fuel type Lancia Ypsilon 2002 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2002, Model line: Ypsilon, Model: Lancia Ypsilon 2002Pages: 191, PDF Size: 2.45 MB

Page 16 of 191

13

G

THE LANCIA

CODE SYSTEM

To further protect your car from at-

tempted theft, it has been fitted with

an electronic engine immobiliser sys-

tem called “Lancia CODE”, which is

currently considered the most effec-

tive way of protecting your car against

theft.This system is automatically

activated each time the engine is

switched off. Each ignition key, in

fact, contains an electronic device

which modulates a radio-frequency

signal emitted by a special aerial dur-

ing ignition. The modulated signal is

a “password” with which the control

unit recognises the key. Engine igni-

tion is enabled only if the key is recog-

nised by the system.THE KEYS

Three types of key (fig. 1) are sup-

plied with the car.

The car is always supplied with a

singleAkey and BorCkeys depend-

ing on the version:

– version without remote control,

twoBkeys;

– versions with door lock/unlock re-

mote control, one Bkey and one Ckey;

KeyA, with a burgundy grip, is the

“master” key. Only one of these keys

is provided, and it is used to store the

codes of new keys replacing ones that

have been lost or damaged, or when

storing duplicate key codes. Given its

importance, it should be kept in a safe

place (not in the car) and only be

used when absolutely necessary.

No repairs can be carried out on

the Lancia CODE system or the en-

gine control unit if this key is lost.KeyB, with a black grip, is the key

that is to be used normally. It will:

– start the engine

– unlock/lock the doors

– unlock/lock the boot

– unlock/lock the fuel tank cap.

– deactivate the passenger airbag.

KeyC, (which may be supplied as

an alternative to the Bkey), has the

same functions as key B, plus the re-

mote control function for the door

lock/unlock system.

The key is supplied together with the

CODE card (fig. 2) which bears:

D- the electronic code to be used for

emergency starting (see “In an emer-

gency”);

fig. 1

P4C00056

fig. 2

P4C00057

4C001-067 ING 11-03-2008 11:57 Pagina 13

Page 70 of 191

67

G

Only change the fuel filler cap with

a genuine spare part in order not to

compromise the petrol fume recovery

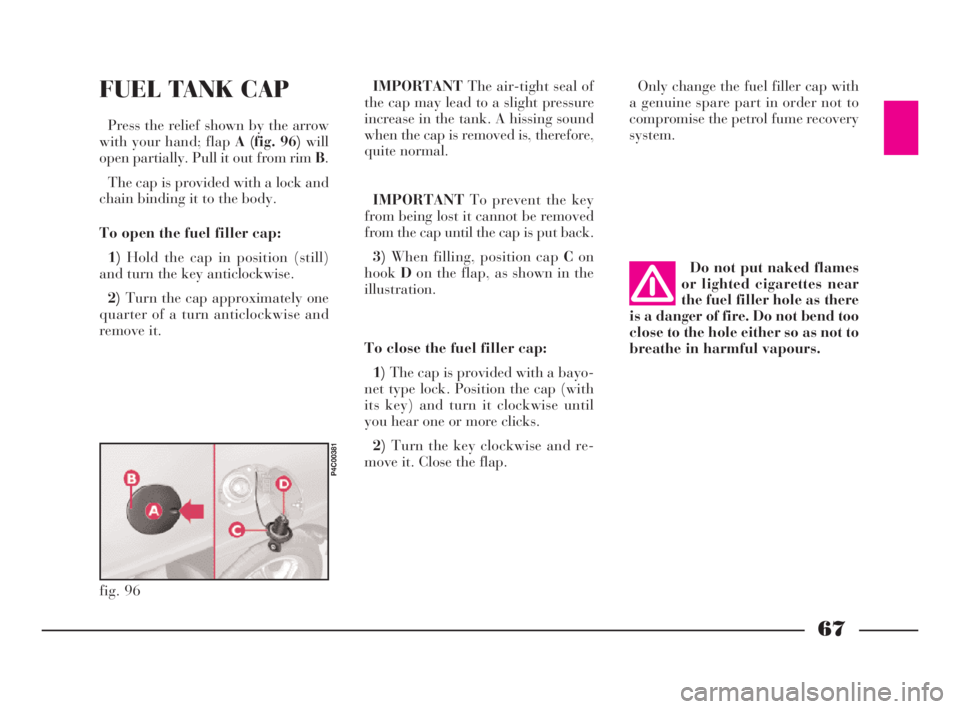

system.FUEL TANK CAP

Press the relief shown by the arrow

with your hand; flapA (fig. 96)will

open partially. Pull it out from rim B.

