technical specifications Lancia Ypsilon 2015 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2015, Model line: Ypsilon, Model: Lancia Ypsilon 2015Pages: 315, PDF Size: 10.85 MB

Page 186 of 315

To change a wheel proceed as follows:

❒Stop the car in a position that is not dangerous

for oncoming traffic where you can change the

wheel safely. The ground must be flat and

sufficiently compact;

❒switch off the engine, pull up the handbrake

and engage the 1

stgear or the reverse gear.

Wear the reflective safety jacket (compulsory by

law in certain countries) before getting out of

the car;

❒open the luggage compartment, pull tab A

fig. 115 and lift up the mat;❒using the wrench A fig. 116 located in the tool

box, loosen the locking device, take the tool

box B and place it close to the wheel to be

replaced. Then take the space-saver wheel C;

fig. 115L0F0099fig. 116L0F0183

182

GETTING TO KNOW

YOUR CAR

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

Page 187 of 315

❒take the wrench A fig. 117 and loosen the fixing

bolts by about one turn. For versions with alloy

rims, shake the car to facilitate detachment of

the rim from the wheel hub.

❒position the jack under the car, near the wheel

to be changed;

❒operate the device A fig. 118 to extend the jack

until the top of the jack B fig. 119 fits correctly

into the side member C (next to the mark on

the side member);

❒alert other passengers that the car is about to be

raised; all persons should be kept away from the

car until it has been lowered;❒fit handle D fig. 118 into the housing in device

A, operate the jack and raise the car until the

wheel is a few centimetres from the ground;

❒remove the wheel cap after loosening the 3

fixing bolts and finally loosen the fourth bolt

and extract the wheel (only for versions with

wheel caps fixed by bolts);

❒make sure the contact surfaces between

space-saver wheel and hub are clean so that the

fastening bolts will not come loose;

❒fit the space-saver wheel by inserting the first

bolt for two threads into the hole closest to the

valve;

❒take the wrench A fig. 117 and fully tighten the

fixing bolts;

❒operate the jack handle D to lower the car. Then

extract the jack;

fig. 117L0F0179fig. 118L0F0025

183

GETTING TO KNOW

YOUR CAR

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

Page 188 of 315

❒use the wrench A provided to fully tighten the

bolts in a criss-cross fashion as per the order

illustrated in fig. 120;

❒when replacing an alloy wheel it is advisable to

place it upside down, with the aesthetic part

facing upwards.Restore the standard wheel as soon as possible,

because, once placed in the associated

compartment, the luggage compartment load

platform is rendered uneven as the standard wheel

is larger than the spare wheel.

REFITTING THE STANDARD WHEEL

Following the procedure described previously,

raise the car and remove the space-saver wheel.

Versions with steel rims

Proceed as follows:

❒make sure the contact surfaces between

standard wheel and hub are clean so that the

fastening bolts will not come loose;

❒fit the standard wheel inserting the 4 bolts into

the holes;

❒using the wrench provided, tighten the fastening

bolts; ❒press-fit the hub cap, aligning the special

splining (on the cap) with the inflation valve;

❒lower the car and remove the jack;

❒using the wrench provided, fully tighten the

bolts in the sequence shown previously.

fig. 119L0F0024

fig. 120L0F0182

184

GETTING TO KNOW

YOUR CAR

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

Page 189 of 315

Versions with alloy wheels

❒insert the wheel on the hub and using the

wrench provided tighten the bolts;

❒lower the car and remove the jack;

❒using the wrench provided, fully tighten the

bolts in the sequence shown ;

❒reinstall the pressure-fitted hub cap, making

sure that the reference hole on the wheel is

aligned with the reference hole on the cap.

IMPORTANT If it is not fitted properly, the hub

cap may detach itself when the car is running.

After tyre replacement

❒stow the space-saver wheel in the compartment

provided in the boot;

❒insert the jack and the other tools in the

container;

❒arrange the container and tools on the

space-saver wheel;

❒correctly reposition the boot stiff cover.

