fuel filter LAND ROVER DEFENDER 1996 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 86 of 455

ENGINE

3

SPECIFICATIONS, TORQUENm

Turbo charger oil drain adaptor to block 42....................................................

Oil drain pipe to turbocharger 25....................................................................

Turbocharger oil drain pipe to adaptor 38.......................................................

Turbocharger oil feed pipe adaptor to block 25...............................................

Turbocharger oil feed pipe to adaptor 25........................................................

Oil feed pipe to turbocharger 19.....................................................................

Turbocharger to cylinder head (stud) 10.........................................................

Turbocharger to cylinder head (nut) 45...........................................................

Turbocharger to blanking plate 25..................................................................

Turbocharger to EGR valve 25.......................................................................

EGR delivery tube to valve 25........................................................................

EGR delivery tube to mixing tube 25..............................................................

Fuel lift pump to filter (union) 15.....................................................................

Fuel filter from lift pump (banjo bolt) 33...........................................................

Fuel filter to fuel injection pump (banjo bolt) 33..............................................

Fuel injection pump from fuel filter (banjo bolt) 25..........................................

Injector pipes to injectors and fuel injection pump 29.....................................

Spill rail to injectors (banjo bolt) 10.................................................................

Spill rail to injection pump (banjo bolt) 25.......................................................

Boost pipe injection pump (banjo bolt) 10.......................................................

Plug, rear of injection pump 29.......................................................................

PAS pump to mounting plate 25.....................................................................

PAS pump mounting plate to auxiliaries mounting bracket 25........................

PAS pump pulley to hub 25............................................................................

Starter motor (bolt and nut) 45........................................................................

Air conditioning compressor

Compressor mounting bracket to front cover 45.............................................

Compressor to mounting bracket (stud) 8......................................................

Compressor to mounting bracket (nut) 25......................................................

Belt tensioner pulley to tensioner arm 45........................................................

Belt tensioner assembly to front cover plate 25..............................................

Idler pulley to front cover plate 45...................................................................

Compressor belt guard (nut) 25......................................................................

Sensors to water outlet elbow (air/con) 25......................................................

Blanking plug, water outlet elbow (air/con) 25................................................

Generator

Generator mounting bracket to front cover 45................................................

Generator to mounting bracket 85..................................................................

Generator pulley to hub 95.............................................................................

Generator belt guard 25..................................................................................

Generator to auxiliaries mounting bracket 25.................................................

Tachometer electrical connection 4...............................................................

Page 88 of 455

FUEL SYSTEM

1

DESCRIPTION AND OPERATION DESCRIPTION

Fuel system

The fuel system incorporates a supply and spill return

line on all models as illustrated below.

On 90 models, see J6191, the fuel tank is mounted at

the RH side of the vehicle chassis under the front

seat.On standard 110 and 130 models the fuel tank is

located at the rear of the vehicle between the chassis

longitudenal sections, as shown in J6192.

As an option, a twin tank system fitted with a

combined change-over tap and 3 way fuel supply and

return system, can be installed on both 110 and 130

models, see J6193.

The tank/s on all vehicles is vented by a 2 way valve

in the filler cap.

FUEL SYSTEM LAYOUT

1.Fuel tank

2.Fuel sedimentor, if fitted

3.Fuel lift pump

4.Fuel filter5.Fuel injection pump

6.Spill return line

7.Fuel injectors

Page 89 of 455

19FUEL SYSTEM

2

DESCRIPTION AND OPERATION A mechanical lift pump, with a hand priming facility, is

driven by the camshaft, and is mounted on the RH

side of the engine.

A fuel filter, with a replaceable element and

incorporating a water separator, is mounted on the

front RH side of the engine compartment.

A fuel sedimentor may be fitted when the vehicle is

operating in more arduous conditions, and is used to

minimise water deposits in the fuel system before

reaching the fuel pump and filter.

Fuel injection is carried out by a Bosch direct injection

pump, incorporating a cold start advance unit and a

high idle setting. The pump is mounted on the RH side

of the engine and is driven directly by gears in the

front cover from the crankshaft. The pump meters and

distributes fuel to 4 pintle type injectors located in

pre-combustion chambers in the cylinder head. Four

heater plugs, located in the cylinder head directly

below each injector, are fitted to improve cold starting.

An optional hand throttle, for use with a centre power

take off, is located on the fascia to the LH side of the

fuse box, and is linked independently to the fuel

injection pump throttle lever.

Air intake

The air cleaner is mounted on the RH side of the

engine and is connected by hoses to the cold air

intake duct and turbocharger inlet. Fitted between the

air cleaner and turbocharger is the crankcase breather

hose which connects to a breather filter on the rocker

cover.

