lock Lancia Ypsilon 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2020, Model line: Ypsilon, Model: Lancia Ypsilon 2020Pages: 200, PDF Size: 4.53 MB

Page 111 of 200

REPLACING AN

EXTERNAL BULB

FRONT LIGHT CLUSTERS

These contain the bulbs for the daytime

running lights (DRL), side lights,

dipped/main beam headlights and

direction indicators.

The bulbs are arranged as follows fig.

83:

Daytime running lights (DRL)

Dipped/main beam headlights and

side lights

Direction indicators

Daytime running lights (DRL)

To replace the bulb, proceed as follows:

remove cover A fig. 83;

turn the snap-fitted bulb holder unit

B fig. 84 anticlockwise, remove bulb

C and replace it;

refit the new bulb then reinsert the

bulb holder B fig. 84 in its housing;

then refit the cover A fig. 83.

Side lights

To replace the bulb, proceed as follows:

remove cover B fig. 83;

remove snap-fitted bulb holder C fig.

85, remove the bulb D and replace it;

refit the new bulb then reinsert

the bulb holder unit C fig. 85 in

its housing;

then refit the cover B fig. 83.

Dipped/main beam headlights

To replace the bulb, proceed as follows:

remove the cover B fig. 83 and

then the snap-fitted bulb holder C fig.

86;

remove bulb D from the connector E

and replace it;

refit the new bulb on the connector

making sure that it is locked correctly,

then reinsert bulb holder C in its

housing;

then refit the cover B fig. 83.

Front direction indicators

To replace the bulb, proceed as follows:

turn the cover C fig. 83

anticlockwise, extract the bulb D fig. 87

from its housing and replace it;

83L0F0033C

84L0F0070C

85L0F0069C

86L0F0068C

109

Page 112 of 200

refit the bulb D in the housing E and

then fit the cover C fig. 83.

Side direction indicators

To replace the bulb, proceed as follows:

adjust the lens A fig. 89 to

compress in the internal catch B, then

pull the unit outwards;

turn the bulb holder C anticlockwise,

extract the bulb and replace it;

refit the bulb holder C in the lens and

turn it clockwise;

refit the cluster making sure that the

internal catch B clips into position.

Front fog lights

(for versions/markets, where provided)

To replace the bulb, proceed as follows:

steer the wheel completely, adjust

the tabs A fig. 89 and remove the

flap B;

adjust the clip C fig. 90 and

disconnect the electrical connector D;

remove the cover E by turning it

clockwise (see the word OFF and the

arrow on the cover);

release the catches F fig. 91

removing them outwards;

release the connector G fig. 92 and

replace the bulb H;

87L0F0071C

88L0F0209C

89L0F0205C

90L0F0206C

91L0F0207C

92L0F0208C

110

IN AN EMERGENCY

Page 113 of 200

refit the new lamp and carry out the

procedure described previously in

reverse.

REAR LIGHT CLUSTERS

These contain the bulbs for the side

lights, brake lights and direction

indicators. The reversing lights and rear

fog lights are located instead in the

rear bumper.

The bulbs are arranged as follows fig.

93:A- Direction indicators

B- Brake lights

Direction indicators/brake lights

Turn the bulb holder in directionO

(open) to replace the bulbs. After

replacing the bulb, turn the bulb holder

in directionC(close).

Side lights

These are LEDs. Contact a Lancia

Dealership for replacement.

THIRD BRAKE LIGHTS

These are located in the tailgate and

are LED lights. Contact a Lancia

Dealership for replacement.

REVERSING LIGHT/REAR FOG

LIGHT

To replace the bulb, proceed as follows:

working from inside the bumper,

turn the bulb holder unit A fig. 94 by a

1/4 turn;

extract the bulb and replace it;

refit the new bulb then reinsert the

bulb holder in its housing.

NUMBER PLATE LIGHTS

To replace the bulbs proceed as

follows:

remove lens A fig. 95;

turn the bulb holder B fig. 96

clockwise, extract the bulb C and

replace it; then refit the lens.

