drain bolt LAND ROVER DEFENDER 1996 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 131 of 455

26COOLING SYSTEM

6

REPAIR RADIATOR

Service repair no - 26.40.01

Remove

1.Disconnect radiator bottom hose and drain

cooling system.

See Adjustment, Drain and

refill cooling system

2.Disconnect radiator top hose.

3.Remove viscous fan unit.

See Viscous

coupling and fan

4.Remove fan cowl.See Fan cowl

5.Disconnect oil cooler pipes. Plug all connections

to prevent oil spillage and ingress of dirt.

6.Disconnect top and bottom intercooler hoses.

7.Disconnect bleed hose at radiator.

8.Remove 2 bolts from both sides securing

radiator mounting brackets to bonnet platform.

9.Lift and remove radiator/intercooler assembly

from vehicle.

10.Remove 2 bolts from both sides and detach

radiator top cover from side covers.

11.Lift and remove radiator from intercooler and RH

side frame.

12.Check condition of locating grommets in radiator

top cover and lower mounting bushes. Renew if

necessary.Refit

13.Position radiator between intercooler and RH

side frame.

14.Fit radiator top cover to side covers.

15.Lower radiator/intercooler assembly into

position.

16.Secure radiator mounting brackets to bonnet

platform.

17.Fit radiator bleed hose.

18.Fit top and bottom intercooler hoses.

19.Fit oil cooler pipes.

20.Fit fan cowl

See Fan cowl.

21.Fit viscous fan unit.

See Viscous coupling

and fan

22.Fit radiator top hose.

23.Fit radiator bottom hose and refill cooling

system.