The cap is provided with a lock and

chain binding it to the body.

To open the fuel filler cap:

1)Hold the cap in position (still)

and turn the key anticlockwise.

2)Turn the cap approximately one

quarter of a turn anticlockwise and

remove it.IMPORTANTThe air-tight seal of

the cap may lead to a slight pressure

increase in the tank. A hissing sound

when the cap is removed is, therefore,

quite normal.

IMPORTANTTo prevent the key

from being lost it cannot be removed

from the cap until the cap is put back.

3)When filling, position cap Con

hookDon the flap, as shown in the

illustration.

To close the fuel filler cap:

1)The cap is provided with a bayo-

net type lock. Position the cap (with

its key) and turn it clockwise until

you hear one or more clicks.

2)Turn the key clockwise and re-

move it. Close the flap.Do not put naked flames

or lighted cigarettes near

the fuel filler hole as there

is a danger of fire. Do not bend too

close to the hole either so as not to

breathe in harmful vapours.

fig. 96

P4C00381

4C001-067 ING 11-03-2008 11:57 Pagina 67

Page 151 of 191

148

G

FUEL SUPPLY / IGNITION

1.2 versions

Integrated electronic injection and

ignition system: a single electronic

control unit controls both functions.

It processes both the time the injec-

tion lasts (for fuel metering) and the

spark advance angle.

– Type: ......................Multi-point.

– Method of measuring the amount

of aspirated air for petrol metering:

“Speed density” (*).

– “Closed loop”: information on

combustion for correct petrol meter-

ing achieved by means of two lambda

sensors (one upstream and the other

downstream with respect to the catal-

yser).– Electric petrol pump: in-tank.

– Injection pressure: ......... 3.5 bar.

– Air cleaner: dry-type with paper

filter element.

– Firing order: ................1-3-4-2.

– Engine idling speed: 750±50 rpm.

– Spark plugs:

Champion.................RC10YCC

NGK ........................... BKR5EZ1.216Vversions

Integrated electronic injection and

ignition system: a single electronic

control unit controls both functions.

It processes both the time the injec-

tion lasts (for fuel metering) and the

spark advance angle.

– Type: ......................Multi-point.

– Method of measuring the amount

of aspirated air for “Speed density”

petrol metering (*).

– “Closed loop”: information on

combustion for correct petrol meter-

ing achieved by means of two lambda

sensors (one upstream and the other

downstream with respect to the catal-

yser).

– Electric petrol pump: in-tank.

4C144-167 ING 11-03-2008 12:02 Pagina 148

Page 152 of 191

149

G

– Injection pressure: ......... 3.5 bar.

– Air cleaner: dry-type with paper

filter element.

– Firing order: ................1-3-4-2.

– Engine idling speed: 700±50 rpm.

– Spark plugs:

NGK ..........................DCPR8E-N

(*) Analytic method, by electronically process-

ing data from the engine rpm (speed) sensor

and from the air temperature and absolute pres-

sure sensors in the intake manifold (density).

LUBRICATION

Forced-fed with gear pump with

pressure relief valve incorporated.

Oil purification through full-flow

cartridge filter.

COOLING

Cooling system with radiator, cen-

trifugal pump and expansion tank.

“Fixed by-pass” thermostat(1.2 en-

gine)” on the secondary circuit for the

recirculation of water from the engine

to the radiator.

Electric fan for radiator cooling on

the radiator with switching on/off

controlled by thermostatic switch lo-

cated on the radiator. Modifications or repairs

to the fuel feed system that

are not carried out prop-

erly or do not take the system’s

technical specifications into ac-

count can cause malfunctions with

the risk of fire.

4C144-167 ING 11-03-2008 12:02 Pagina 149