93L0F0034C

94L0F0219C

95L0F0259C

96L0F0214C

111

Page 117 of 200

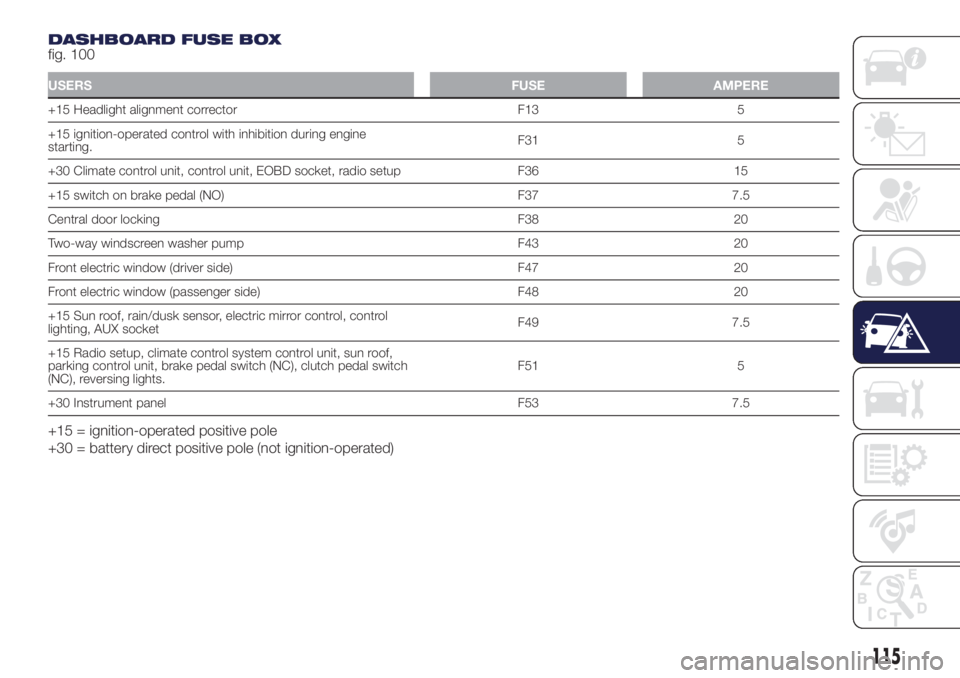

DASHBOARD FUSE BOX

fig. 100

USERSFUSE AMPERE

+15 Headlight alignment corrector F13 5

+15 ignition-operated control with inhibition during engine

starting.F31 5

+30 Climate control unit, control unit, EOBD socket, radio setup F36 15

+15 switch on brake pedal (NO) F37 7.5

Central door locking F38 20

Two-way windscreen washer pump F43 20

Front electric window (driver side) F47 20

Front electric window (passenger side) F48 20

+15 Sun roof, rain/dusk sensor, electric mirror control, control

lighting, AUX socketF49 7.5

+15 Radio setup, climate control system control unit, sun roof,

parking control unit, brake pedal switch (NC), clutch pedal switch

(NC), reversing lights.F51 5

+30 Instrument panel F53 7.5

+15 = ignition-operated positive pole

+30 = battery direct positive pole (not ignition-operated)

115

Page 119 of 200

REPLACING A

WHEEL

129) 130) 131) 132) 133) 134) 135)

54) 55)

JACK

Please note that:

the jack weight is 1,76 kg;

the jack requires no adjustment;

the jack cannot be repaired and in

the event of a fault it must be replaced

by another genuine one;

no tool other than its cranking

device may be fitted on the jack.