A single stage turbocharger, fitted between the

exhaust manifold and exhaust down pipe, is

connected by hoses to the air cleaner and an

intercooler which is mounted on the LH side of the

radiator. The intercooler is connected by a hose to the

inlet manifold. When an EGR valve is fitted to the

turbocharger, additional pipes/hoses are used to

connect the components.Exhaust gas recirculation (EGR), when fitted.

Exhaust gas recirculation is controlled by an ECU

mounted under the front centre seat or cubby box and

receives the following inputs:

·Engine temperature from coolant temperature

sender unit on LH side of cylinder head.

·Throttle position from potentiometer on injection

pump.

·Engine speed from speedometer.

When all correct signals are received, the EGR

solenoid allows vacuum to open EGR valve and

recirculate a portion of the exhaust gas. See J6196 for

the EGR system component location and 'Operation'

for full system function.

Page 90 of 455

FUEL SYSTEM

3

DESCRIPTION AND OPERATION

90 FUEL SYSTEM

110 FUEL SYSTEM

1.Fuel filter

2.Supply pipe, lift pump to filter

3.Supply pipe, fuel filter to injection pump

4.Fuel injection pump

5.Fuel lift pump

6.Spill return pipe, injection pump to tank7.Supply pipe, sedimentor to fuel pump

8.Fuel tank

9.Supply pipe, fuel tank to sedimentor

10.Fuel filler pipe

11.Breather pipe

12.Sedimentor, if fitted

NOTE: If a sedimentor is not fitted, the fuel

supply pipe from the tank will connect

directly to the fuel lift pump.

