instrument panel LAND ROVER DEFENDER 1996 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 370 of 455

HEATING AND VENTILATION

7

REPAIR Refit

14.Fit new control cable through heater duct cover

and secure to vent flap trunnion. Bend over

cable end to fully secure.

15.Fit heater duct cover.

16.Fit lower fascia panel assembly to fascia

bulkhead

See CHASSIS AND BODY, Repair,

lower fascia panel (heater duct) assembly.

17.Route control cable along fascia bulkhead to

contol lever assembly.

18.With control lever in closed position, secure

cable to clevis.

19.Fit outer cable retaining clip to lever assembly.

20.Fit lever assembly to side cover. Ensure screw

spacers are fitted between cover and lever

assembly.

21.Fit side cover to fascia cowl.

22.Fit control lever knobs.

23.Fit instrument panel

See INSTRUMENTS,

Repair, Instrument panel.

24.Fit steering column nacelleSee STEERING,

Repair, Steering column nacelle.

CONTROL CABLE AND BLOWER MOTOR SWITCH

Service repair no - 80.10.17 - Control cable

Service repair no - 80.10.22 - Blower motor switch

Remove

1.Disconnect battery.

2.From inside engine compartment, release outer

cable retaining clip at heater unit.

3.Slacken trunnion fixing and release inner cable

from heater unit flap lever.

4.Release 2 retaining clips securing control cables

to engine bulkhead and heater hoses.

5.Remove 4 screws securing instrument panel to

fascia cowl.

6.Pull instrument panel away from fascia and

disconnect speedometer cable to ease access to

control cable.

7.Remove 2 screws securing control lever

assembly to side of fascia panel cowl. Note

plastic screw spacers fitted between cowl and

lever assembly and retain.

Page 371 of 455

80HEATING AND VENTILATION

8

REPAIR

8.Release lever assembly and disconnect 3

blower motor leads, noting their positions.

9.Pull control cable through bulkhead grommet

and out from instrument panel cowl.

10.Release retaining clip securing outer cable to

lever assembly.

11.Release inner cable from lever peg.

NOTE: If the blower motor switch is faulty

the complete lever assembly will have to

be renewed.

Refit

12.Fit new control cable to lever assembly peg.

13.Fit retaining clip to secure outer cable.

14.Reconnect blower motor leads.

15.Route cable to rear of instrument panel cowl,

along bulkhead and out through grommet into

engine compartment.

16.Fit lever assembly to panel cowl. Ensure screw

spacers are fitted between cowl and lever

assembly.

17.Fit instrument panel to fascia cowl.

18.With lever in closed position, fit control cable to

heater unit flap lever trunnion.

19.Secure outer cable with retaining clip.

20.Secure control cables to engine bulkhead and

heater hoses with retaining clips.

21.Reconnect battery.

Page 403 of 455

WIPERS AND WASHERS

3

REPAIR WIPER MOTOR AND DRIVE RACK - VEHICLE

WITH AIR CONDITIONING, LH DRIVE

Service repair no - 84.15.20

Remove

1.Disconnect battery.

2.Remove wiper arms.

3.Remove single screw and remove fascia side

panel.

4.Remove 5 screws and withdraw instrument

panel as far as possible without straining wires

and cables.

5.Remove steering wheel

See STEERING,

Repair, Steering wheel.

6.Remove 2 screws at RH side and single screw

at LH side, inside instrument cowel, and

withdraw air conditioning panel and controls.

7.Release fascia panel LH support bracket.

8.Remove wiper motor cover finisher.

Page 404 of 455

84WIPERS AND WASHERS

4

REPAIR

9.Remove door check strap cover and 3 screws

and withdraw wiper motor cover. If applicable,

disconnect switch multi-plugs and/or radio

speaker leads.

10.Disconnect wiper motor multi-plug.

11.Disconnect earth lead. (Not applicable on later

models)

12.Lift rubber sleeve from wiper motor and slacken

wiper motor to drive tube nut.

13.Remove 2 screws and release wiper motor

retaining strap, complete with mounting pad and

earth tag.

14.Pull wiper motor and drive rack clear of drive

tubes.Refit

15.Feed drive rack into drive tube until fully located

in wheel boxes.

16.Finger tighten drive tube nut.

17.Position motor mounting pad, fit retaining strap,

including earth tag and secure wiper motor

assembly.

18.Fully tighten drive tube nut and fit rubber sleeve.

19.Fit wiper motor multi-plug and earth lead to tag

on motor retaining strap.

20.Before fitting fascia panels, fit wiper blades,

reconnect battery and test wiper operation.

21.Refit fascia panels, noting that air conditioning

panel must be located and secured, on LH side,

with single screw, before instrument panel is

fitted.

22.Fit steering wheel

See STEERING, Repair,

Steering wheel.

Page 406 of 455

84WIPERS AND WASHERS

6

REPAIR WINDSCREEN WIPER WHEEL BOXES - NON AIR

CONDITIONED VEHICLES

Service repair no - 84.15.25

Remove

1.Disconnect battery.

2.Remove wiper arms

See Windscreen wiper

arms.

3.Remove wiper motorSee Wiper motor and

drive rack - vehicle with air conditioning, LH

drive

.

4.Remove instrument housing, fascia crash pad,

and ventilator grille panel.

5.Slacken steering column support rod lower

fixing.6.Remove steering column upper support fixing.

7.Slacken nuts to release back plates from LH and

RH wheel boxes.

8.Remove drive rack tubes.

9.Slacken grub screws and remove wiper arm

adaptors.

10.Remove LH and RH wheelbox spindle nuts.

11.Remove wheel box assemblies from vehicle.

Page 407 of 455

WIPERS AND WASHERS

7

REPAIR Refit

NOTE: During reassembly all fixings

related to wiper motor and wheelboxes are

finger tightened only, until all components

are correctly aligned.

12.Fit wheelboxes to bulkhead and secure with

retaining nuts and washers.

13.Fit drive rack tubes to wheelboxes.

14.Apply grease to drive rack and wheelboxes.

15.Align wiper motor and mounting pad, secure with

retaining strap and tighten drive tube nut.

16.Fully tighten wheelbox back plate nuts.

17.Fully tighten both wheelbox spindle nuts.

18.Fit wiper arm adaptors and secure with grub

screw.

19.Before refitting panels fit wiper blades, connect

multi-plug and earth lead, reconnect battery and

check wiper operation.

20.If satisfactory, secure steering column upper and

lower fixings and tighten to correct torque.

21.Fit ventilator grille panel, fascia crash pad,

instrument housing and all other components

removed to gain access to wiper motor and

wheelboxes.

Page 415 of 455

ELECTRICAL

3

DESCRIPTION AND OPERATION Door and bonnet switches

Perimetric protection for the vehicle is provided by

ECU inputs connected to the starter switch, bonnet

switch and door switches.

Ultrasonic sensor

The ultrasonic sensor operates by emitting an air

pressure carrier wave which is subsequently received

by the sensor as it bounces back from objects inside

the vehicle. Once armed, the alarm will sound if wave

is disturbed by a door opening, or if movement is

detected inside the vehicle.

When the volumetric sensor is activated it monitors

movement within the vehicle for 15 seconds before

detecting and responding to intrusions. If the sensor

detects movement it delays arming until a quiet period

has lapsed; if continuous movement is detected, the

alarm will not arm volumetrically.

NOTE: Interior protection will not operate

until 15 seconds after alarm is set.

The ultrasonic sensor is positioned in a different

location, according to vehicle type, as follows:

·90/110 Station Wagon - RH cantrail trim

·90/110 Pick-up - On headlining, between interior

lamp and rear view mirror

·130 Crewcab - On headlining above RH door

Alarm sounder

Two types of alarm sounder can be fitted, one with a

battery back-up facility and or without battery back-up,

both providing an audible warning whenever the alarm

is triggered. The vehicle horn will also operate if the

alarm sounds.

The alarm sounder is fitted to LH inner front wing in

the engine compartment.

NOTE: Disconnecting the battery on

vehicles fitted with the battery backed-up

facility will result in the alarm sounding, if

correct procedure has not been followed.Engine immobilisation warning light

The engine immobilisation warning light is located on

the instrument panel, and provides a visual indication

that the engine is immobilised.

Anti-theft alarm indicator light

The anti-theft alarm indicator light is located on the

instrument panel, between the fuel and coolant

temperature indicators, and provides a visual

indication of the alarm/ immobiliser status.

Page 416 of 455

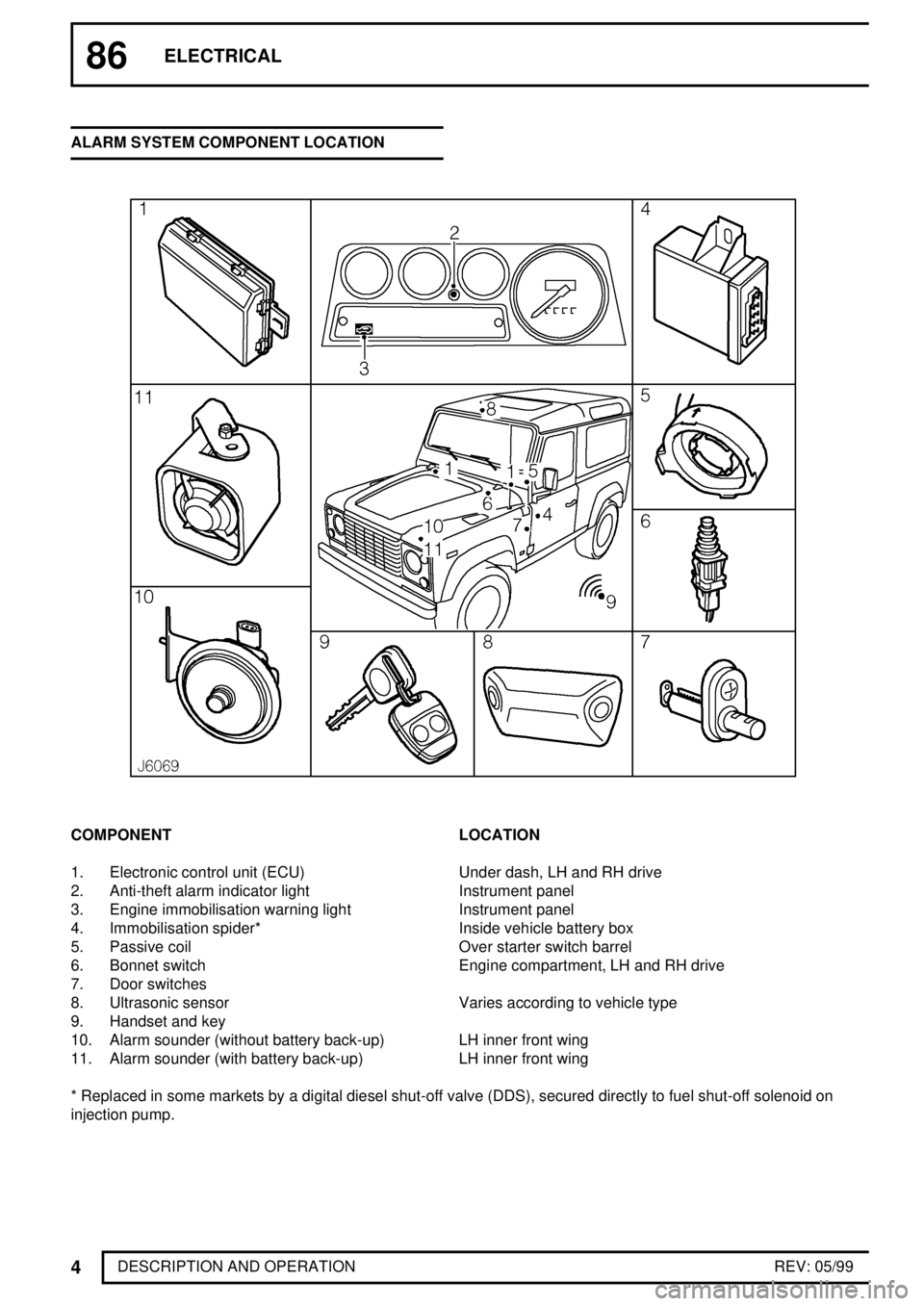

86ELECTRICAL

4

DESCRIPTION AND OPERATION REV: 05/99 ALARM SYSTEM COMPONENT LOCATION

COMPONENT LOCATION

1. Electronic control unit (ECU) Under dash, LH and RH drive

2. Anti-theft alarm indicator light Instrument panel

3. Engine immobilisation warning light Instrument panel

4. Immobilisation spider* Inside vehicle battery box

5. Passive coil Over starter switch barrel

6. Bonnet switch Engine compartment, LH and RH drive

7. Door switches

8. Ultrasonic sensor Varies according to vehicle type

9. Handset and key

10. Alarm sounder (without battery back-up) LH inner front wing

11. Alarm sounder (with battery back-up) LH inner front wing

* Replaced in some markets by a digital diesel shut-off valve (DDS), secured directly to fuel shut-off solenoid on

injection pump.

Page 417 of 455

ELECTRICAL

5

DESCRIPTION AND OPERATION REV: 05/99 ALARM SYSTEM OPERATION

Arming alarm

To arm the alarm, aim handset at vehicle and press

the RH button (Padlock symbol). Provided all doors

and or apertures are closed, the direction indicator

lamps will flash three times to confirm that the alarm is

armed. All security features previously described will

be active.

Once armed, the alarm will sound if a door or the

bonnet is opened, or if movement is detected inside

the vehicle.

Disarming alarm

Within range of the vehicle, briefly press the LH

(Plain) button on the handset; the direction indicator

lamps will flash once to indicate that the alarm has

been disarmed and the engine re-mobilised.

NOTE: In some territories, the interior

lamps will illuminate when the alarm is

disarmed.

If the direction indicators fail to flash when the

alarm is armed:

This indicates that a door or the bonnet is not fully

closed, in which case the alarm will be partially armed

and engine immobilised, but interior protection will not

be active.

Once the open door or bonnet is closed, the direction

indicators will flash three times and the alarm will fully

arm as described previously.

If the alarm sounds:

The vehicle horn and alarm sounder will operate

continuously for 30 seconds when the alarm is

triggered. The horn and alarm sounder can be

triggered up to three times.

To silence the alarm, press either handset button. If

the handset is inoperative, the alarm can only be

disarmed by entering the emergency key access

code, seeEngine immobilisation override.Anti-theft alarm indicator light

A RED indicator light on the instrument panel

indicates the status of the alarm system. When the

alarm is armed successfully, the light flashes rapidly.

After 10 seconds, the light adjusts to a slower

frequency and continues flashing as an anti-theft

deterrent.

If the light fails to illuminate during the rapid flash

phase, this indicates a 'mislock' (door or the bonnet

not fully closed or key in starter switch). If this occurs,

the indicator light will still flash at slower frequency as

an anti-theft deterrent.

The indicator light will illuminate continuously under

the following conditions:

1.Alarm system armed and immobilised with

ignition 'on' or driver's door open.

2.Engine immobilised with ignition 'on' or driver's

door open.

Interior protection

Interior protection is activated automatically when the

alarm system is armed; twin sensors inside the

vehicle monitor interior space and will activate the

alarm if an intrusion is detected.

However, if passengers or animals are to be left inside

the vehicle, or if a window or sunroof is to be left

open, the alarm must be armed with the interior

protection DISABLED as follows:

To disable interior protection:

1.Open the driver's door.

2.Use the handset to arm the alarm in normal way.

3.Close the driver's door (the direction indicator

lamps will flash three times and the anti-theft

indicator light commences flashing rapidly). The

alarm system is now armed with the interior

protection disabled.

NOTE: Interior protection will not operate

until 15 seconds after the alarm is set.

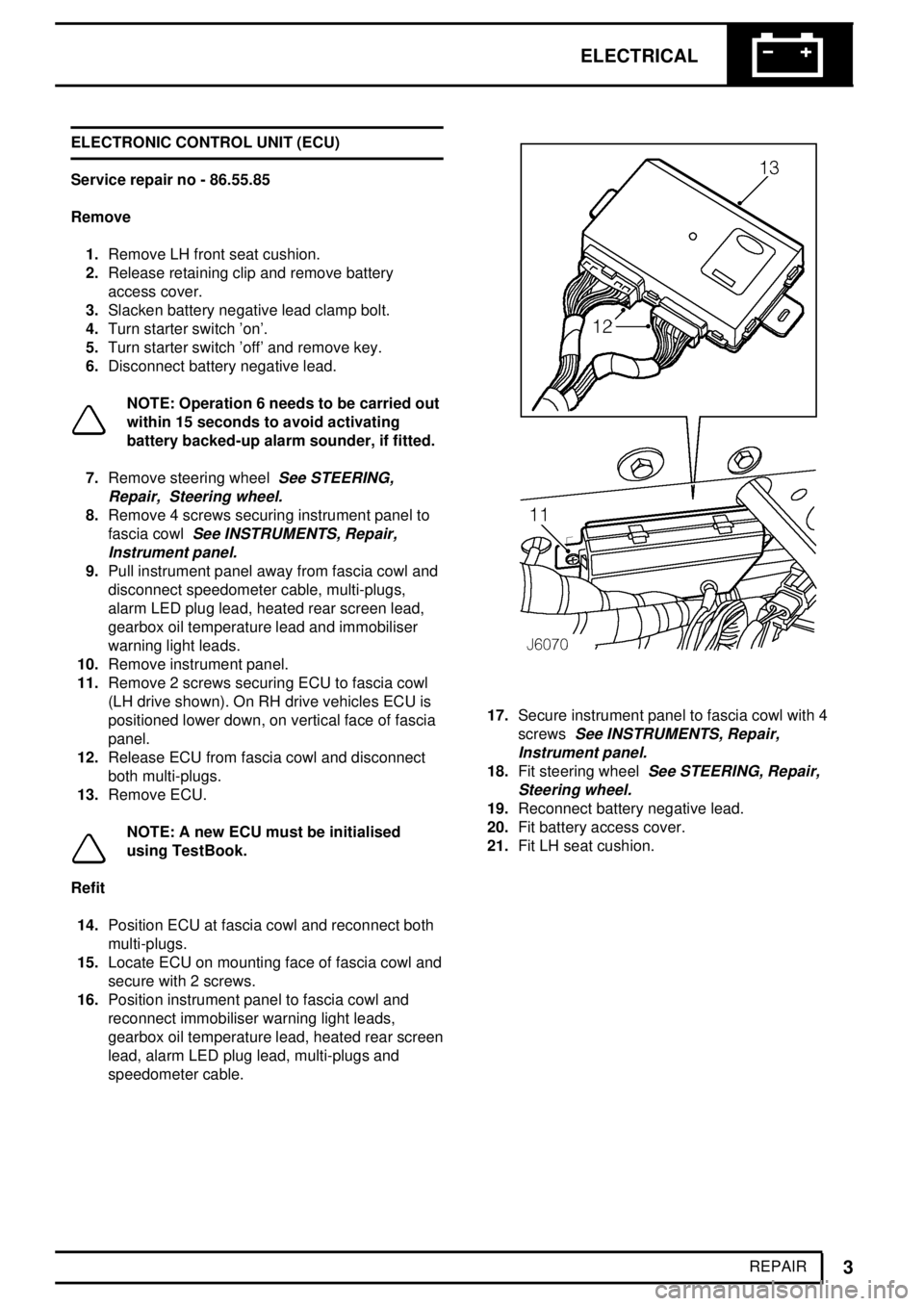

Page 428 of 455

ELECTRICAL

3

REPAIR ELECTRONIC CONTROL UNIT (ECU)

Service repair no - 86.55.85

Remove

1.Remove LH front seat cushion.

2.Release retaining clip and remove battery

access cover.

3.Slacken battery negative lead clamp bolt.

4.Turn starter switch 'on'.

5.Turn starter switch 'off' and remove key.

6.Disconnect battery negative lead.

NOTE: Operation 6 needs to be carried out

within 15 seconds to avoid activating

battery backed-up alarm sounder, if fitted.

7.Remove steering wheel

See STEERING,

Repair, Steering wheel.

8.Remove 4 screws securing instrument panel to

fascia cowl

See INSTRUMENTS, Repair,

Instrument panel.

9.Pull instrument panel away from fascia cowl and

disconnect speedometer cable, multi-plugs,

alarm LED plug lead, heated rear screen lead,

gearbox oil temperature lead and immobiliser

warning light leads.

10.Remove instrument panel.

11.Remove 2 screws securing ECU to fascia cowl

(LH drive shown). On RH drive vehicles ECU is

positioned lower down, on vertical face of fascia

panel.

12.Release ECU from fascia cowl and disconnect

both multi-plugs.

13.Remove ECU.

NOTE: A new ECU must be initialised

using TestBook.

Refit

14.Position ECU at fascia cowl and reconnect both

multi-plugs.

15.Locate ECU on mounting face of fascia cowl and

secure with 2 screws.

16.Position instrument panel to fascia cowl and

reconnect immobiliser warning light leads,

gearbox oil temperature lead, heated rear screen

lead, alarm LED plug lead, multi-plugs and

speedometer cable.

17.Secure instrument panel to fascia cowl with 4

screws

See INSTRUMENTS, Repair,

Instrument panel.

18.Fit steering wheelSee STEERING, Repair,

Steering wheel.

19.Reconnect battery negative lead.

20.Fit battery access cover.

21.Fit LH seat cushion.