See Adjustment, Drain and refill

cooling system

Page 146 of 455

33CLUTCH

2

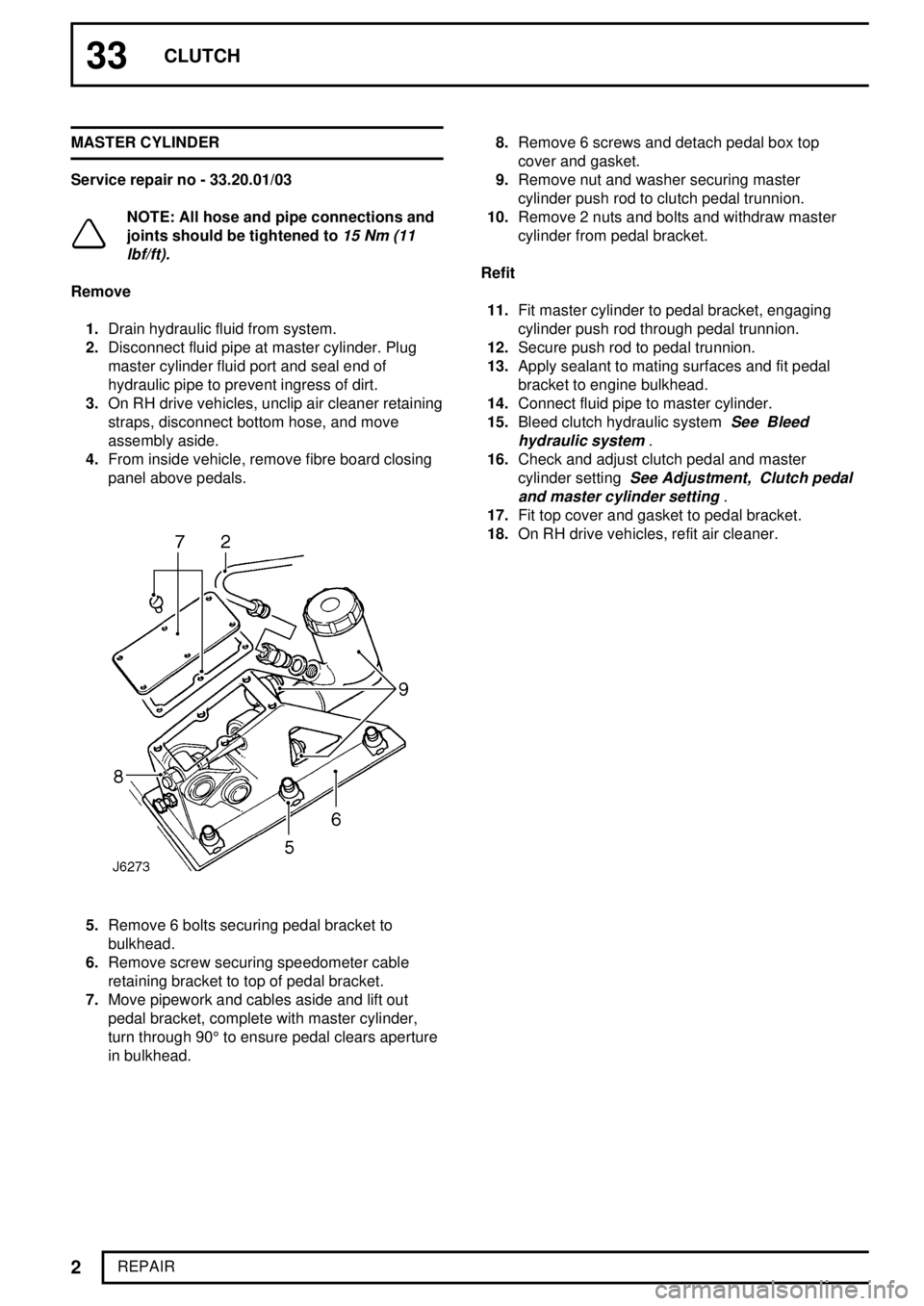

REPAIR MASTER CYLINDER

Service repair no - 33.20.01/03

NOTE: All hose and pipe connections and

joints should be tightened to

15 Nm (11

lbf/ft).

Remove

1.Drain hydraulic fluid from system.

2.Disconnect fluid pipe at master cylinder. Plug

master cylinder fluid port and seal end of

hydraulic pipe to prevent ingress of dirt.

3.On RH drive vehicles, unclip air cleaner retaining

straps, disconnect bottom hose, and move

assembly aside.

4.From inside vehicle, remove fibre board closing

panel above pedals.

5.Remove 6 bolts securing pedal bracket to

bulkhead.

6.Remove screw securing speedometer cable

retaining bracket to top of pedal bracket.

7.Move pipework and cables aside and lift out

pedal bracket, complete with master cylinder,

turn through 90°to ensure pedal clears aperture

in bulkhead.8.Remove 6 screws and detach pedal box top

cover and gasket.

9.Remove nut and washer securing master

cylinder push rod to clutch pedal trunnion.

10.Remove 2 nuts and bolts and withdraw master

cylinder from pedal bracket.

Refit

11.Fit master cylinder to pedal bracket, engaging

cylinder push rod through pedal trunnion.

12.Secure push rod to pedal trunnion.

13.Apply sealant to mating surfaces and fit pedal

bracket to engine bulkhead.

14.Connect fluid pipe to master cylinder.

15.Bleed clutch hydraulic system

See Bleed

hydraulic system

.

16.Check and adjust clutch pedal and master

cylinder setting

See Adjustment, Clutch pedal

and master cylinder setting

.

17.Fit top cover and gasket to pedal bracket.

18.On RH drive vehicles, refit air cleaner.

Page 148 of 455

33CLUTCH

4

REPAIR RELEASE BEARING ASSEMBLY

Service repair no - 33.10.07

Remove

1.Remove gearbox

See MANUAL GEARBOX,

Repair, R380 Gearbox

.

2.Remove clutch slave cylinder

See Slave

cylinder

.

3.Remove release bearing sleeve retainer staple.

4.Withdraw bearing and sleeve.

5.Remove clutch release lever from bearing guide,

complete with sliper pads.

6.If necessary, unscrew 2 bolts and remove

bearing guide from bell housing.

Refit

7.If removed, fit bearing guide to bell housing.

Tighten bolts to

25 Nm (18 lbf/ft).

8.Prior to reassembly, grease pivot post, socket,

slipper pads, pins, and ball end of slave cylinder

push-rod.

9.Fit slipper pads onto release lever pins and

locate lever on pivot post.

10.Smear release bearing sleeve inner diameter

with molybdenum disulphide grease and fit to

bearing guide, locating slipper pads to sleeve

flats.

11.Fit new bearing sleeve retainer staple.

12.Fit clutch slave cylinder

See Slave cylinder.

13.Fit gearbox

See MANUAL GEARBOX, Repair,

R380 Gearbox

.SLAVE CYLINDER

Service repair no - 33.35.01

NOTE: All hose and pipe connections and

joints should be tightened to

15 Nm (11

lbf/ft).

Remove

1.Drain hydraulic fluid from system at slave

cylinder bleed valve.

2.Disconnect fluid pipe.

3.Remove 2 bolts and withdraw slave cylinder and

backing plate.

4.If dust cover is not withdrawn with slave cylinder,

withdraw it from bell housing.

CAUTION: If removing slave cylinder with

gearbox in situ, DO NOT detach push-rod

and clip from clutch release lever in bell

housing.

