instrument panel LAND ROVER DEFENDER 1996 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 430 of 455

ELECTRICAL

5

REPAIR PASSIVE COIL

Service repair no - 86.77.35

Remove

1.Remove LH front seat cushion.

2.Release retaining clip and remove battery

access cover.

3.Slacken battery negative lead clamp bolt.

4.Turn starter switch 'on'.

5.Turn starter switch 'off' and remove key.

6.Disconnect battery negative lead.

NOTE: Operation 6 needs to be carried out

within 15 seconds to avoid activating

battery backed-up alarm sounder, if fitted.

7.Remove steering wheel

See STEERING,

Repair, Steering wheel.

8.Remove 4 screws securing instrument panel to

fascia cowl

See INSTRUMENTS, Repair,

Instrument panel.

9.Pull instrument panel away from fascia and

disconnect speedometer cable, multi-plugs,

alarm LED plug lead, heated rear screen lead,

gearbox oil temperature lead and immobiliser

warning light leads.

10.Remove instrument panel.

11.Remove 7 screws securing upper and lower

halves of nacelle to steering column mounting

bracket

See STEERING, Repair, Steering

column nacelle.

12.Release multi-switch gaiters from both sides of

nacelle.

13.Remove nacelle upper and lower halves from

steering column; collect blanking grommet from

RH side.

14.Disconnect multi-plug and remove passive coil

from starter switch.

Refit

15.Feed passive coil plug lead into fascia cowl area

and reconnect multi-plug .

16.Fit coil on starter switch.

17.Position nacelle upper and lower halves to

steering column mounting bracket and secure

with 7 screws. Do not fully tighten screws at this

stage

See STEERING, Repair, Steering

column nacelle.

18.Check that passive coil is still fitted correctly on

starter switch.

19.Check fit of nacelle at starter switch and steering

column and fully tighten fixing screws.

20.Fit multi-switch gaiters to both sides of nacelle

and check that blanking grommet is located.

21.Position instrument panel to fascia cowl area

and reconnect immobiliser warning light leads,

gearbox oil temperature lead, heated rear screen

lead, alarm LED plug lead, main harness multi-

plugs and speedometer.

22.Secure instrument panel to fascia cowl with 4

screws

See INSTRUMENTS, Repair,

Instrument panel.

23.Fit steering wheelSee STEERING, Repair,

Steering wheel.

24.Reconnect battery negative lead.

25.Fit battery access cover.

26.Fit LH seat cushion.

27.Test immobilisation and alarm system.