185

GETTING TO KNOW

YOUR CAR

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

QUICK TYRE REPAIR KIT - Fix&Go

It is located in a special container in the luggage

compartment fig. 121. The container also contains a

screwdriver and the tow hook.

The Fix&Go kit fig. 122 consists of:

❒spray bottle A with the sealant, equipped with

filling pipe B, separated by the compressor C;

❒compressor C with pressure gauge, valve-fitting

to couple the bottle A, cable with supply socket

D and pipe N to restore pressure (the same is

inside the body as shown);

❒adhesive label under the spray bottle A, with the

message “max. 80 km/h” to be placed where

the driver can easily see it (for example on the

dashboard) after repairing the tyre;

fig. 121L0F0307

Page 190 of 315

186

GETTING TO KNOW

YOUR CAR

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

❒instruction booklet fig. 123, explaining the

quick and correct use of the Fix&Go;

❒protective gloves.

fig. 122L0F0300

fig. 123L0F0301

WARNING

Give the booklet to the technicians

who will be handling the tyre that

was treated using the Fix&Go kit.

WARNING

In the event of a puncture caused by

foreign bodies, the kit may be used to

repair tyres showing damage on the track or

shoulder up to max 4 mm diameter. Holes

and damage on the tyre side walls cannot be

repaired. Do not attempt to use the Fix&Go

kit if the tyre was damaged as a result of

being used when underinflated.

WARNING

If the wheel rim has been damaged

(bent so as to cause pressure loss), the

wheel may not be repaired. Do not remove

the foreign body (screws or nails) from the

tyre.

IMPORTANT INFORMATION

The sealing fluid of the quick tyre repair kit is

effective at external temperatures of between

-20°C and +50°C.

Page 191 of 315

187

GETTING TO KNOW

YOUR CAR

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

The sealing fluid has an expiry date.

WARNING

Never operate the compressor for

longer than 20 consecutive minutes.

Risk of overheating. The Fix&Go kit is not

suitable for definitive repairs, so the

repaired tyres may only be used temporarily.

WARNING

The bottle contains ethylene glycol. It

contains latex that might cause

allergic reactions. It is harmful if swallowed.

It is irritant for the eyes. May cause a

reaction if inhaled or on contact. Avoid

contact with eyes, skin and clothes. In the

event of contact, wash immediately with

plenty of water. If ingested, do not induce

vomiting. Rinse out your mouth, drink large

quantities of water and seek immediate

medical attention. Keep out of the reach of

children. The product must not be used

by asthmatics. Do not inhale the vapours

during insertion and suction. Call a doctor

immediately if allergic reactions are noted.

Store the spray bottle away from heat

sources. The sealing fluid has an expiry

date.

Replace the bottle if the sealing fluid

has expired. Dispose of the bottle

and the sealant liquid properly. Have

the sealing fluid and the bottle disposed of in

compliance with national and local

regulations.

INFLATION PROCEDURE

WARNING

Wear the protective gloves provided

with the Fix&Go kit.

To carry out the inflation procedure proceed as

follows:

❒engage the handbrake;

❒place the Fix&Go kit close to the tyre to be

repaired;

❒locate the filler pipe fig. 124 already

connected to the spray bottle A;

❒open the side lid E fig. 125 then connect the

spray bottle A to the fitting, following the

direction of the arrow;

❒undo the cap of the tyre valve F and connect the

filling pipe B tightening the relevant ring nut on

the tyre valve;

❒Make sure that the switch G fig. 126 is in position

0(off), then start the engine;