Page 91 of 455

19FUEL SYSTEM

4

DESCRIPTION AND OPERATION

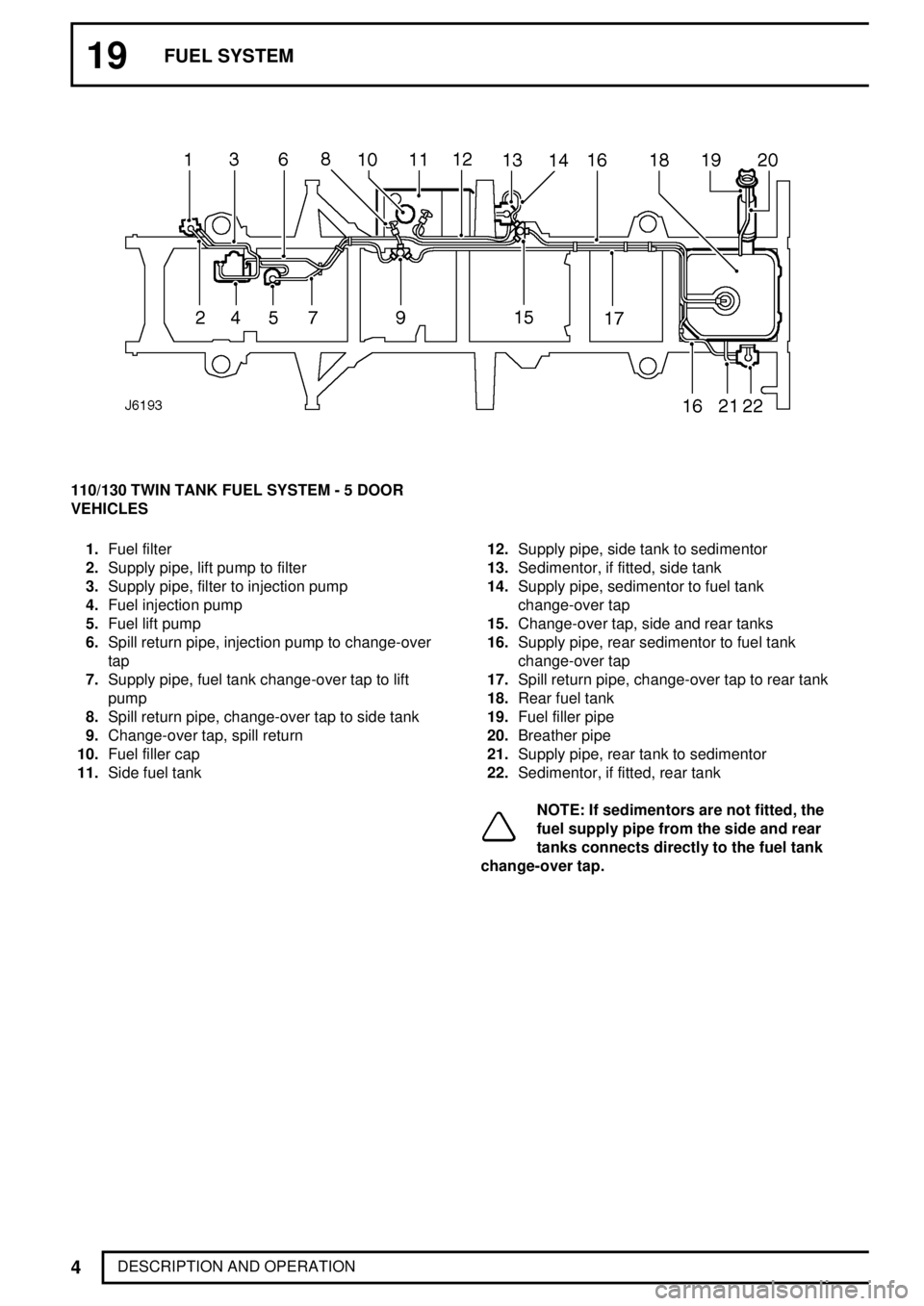

110/130 TWIN TANK FUEL SYSTEM - 5 DOOR

VEHICLES

1.Fuel filter

2.Supply pipe, lift pump to filter

3.Supply pipe, filter to injection pump

4.Fuel injection pump

5.Fuel lift pump

6.Spill return pipe, injection pump to change-over

tap

7.Supply pipe, fuel tank change-over tap to lift

pump

8.Spill return pipe, change-over tap to side tank

9.Change-over tap, spill return

10.Fuel filler cap

11.Side fuel tank12.Supply pipe, side tank to sedimentor

13.Sedimentor, if fitted, side tank

14.Supply pipe, sedimentor to fuel tank

change-over tap

15.Change-over tap, side and rear tanks

16.Supply pipe, rear sedimentor to fuel tank

change-over tap

17.Spill return pipe, change-over tap to rear tank

18.Rear fuel tank

19.Fuel filler pipe

20.Breather pipe

21.Supply pipe, rear tank to sedimentor

22.Sedimentor, if fitted, rear tank

NOTE: If sedimentors are not fitted, the

fuel supply pipe from the side and rear

tanks connects directly to the fuel tank

change-over tap.

