steering wheel LAND ROVER DEFENDER 1996 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 56 of 455

MAINTENANCE

13

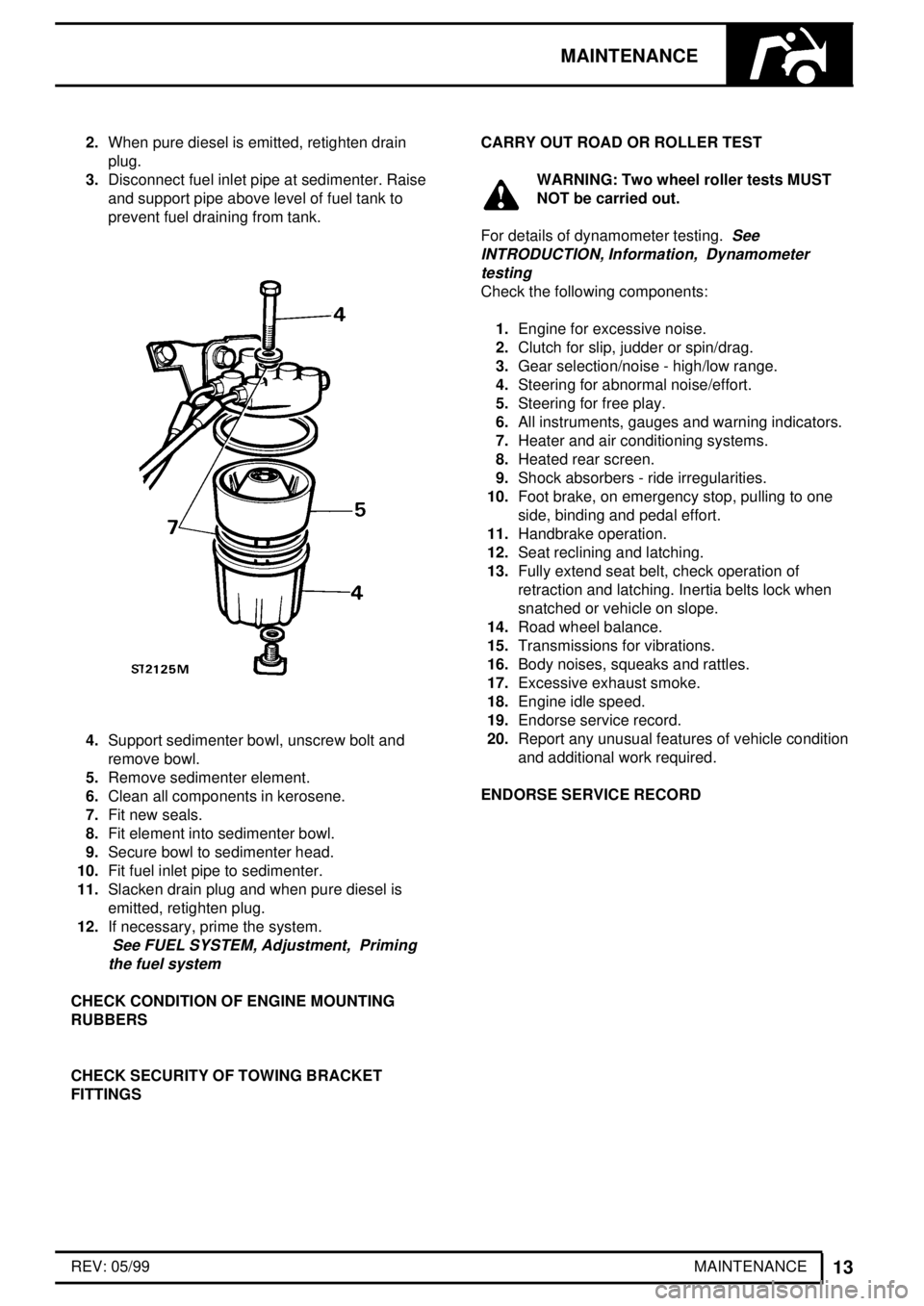

MAINTENANCE REV: 05/992.When pure diesel is emitted, retighten drain

plug.

3.Disconnect fuel inlet pipe at sedimenter. Raise

and support pipe above level of fuel tank to

prevent fuel draining from tank.

