ESP LAND ROVER DEFENDER 1996 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 291 of 455

70BRAKES

10

REPAIR FRONT BRAKE CALIPERS

Service repair no - 70.55.05

Service repair no - 70.55.16

Before starting repair refer to general brake service

practice

See General Brake Service Practice.

Remove

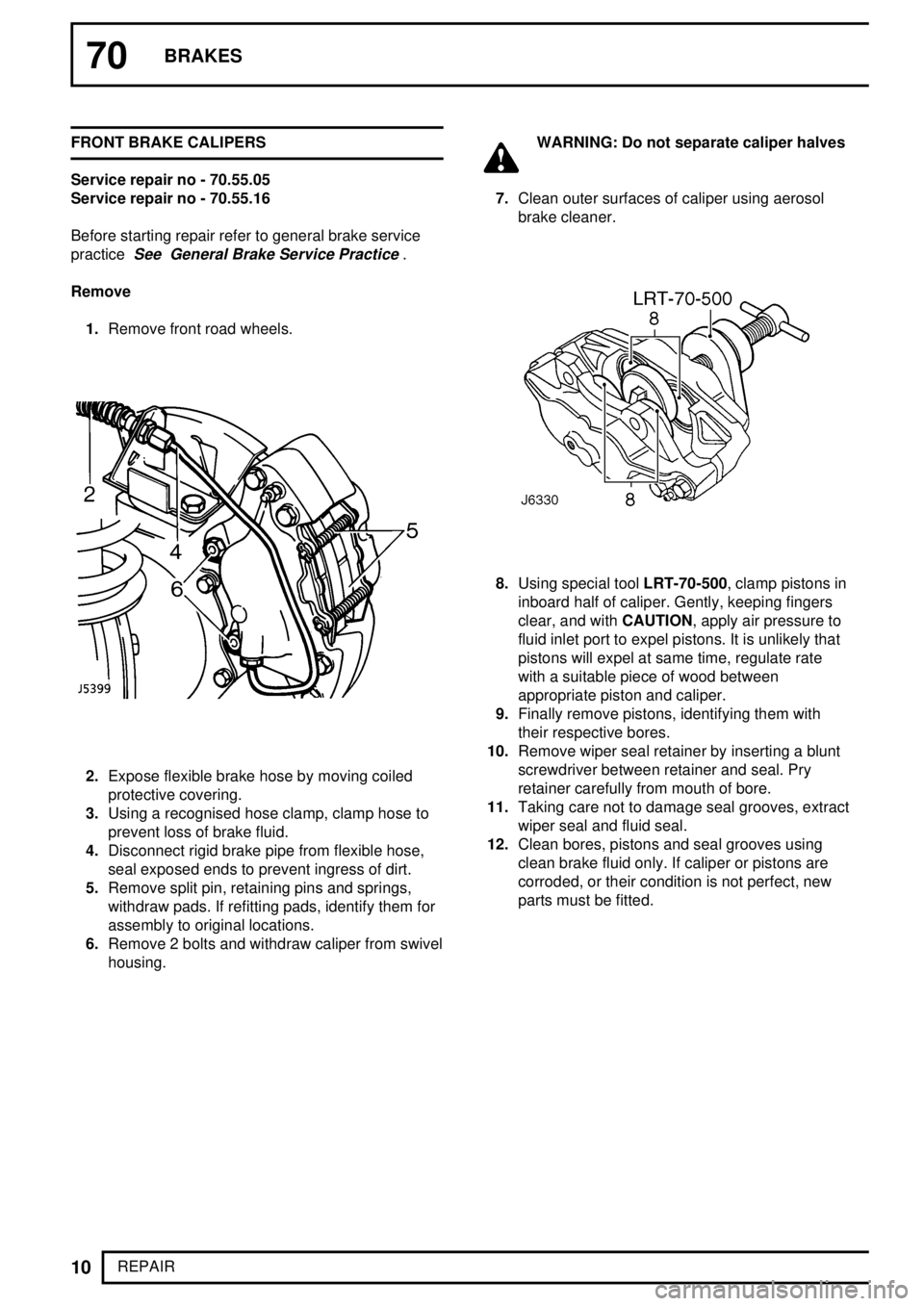

1.Remove front road wheels.