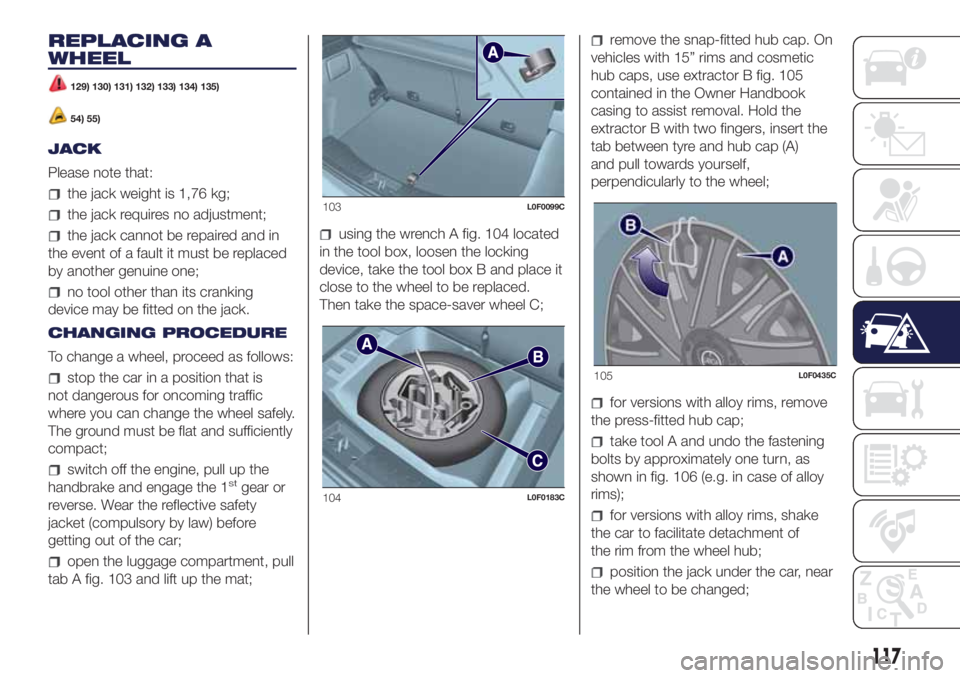

CHANGING PROCEDURE

To change a wheel, proceed as follows:

stop the car in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground must be flat and sufficiently

compact;

switch off the engine, pull up the

handbrake and engage the 1stgear or

reverse. Wear the reflective safety

jacket (compulsory by law) before

getting out of the car;

open the luggage compartment, pull

tab A fig. 103 and lift up the mat;

using the wrench A fig. 104 located

in the tool box, loosen the locking

device, take the tool box B and place it

close to the wheel to be replaced.

Then take the space-saver wheel C;

remove the snap-fitted hub cap. On

vehicles with 15” rims and cosmetic

hub caps, use extractor B fig. 105

contained in the Owner Handbook

casing to assist removal. Hold the

extractor B with two fingers, insert the

tab between tyre and hub cap (A)

and pull towards yourself,

perpendicularly to the wheel;

for versions with alloy rims, remove

the press-fitted hub cap;

take tool A and undo the fastening

bolts by approximately one turn, as

shown in fig. 106 (e.g. in case of alloy

rims);

for versions with alloy rims, shake

the car to facilitate detachment of

the rim from the wheel hub;

position the jack under the car, near

the wheel to be changed;

