engine Lancia Ypsilon 2002 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2002, Model line: Ypsilon, Model: Lancia Ypsilon 2002Pages: 191, PDF Size: 2.45 MB

Page 144 of 191

141

G

IMPORTANTCars with optional

“Kaleidos” options (non-standard

personalised paint colours), can be re-

paired in exactly the same way as

other cars painted with standard

colours at your LANCIA Dealership.To wash the car properly:

1)Remove the aerial from the roof

to prevent damaging it when washing

the car in an automatic carwash.

2)Wet the body using a low pressure

jet of water.

3)Wipe a sponge with a slightly

soapy solution over the bodywork,

frequently rinsing the sponge.

4)Rinse well with water and dry

with a jet of air or a chamois leather.

When drying the car, be careful to

get at those parts which are not so

easily seen e.g. the door frames, bon-

net and around the headlights where

water can most readily collect. You

are advised not to take the car into a

closed area immediately, but to leave

it out in the open so any water left can

evaporate more easily.

Do not wash the car after it has been

parked in the sun or while the bonnet

is hot: it could take the shine off the

paint.

External plastic parts must be

cleaned following the usual car wash-

ing procedure. As far as possible avoid parking your

car under trees; the resinous sub-

stances which often drop from certain

types of trees could dull the paint and

increase the possibility of rusting.

IMPORTANTBird droppings must

be washed off immediately and with

great care as their acid is particularly

aggressive.

Detergents pollute water.

For this reason, the car

must be washed in an area

equipped for the collection and

purification of the liquids used

while washing.

IMPORTANTWashing is to be car-

ried out with the engine cold and the

ignition key on STOP. After washing

make sure that the various protections

(rubber sheaths and other guards)

have not moved from their positions

or been damaged.

4C120-143 ING 11-03-2008 12:01 Pagina 141

Page 145 of 191

Detergents pollute water.

The car must therefore be

washed in an area

equipped for the collection and

purification of the liquids used

while washing.

IMPORTANTThe car should be

washed while the engine is cold and

with the ignition key at STOP. After

washing the car, make sure that the

various protections (e.g. rubber boots

and various guards) have not been re-

moved or damaged.

142

G

Windows

Use specific window cleaners to

clean the windows. Use very clean

cloths to avoid scratching the glass or

damaging its transparency.

IMPORTANTTo prevent damage

to the electric heater elements, wipe

the inside of the heated rear window

gently in the same direction as the el-

ements.

Engine compartment

At the end of each winter season,

carefully clean the engine compart-

ment. Be careful not to direct the jet

of water on the electronic control

units. Have this done at a garage.INTERIORS

From time to time check that water

has not collected under the mats

(from dripping shoes, umbrellas etc.)

which could cause the steel to rust.

CLEANING THE SEATS

AND FABRIC UPHOLSTERY

– Remove the dust with a soft brush

or a vacuum cleaner.

– Rub the seats with a sponge moist-

ened in a solution of water and neu-

tral detergent.