Page 92 of 455

FUEL SYSTEM

5

DESCRIPTION AND OPERATION

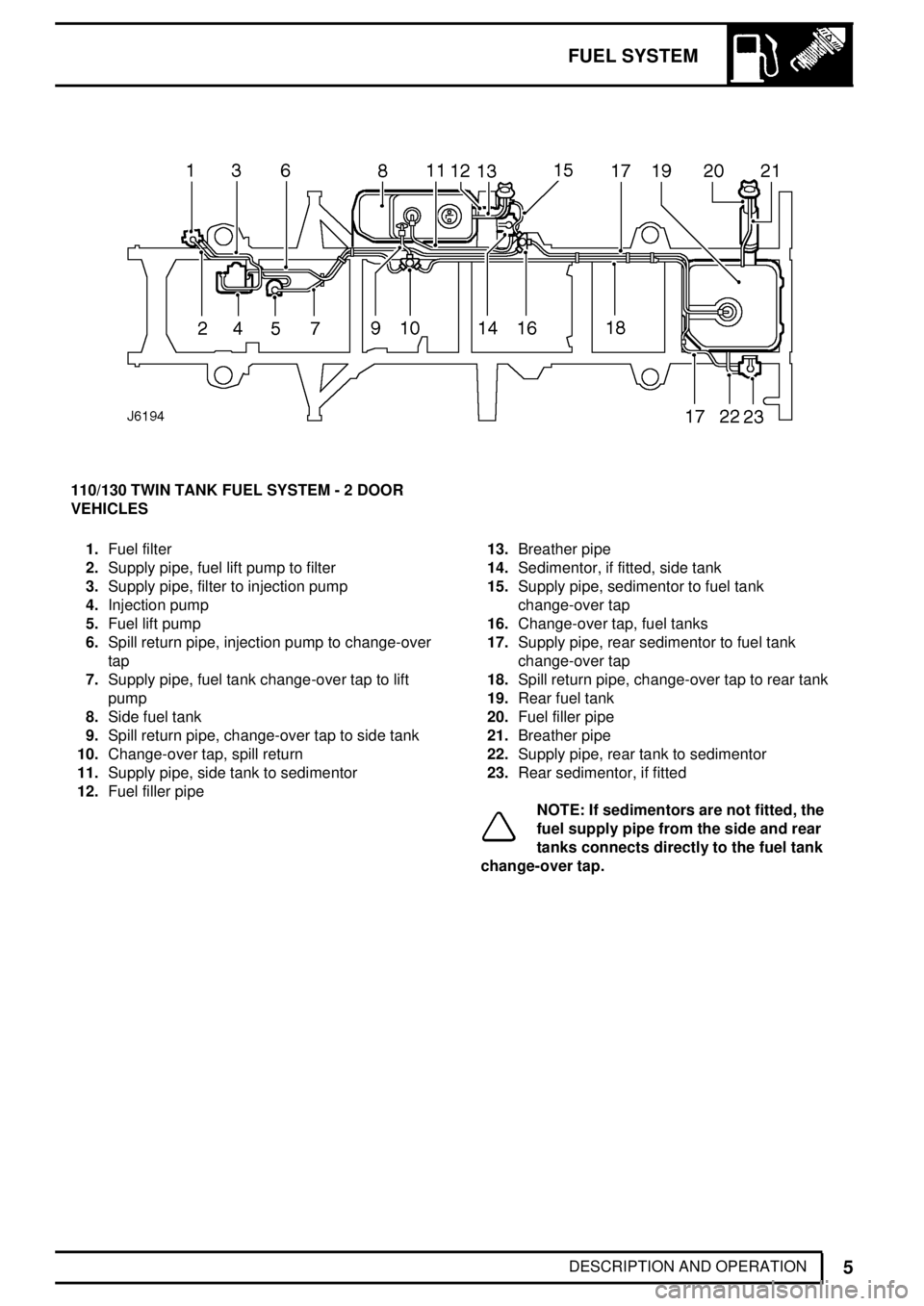

110/130 TWIN TANK FUEL SYSTEM - 2 DOOR

VEHICLES

1.Fuel filter

2.Supply pipe, fuel lift pump to filter

3.Supply pipe, filter to injection pump

4.Injection pump

5.Fuel lift pump

6.Spill return pipe, injection pump to change-over

tap

7.Supply pipe, fuel tank change-over tap to lift

pump

8.Side fuel tank

9.Spill return pipe, change-over tap to side tank

10.Change-over tap, spill return

11.Supply pipe, side tank to sedimentor

12.Fuel filler pipe13.Breather pipe

14.Sedimentor, if fitted, side tank

15.Supply pipe, sedimentor to fuel tank

change-over tap

16.Change-over tap, fuel tanks

17.Supply pipe, rear sedimentor to fuel tank

change-over tap

18.Spill return pipe, change-over tap to rear tank

19.Rear fuel tank

20.Fuel filler pipe

21.Breather pipe

22.Supply pipe, rear tank to sedimentor

23.Rear sedimentor, if fitted

NOTE: If sedimentors are not fitted, the

fuel supply pipe from the side and rear

tanks connects directly to the fuel tank

change-over tap.