103L0F0099C

104L0F0183C

105L0F0435C

117

Page 121 of 200

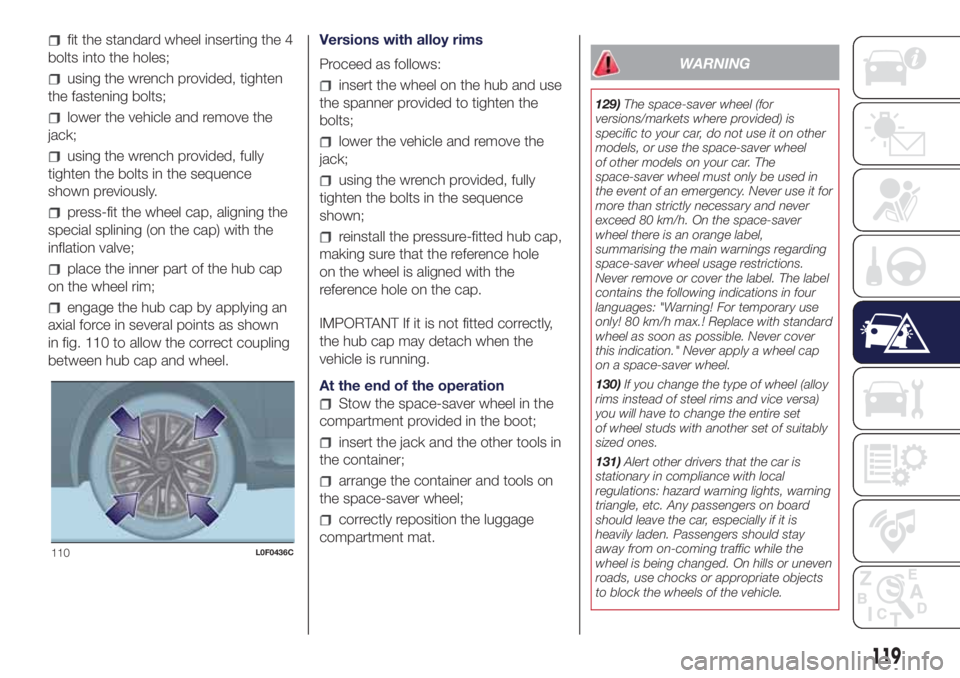

fit the standard wheel inserting the 4

bolts into the holes;

using the wrench provided, tighten

the fastening bolts;

lower the vehicle and remove the

jack;

using the wrench provided, fully

tighten the bolts in the sequence

shown previously.

press-fit the wheel cap, aligning the

special splining (on the cap) with the

inflation valve;

place the inner part of the hub cap

on the wheel rim;

engage the hub cap by applying an

axial force in several points as shown

in fig. 110 to allow the correct coupling

between hub cap and wheel.Versions with alloy rims

Proceed as follows:

insert the wheel on the hub and use

the spanner provided to tighten the

bolts;

lower the vehicle and remove the

jack;

using the wrench provided, fully

tighten the bolts in the sequence

shown;

reinstall the pressure-fitted hub cap,

making sure that the reference hole

on the wheel is aligned with the

reference hole on the cap.

IMPORTANT If it is not fitted correctly,

the hub cap may detach when the

vehicle is running.

At the end of the operation

Stow the space-saver wheel in the

compartment provided in the boot;

insert the jack and the other tools in

the container;

arrange the container and tools on

the space-saver wheel;

correctly reposition the luggage

compartment mat.

WARNING

129)The space-saver wheel (for

versions/markets where provided) is

specific to your car, do not use it on other

models, or use the space-saver wheel

of other models on your car. The

space-saver wheel must only be used in

the event of an emergency. Never use it for

more than strictly necessary and never

exceed 80 km/h. On the space-saver

wheel there is an orange label,

summarising the main warnings regarding

space-saver wheel usage restrictions.

Never remove or cover the label. The label

contains the following indications in four

languages: "Warning! For temporary use

only! 80 km/h max.! Replace with standard

wheel as soon as possible. Never cover

this indication." Never apply a wheel cap

on a space-saver wheel.

130)If you change the type of wheel (alloy

rims instead of steel rims and vice versa)

you will have to change the entire set

of wheel studs with another set of suitably

sized ones.

131)Alert other drivers that the car is

stationary in compliance with local

regulations: hazard warning lights, warning

triangle, etc. Any passengers on board

should leave the car, especially if it is

heavily laden. Passengers should stay

away from on-coming traffic while the

wheel is being changed. On hills or uneven

roads, use chocks or appropriate objects

to block the wheels of the vehicle.