2.Expose flexible brake hose by moving coiled

protective covering.

3.Using a recognised hose clamp, clamp hose to

prevent loss of brake fluid.

4.Disconnect rigid brake pipe from flexible hose,

seal exposed ends to prevent ingress of dirt.

5.Remove split pin, retaining pins and springs,

withdraw pads. If refitting pads, identify them for

assembly to original locations.

6.Remove 2 bolts and withdraw caliper from swivel

housing.

WARNING: Do not separate caliper halves

7.Clean outer surfaces of caliper using aerosol

brake cleaner.

8.Using special toolLRT-70-500, clamp pistons in

inboard half of caliper. Gently, keeping fingers

clear, and withCAUTION, apply air pressure to

fluid inlet port to expel pistons. It is unlikely that

pistons will expel at same time, regulate rate

with a suitable piece of wood between

appropriate piston and caliper.

9.Finally remove pistons, identifying them with

their respective bores.

10.Remove wiper seal retainer by inserting a blunt

screwdriver between retainer and seal. Pry

retainer carefully from mouth of bore.

11.Taking care not to damage seal grooves, extract

wiper seal and fluid seal.

12.Clean bores, pistons and seal grooves using

clean brake fluid only. If caliper or pistons are

corroded, or their condition is not perfect, new

parts must be fitted.

Page 294 of 455

BRAKES

13

REPAIR REAR BRAKE CALIPERS

Service repair no - 70.55.06

Service repair no - 70.55.17

Before starting repair refer to General brake service

practice

See General Brake Service Practice.

Remove caliper

1.Remove rear road wheels.

2.Using a recognised hose clamp, clamp flexible

brake hose above rear axle.

90 Models

110/130 Models

3.Remove brake pipe from rear brake caliper.4.Seal pipe ends to prevent ingress of dirt.

5.Remove retaining pins and springs and withdraw

pads. If same pads are to be refitted, identify

them for assembly in original positions.

6.Remove 2 bolts and withdraw caliper from rear

axle.

Repair

WARNING: Do not separate caliper halves.

7.Clean outer surfaces of caliper with aerosol

brake cleaner.

8. WITH CAUTIONexpel pistons from their bores

by applying air pressure to fluid inlet port. It is

unlikely both pistons will expel at same time,

regulate rate with a suitable piece of wood

inserted between two pistons.

9.Finally, remove pistons keeping them identified

with their respective bores.

10.Remove wiper seal retainer by inserting a blunt

screwdriver between retainer and seal and pry

retainer carefully from mouth of bore.

11.Taking care not to damage seal grooves, extract

wiper seal and fluid seal.

12.Clean bores, pistons and particularly seal

grooves using clean brake fluid only. If caliper or

pistons are corroded or their condition is not

perfect new parts must be fitted.

13.Apply brake fluid to new seal. Fit seal into

groove in bore. When seal is seated it feels

raised to touch at edge furthest away from

mouth of bore.

14.Coat piston with brake fluid. Insert it squarely

into bore. Do not tilt piston during insertion and

leave 8mm projecting from bore.

Page 303 of 455

70BRAKES

4

OVERHAUL Assembling master cylinder

CAUTION: It is important that the following

instructions are carried out precisely,

otherwise damage could be caused to new

seals when inserting plungers into cylinder bore.

Generous amounts of new brake fluid should be

used to lubricate parts during assembly.

NOTE: Thoroughly check that no debris is

lodged in fluid passageways and drillings.

If debris is found, carefully remove,

re-clean cylinder and re-check.

16.Fit new swirl tube to bottom of cylinder bore.

17.Lubricate secondary plunger and cylinder bore.

Offer plunger assembly to cylinder until

recuperation seal is resting centrally in mouth of

bore. Gently introduce plunger with a circular

rocking motion, as illustrated. Ensuring that seal

does not become trapped, ease seal into bore

and slowly push plunger down bore in one

continuous movement.

18.Fit primary plunger assembly using same

method as for secondary plunger, push plunger

down bore.