Page 94 of 455

FUEL SYSTEM

7

DESCRIPTION AND OPERATION

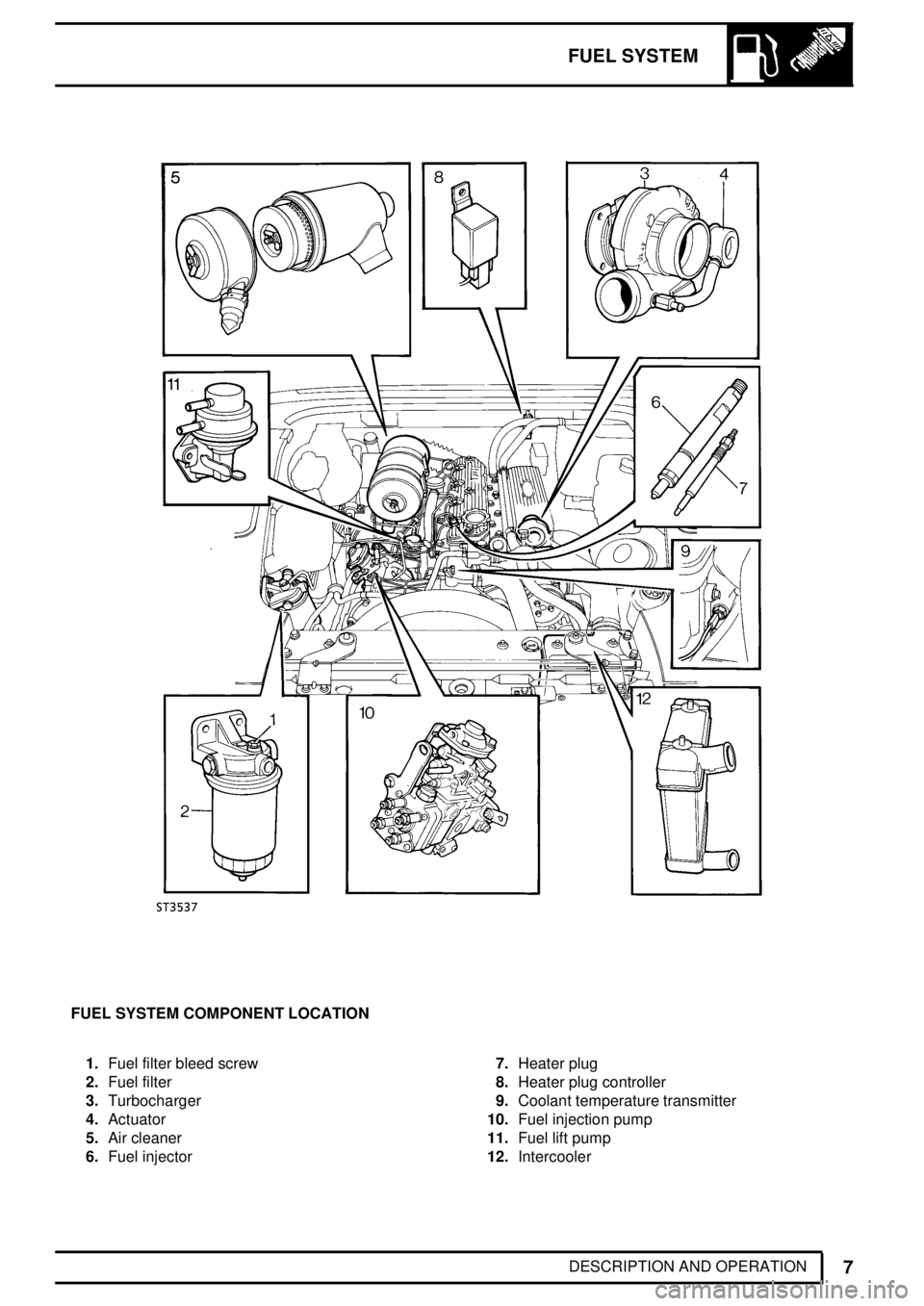

FUEL SYSTEM COMPONENT LOCATION

1.Fuel filter bleed screw

2.Fuel filter

3.Turbocharger

4.Actuator

5.Air cleaner

6.Fuel injector7.Heater plug

8.Heater plug controller

9.Coolant temperature transmitter

10.Fuel injection pump

11.Fuel lift pump

12.Intercooler

Page 96 of 455

FUEL SYSTEM

9

DESCRIPTION AND OPERATION OPERATION

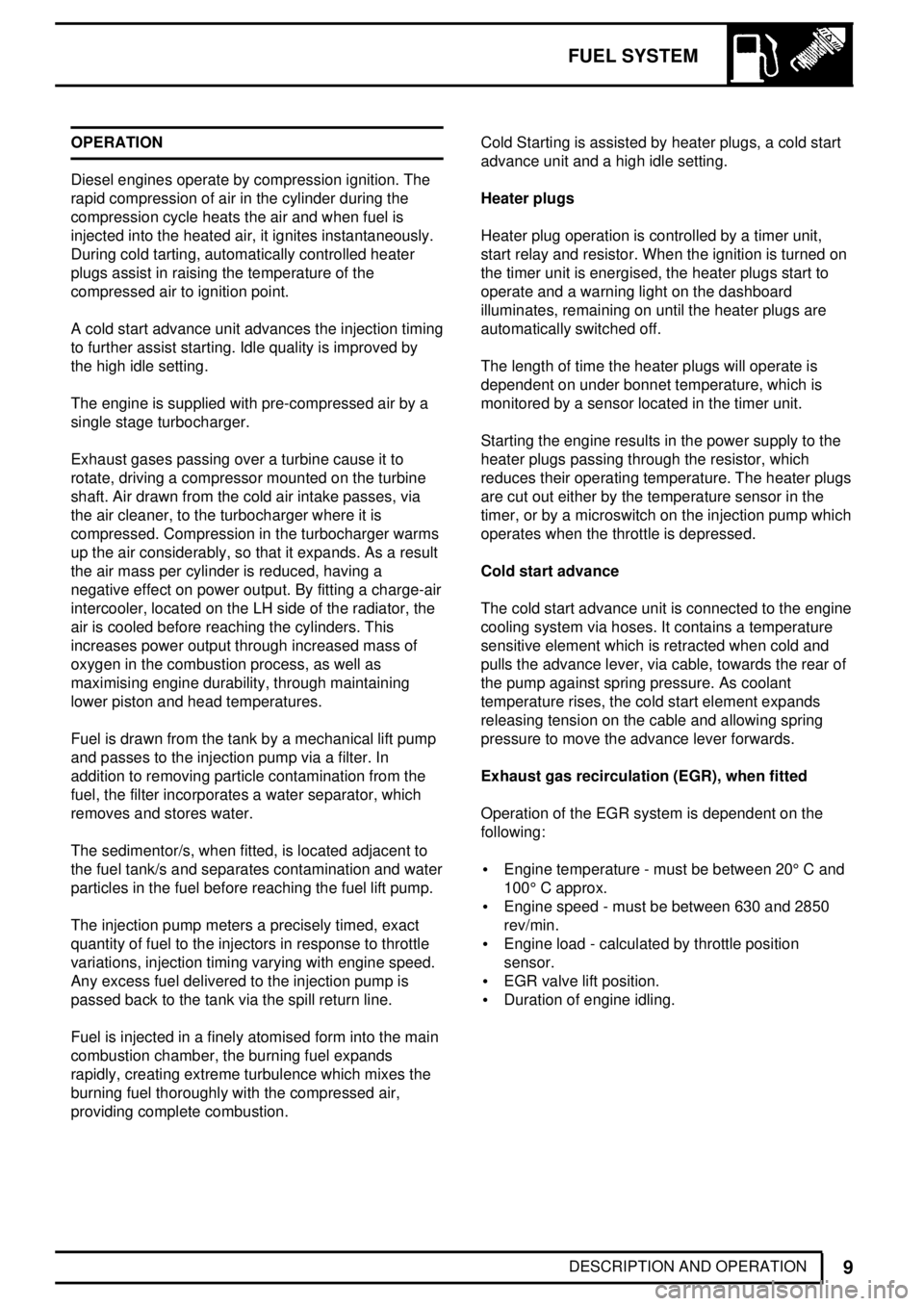

Diesel engines operate by compression ignition. The

rapid compression of air in the cylinder during the

compression cycle heats the air and when fuel is

injected into the heated air, it ignites instantaneously.

During cold tarting, automatically controlled heater

plugs assist in raising the temperature of the

compressed air to ignition point.

A cold start advance unit advances the injection timing

to further assist starting. Idle quality is improved by

the high idle setting.

The engine is supplied with pre-compressed air by a

single stage turbocharger.

Exhaust gases passing over a turbine cause it to

rotate, driving a compressor mounted on the turbine

shaft. Air drawn from the cold air intake passes, via

the air cleaner, to the turbocharger where it is

compressed. Compression in the turbocharger warms

up the air considerably, so that it expands. As a result

the air mass per cylinder is reduced, having a

negative effect on power output. By fitting a charge-air

intercooler, located on the LH side of the radiator, the

air is cooled before reaching the cylinders. This

increases power output through increased mass of

oxygen in the combustion process, as well as

maximising engine durability, through maintaining

lower piston and head temperatures.

Fuel is drawn from the tank by a mechanical lift pump

and passes to the injection pump via a filter. In

addition to removing particle contamination from the

fuel, the filter incorporates a water separator, which

removes and stores water.

The sedimentor/s, when fitted, is located adjacent to

the fuel tank/s and separates contamination and water

particles in the fuel before reaching the fuel lift pump.