Refit

5.Coat both sides of backing plate with Hylomar

P232M waterproof jointing compound.

6.Locate backing plate and dust cover in position

on slave cylinder.

7.Fit slave cylinder, engaging push-rod through

centre of dust cover and with bleed screw

uppermost.

8.Reconnect fluid pipe.

9.Replenish and bleed clutch hydraulic system

See Bleed hydraulic system.

10.Check for fluid leaks with pedal depressed and

also with system at rest.

Page 159 of 455

37MANUAL GEARBOX

2

REPAIR

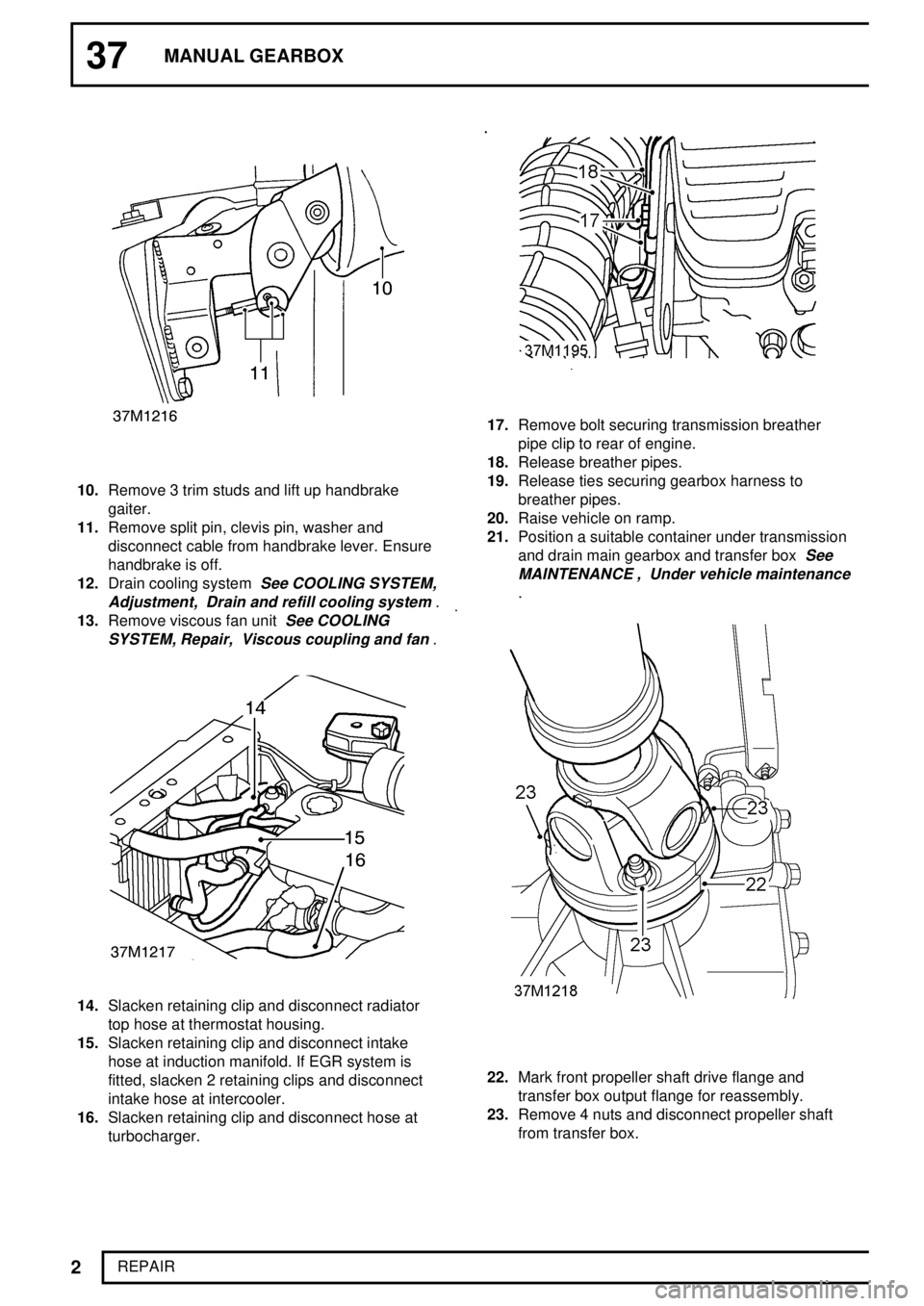

10.Remove 3 trim studs and lift up handbrake

gaiter.

11.Remove split pin, clevis pin, washer and

disconnect cable from handbrake lever. Ensure

handbrake is off.