Page 434 of 455

ELECTRICAL

9

REPAIR ALARM SOUNDER RELAY

Service repair no - 86.77.09

Remove

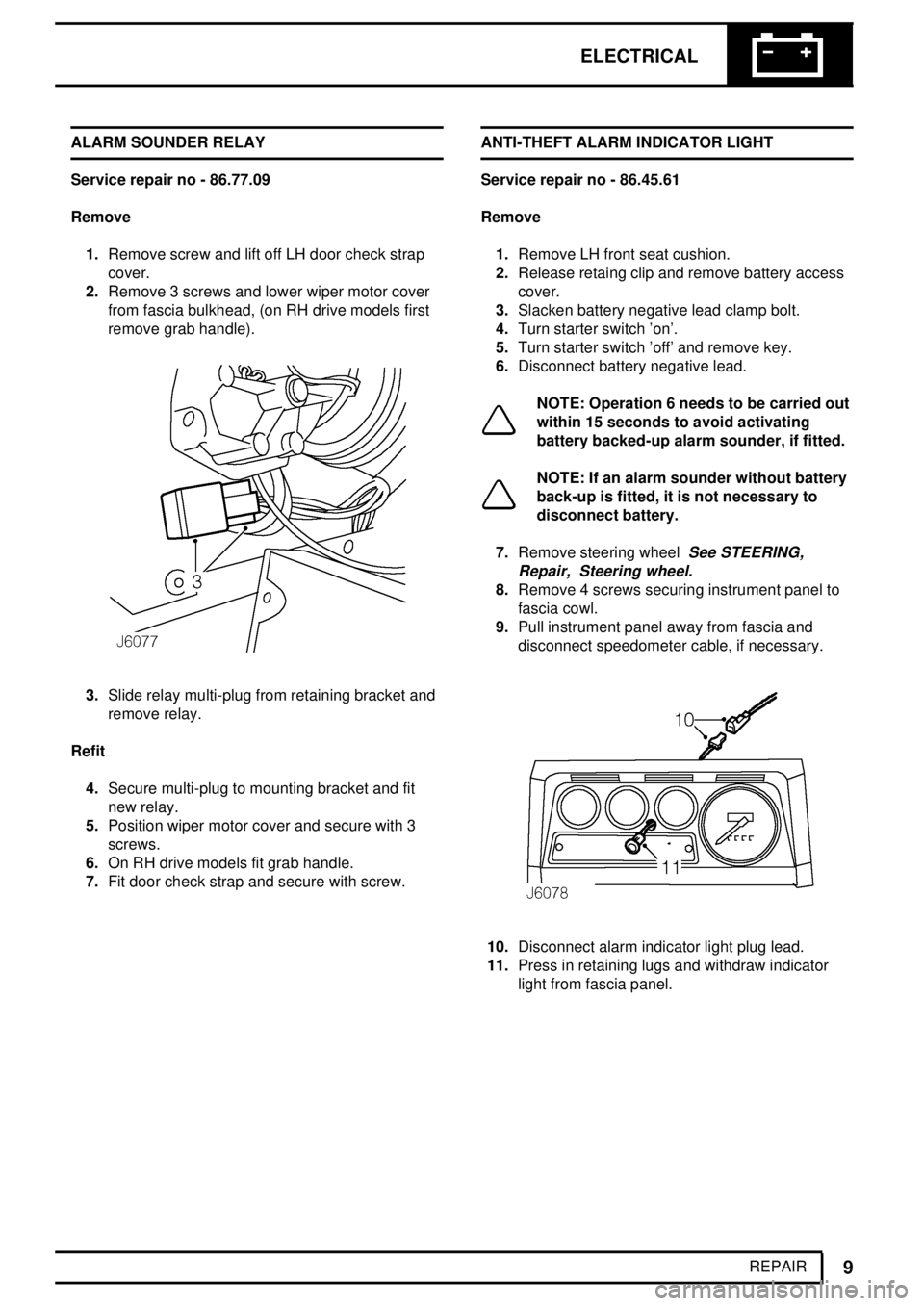

1.Remove screw and lift off LH door check strap

cover.

2.Remove 3 screws and lower wiper motor cover

from fascia bulkhead, (on RH drive models first

remove grab handle).

3.Slide relay multi-plug from retaining bracket and

remove relay.

Refit

4.Secure multi-plug to mounting bracket and fit

new relay.

5.Position wiper motor cover and secure with 3

screws.

6.On RH drive models fit grab handle.

7.Fit door check strap and secure with screw.ANTI-THEFT ALARM INDICATOR LIGHT

Service repair no - 86.45.61

Remove

1.Remove LH front seat cushion.

2.Release retaing clip and remove battery access

cover.

3.Slacken battery negative lead clamp bolt.

4.Turn starter switch 'on'.

5.Turn starter switch 'off' and remove key.

6.Disconnect battery negative lead.

NOTE: Operation 6 needs to be carried out

within 15 seconds to avoid activating

battery backed-up alarm sounder, if fitted.

NOTE: If an alarm sounder without battery

back-up is fitted, it is not necessary to

disconnect battery.

7.Remove steering wheel

See STEERING,

Repair, Steering wheel.

8.Remove 4 screws securing instrument panel to

fascia cowl.

9.Pull instrument panel away from fascia and

disconnect speedometer cable, if necessary.

10.Disconnect alarm indicator light plug lead.

11.Press in retaining lugs and withdraw indicator

light from fascia panel.

Page 435 of 455

86ELECTRICAL

10

REPAIR Refit

12.Fit alarm indicator light into fascia panel and

reconnect plug lead.

13.Reconnect speedometer cable and fit instrument

panel to fascia cowl.

14.Fit steering wheel

See STEERING, Repair,

Steering wheel.

15.Reconnect battery negative lead.

16.Fit battery access cover.

17.Fit LH seat cushion.ALARM SYSTEM FUSE

Service repair no - 86.77.04

Remove

1.Remove LH front seat cushion.

2.Release retaining clip and remove battery

access cover.

3.Slacken battery negative lead clamp bolt.

4.Turn starter switch 'on'.

5.Turn starter switch 'off' and remove key.

6.Disconnect battery negative lead.