The injection pump meters a precisely timed, exact

quantity of fuel to the injectors in response to throttle

variations, injection timing varying with engine speed.

Any excess fuel delivered to the injection pump is

passed back to the tank via the spill return line.

Fuel is injected in a finely atomised form into the main

combustion chamber, the burning fuel expands

rapidly, creating extreme turbulence which mixes the

burning fuel thoroughly with the compressed air,

providing complete combustion.Cold Starting is assisted by heater plugs, a cold start

advance unit and a high idle setting.

Heater plugs

Heater plug operation is controlled by a timer unit,

start relay and resistor. When the ignition is turned on

the timer unit is energised, the heater plugs start to

operate and a warning light on the dashboard

illuminates, remaining on until the heater plugs are

automatically switched off.

The length of time the heater plugs will operate is

dependent on under bonnet temperature, which is

monitored by a sensor located in the timer unit.

Starting the engine results in the power supply to the

heater plugs passing through the resistor, which

reduces their operating temperature. The heater plugs

are cut out either by the temperature sensor in the

timer, or by a microswitch on the injection pump which

operates when the throttle is depressed.

Cold start advance

The cold start advance unit is connected to the engine

cooling system via hoses. It contains a temperature

sensitive element which is retracted when cold and

pulls the advance lever, via cable, towards the rear of

the pump against spring pressure. As coolant

temperature rises, the cold start element expands

releasing tension on the cable and allowing spring

pressure to move the advance lever forwards.

Exhaust gas recirculation (EGR), when fitted

Operation of the EGR system is dependent on the

following:

·Engine temperature - must be between 20°C and

100°C approx.

·Engine speed - must be between 630 and 2850

rev/min.

·Engine load - calculated by throttle position

sensor.

·EGR valve lift position.

·Duration of engine idling.