4C120-143 ING 11-03-2008 12:01 Pagina 142

Page 147 of 191

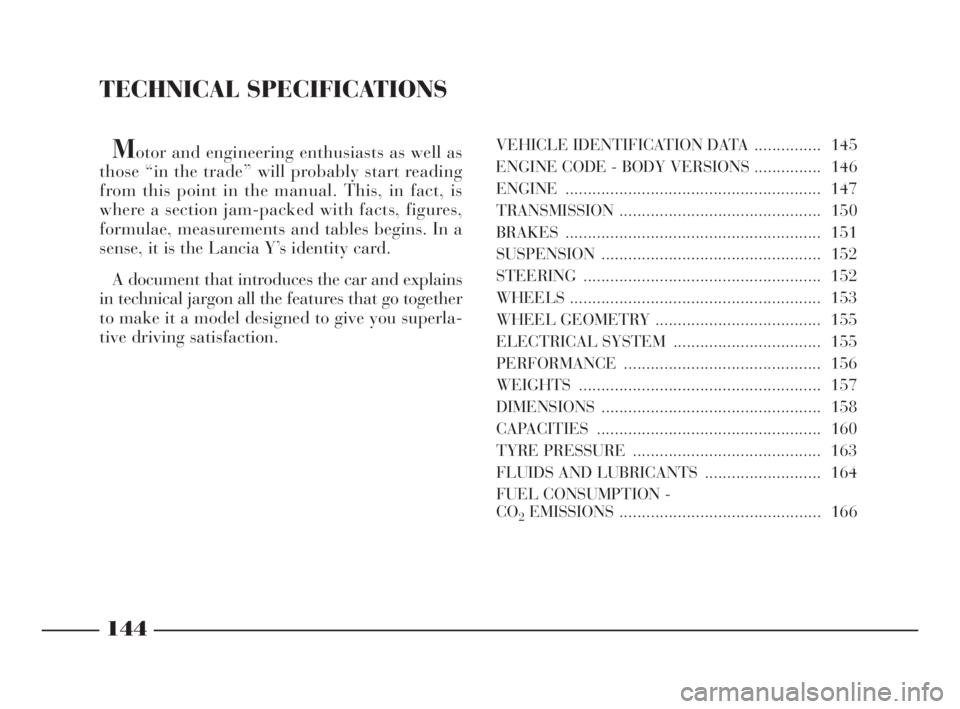

TECHNICAL SPECIFICATIONS

Motor and engineering enthusiasts as well as

those “in the trade” will probably start reading

from this point in the manual. This, in fact, is

where a section jam-packed with facts, figures,

formulae, measurements and tables begins. In a

sense, it is the Lancia Y’s identity card.

A document that introduces the car and explains

in technical jargon all the features that go together

to make it a model designed to give you superla-

tive driving satisfaction.VEHICLE IDENTIFICATION DATA ............... 145

ENGINE CODE - BODY VERSIONS............... 146

ENGINE......................................................... 147

TRANSMISSION............................................. 150

BRAKES......................................................... 151

SUSPENSION ................................................. 152

STEERING..................................................... 152

WHEELS........................................................ 153

WHEEL GEOMETRY ..................................... 155

ELECTRICAL SYSTEM ................................. 155

PERFORMANCE............................................ 156

WEIGHTS...................................................... 157

DIMENSIONS................................................. 158

CAPACITIES .................................................. 160

TYRE PRESSURE .......................................... 163

FLUIDS AND LUBRICANTS .......................... 164

FUEL CONSUMPTION -

CO

2EMISSIONS ............................................. 166

144

G

4C144-167 ING 11-03-2008 12:02 Pagina 144

Page 148 of 191

145

G

VEHICLE

IDENTIFICATION

DATA

CHASSIS MARKING (fig. 1)

This is stamped on the passenger

cabin floor, near the front right seat.

It can be reached by lifting the flap

in the carpet, and it bears:

– vehicle model .........ZLA 840000

– chassis serial number.ENGINE MARKING

The marking is stamped on the

cylinder block and includes the model

and serial number.

MODEL PLATE (fig. 2)

The plate (fig. 2)is applied to the

front cross member of the engine

compartment(fig. 3).

The plate bears the following iden-

tification data:

A- Manufacturer’s name.

B- Homologation number.C- Vehicle ID code.

D- Chassis serial number.

E- Maximum fully-laden vehicle

weight.

F- Maximum train weight of the

fully-laden vehicle plus trailer.

G- Maximum vehicle weight on first

(front) axle.

H- Maximum vehicle weight on sec-

ond (rear) axle.

I- Engine type.

L- Body version code.

M- Number for spares.

fig. 1

P4C00010

fig. 2

P4C00145

ffig. 3

P4C00415

4C144-167 ING 11-03-2008 12:02 Pagina 145

Page 149 of 191

146

G

BODYWORK PAINT

IDENTIFICATION PLATE

The plate(fig. 4)is fastened to the

inside of the tailgate.

It bears the following data:

A- Paint manufacturer.

B- Colour name.

C- LANCIA colour code.