110L0F0436C

119

Page 126 of 200

FUEL CUT-OFF

SYSTEM

147)

FUEL CUT-OFF SYSTEM

This intervenes in the case of an impact

causing:

the interruption of the fuel supply

with the engine consequently cutting

out;

the automatic unlocking of the

doors;

turning on of the lights inside the

vehicle;

the switching on of the hazard

warning lights.

On some versions, the intervention of

the system is indicated by a message

shown on the display.

IMPORTANT Carefully check the vehicle

for fuel leaks, for instance in the engine

compartment, under the vehicle or

near the tank area. After an impact, turn

the ignition key to STOP to prevent the

battery from running down.

To restore the correct operation of the

vehicle, proceed as follows:

turn the ignition key to the MAR

position;

activate the right direction indicator;

deactivate the right direction

indicator;

activate the left direction indicator;

deactivate the left direction indicator;

activate the right direction indicator;

deactivate the right direction

indicator;

activate the left direction indicator;

deactivate the left direction indicator;

ignition key turned to the OFF

position;

turn the ignition key to the MAR-ON

position.

LPG / Natural Power versions:inthe

event of an impact, petrol supply is

immediately cut-off, the LPG safety

valves are closed and the injection is

interrupted, switching off the engine.

WARNING

147)If, after an impact, you smell fuel or

notice leaks from the fuel system, do

not reactivate the system to avoid the risk

of fire.

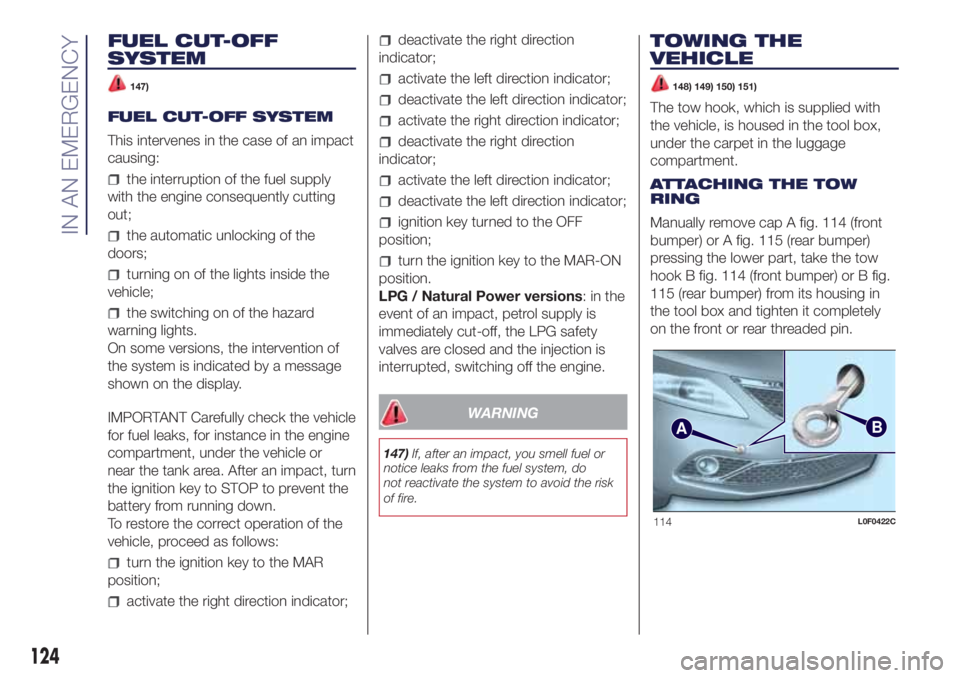

TOWING THE

VEHICLE

148) 149) 150) 151)

The tow hook, which is supplied with

the vehicle, is housed in the tool box,

under the carpet in the luggage

compartment.