NOTE: Operation 6 needs to be carried out

within 15 seconds to avoid activating

battery backed-up alarm sounder, if fitted.

NOTE: If an alarm sounder without battery

back-up is fitted, it is not necessary to

disconnect battery.

7.Remove steering wheel

See STEERING,

Repair, Steering wheel.

8.Remove 4 screws securing instrument panel to

fascia cowl

See INSTRUMENTS, Repair,

Instrument panel.

9.Pull instrument panel away from fascia and

disconnect speedometer cable, main harness

multi-plugs, alarm LED plug lead, heated rear

screen leads, gearbox oil temperature lead and

immobiliser warning light lead.

10.Remove instrument panel.

11.Remove alarm system 15 amp (blue) fuse from

holder located behind starter switch.

Page 436 of 455

ELECTRICAL

11

REPAIR REV: 05/99 Refit

12.Fit new fuse.

13.Position instrument panel to fascia cowl area

and reconnect immobiliser warning light leads,

gearbox oil temperature lead, heated rear screen

leads, alarm LED plug lead, main harness

multi-plugs and speedometer cable,

14.Secure instrument panel to fascia cowl with 4

screws

See INSTRUMENTS, Repair,

Instrument panel.

15.Fit steering wheelSee STEERING, Repair,

Steering wheel.

16.Reconnect battery negative lead.

17.Fit battery access cover.

18.Fit LH front seat cushion.GENERATOR

Service repair no - 86.10.02

Remove

1.Disconnect battery.

2.Remove drive belt

See Auxiliary drive belt.

3.Unscrew 3 fixings, remove heat shield from rear

of generator, and disconnect electrical leads

from generator.

4.Remove generator bottom fixing bolt.

5.Remove long through bolt from top fixing and lift

generator from engine.

Refit

6.Fit generator to engine mounting bracket and

secure with top and bottom fixing bolts.

7.Connect electrical leads.

8.Fit heat shield.

9.Fit drive belt

See Auxiliary drive belt; Refit.

10.Reconnect battery.

Page 443 of 455

86ELECTRICAL

18

REPAIR REVERSE LAMP SWITCH

Service repair no - 37.27.01

Remove

The reverse lamp switch is located on the LH side of

the gearbox extension housing and is accessible from

underneath the vehicle.

1.Place vehicle on suitable ramp.

2.Disconnect reverse lamp switch lead multi-plug

from harness connector.

3.Unscrew switch from extension housing.

Refit

4.Fit new switch to gearbox extension housing.

Tighten to

25 Nm (18 lbf/ft).

5.Fit lamp switch lead multi-plug to harness

connector.

6.Check operation of lamp switch.WARNING LAMP ASSEMBLY

Service repair no - 86.45.60 - Warning lamp

assembly

Service repair no - 86.45.61 - Warning lamp bulb

renewal

Remove

1.Disconnect battery.

2.Remove 2 screws and withdraw warning light

assembly from instrument panel.

3.Remove multi-plug to give access to warning

lamp bulbs.

4.Twist bulb holder and pull it from its socket.

5.Pull bulb from holder.

Refit

6.Fit new bulb and refit holder.

7.Fit multi-plug.

8.Fit warning lamp assembly to instrument panel

9.Reconnect battery.

Page 444 of 455

ELECTRICAL

19

REPAIR INSTRUMENT ILLUMINATION - BULB RENEWAL

Service repair no - 86.45.49 - Speedometer

Service repair no - 86.45.51 - Temperature gauge

Service repair no - 86.45.52 - Fuel gauge

Remove

1.Disconnect battery.

2.Remove 4 screws retaining instrument panel.

3.Ease panel forward and disconnect

speedometer cable to improve access to

illumination bulbs.

4.Twist bulb holder and pull from socket.

5.Pull bulb from holder.

Refit

6.Fit new bulb and refit holder.

7.Reconnect speedometer cable and fit instrument

panel.

8.Reconnect battery.STARTER SWITCH

Service repair no - 86.65.03

Remove

1.Remove instrument panel

See INSTRUMENTS,

Repair, Instrument panel.

2.Remove steering column nacelleSee

STEERING, Repair, Steering column nacelle.

3.Note position of harness leads on back of starter

switch and disconnect lukars. If fitted, remove

alarm system passive coil from switch

See

Passive coil.

4.Remove single screw and withdraw starter

switch from steering column lock.

Refit

5.Fit new switch in steering column lock.