D- Respray and touch-up code.ENGINE CODE - BODY VERSIONS

fig. 4

P4C00146

Version Engine type code Body version code

1.2 188A4.000 840AF1A 07

1.2

16V188A5.000 840AG1A 08

188A5.000 840AG1A 08B

4C144-167 ING 11-03-2008 12:02 Pagina 146

Page 150 of 191

147

G

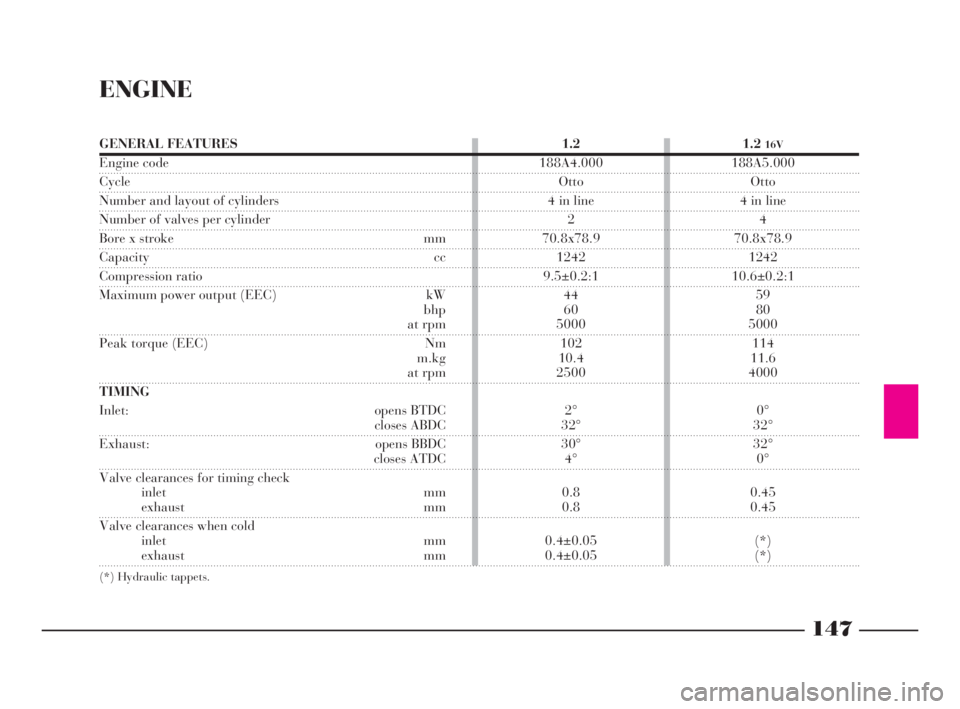

ENGINE

GENERAL FEATURES

Engine code

Cycle

Number and layout of cylinders

Number of valves per cylinder

Bore x stroke mm

Capacity cc

Compression ratio

Maximum power output (EEC) kW

bhp

at rpm

Peak torque (EEC) Nm

m.kg

at rpm

TIMING

Inlet: opens BTDC

closes ABDC

Exhaust: opens BBDC

closes ATDC

Valve clearances for timing check

inlet mm

exhaust mm

Valve clearances when cold

inlet mm

exhaust mm1.2

188A4.000

Otto

4 in line

2

70.8x78.9

1242

9.5±0.2:1

44

60

5000

102

10.4

2500

2°

32°

30°

4°

0.8

0.8

0.4±0.05

0.4±0.051.2

16V

188A5.000

Otto

4 in line

4

70.8x78.9

1242

10.6±0.2:1

59

80

5000

114

11.6

4000

0°

32°

32°

0°

0.45

0.45

(*)

(*)

(*) Hydraulic tappets.

4C144-167 ING 11-03-2008 12:02 Pagina 147

Page 151 of 191

148

G

FUEL SUPPLY / IGNITION

1.2 versions

Integrated electronic injection and

ignition system: a single electronic

control unit controls both functions.

It processes both the time the injec-

tion lasts (for fuel metering) and the

spark advance angle.

– Type: ......................Multi-point.

– Method of measuring the amount

of aspirated air for petrol metering:

“Speed density” (*).

– “Closed loop”: information on

combustion for correct petrol meter-

ing achieved by means of two lambda

sensors (one upstream and the other

downstream with respect to the catal-

yser).– Electric petrol pump: in-tank.

– Injection pressure: ......... 3.5 bar.

– Air cleaner: dry-type with paper

filter element.

– Firing order: ................1-3-4-2.

– Engine idling speed: 750±50 rpm.

– Spark plugs:

Champion.................RC10YCC

NGK ........................... BKR5EZ1.216Vversions

Integrated electronic injection and

ignition system: a single electronic

control unit controls both functions.

It processes both the time the injec-

tion lasts (for fuel metering) and the

spark advance angle.

– Type: ......................Multi-point.

– Method of measuring the amount

of aspirated air for “Speed density”

petrol metering (*).

– “Closed loop”: information on

combustion for correct petrol meter-

ing achieved by means of two lambda

sensors (one upstream and the other

downstream with respect to the catal-

yser).

– Electric petrol pump: in-tank.

4C144-167 ING 11-03-2008 12:02 Pagina 148

Page 152 of 191

149

G

– Injection pressure: ......... 3.5 bar.

– Air cleaner: dry-type with paper

filter element.

– Firing order: ................1-3-4-2.

– Engine idling speed: 700±50 rpm.

– Spark plugs:

NGK ..........................DCPR8E-N

(*) Analytic method, by electronically process-

ing data from the engine rpm (speed) sensor

and from the air temperature and absolute pres-

sure sensors in the intake manifold (density).

LUBRICATION

Forced-fed with gear pump with

pressure relief valve incorporated.

Oil purification through full-flow

cartridge filter.

COOLING

Cooling system with radiator, cen-

trifugal pump and expansion tank.

“Fixed by-pass” thermostat(1.2 en-

gine)” on the secondary circuit for the

recirculation of water from the engine

to the radiator.

Electric fan for radiator cooling on

the radiator with switching on/off

controlled by thermostatic switch lo-

cated on the radiator. Modifications or repairs

to the fuel feed system that

are not carried out prop-

erly or do not take the system’s

technical specifications into ac-

count can cause malfunctions with

the risk of fire.

