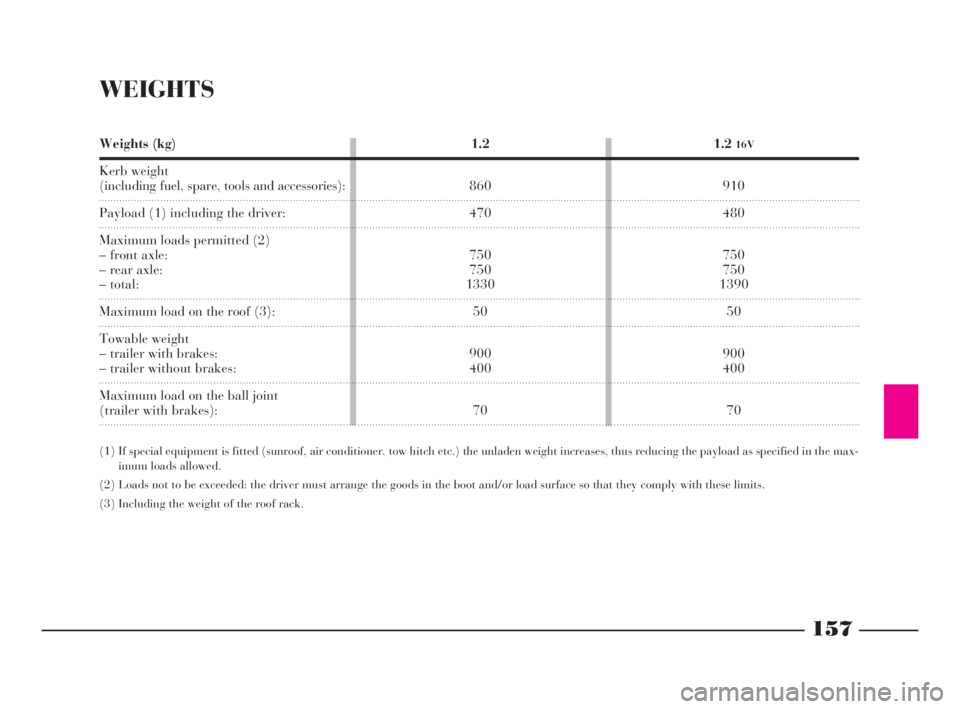

WEIGHTS

Weights (kg)

Kerb weight

(including fuel, spare, tools and accessories):

Payload (1) including the driver:

Maximum loads permitted (2)

– front axle:

– rear axle:

– total:

Maximum load on the roof (3):

Towable weight

– trailer with brakes:

– trailer without brakes:

Maximum load on the ball joint

(trailer with brakes):1.2

16V

910

480

750

750

1390

50

900

400

70 1.2

860

470

750

750

1330

50

900

400

70

(1) If special equipment is fitted (sunroof, air conditioner, tow hitch etc.) the unladen weight increases, thus reducing the payload as specified in the max-

imum loads allowed.

(2) Loads not to be exceeded: the driver must arrange the goods in the boot and/or load surface so that they comply with these limits.

(3) Including the weight of the roof rack.