ATTACHING THE TOW

RING

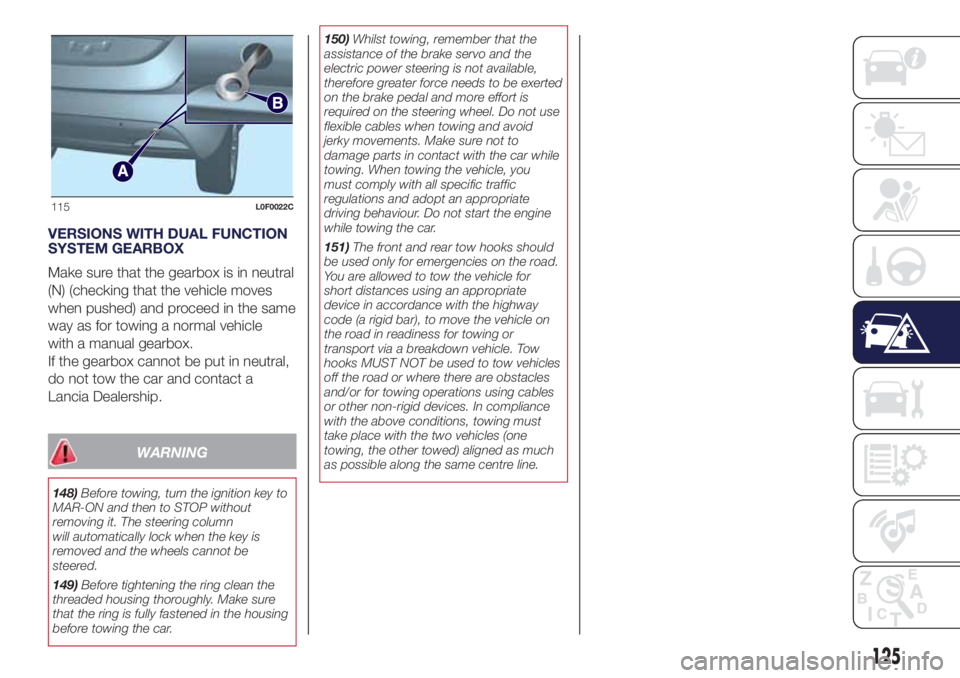

Manually remove cap A fig. 114 (front

bumper) or A fig. 115 (rear bumper)

pressing the lower part, take the tow

hook B fig. 114 (front bumper) or B fig.

115 (rear bumper) from its housing in

the tool box and tighten it completely

on the front or rear threaded pin.

AB

114L0F0422C

124

IN AN EMERGENCY

Page 127 of 200

VERSIONS WITH DUAL FUNCTION

SYSTEM GEARBOX

Make sure that the gearbox is in neutral

(N) (checking that the vehicle moves

when pushed) and proceed in the same

way as for towing a normal vehicle

with a manual gearbox.

If the gearbox cannot be put in neutral,

do not tow the car and contact a

Lancia Dealership.

WARNING

148)Before towing, turn the ignition key to

MAR-ON and then to STOP without

removing it. The steering column

will automatically lock when the key is

removed and the wheels cannot be

steered.

149)Before tightening the ring clean the

threaded housing thoroughly. Make sure

that the ring is fully fastened in the housing

before towing the car.150)Whilst towing, remember that the

assistance of the brake servo and the

electric power steering is not available,

therefore greater force needs to be exerted

on the brake pedal and more effort is

required on the steering wheel. Do not use

flexible cables when towing and avoid

jerky movements. Make sure not to

damage parts in contact with the car while

towing. When towing the vehicle, you

must comply with all specific traffic

regulations and adopt an appropriate

driving behaviour. Do not start the engine

while towing the car.

151)The front and rear tow hooks should

be used only for emergencies on the road.

You are allowed to tow the vehicle for

short distances using an appropriate

device in accordance with the highway

code (a rigid bar), to move the vehicle on

the road in readiness for towing or

transport via a breakdown vehicle. Tow

hooks MUST NOT be used to tow vehicles

off the road or where there are obstacles

and/or for towing operations using cables

or other non-rigid devices. In compliance

with the above conditions, towing must

take place with the two vehicles (one

towing, the other towed) aligned as much

as possible along the same centre line.