4C144-167 ING 11-03-2008 12:02 Pagina 149

Page 158 of 191

155

G

ELECTRICAL

SYSTEM

Power supply voltage: 12 Volts.

BATTERY

With negative earth.STARTER MOTOR

With pinion and free wheel. En-

gagement through electromagnet op-

erated by the ignition key.

Power output:

All versions ......................... 0.8 kW

ALTERNATOR

Rectifier bridge and built-in elec-

tronic voltage regulator. Battery be-

gins recharging as soon as the engine

starts.

Maximum rated current output:

1.2

1.216V....................................65A

All versions

with climate control ..................75A

WHEEL GEOMETRY

Front wheel toe-in measured from

rim to rim: 0±1 mm.

The figures refer to the car in full

running order.Modifications or repairs

to the electrical system

carried out incorrectly and

without bearing the features of the

system in mind can cause mal-

functions with the risk of fire.

Version Capacity 20 hr Cold crankingdischarge rate power (–18°C)

1.2 - 1.2 16V40Ah 200A

4C144-167 ING 11-03-2008 12:02 Pagina 155

Page 163 of 191

160

G

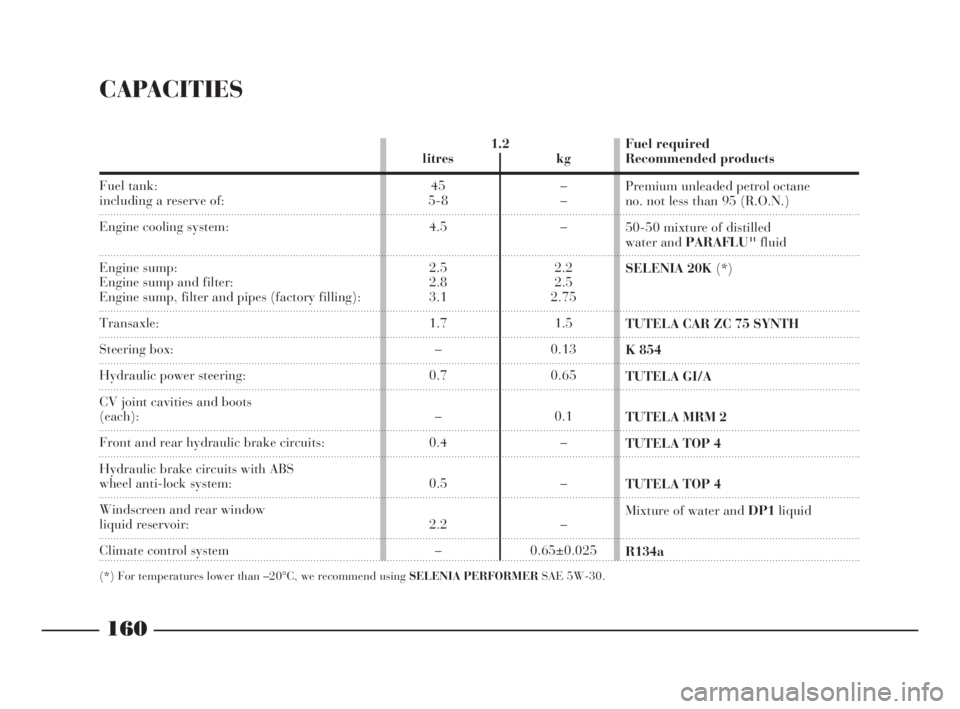

CAPACITIES

Fuel tank:including a reserve of:

Engine cooling system:

Engine sump:

Engine sump and filter:

Engine sump, filter and pipes (factory filling):

Transaxle:

Steering box:

Hydraulic power steering:

CV joint cavities and boots

(each):

Front and rear hydraulic brake circuits:

Hydraulic brake circuits with ABS

wheel anti-lock system:

Windscreen and rear window

liquid reservoir:

Climate control system

(*) For temperatures lower than –20°C, we recommend using SELENIA PERFORMERSAE 5W-30.

1.2

litres kg

45 –

5-8 –

4.5 –

2.5 2.2

2.8 2.5

3.1 2.75

1.7 1.5

–0.13

0.7 0.65

– 0.1

0.4 –

0.5 –

2.2 –

– 0.65±0.025Fuel required

Recommended products

Premium unleaded petrol octane

no. not less than 95 (R.O.N.)

50-50 mixture of distilled

water and PARAFLU

11fluid

SELENIA 20K(*)

TUTELA CAR ZC 75 SYNTH

K 854

TUTELA GI/A

TUTELA MRM 2

TUTELA TOP 4

TUTELA TOP 4

Mixture of water and DP1liquid

R134a

rs

4C144-167 ING 11-03-2008 12:02 Pagina 160