4C144-167 ING 11-03-2008 12:02 Pagina 157

Page 163 of 191

160

G

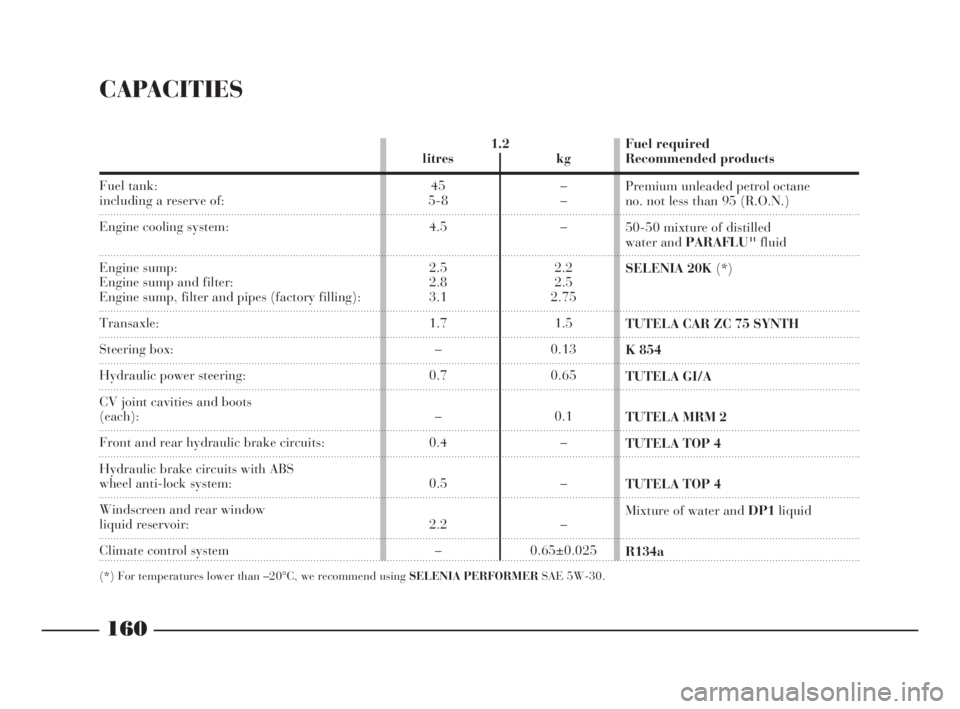

CAPACITIES

Fuel tank:including a reserve of:

Engine cooling system:

Engine sump:

Engine sump and filter:

Engine sump, filter and pipes (factory filling):

Transaxle:

Steering box:

Hydraulic power steering:

CV joint cavities and boots

(each):

Front and rear hydraulic brake circuits:

Hydraulic brake circuits with ABS

wheel anti-lock system:

Windscreen and rear window

liquid reservoir:

Climate control system

(*) For temperatures lower than –20°C, we recommend using SELENIA PERFORMERSAE 5W-30.

1.2

litres kg

45 –

5-8 –

4.5 –

2.5 2.2

2.8 2.5

3.1 2.75

1.7 1.5

–0.13

0.7 0.65

– 0.1

0.4 –

0.5 –

2.2 –

– 0.65±0.025Fuel required

Recommended products

Premium unleaded petrol octane

no. not less than 95 (R.O.N.)

50-50 mixture of distilled

water and PARAFLU

11fluid

SELENIA 20K(*)

TUTELA CAR ZC 75 SYNTH

K 854

TUTELA GI/A

TUTELA MRM 2

TUTELA TOP 4

TUTELA TOP 4

Mixture of water and DP1liquid

R134a

rs

4C144-167 ING 11-03-2008 12:02 Pagina 160

Page 164 of 191

161

G

Fuel tank:

including a reserve of:

Engine cooling system:

Engine sump:

Engine sump and filter:

Engine sump, filter and pipes (factory filling):

Transaxle:

Steering box:

Hydraulic power steering:

CV joint cavities and boots

(each):

Front and rear hydraulic brake circuits:

Hydraulic brake circuits with ABS

wheel anti-lock system:

Windscreen and rear window

liquid reservoir:

Climate control system:

(*) For temperatures lower than –20°C, we recommend using SELENIA PERFORMERSAE 5W-30.

1.216V

litres kg

45 –

5-8 –

4.5 –

2.5 2.2

2.8 2.5

3.1 2.75

1.7 1.5

–0.13

0.7 0.65

– 0.1

0.4 –

0.5 –

2.2 –

– 0.65±0.025

Fuel required

Recommended products

Premium unleaded petrol octane

no. not less than 95 (R.O.N.)

50-50 mixture of distilled

water and PARAFLU

11fluid

SELENIA 20K(*)

TUTELA CAR ZC 75 SYNTH

K 854

TUTELA GI/A

TUTELA MRM 2

TUTELA TOP 4

TUTELA TOP 4

Mixture of water and DP1liquid

R134a

4C144-167 ING 11-03-2008 12:02 Pagina 161

Page 169 of 191

166

G

FUEL

CONSUMPTION -

CO

2EMISSIONS

The fuel consumption values, in

litres x 100 km, indicated in the fol-

lowing tables, have been determined

according to homologation tests pre-

scribed in the European Directive

specifications. The following proce-

dures are used to define the con-

sumption values:Consumption values are defined by

means of the following procedures:

– an urban cycleconsisting of a

cold start and a simulated drive in

city streets;

– an extra-urban cycleconsisting

in frequent accelerations, in all gears,

simulating normal conditions of use.

Speed ranges from 0 to 120 km/h;

– the combined consumptionis

calculated as approximately 37% of

the urban cycle and approximately

63% of the extra-urban cycle. IMPORTANT Road and traffic

conditions, weather, general con-

ditions of the car, driving style, fit-

tings and accessories, use of the

climate control system, load, roof

racks and other situations penal-

ising aerodynamic penetration and

effecting rolling resistance will in-

fluence fuel consumption rates

which can be different from the

values shown in the table (see

“Cheap running that respects the

environment” in “Driving your

car” chapter).

Consumption may be greater during

the first 2000 km due to running in.

Consumption according1.2 1.2 16V1.216VM Nblue

to Directive 1999/100/EC1.216VM

Nred

Urban7.3 7.5 8.3

Extra-urban4.8 5.0 5.5

Combined5.7 6.0 6.5

4C144-167 ING 11-03-2008 12:02 Pagina 166