115L0F0022C

125

Page 131 of 200

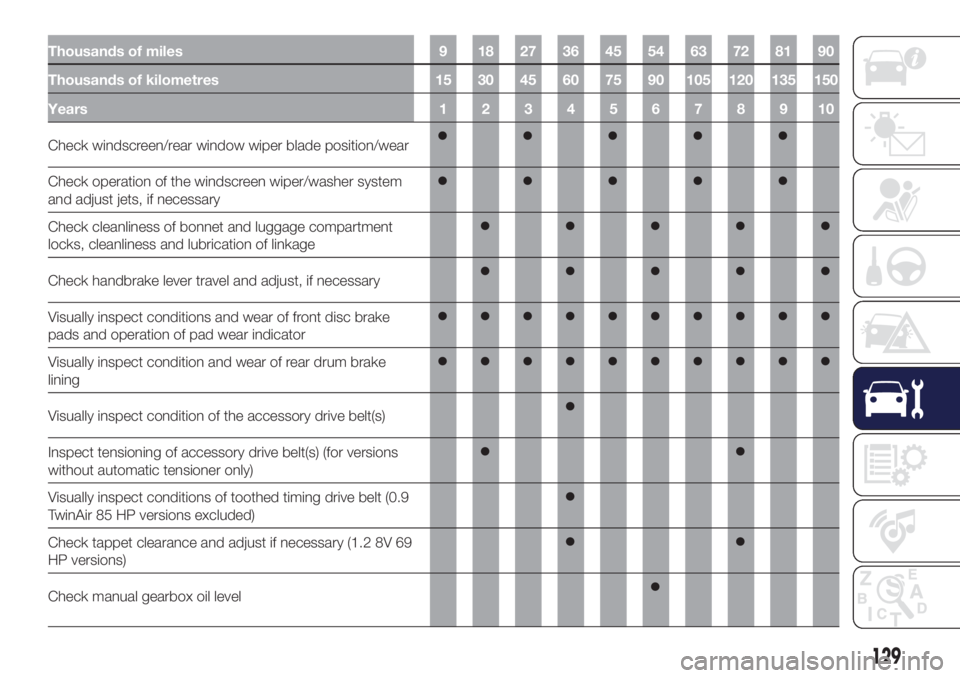

Thousands of miles 9 18 27 36 45 54 63 72 81 90

Thousands of kilometres 15 30 45 60 75 90 105 120 135 150

Years12345678910

Check windscreen/rear window wiper blade position/wear

Check operation of the windscreen wiper/washer system

and adjust jets, if necessary

Check cleanliness of bonnet and luggage compartment

locks, cleanliness and lubrication of linkage

Check handbrake lever travel and adjust, if necessary

Visually inspect conditions and wear of front disc brake

pads and operation of pad wear indicator

Visually inspect condition and wear of rear drum brake

lining

Visually inspect condition of the accessory drive belt(s)

Inspect tensioning of accessory drive belt(s) (for versions

without automatic tensioner only)

Visually inspect conditions of toothed timing drive belt (0.9

TwinAir 85 HP versions excluded)

Check tappet clearance and adjust if necessary (1.2 8V 69

HP versions)

Check manual gearbox oil level

129

Page 136 of 200

Thousands of miles 12 24 36 48 60 72 84 96 108 120

Thousands of kilometres 20 40 60 80 100 120 140 160 180 200

Years12345678910

Check windscreen/rear window wiper blade position/wear

Check operation of the windscreen wiper/washer system

and adjust jets, if necessary

Check cleanliness of bonnet and luggage compartment

locks, cleanliness and lubrication of linkage

Check handbrake lever travel and adjust, if necessary

Visually inspect conditions and wear of front disc brake

pads and operation of pad wear indicator

Visually inspect condition and wear of rear drum brake

lining

Visually inspect condition of the accessory drive belt(s)

Check manual gearbox oil level

134

SERVICING AND CARE