19.Fit original guide ring to support primary plunger.

20.Coat a new 'O' ring with brake fluid and fit to its

respective groove on outer location surface of

master cylinder.

CAUTION: 'O' ring should not be rolled

down outer location surface of master

cylinder but should be slightly stretched

and eased down cylinder and into its groove. Do

not over stretch seal.21.Fit a new retaining ring on outer surface of

master cylinder ensuring that serrations of ring

are facing mounting flange.

22.Fit two new reservoir seals in their respective

ports.

23.Fit a new vacuum seal to either primary plunger

or to bottom of transfer housing bore, open face

of seal towards primary plunger guide ring.

24.Lubricate vacuum seal with brake fluid, fit

transfer housing to master cylinder, push

housing fully up to cylinder mounting flange. Do

not adjust transfer housing after fitting.

25.Lubricate a new water ingress seal with brake

fluid, slightly stretch seal and ease it down

housing until seal is in correct position between

housing and flange.

26.Roll reservoir into top of master cylinder,

reversing procedure described in instruction 3.

27.Fit master cylinder to servo

See Repair,

Master cylinder

.

28.Reconnect battery, and road test vehicle.

Page 376 of 455

AIR CONDITIONING

1

ADJUSTMENT GENERAL PRECAUTIONS

The refrigerant used in the air conditioning system is

HFC (Hydrofluorocarbon) R134a.

WARNING: R134a is a hazardous liquid

and when handled incorrectly can cause

serious injury. Suitable protective clothing

must be worn when carrying out servicing

operations on the air conditioning system.

WARNING: R134a is odourless and

colourless. Do not handle or discharge in

an enclosed area, or in any area where the

vapour or liquid can come in contact with naked

flame or hot metal. R134a is not flammable, but

can form a highly toxic gas.

WARNING: Do not smoke or weld in areas

where R134a is in use. Inhalation of

concentrations of the vapour can cause

dizziness, disorientation. uncoordination,

narcosis, nausea or vomiting.

WARNING: Do not allow fluids other than

R134a or compressor lubricant to enter the

air conditioning system. Spontaneous

combustion may occur.

WARNING: R134a splashed on any part of

the body will cause immediate freezing of

that area. Also refrigerant cylinders and

replenishment trolleys when discharging will

freeze skin to them if contact is made.

WARNING: The refrigerant used in an air

conditioning system must be reclaimed in

accordance with the recommendations

given with a Refrigerant Recovery Recycling

Recharging Station.

NOTE: Suitable protective clothing

comprises: Wrap around safety glasses or

helmet, heatproof gloves, rubber apron or

waterproof overalls and rubber boots.REMEDIAL ACTIONS

1.If liquid R134a strikes the eye, do not rub it.

Gently run large quantities of eyewash over the

eye to raise the temperature. If eyewash is not

available cool, clean water may be used. Cover

eye with clean pad and seek immediate medical

attention.

2.If liquid R134a is splashed on the skin run large

quantities of water over the area as soon as

possible to raise the temperature. Carry out the

same actions if skin comes into contact with

discharging cylinders. Wrap affected parts in

blankets or similar material and seek immediate

medical attention.

3.If suspected of being overcome by inhalation of

R134a vapour seek fresh air. If unconscious

remove to fresh air. Apply artificial respiration

and/or oxygen and seek immediate medical

attention.

NOTE: Due to its low evaporating

temperature of -30°C, R134a should be

handled with care.

WARNING: Do not allow a refrigerant

container to be heated by a direct flame or

to be placed near any heating appliance. A

refrigerant container must not be heated above

50°C.

WARNING: Do not leave a container of

refrigerant without its cap fitted. Do not

transport a container of refrigerant that is

unrestrained, especially in the boot of a car.

Page 389 of 455

AIR CONDITIONING

7

REPAIR EVAPORATOR - LH DRIVE

Service repair no - 82.25.20

Remove

1.Remove heater/cooler unit

See Heater/cooler

unit.

2.Suitably support unit on a bench to prevent

damage to heater matrix pipes.

3.Release 3 nuts and remove mounting bracket

from underneath unit casing.