Page 101 of 455

19FUEL SYSTEM

4

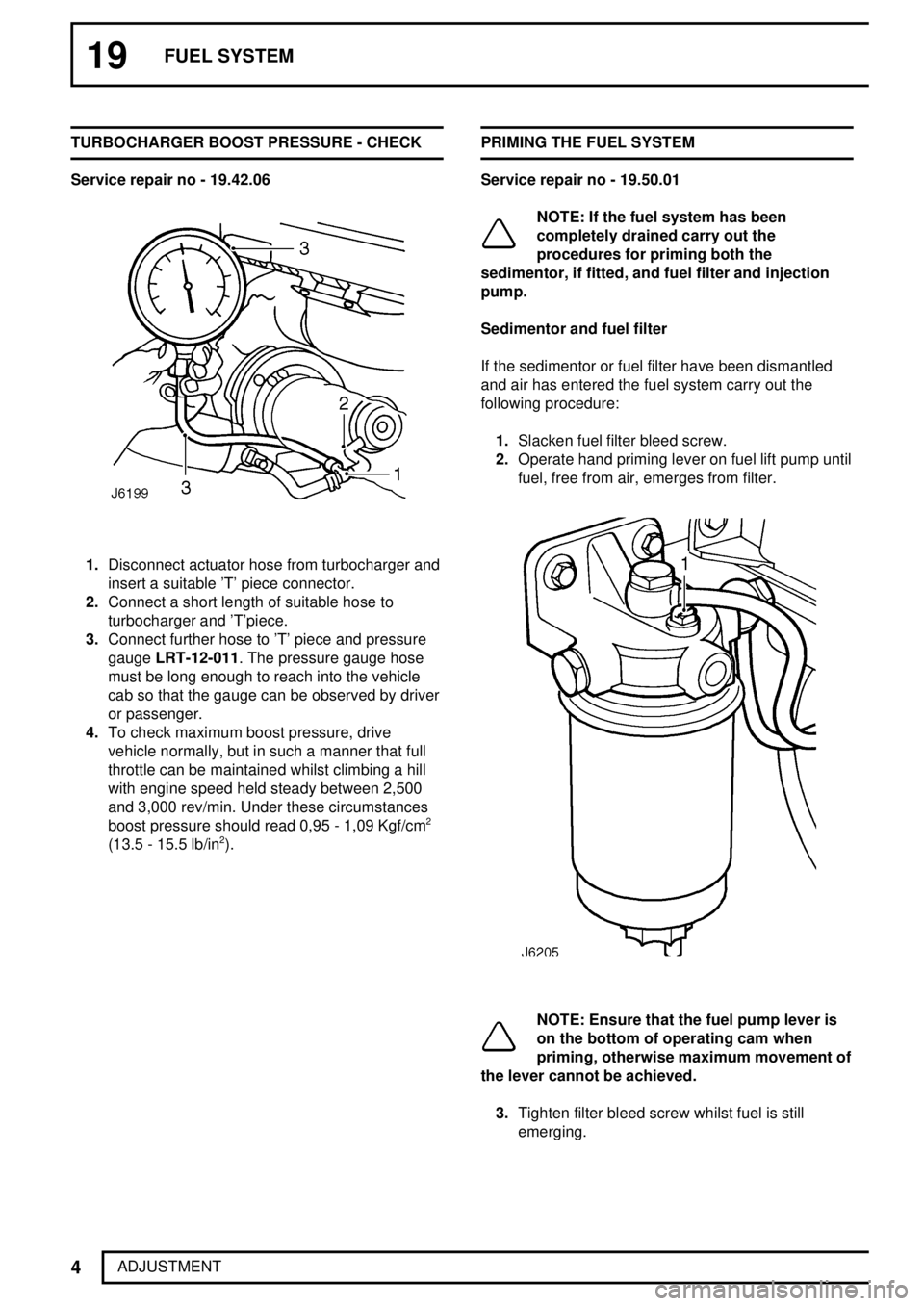

ADJUSTMENT TURBOCHARGER BOOST PRESSURE - CHECK

Service repair no - 19.42.06

1.Disconnect actuator hose from turbocharger and

insert a suitable 'T' piece connector.

2.Connect a short length of suitable hose to

turbocharger and 'T'piece.

3.Connect further hose to 'T' piece and pressure

gaugeLRT-12-011. The pressure gauge hose

must be long enough to reach into the vehicle

cab so that the gauge can be observed by driver

or passenger.

4.To check maximum boost pressure, drive

vehicle normally, but in such a manner that full

throttle can be maintained whilst climbing a hill

with engine speed held steady between 2,500

and 3,000 rev/min. Under these circumstances

boost pressure should read 0,95 - 1,09 Kgf/cm

2

(13.5 - 15.5 lb/in2).PRIMING THE FUEL SYSTEM

Service repair no - 19.50.01

NOTE: If the fuel system has been

completely drained carry out the

procedures for priming both the

sedimentor, if fitted, and fuel filter and injection

pump.

Sedimentor and fuel filter

If the sedimentor or fuel filter have been dismantled

and air has entered the fuel system carry out the

following procedure:

1.Slacken fuel filter bleed screw.

2.Operate hand priming lever on fuel lift pump until

fuel, free from air, emerges from filter.

NOTE: Ensure that the fuel pump lever is

on the bottom of operating cam when

priming, otherwise maximum movement of

the lever cannot be achieved.

3.Tighten filter bleed screw whilst fuel is still

emerging.

Page 107 of 455

FUEL SYSTEM

5

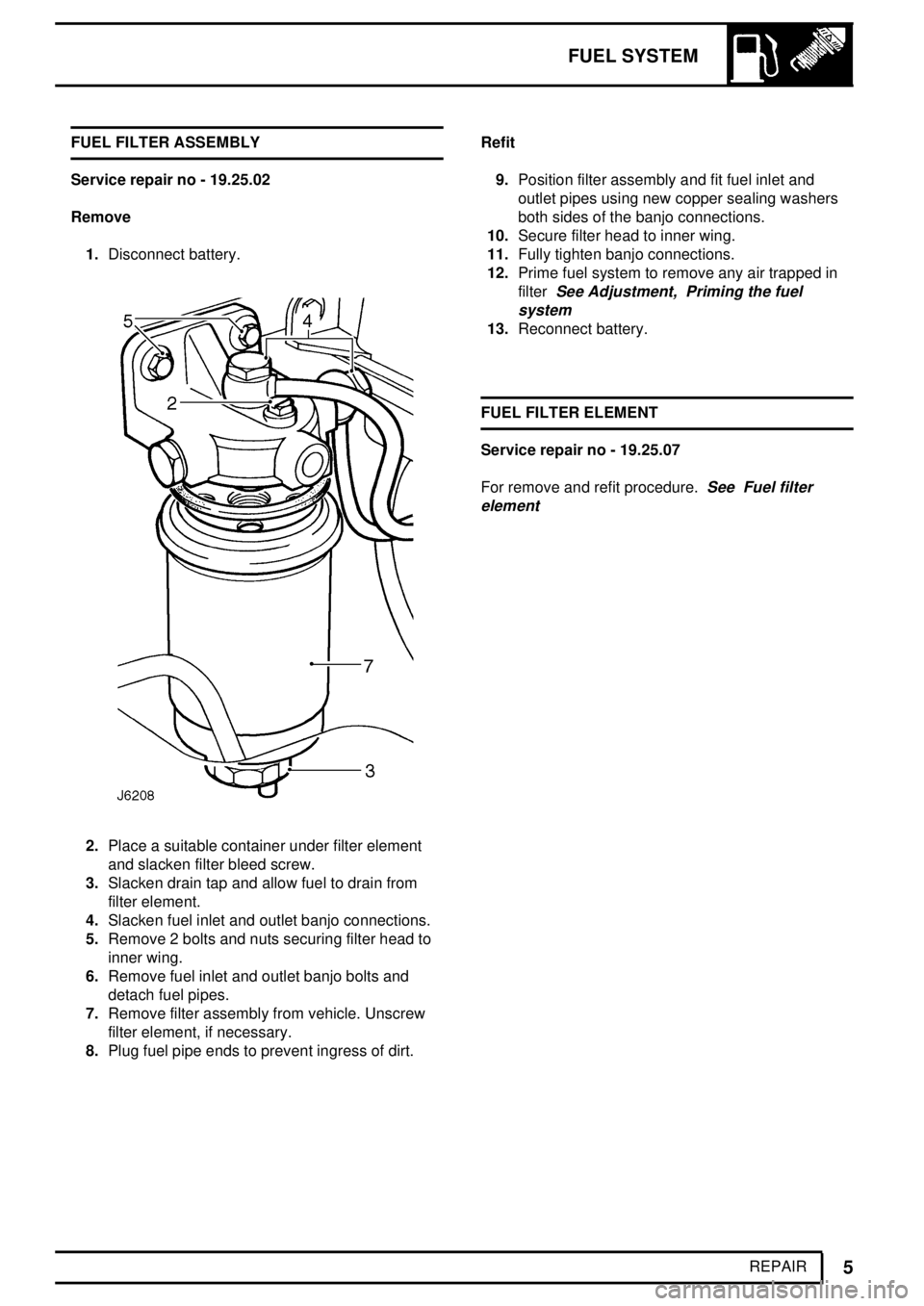

REPAIR FUEL FILTER ASSEMBLY

Service repair no - 19.25.02

Remove

1.Disconnect battery.

2.Place a suitable container under filter element

and slacken filter bleed screw.

3.Slacken drain tap and allow fuel to drain from

filter element.

4.Slacken fuel inlet and outlet banjo connections.

5.Remove 2 bolts and nuts securing filter head to

inner wing.

6.Remove fuel inlet and outlet banjo bolts and

detach fuel pipes.

7.Remove filter assembly from vehicle. Unscrew

filter element, if necessary.

8.Plug fuel pipe ends to prevent ingress of dirt.Refit

9.Position filter assembly and fit fuel inlet and

outlet pipes using new copper sealing washers

both sides of the banjo connections.

10.Secure filter head to inner wing.

11.Fully tighten banjo connections.

12.Prime fuel system to remove any air trapped in

filter

See Adjustment, Priming the fuel

system

13.Reconnect battery.

FUEL FILTER ELEMENT

Service repair no - 19.25.07

For remove and refit procedure.

See Fuel filter

element