4.Support sedimenter bowl, unscrew bolt and

remove bowl.

5.Remove sedimenter element.

6.Clean all components in kerosene.

7.Fit new seals.

8.Fit element into sedimenter bowl.

9.Secure bowl to sedimenter head.

10.Fit fuel inlet pipe to sedimenter.

11.Slacken drain plug and when pure diesel is

emitted, retighten plug.

12.If necessary, prime the system.

See FUEL SYSTEM, Adjustment, Priming

the fuel system

CHECK CONDITION OF ENGINE MOUNTING

RUBBERS

CHECK SECURITY OF TOWING BRACKET

FITTINGSCARRY OUT ROAD OR ROLLER TEST

WARNING: Two wheel roller tests MUST

NOT be carried out.

For details of dynamometer testing.

See

INTRODUCTION, Information, Dynamometer

testing

Check the following components:

1.Engine for excessive noise.

2.Clutch for slip, judder or spin/drag.

3.Gear selection/noise - high/low range.

4.Steering for abnormal noise/effort.

5.Steering for free play.

6.All instruments, gauges and warning indicators.

7.Heater and air conditioning systems.

8.Heated rear screen.

9.Shock absorbers - ride irregularities.

10.Foot brake, on emergency stop, pulling to one

side, binding and pedal effort.

11.Handbrake operation.

12.Seat reclining and latching.

13.Fully extend seat belt, check operation of

retraction and latching. Inertia belts lock when

snatched or vehicle on slope.

14.Road wheel balance.

15.Transmissions for vibrations.

16.Body noises, squeaks and rattles.

17.Excessive exhaust smoke.

18.Engine idle speed.

19.Endorse service record.

20.Report any unusual features of vehicle condition

and additional work required.

ENDORSE SERVICE RECORD

Page 209 of 455

FRONT AXLE AND FINAL DRIVE

1

REPAIR REV: 05/99 FRONT AXLE ASSEMBLY

Service repair no - 54.10.01

Remove

WARNING: Remove and refit of axle

requires a further two persons to steady

axle when lowering or repositioning axle.

1.Support chassis front.

2.Remove road wheels.

3.Support axle weight with hydraulic jack.

4.Remove radius arms to chassis frame nuts.

5.Disconnect steering damper from track rod.

Using a extractor remove track rod links from

swivel pin arms.

6.Remove four nuts and bolts securing radius

arms to axle bracket.

7.Remove radius arms.

8.Remove bolts securing brake hose brackets .

Refit bolts to prevent oil leakage.

9.Remove bolts from brake calipers and tie to one

side.

10.Remove nuts and washers securing shock

absorbers to axle.

11.Disconnect drag link from swivel pin housing

arm.

12.Remove two nuts and bolts securing panhard

rod to axle bracket. Lift rod clear of axle.

13.Mark for reassembly drive shaft flanges.

Remove four nuts and bolts, tie propeller shaft to

one side.

14.Release axle ventilation pipe banjo and lower

axle assembly. Remove road springs.

15.Disconnect anti-roll bar link

See FRONT

SUSPENSION, Repair, Anti-roll bar ball

.

16.Remove axle assembly.

Refit

17.Position axle under vehicle, supporting left side

of axle, and fit anti-roll bar links

See FRONT

SUSPENSION, Repair, Anti-roll bar links

.

18.Fit propeller shaft. Tighten bolts to

47 Nm (35

lbf/ft).

19.Fit panhard rod to axle bracket. Tighten bolts to

88 Nm (65 lbf/ft).

20.Fit drag link to swivel pin arm. Tighten fixings to

40 Nm (30 lbf/ft).

21.Fit shock absorbers to axle.

22.Fit brake calipers. Tighten bolts to

82 Nm (60

lbf/ft).

23.Tighten upper swivel pin bolts to78 Nm (58

lbf/ft).

24.Fit radius arms to axle brackets. Tighten bolts to

197 Nm (145 lbf/ft).

25.Fit steering damper to track rod.

26.Fit radius arms to chassis side member. Tighten

fixings to

197 Nm (145 lbf/ft).

27.Tighten track rod end to40 Nm (30 lbf/ft)and fit

new split pin.

28.Remove chassis supports, fit road wheels and

tighten to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

Page 218 of 455

STEERING

1

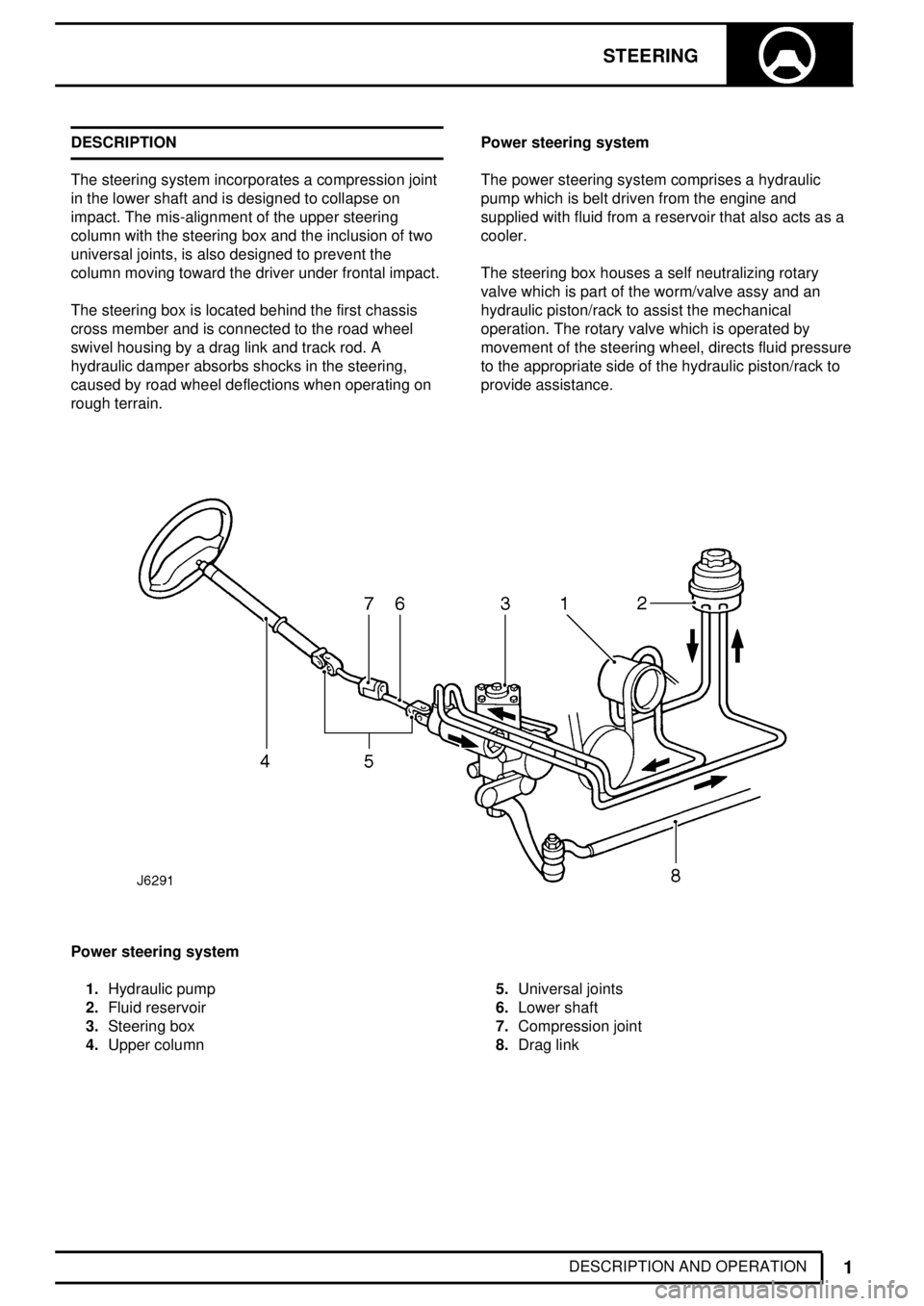

DESCRIPTION AND OPERATION DESCRIPTION

The steering system incorporates a compression joint

in the lower shaft and is designed to collapse on

impact. The mis-alignment of the upper steering

column with the steering box and the inclusion of two

universal joints, is also designed to prevent the

column moving toward the driver under frontal impact.

The steering box is located behind the first chassis

cross member and is connected to the road wheel

swivel housing by a drag link and track rod. A

hydraulic damper absorbs shocks in the steering,

caused by road wheel deflections when operating on

rough terrain.Power steering system

The power steering system comprises a hydraulic

pump which is belt driven from the engine and

supplied with fluid from a reservoir that also acts as a

cooler.

The steering box houses a self neutralizing rotary

valve which is part of the worm/valve assy and an

hydraulic piston/rack to assist the mechanical

operation. The rotary valve which is operated by

movement of the steering wheel, directs fluid pressure

to the appropriate side of the hydraulic piston/rack to

provide assistance.

Power steering system

1.Hydraulic pump

2.Fluid reservoir

3.Steering box

4.Upper column5.Universal joints

6.Lower shaft

7.Compression joint

8.Drag link

Page 220 of 455

STEERING

3

DESCRIPTION AND OPERATION Rotary valve operation

Rotary valve at neutral

The rotary valve assembly comprises a worm (1),

valve sleeve (2), input shaft (4) and torsion bar (5).

The valve sleeve is retained inside the worm by a trim

screw (3), and incorporates valve ports in its inner

bore. The input shaft is attached to the steering wheel

via a steering shaft and steering column and

incorporates valve ports in its outer diameter to align

with those in the sleeve.

The torsion bar, which is secured to the worm and

input shaft with pins (6) at each end, holds the valve

ports in neutral alignment when there is no demand

for assistance.No demand for assistance (Valve at neutral)

When there is no demand for assistance the torsion

bar holds the input shaft and sleeve valve ports in

neutral relationship to one another, allowing equal

pump pressure (A) to both sides of the piston/rack (9).

Any excess fluid flow from the pump returns to the

reservoir via (B).

Page 221 of 455

57STEERING

4

DESCRIPTION AND OPERATION Rotary valve misaligned

Demand for assistance (Valve misaligned)

When the steering wheel and input shaft is turned,

steering resistance transmitted to the worm causes

the torsion bar to be twisted and the valve ports to be

misaligned for a right or left turn. The misalignment of

the valve ports directs all fluid pressure A to one side

of the piston only and allows displaced fluid B on the

other side.

When demanding maximum assistance, any

excessive fluid output from the pump due to high

pump speed, will circulate through the regulator valve

located in the pump unit, causing the temperature of

the fluid and the pump to rise rapidly.CAUTION: To avoid excessive fluid

temperatures which could damage the oil

seals, the steering must not be held on full

lock for more than 30 seconds in one minute.

Only when the steering wheel, and the demand for

assistance, is released, will the torsion bar return the

valve to neutral, allowing the fluid to circulate through

the reservoir where it is cooled.

In the unlikely event of mechanical failure of the

torsion bar, a coarse splined connection (7) between

the input shaft and worm, ensures steering control is

maintained sufficient to allow the vehicle to be

recovered.

Page 222 of 455

STEERING

5

DESCRIPTION AND OPERATION Pump and regulator valve operation

The pump which is belt driven from the engine is an

eccentric roller type and also houses the pressure

regulator and flow control valve. The pressure is

controlled by a spring loaded ball valve (3) which is

housed inside the flow control valve piston (4).

No demand for assistance High flow through box -

Low pressure

With no demand for assistance the rotary valve in the

steering box acts as a pressure relief valve, allowing

fluid (A) to flow freely through the steering box and

back to the reservoir and pump inlet (B).

No demand for assistance

1.Reservoir

2.Pump

3.Pressure control ball valve and spring

4.Flow control valve and spring

5.Press fit plug (ball bearing)

6.Restrictor

The ball plug (5) is pressed into the valve (4)

during manufacture and determines the opening

pressure of pressure relief valve (3).No flow, through box - High pressure

When the steering is turned, the rotary valve

effectively stops all fluid flow through the steering box,

thus causing an increase in pressure (A). This

increase in pressure is felt in the flow control valve

spring chamber where, at a pre-determined pressure

the relief valve (3) will open and allow the pressure to

escape. The fall in pressure in the flow control spring

chamber, allows the flow control valve to move to the

right, which in turn allows pump output (A) to escape

directly into the pump inlet (B).

Assistance demanded

As soon as the steering wheel is released after

making a turn, the system reverts to the condition

seen in J6292 and the road wheels are returned to the

straight ahead position by the mechanical steering

geometry.

In the event of any hydraulic failure, steering control,

though heavy, will be maintained through the

mechanical components in the steering box.

Page 223 of 455

STEERING

1

FAULT DIAGNOSIS INSUFFICIENT POWER ASSISTANCE

1.Is fluid level correct?

YES - go to 3.

NO - Fill/bleed sytem

2.Is problem a leak?

YES - Diagnose

See Power Steering Fluid

Leaks

.

NO - continue

3.Is drive belt tension correct?

YES - go to 5.

NO - Is drive belt worn or contaminated with oil?

See ELECTRICAL, Repair, Auxiliary drive

belt

.

4.Is problem resolved?

YES - end

NO - continue

5.Carry out pressure test at idle and 1000 rev/min.

See Power Steering System - Test.

6.Is correct pressure achieved?

YES - steering box defective

Not at any speed go to 9.

Not at idle go to 7.

7.Is idle speed correct?

YES-Goto8.

NO - Correct idle speed -

See ENGINE TUNING

DATA, Information, 300 Tdi Engine

.

8.Is problem resolved?

YES - end

NO - go to 9.

9.Bypass steering box using adaptor tap

LRT-57-001

10.Is correct pressure obtained?

YES - defective steering box

NO - defective steering pump

CAUTION: Do not hold steering wheel on

full lock for more than 30 seconds in any

one minute to avoid overheating fluid and

possibly damaging seals.

NOTE: 1. Excessive pressure in the

system is almost always caused by a

faulty relief valve in the PAS pump.

NOTE: 2. Insufficient pressure in the

system is usually caused by low fluid level

or PAS pump drive belt slip, or one of the

following: PAS system leaks, faulty PAS pump

relief valve, fault in steering box valve and worm

assembly, leak at piston in steering box, worn

components in PAS pump or box.

Page 224 of 455

57STEERING

2

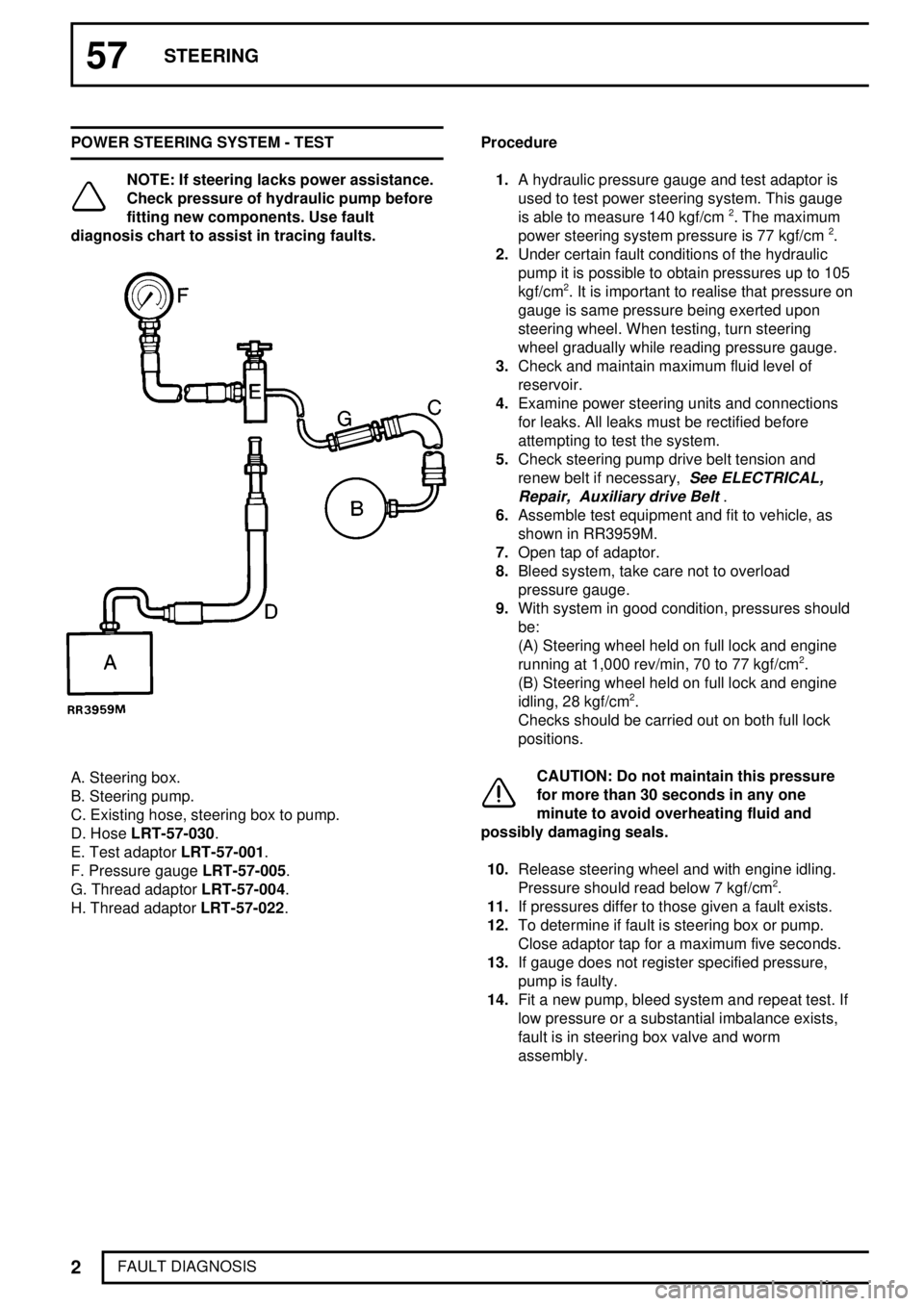

FAULT DIAGNOSIS POWER STEERING SYSTEM - TEST

NOTE: If steering lacks power assistance.

Check pressure of hydraulic pump before

fitting new components. Use fault

diagnosis chart to assist in tracing faults.

A. Steering box.

B. Steering pump.

C. Existing hose, steering box to pump.

D. HoseLRT-57-030.

E. Test adaptorLRT-57-001.

F. Pressure gaugeLRT-57-005.

G. Thread adaptorLRT-57-004.

H. Thread adaptorLRT-57-022.Procedure

1.A hydraulic pressure gauge and test adaptor is

used to test power steering system. This gauge

is able to measure 140 kgf/cm

2. The maximum

power steering system pressure is 77 kgf/cm2.

2.Under certain fault conditions of the hydraulic

pump it is possible to obtain pressures up to 105

kgf/cm

2. It is important to realise that pressure on

gauge is same pressure being exerted upon

steering wheel. When testing, turn steering

wheel gradually while reading pressure gauge.

3.Check and maintain maximum fluid level of

reservoir.

4.Examine power steering units and connections

for leaks. All leaks must be rectified before

attempting to test the system.

5.Check steering pump drive belt tension and

renew belt if necessary,

See ELECTRICAL,

Repair, Auxiliary drive Belt

.

6.Assemble test equipment and fit to vehicle, as

shown in RR3959M.

7.Open tap of adaptor.

8.Bleed system, take care not to overload

pressure gauge.

9.With system in good condition, pressures should

be:

(A) Steering wheel held on full lock and engine

running at 1,000 rev/min, 70 to 77 kgf/cm

2.

(B) Steering wheel held on full lock and engine

idling, 28 kgf/cm

2.

Checks should be carried out on both full lock

positions.

CAUTION: Do not maintain this pressure

for more than 30 seconds in any one

minute to avoid overheating fluid and

possibly damaging seals.

10.Release steering wheel and with engine idling.

Pressure should read below 7 kgf/cm

2.

11.If pressures differ to those given a fault exists.

12.To determine if fault is steering box or pump.

Close adaptor tap for a maximum five seconds.

13.If gauge does not register specified pressure,

pump is faulty.

14.Fit a new pump, bleed system and repeat test. If

low pressure or a substantial imbalance exists,

fault is in steering box valve and worm

assembly.

Page 225 of 455

STEERING

3

FAULT DIAGNOSIS STEERING DAMPER

The power steering system, as well as reducing the

effort required to manoeuvre the vehicle when

parking, also helps to dampen any deflections of the

road wheels, being transmitted back to the steering

wheel.

When operating the vehicle off road, the road wheels

are often deflected by ruts and boulders causing the

steering wheel to turn left and right. This phenomenon

is known as 'steering kickback'. To subdue the effects

of 'steering kickback', a hydraulic damper is fitted in

the steering linkage between the track rod and the

differential casing. The damper, which offers the same

resistance in extension and compression, is sealed for

life.

Steering damper check

Check the condition operation of the hydraulic

steering damper as follows:

Check procedure

1.Inspect damper for casing damage or leaks.

2.Clamp one end of the damper horizontally in a

vice using soft jaws. Compress and extend the

unit by hand. Resistance should be equal in both

directions.

3.If it is felt that the unit is outside acceptable

limits, fit a new steering damperSTEERING FAULTS

Symptom:-

Excessive kickback through steering wheel - when

driven on rough terrain.

1.Is the steering damper in good working order?

See Steering Damper.

NO - Renew unit

See Repair, Steering

Damper

.

YES - Continue.

2.Is there any looseness or free play in the

steering ball joints and linkage?

YES -

See Steering Linkage Inspect.

NO - Continue.

3.Is there any looseness or worn bushes in front

suspension?

YES -

See FRONT SUSPENSION, Repair,

Radius Arm

.

NOTE: When replacing suspension bushes

ALL bushes and fixings must be replaced.

NO - Continue.

4.Is the steering exceptionally light/sensitive when

driven on good road surface?

YES - See fault symptom -Steering

excessively light/sensitive and freeplay at

steering wheel.

NO - Suspect axle swivel resistance.

5.Check the resistance of the axle swivels

See

FRONT AXLE AND FINAL DRIVE, Overhaul,

Front Stub Axle, Constant Velocity Joint and

Swivel Pin Housing

.

Page 226 of 455

57STEERING

4

FAULT DIAGNOSIS Symptom:-

Fluid leaks from steering box seals.

CAUTION: The steering wheel must not be

held on full lock for more than 30 seconds

in one minute, as this may overheat the

fluid and cause damage to the oil seals.

1.Check fluid level

See Repair, Power Steering

Fluid Reservoir

.

Check fluid pressure

See Power Steering

System - Test

.

2.Is pressure high?

YES - Renew pump

See Repair, Power

steering Pump

.

If oil seal leaks persist after renewing the pump

See Overhaul, Power Steering Box.

NO -

See Overhaul, Power Steering Box.

Symptom:-

Insufficient power assistance - castor return

action normal.

1.Are tyres correct type and pressure?

NO -

See GENERAL SPECIFICATION DATA,

Information, Wheels and Tyres

.

YES - Continue.

2.Is fluid level correct?

NO - Check fluid level

See Repair, Power

Steering Fluid Reservoir

.

YES - Check system for air locks

See Repair,

Power Steering System - Bleed

.

3.Is pressure correct?

NO - Check fluid pressure

See Power Steering

System - Test

.

If pressure is not correct after bleeding the

system, renew pump

See Repair, Power

Steering Pump

.

YES -

See Overhaul, Power Steering Box.Symptom:-

Steering heavy - stiff, poor castor return action.

1.Are tyres correct type and pressure?

NO -

See INTRODUCTION, Information,

Wheels and Tyres

.

YES - Check universal joints for seizure and

correct alignment

See Repair, Lower Steering

Shaft and Universal Joints

.

Check power steering box adjustments

See

Overhaul, Power Steering Box

.

2.Is the power assistance satisfactory?

NO - See fault symptomInsufficient

assistance, (castor return action normal).

YES - Disconnect drag link from drop arm and

check steering column and box for stiffness

See

Repair, Drag Link and Drag Link Ends

.

3.Is the steering stiff with the drag link

disconnected?

NO - Check steering ball joints for seizure and

axle swivels lubrication and resistance

See

Repair, Drag Link and Drag Link Ends

,See

FRONT AXLE AND FINAL DRIVE, Overhaul,

Front Stub Axle, Constant Velocity Joint and

Swivel Pin Housing

.

YES - Disconnect the lower steering shaft and

check the column and box for stiffness

See

Repair, Lower Steering Shaft and Universal

Joints

.

4.Is the steering column stiff to turn when

disconnected from the box?

NO - Remove and overhaul box

See Overhaul,

Power Steering Box

.

YES - Adjust steering column

See Stiff

Steering Checklist

.