4.Remove 7 screws securing outlet duct to

heater/cooler unit.

5.Carefully break sealing compound around edge

of duct and pull ducting from unit.

6.Remove 15 screws located around cover seam.

Break sealing compound from unit body and top

cover.

7.Remove 4 screws and 4 nuts from top of cover.

8.From front of unit remove 2 screws adjacent to

low pressure pipe moulding.

9.At side of unit remove 2 screws adjacent to air

intake aperture.

10.Lift off top cover, release grommet and feed

blower motor wiring and air control flap rod

through respective apertures. Note thermostat

temperature probe which is inserted in

evaporator matrix through top cover.

11.Lift support plate and insulation pad from heater

matrix.

12.From bottom of unit casing, remove 3 screws

adjacent to dump valve outlet, and screws next

to heater matrix pipes.

Page 391 of 455

AIR CONDITIONING

9

REPAIR EXPANSION VALVE - LH DRIVE

Service repair no - 82.25.01

Remove

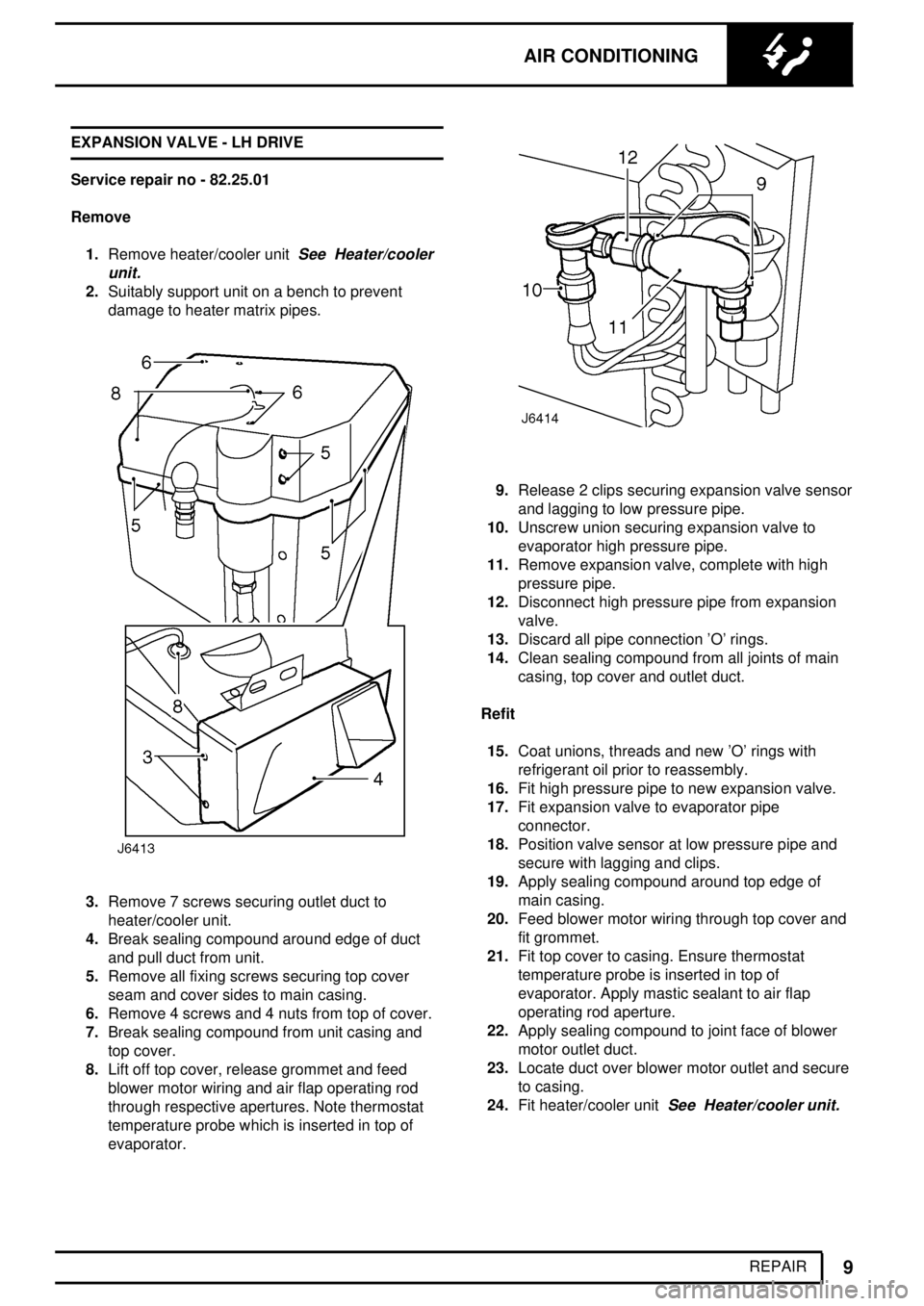

1.Remove heater/cooler unit

See Heater/cooler

unit.

2.Suitably support unit on a bench to prevent

damage to heater matrix pipes.

3.Remove 7 screws securing outlet duct to

heater/cooler unit.

4.Break sealing compound around edge of duct

and pull duct from unit.

5.Remove all fixing screws securing top cover

seam and cover sides to main casing.

6.Remove 4 screws and 4 nuts from top of cover.

7.Break sealing compound from unit casing and

top cover.

8.Lift off top cover, release grommet and feed

blower motor wiring and air flap operating rod

through respective apertures. Note thermostat

temperature probe which is inserted in top of

evaporator.

9.Release 2 clips securing expansion valve sensor

and lagging to low pressure pipe.

10.Unscrew union securing expansion valve to

evaporator high pressure pipe.

11.Remove expansion valve, complete with high

pressure pipe.

12.Disconnect high pressure pipe from expansion

valve.

13.Discard all pipe connection 'O' rings.

14.Clean sealing compound from all joints of main