Page 192 of 315

188

GETTING TO KNOW

YOUR CAR

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

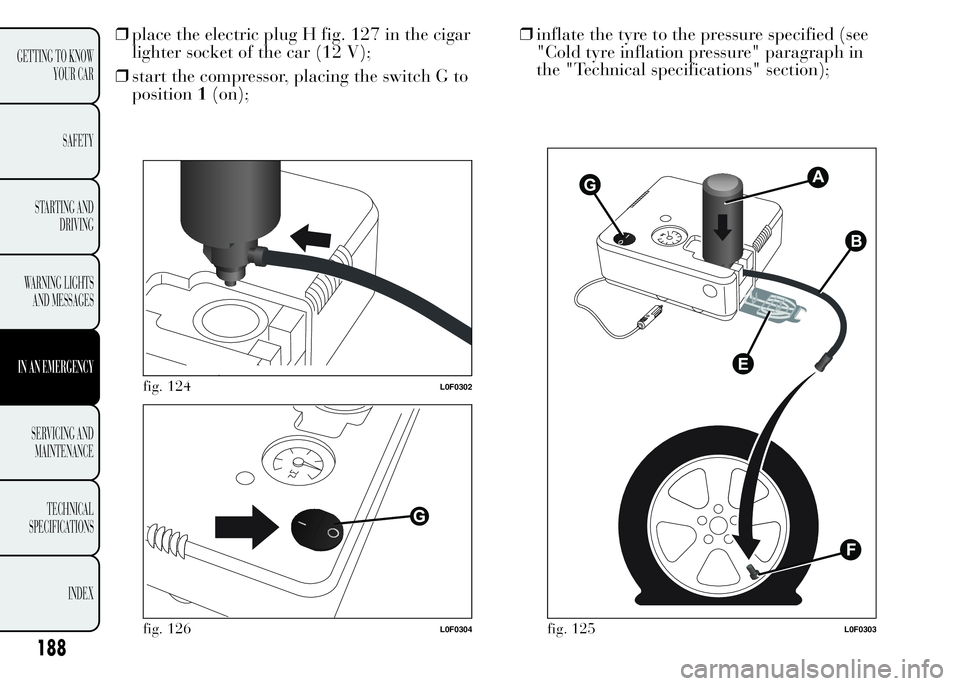

❒place the electric plug H fig. 127 in the cigar

lighter socket of the car (12 V);

❒start the compressor, placing the switch G to

position1(on);

fig. 124L0F0302

fig. 126L0F0304

❒inflate the tyre to the pressure specified (see

"Cold tyre inflation pressure" paragraph in

the "Technical specifications" section);

fig. 125L0F0303

Page 193 of 315

189

GETTING TO KNOW

YOUR CAR

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

IMPORTANT To get a more precise reading, it is

recommended to check the value with compressor

off.

❒If the pressure does not reach at least 1.5 bar in

5 minutes, switch the compressor off and

disconnect the filling pipe B from the tyre valve,

then remove the plug H;

❒move the car of about 10 m, to distribute the

sealant inside the tyre, then inflate again;

IMPORTANT If after this operation it is still

impossible, after 5 minutes, to reach at least 1.5

bar, do not start driving since the tyre is

excessively damaged and the Fix&Go kit cannot

guarantee proper hold. In this case, go to a Lancia

Dealership.

fig. 127L0F0305

❒if the tyre reaches the pressure specified, start

driving immediately;

❒after driving for about 10 minutes stop, operate

the handbrake and check the tyre pressure

again.

WARNING

Apply the adhesive label where it can

be easily seen by the driver as a

reminder that the tyre has been treated with

the Fix&Go kit. Drive carefully, particularly

on bends. Do not exceed 80 km/h. Do not

accelerate or brake suddenly.

WARNING

If pressure has fallen below 1.5 bar,

do not drive any further: the Fix&Go

kit cannot guarantee the correct hold

because the tyre is too damaged, contact a

Lancia Dealership. If instead a pressure

value of at least 1.5 bar is detected, restore

the correct pressure (with the engine

running and the handbrake engaged),

resume driving and drive with care to the

nearest Lancia Dealership.