6.Connect harness leads to starter switch.

7.If applicable, fit alarm system passive coil

See

Passive coil.

8.Fit steering column nacelleSee STEERING,

Repair, Steering column nacelle.

9.Fit instrument panelSee INSTRUMENTS,

Repair, Instrument panel.

Page 451 of 455

INSTRUMENTS

1

REPAIR INSTRUMENT PANEL

Service repair no - 88.20.02

Remove

1.Disconnect battery.

2.Remove 4 screws securing instrument panel to

fascia cowl.

3.Pull instrument panel away from fascia sufficent

to disconnect speedometer cable.

4.Disconnect multi-plugs, electrical leads and

connections to vehicle alarm system, if fitted

See ELECTRICAL, Repair, Vehicle

immobilisation and alarm system

.

5.Withdraw panel, complete with instruments.

Refit

6.Offer up instrument panel, connect multi-plugs,

electrical leads and connections to vehicle alarm

system, if fitted

See ELECTRICAL, Repair,

Vehicle immobilisation and alarm system

.

7.Connect speedometer cable.

8.Secure instrument panel.

9.Reconnect battery.SPEEDOMETER

Service repair no - 88.30.01

Remove

1.Remove 4 screws securing instrument panel to

fascia cowl.

2.Pull instrument panel away from fascia sufficent

to disconnect speedometer cable.

3.Release both bulb holders from speedometer.

4.Unscrew 2 knurled nuts and remove clamps

securing speedometer.

5.Wihdraw speedometer from instrument panel.

Refit

6.Fit speedometer into instrument panel and

secure with clamps.

7.Fit bulb holders to speedometer.

8.Connect speedometer cable.

9.Secure instrument panel to fascia cowl.