casing, top cover and outlet duct.

Refit

15.Coat unions, threads and new 'O' rings with

refrigerant oil prior to reassembly.

16.Fit high pressure pipe to new expansion valve.

17.Fit expansion valve to evaporator pipe

connector.

18.Position valve sensor at low pressure pipe and

secure with lagging and clips.

19.Apply sealing compound around top edge of

main casing.

20.Feed blower motor wiring through top cover and

fit grommet.

21.Fit top cover to casing. Ensure thermostat

temperature probe is inserted in top of

evaporator. Apply mastic sealant to air flap

operating rod aperture.

22.Apply sealing compound to joint face of blower

motor outlet duct.

23.Locate duct over blower motor outlet and secure

to casing.

24.Fit heater/cooler unit

See Heater/cooler unit.

Page 392 of 455

82AIR CONDITIONING

10

REPAIR HEATER MATRIX - LH DRIVE

Service repair no - 82.25.19

Remove

1.Remove evaporator

See Evaporator.

2.Leaving evaporator in place, remove single

screw securing heater matrix pipe plate to base

of support frame.

3.Remove heater matrix and insulation pad.

Refit

4.Position insulation pad and fit heater matrix to

support frame.

5.Fit heater matrix and evaporator assembly

See

Evaporator.

BLOWER MOTOR ASSEMBLY- LH DRIVE

Service repair no - 82.25.14

Remove

1.Remove heater/cooler unit

See Heater/cooler

unit.

2.Remove 7 screws securing outlet duct to

heater/cooler unit.

3.Carefully break sealing compound around edge

of duct and pull ducting from unit.

4.Remove 15 screws located around cover seam.

Break sealing compound from unit body and top

cover.

5.Remove 4 screws and 4 nuts from top of cover.

6.From front of unit remove 2 screws adjacent to

low pressure pipe moulding.

7.At side of unit remove 2 screws adjacent to air

intake aperture.

8.Lift off top cover, release grommet and feed

blower motor wiring and air control flap rod

through respective apertures. Note thermostat

probe which is inserted in evaporator matrix

through top cover.

Page 414 of 455

86ELECTRICAL

2

DESCRIPTION AND OPERATION VEHICLE IMMOBILISATION AND ALARM SYSTEM

A sophisticated engine immobilisation and anti-theft

alarm system is offered on the Land Rover Defender

300 Tdi vehicle range, which incorporates the

following features:

Perimeter protection

This part of the alarm system protects side doors,

bonnet and rear door against unauthorised entry -

alarm sounding if any one of these apertures is

opened without alarm first being disarmed.

Interior protection

Also known as volumetric protection, this part of the

system protects space inside the vehicle. Once

armed, the alarm will sound if a door is opened, or if

movement is detected inside the vehicle.

Engine immobilisation

The engine is immobilised electronically whenever the

alarm system is armed. Even if the alarm has not

been armed, engine immobilisation will occur

automatically thirty seconds after the driver's door is

opened, or five minutes after the starter switch is

turned to position '0'.

ALARM SYSTEM COMPONENTS

Electronic control unit (ECU)

The ECU is the alarm system brain and controls all

vehicle immobilisation and alarm functions. It

responds to the inputs received, by supplying suitable

outputs to indicate status of the alarm system or

activating relevant warning devices. unit is located

under fascia behind instrument binnacle.

Handset and key

The handset is the primary source of control for the

alarm system i.e. it arms and disarms the alarm

components. The key can be used to override engine

immoblisation if the handset is lost or fails to operate,

seeEngine immobilisation override.The handset battery should last for approximately

three years dependent upon use. The following

symptoms will be noticed when the battery requires

replacement:

1.The handset will only work every other operation

while disarming.

2.The direction indicator lamps will not flash when

the alarm is disarmed.

For battery replacement procedure, seeHandset

Battery.

Passive coil

The passive coil is fitted on the starter switch and

activates a receiving coil in the handset, causing it to

automatically transmit a remobilisation signal to the

ECU.

Aerial

The aerial is integral within the alarm system harness

and supplies the ECU with the signal received from

handset.

Immobilisation spider

The immobilisation spider provides an interface

between ECU and immobilised areas of the vehicle.

This is installed in a sealed (safe) box inside the

vehicle battery box.

Digital diesel shut-off valve - 97 MY

When fitted, the digital diesel shut-off valve

immobilises the fuel injection pump by preventing

power reaching the fuel shut-off solenoid,

See

Immobilisation and alarm system circuit diagram -

with DDS

.

Page 415 of 455

ELECTRICAL

3

DESCRIPTION AND OPERATION Door and bonnet switches

Perimetric protection for the vehicle is provided by

ECU inputs connected to the starter switch, bonnet

switch and door switches.

Ultrasonic sensor

The ultrasonic sensor operates by emitting an air

pressure carrier wave which is subsequently received

by the sensor as it bounces back from objects inside

the vehicle. Once armed, the alarm will sound if wave

is disturbed by a door opening, or if movement is

detected inside the vehicle.

When the volumetric sensor is activated it monitors

movement within the vehicle for 15 seconds before

detecting and responding to intrusions. If the sensor

detects movement it delays arming until a quiet period

has lapsed; if continuous movement is detected, the

alarm will not arm volumetrically.

NOTE: Interior protection will not operate

until 15 seconds after alarm is set.

The ultrasonic sensor is positioned in a different

location, according to vehicle type, as follows:

·90/110 Station Wagon - RH cantrail trim

·90/110 Pick-up - On headlining, between interior

lamp and rear view mirror

·130 Crewcab - On headlining above RH door

Alarm sounder

Two types of alarm sounder can be fitted, one with a

battery back-up facility and or without battery back-up,

both providing an audible warning whenever the alarm

is triggered. The vehicle horn will also operate if the

alarm sounds.

The alarm sounder is fitted to LH inner front wing in

the engine compartment.

NOTE: Disconnecting the battery on

vehicles fitted with the battery backed-up

facility will result in the alarm sounding, if

correct procedure has not been followed.Engine immobilisation warning light

The engine immobilisation warning light is located on

the instrument panel, and provides a visual indication

that the engine is immobilised.

Anti-theft alarm indicator light

The anti-theft alarm indicator light is located on the

instrument panel, between the fuel and coolant

temperature indicators, and provides a visual

indication of the alarm/ immobiliser status.