Page 194 of 315

190

GETTING TO KNOW

YOUR CAR

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

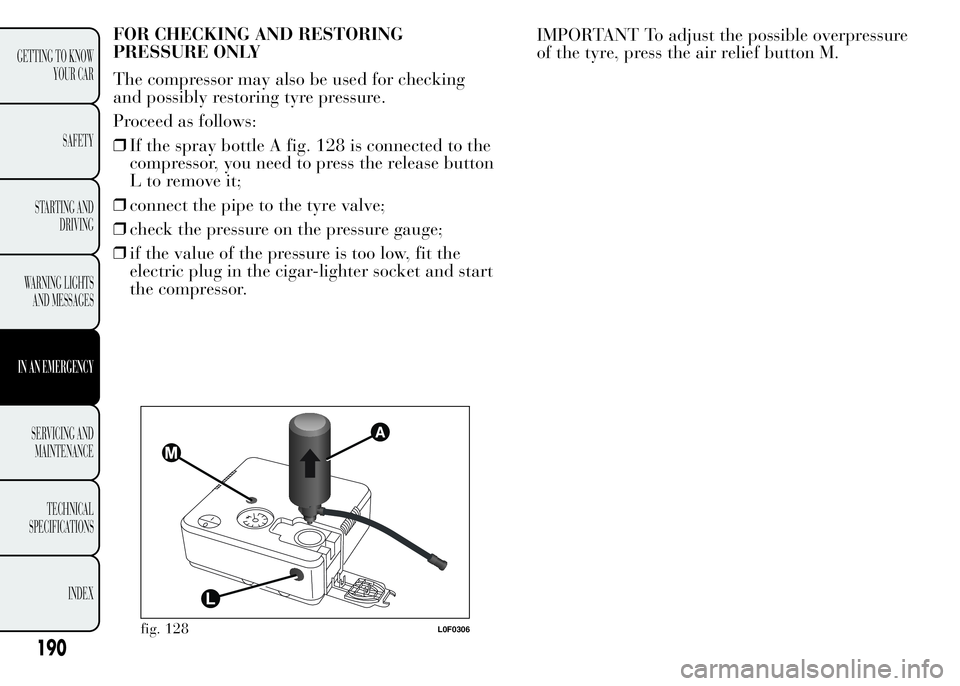

FOR CHECKING AND RESTORING

PRESSURE ONLY

The compressor may also be used for checking

and possibly restoring tyre pressure.

Proceed as follows:

❒If the spray bottle A fig. 128 is connected to the

compressor, you need to press the release button

L to remove it;

❒connect the pipe to the tyre valve;

❒check the pressure on the pressure gauge;

❒if the value of the pressure is too low, fit the

electric plug in the cigar-lighter socket and start

the compressor.IMPORTANT To adjust the possible overpressure

of the tyre, press the air relief button M.

fig. 128L0F0306

Page 195 of 315

CHANGING A BULB

GENERAL INSTRUCTIONS

❒Before changing a bulb check the contacts for

oxidation;

❒Burnt bulbs must be replaced by others of the

same type and power;

❒after replacing a headlight bulb, always check

its alignment;

❒when a light is not working, check that the

corresponding fuse is intact before changing

a bulb. For the location of fuses, refer to the

paragraph “If a fuse blows” in this section;

WARNING

Modifications or repairs to the

electric system that are not carried

out properly or do not take the system

technical specifications into account can

cause malfunctions leading to the risk of

fire.

WARNING

Halogen bulbs contain pressurised

gas, in the case of breakage they may

burst.

Halogen bulbs must be handled

holding the metallic part only.

Touching the transparent part of the

bulb with your fingers may reduce the

intensity of the emitted light and even reduce

the lifespan of the bulb. In case of accidental

contact, wipe the bulb with a cloth moistened

with alcohol and let the bulb dry.

191

GETTING TO KNOW

YOUR CAR

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX