charging LAND ROVER DEFENDER 1996 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 395 of 455

AIR CONDITIONING

13

REPAIR HEATER/COOLER UNIT - RH DRIVE

Service repair no - 82.25.21

Remove

1.Disconnect battery.

2.Recover refrigerant from air conditioning system

See Refrigerant recovery, recycling,

recharging.

3.Release ties, remove insulation cover and

disconnect evaporator low pressure pipe.

4.Disconnect evaporator high pressure pipe.

5.Discard all pipe connection 'O' rings. Cap or plug

all connections to prevent ingress of dirt and

moisture.

6.Using suitable pipe clamps, clamp heater matrix

feed and return pipes at heater/cooler unit.

7.Remove screw securing air control flap solenoid.

8.Disconnect 2 leads from thermostat.

9.Remove pipe from water valve vacuum switch.

10.Remove retaining clip and disconnect control

cable from evaporator flap operating rod.

11.Remove screw and release outer cable retaining

bracket.12.Disconnect blower motor wiring plugs and

release harness retaining clip from housing.

13.Remove bolt securing front support bracket to

blower motor housing. If necessary, remove

blower motor resistor block to facilitate

operation.

14.From inside vehicle remove front passenger

carpet, if fitted.

15.Remove fixing screws and fold back footwell

insulation.

16.Remove 4 bolts securing heater/cooler unit lower

mounting bracket to bulkhead. Ensure spacing

washers from two innermost bolts are retrieved

from engine bulkhead side.

17.From inside engine compartment remove 2 bolts

securing top heater/cooler unit mounting bracket

to engine bullkhead.

18.Lift heater/cooler unit clear of air duct seal and

remove from vehicle.

Page 396 of 455

82AIR CONDITIONING

14

REPAIR Refit

19.Coat unions, threads and new 'O' rings with

refrigerant oil prior to reassembly.

20.Position heater/cooler unit in engine

compartment and locate with air duct seal.

21.Secure unit top and bottom mounting brackets to

bulkhead and support bracket to front of unit

casing. Fully tighten fixing bolts when unit is

correctly positioned.

22.If applicable, fit blower motor resistor block to

vehicle wing.

23.Connect blower motor wiring plugs.

24.Fit footwell insulation and carpet.

25.Fit control cable to evaporator flap operating rod

using new clip. Secure outer cable.

26.Connect water valve vacuum switch pipe and

thermostat leads.

27.Fit air control flap solenoid to side of

heater/cooler unit.

28.Reconnect heater matrix hoses.

29.Connect high pressure pipe to evaporator.

30.Connect low pressure pipe and fit insulation

cover.

31.Evacuate and recharge air conditioning system

See Adjustment, Refrigerant recovery,

recycling, recharging.

32.Reconnect battery.

Page 413 of 455

ELECTRICAL

1

DESCRIPTION AND OPERATION ELECTRICAL EQUIPMENT

Description

The electrical system is Negative ground, and it is

most important to ensure correct polarity of electrical

connections at all times. Any incorrect connections

made when reconnecting cables may cause

irreparable damage to semi-conductor devices used in

generator and regulator. Incorrect polarity would also

seriously damage any transistorized equipment such

as a radio.

WARNING: During battery removal or

before carrying out any repairs or

maintenance to electrical components

always disconnect battery negative lead first. If

positive lead is disconnected with negative lead in

place, accidental contact of wrench to any

grounded metal part could cause a severe spark,

possibly resulting in personal injury. Upon

installation of battery positive lead should be

connected first.

GENERATOR

The generator is a three phase, field sensed unit. The

rotor and stator windings produce three phase

alternating current, AC, which is rectified to direct

current, DC. The electronic voltage regulator unit

controls generator output voltage by high frequency

switching of the rotor field circuit. Use only correct

replacement drive belt. Occasionally check that

engine and generator pulleys are accurately aligned.

It is essential that good electrical connections are

maintained at all times. Of particular importance are

those in the charging circuit (including those at

battery) which should be occasionally inspected to

see that they are clean and tight. In this way any

significant increase in circuit resistance can be

prevented.Do not disconnect battery cables while engine is

running or damage to semi-conductor devices may

occur. It is also inadvisable to break or make any

connections in the generator charging and control

circuits while engine is running.

The electronic voltage regulator employs micro-circuit

techniques resulting in improved performance under

difficult service conditions. The whole assembly is

encapsulated in silicone rubber and housed in an

aluminium heat sink, ensuring complete protection

against adverse effects of temperature, dust, and

moisture etc.

The regulating voltage is set during manufacture to

give required regulating voltage range of 14.2±0.2

volts, and no adjustment is necessary. The only

maintenance needed is occasional check on terminal

connections and wiping with a clean dry cloth.

The generator system provides for direct connection

of a charge (ignition) indicator warning lamp, and

eliminates the need for a field switching relay or

warning light control unit. In the event of bulb failure,

an 'exciter' voltage is supplied through a resistor,

wired in parallel to the bulbs, ensuring that generator

output is maintained. The lamp should be checked

regularly.

When using rapid charge equipment to re-charge

battery, the battery must be disconnected from the

vehicle.

Page 425 of 455

ELECTRICAL

1

FAULT DIAGNOSIS GENERAL INFORMATION

Detailed information of electrical systems, component

locations and circuit diagrams are covered in the

Defender Electrical Troubleshooting Manual.

This section covers checks of the charging system.

GENERATOR TESTING

Service repair no - 86.10.01

Charging system check

1.Check battery is in good condition, with an open

circuit voltage of at least 12.6 V. Recharge or

substitute battery to carry out test.

2.Check drive belt condition

See SECTION 10,

Maintenance, Under bonnet maintenance.

3.Check battery connections are clean and tight.

4.Check generator connections are clean and

tight.

5.Ensure there is no drain on battery from, for

example, interior or exteriorlamps.

Generator test

Following instructions refer to use of suitable test

equipment using a carbon pile rheostat.

6.Connect test equipment referring to

manufacturer's instructions.

7.Start engine and run at 3000 rev/min without

accessory load.

8.Rotate carbon pile load control to achieve

greatest output (amps) without allowing voltage

to fall below 12.0 V. A reading in amps, of

generator output should be obtained.

9.Run engine at 3000 rev/min, switch selector to

regulator test, read voltmeter. A reading of 13.6

to 14.4 V should be obtained.

10.Switch selector to diode/stator test, switch on

headlamps to load generator. Raise engine

speed to 3000 rev/min, read voltmeter, needle

must be within 'OK' range.TESTING IN POSITION

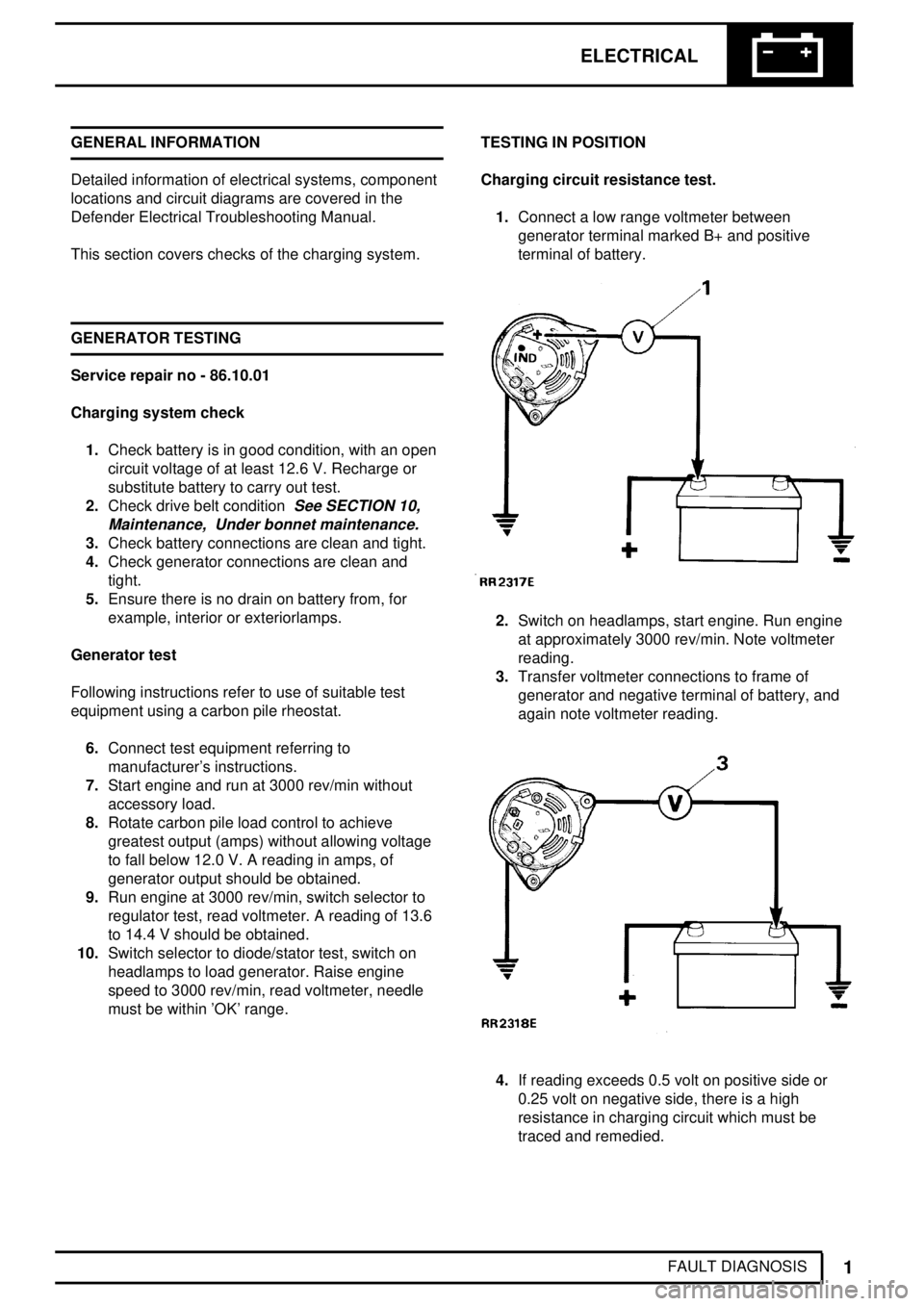

Charging circuit resistance test.

1.Connect a low range voltmeter between

generator terminal marked B+ and positive

terminal of battery.

2.Switch on headlamps, start engine. Run engine

at approximately 3000 rev/min. Note voltmeter

reading.

3.Transfer voltmeter connections to frame of

generator and negative terminal of battery, and

again note voltmeter reading.

4.If reading exceeds 0.5 volt on positive side or

0.25 volt on negative side, there is a high

resistance in charging circuit which must be

traced and remedied.

Page 426 of 455

ELECTRICAL

1

REPAIR ELECTRICAL PRECAUTIONS

The following guidelines are intended to ensure the

safety of the operator whilst preventing damage to

electrical and electronic components fitted to the

vehicle.

Polarity

Never reverse connect the vehicle battery and always

observe the correct polarity when connecting test

equipment.

High voltage circuits

WARNING: Before commencing work on

an ignition system, all high tension

terminals, adaptors and diagnostic

equipment for testing should be inspected to

ensure that they are adequately insulated and

shielded to prevent accidental personal contacts

and minimize the risk of shock. Wearers of

surgically implanted pacemaker devices should

not be in close proximity to ignition circuits or

diagnostic equipment.

Whenever disconnecting live high tension circuits

always use insulated pliers and never allow the open

end of a high tension lead to come into contact with

other components particularly electronic control units.

Exercise caution when measuring the voltage on the

coil terminals while the engine is running, since, high

voltage spikes can occur on these terminals.

Connectors and harness

Always ensure that these items are dry and oil free

before disconnecting and connecting test equipment.

Never force connectors apart either by using tools or

by pulling on the wiring harness. Always ensure

locking tabs are disengaged before removal and note

orientation to enable correct reconnection. Ensure that

any protective covers and substances are replaced if

disturbed. Having confirmed a component to be faulty

switch-off the ignition and disconnect the battery.

Remove the component and support the disconnected

harness. When replacing the component keep oily

hands away from electrical connection areas and

push connectors home until any locking tabs fully

engage.Battery disconnecting

Before disconnecting the battery, switch off all

electrical equipment.

Battery charging

Recharge the battery out of the vehicle and keep the

top well ventilated. While being charged or

discharged, and for approximately 15 minutes

afterwards, batteries emit hydrogen gas which is

flammable. Always ensure any battery charging area

is well ventilated and that every precaution is taken to

avoid naked flames and sparks.

GENERAL PRECAUTIONS

Switch-off ignition prior to making any connection or

disconnection in the system as electrical surge

caused by disconnecting 'live' connections can

damage electronic components.

Ensure hands and work surfaces are clean and free of

grease, swarf, etc. as grease collects dirt which can

cause tracking or high-resistance contacts.

When handling printed circuit boards, treat them as

you would a disc - hold by the edges only.

Prior to commencing a test, and periodically during a

test, touch a good earth, for instance, a cigar lighter

socket, to discharge body static as some electronic

components are vulnerable to static electricity.