Page 452 of 455

88INSTRUMENTS

2

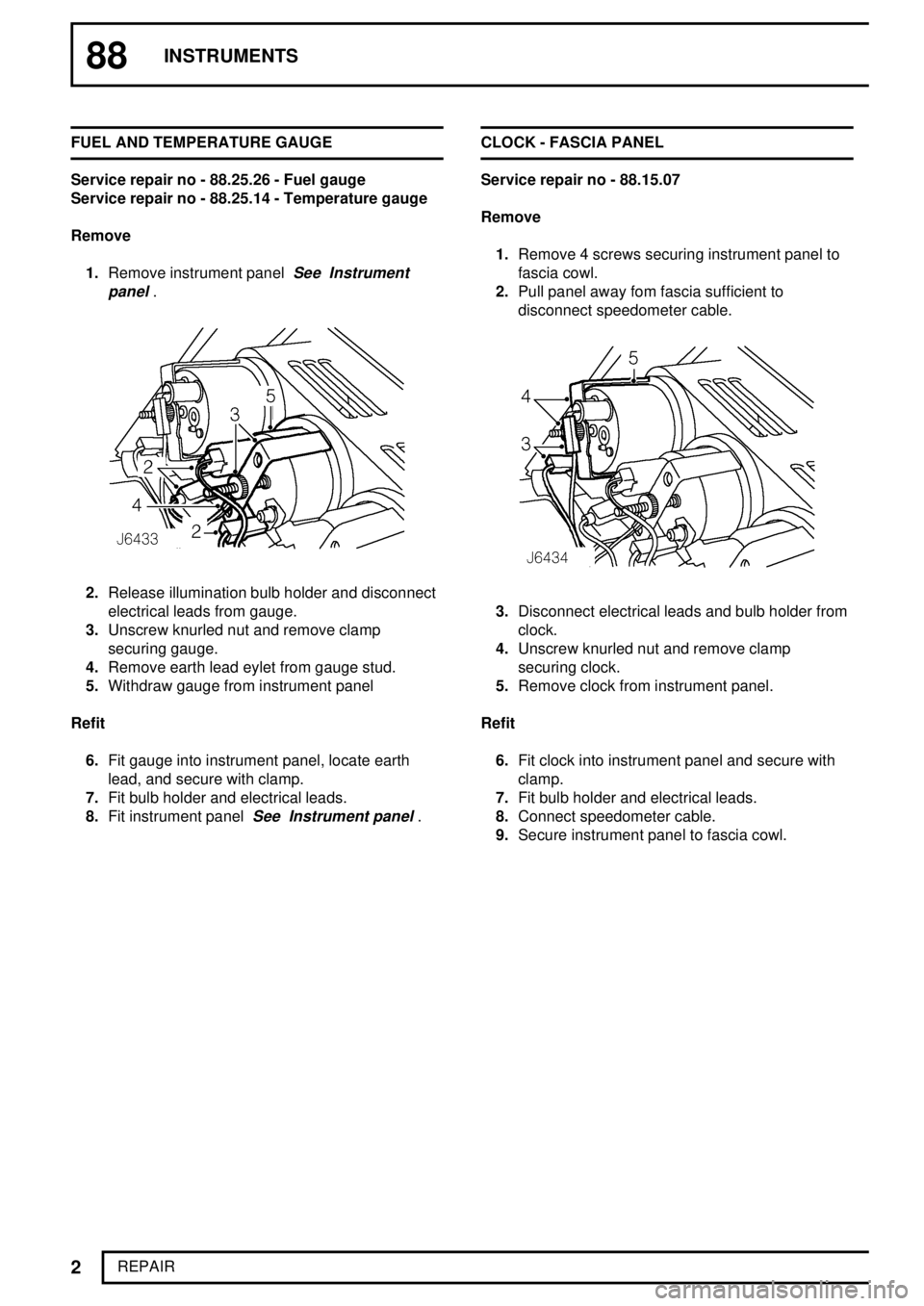

REPAIR FUEL AND TEMPERATURE GAUGE

Service repair no - 88.25.26 - Fuel gauge

Service repair no - 88.25.14 - Temperature gauge

Remove

1.Remove instrument panel

See Instrument

panel

.

2.Release illumination bulb holder and disconnect

electrical leads from gauge.

3.Unscrew knurled nut and remove clamp

securing gauge.

4.Remove earth lead eylet from gauge stud.

5.Withdraw gauge from instrument panel

Refit

6.Fit gauge into instrument panel, locate earth

lead, and secure with clamp.

7.Fit bulb holder and electrical leads.

8.Fit instrument panel

See Instrument panel.CLOCK - FASCIA PANEL

Service repair no - 88.15.07

Remove

1.Remove 4 screws securing instrument panel to

fascia cowl.

2.Pull panel away fom fascia sufficient to

disconnect speedometer cable.

3.Disconnect electrical leads and bulb holder from

clock.

4.Unscrew knurled nut and remove clamp

securing clock.

5.Remove clock from instrument panel.

Refit

6.Fit clock into instrument panel and secure with

clamp.

7.Fit bulb holder and electrical leads.

8.Connect speedometer cable.

9.Secure instrument panel to fascia cowl.

Page 453 of 455

INSTRUMENTS

3

REPAIR CLOCK - CENTRE DASH PANEL

Service repair no - 88.15.07

Remove

1.Remove 2 screws and withdraw switch panel

from centre dash.

2.Release illumination bulb holder and disconnect

electrical leads from clock.

3.Press in spring retainers and remove clock from

panel.

Refit

4.Fit clock into dash panel.

5.Fit electrical leads and bulb holder.

6.Secure switch panel to centre dash.WARNING LIGHT PANEL

Service repair no - 88.20.18

Remove

1.Remove 2 screws and withdraw warning light

panel.

2.Disconect both multi-plugs.

3.Disconnect illumination bulb leads.

4.Remove warning light panel.

Refit

5.Fit illumination bulb leads and multi-plugs to

warning light panel.

6.Secure warning light panel to instrument panel.

Page 454 of 455

88INSTRUMENTS

4

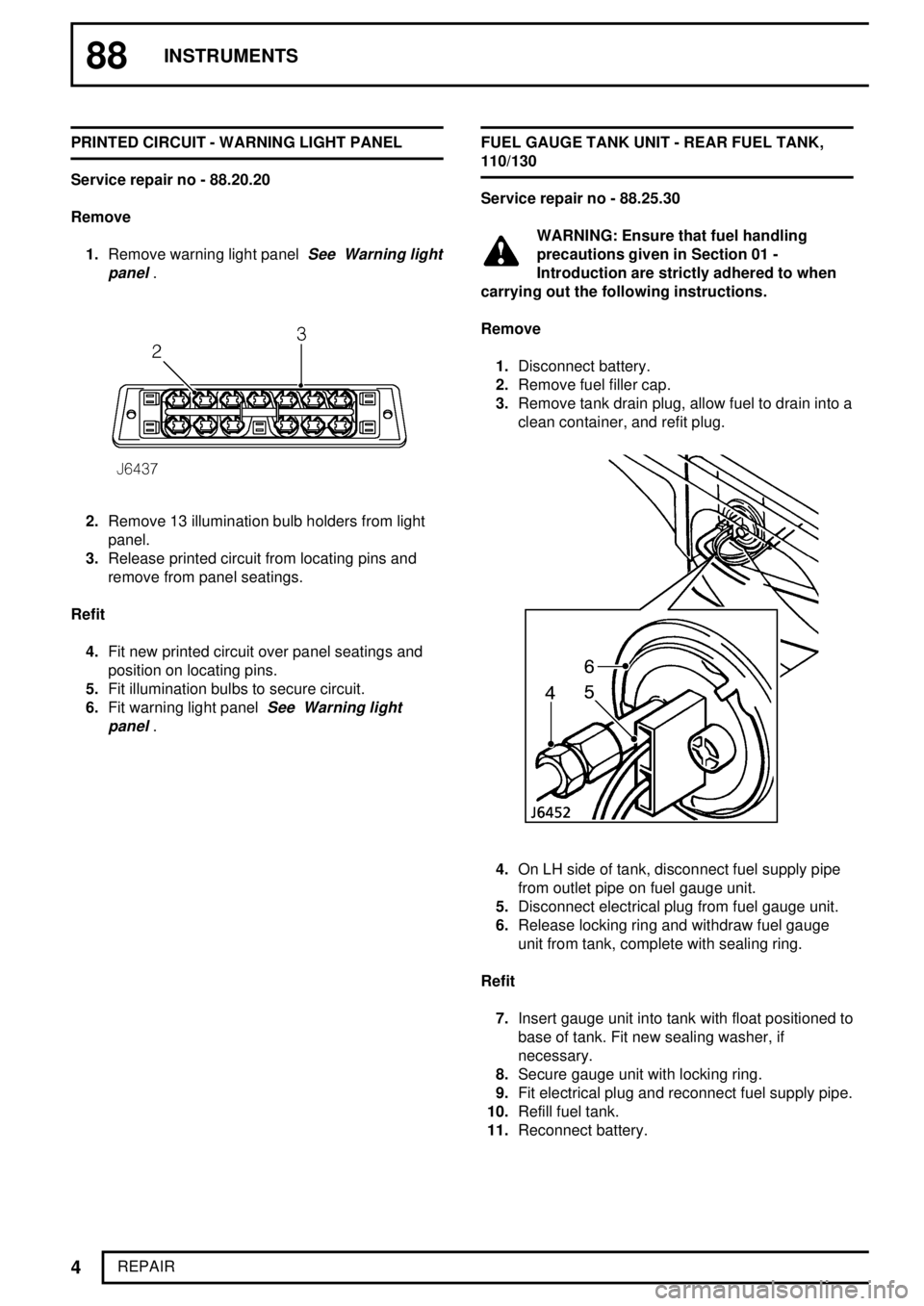

REPAIR PRINTED CIRCUIT - WARNING LIGHT PANEL

Service repair no - 88.20.20

Remove

1.Remove warning light panel

See Warning light

panel

.

2.Remove 13 illumination bulb holders from light

panel.

3.Release printed circuit from locating pins and

remove from panel seatings.

Refit

4.Fit new printed circuit over panel seatings and

position on locating pins.

5.Fit illumination bulbs to secure circuit.

6.Fit warning light panel

See Warning light

panel

.FUEL GAUGE TANK UNIT - REAR FUEL TANK,

110/130

Service repair no - 88.25.30

WARNING: Ensure that fuel handling

precautions given in Section 01 -

Introduction are strictly adhered to when

carrying out the following instructions.

Remove

1.Disconnect battery.

2.Remove fuel filler cap.

3.Remove tank drain plug, allow fuel to drain into a

clean container, and refit plug.

4.On LH side of tank, disconnect fuel supply pipe

from outlet pipe on fuel gauge unit.

5.Disconnect electrical plug from fuel gauge unit.

6.Release locking ring and withdraw fuel gauge

unit from tank, complete with sealing ring.

Refit

7.Insert gauge unit into tank with float positioned to

base of tank. Fit new sealing washer, if

necessary.

8.Secure gauge unit with locking ring.

9.Fit electrical plug and reconnect fuel supply pipe.

10.Refill fuel tank.

11.Reconnect battery.