12.Drain cooling system

See COOLING SYSTEM,

Adjustment, Drain and refill cooling system

.

13.Remove viscous fan unit

See COOLING

SYSTEM, Repair, Viscous coupling and fan

.

14.Slacken retaining clip and disconnect radiator

top hose at thermostat housing.

15.Slacken retaining clip and disconnect intake

hose at induction manifold. If EGR system is

fitted, slacken 2 retaining clips and disconnect

intake hose at intercooler.

16.Slacken retaining clip and disconnect hose at

turbocharger.

17.Remove bolt securing transmission breather

pipe clip to rear of engine.

18.Release breather pipes.

19.Release ties securing gearbox harness to

breather pipes.

20.Raise vehicle on ramp.

21.Position a suitable container under transmission

and drain main gearbox and transfer box

See

MAINTENANCE , Under vehicle maintenance

.

22.Mark front propeller shaft drive flange and

transfer box output flange for reassembly.

23.Remove 4 nuts and disconnect propeller shaft

from transfer box.

Page 163 of 455

37MANUAL GEARBOX

6

REPAIRREV: 05/99 78.Position crossmember and locate over fixing

studs of LH and RH gearbox mounting rubbers.

79.Align crossmember and secure to chassis with 4

nuts and bolts on each side.

NOTE: Fit battery earth strap retaining clip

to LH top bolt.

80.Fit intermediate silencer.

See MANIFOLD AND

EXHAUST SYSTEM, Repair, Intermediate

pipe - 90

orSee MANIFOLD AND EXHAUST

SYSTEM, Repair, Intermediate pipe - 110/130

.

81.Fit front pipe to exhaust manifold

See

MANIFOLD AND EXHAUST SYSTEM, Repair,

Exhaust front pipe

.

82.Fit rear propeller shaft to transmission brake

drum. Tighten nuts to

47 Nm (33 lbf/ft).

83.Remove 3 bolts securing support cradle to

transmission and remove hoist.

84.Reconnect battery earth strap to transfer box

fixing.

85.Connect speedometer cable to transfer box and

secure with retaining clip.

86.Coat both sides of clutch slave clinder backing

plate with Hylomar P232M waterproof sealant.

87.Locate backing plate on slave cylinder.

88.Fit slave cylinder to bell housing, engaging

push-rod through centre of dust cover, and with

bleed screw uppermost. Tighten bolts to

25 Nm

(18 lbf/ft).

89.Fit front propeller shaft to transfer box. Tighten

nuts to

47 Nm (33 lbf/ft).

90.Refill main gearbox and transfer boxSee

MAINTENANCE , Under vehicle maintenance

.

91.Feed transmission brake cable through heel

board and ensure grommet is correctly located.

NOTE: Apply a soap solution to aid fitment

of cable.

92.Lower vehicle on ramp.

93.Fit ties to secure gearbox harness to

transmission breather pipes.

94.Fit breather pipe retaining clip to rear of engine.

95.Reconnect charge air hose at turbocharger.

96.Reconnect intake hose at induction manifold. If

EGR system is fitted, reconnect intake hose at

intercooler.

97.Reconnect radiator top hose at thermostat

housing.

98.Fit viscous fan unit

See COOLING SYSTEM,

Repair, Viscous coupling and fan

.

99.Reconnect battery.100.Refill cooling system

See COOLING SYSTEM,

Adjustment, Drain and refill cooling system

.

101.Connect cable clevis to handbrake lever and fit

handbrake gaiter.

102.Locate insulation pad over gear levers and fit to

tunnel cover.

103.Fit gear lever with gaiter to lower lever spline

and secure with retaining nut.

104.Fit gear lever cover.

105.Fit gear lever and transfer box lever knobs.

106.Fit gearbox cover carpet.

107.Check operation of handbrake and adjust as

necessary

See MAINTENANCE , Under

vehicle maintenance

.

Page 167 of 455

41TRANSFER GEARBOX

2

FAULT DIAGNOSIS OIL LEAKS

Verify that oil leak is from transfer box and not main

gearbox before proceeding with checks.

Prior to road test

1.Check oil level in transfer box is correct.

2.Check tightness of level and drain plugs.

3.Check breather system for blockage. To validate

system pipe must be removed, inspected,

rectified as necessary and refitted.

4.Remove all traces of oil from exterior of transfer

box.

Take vehicle for short road test.

5.Identify source of leaks and rectify as follows.

Front or rear output seal leaking:-

1.Drain oil and remove leaking output flange.

2.Inspect seal track on flange for surface damage.

If damaged renew component.

3.Remove and discard oil seal.

4.Inspect seal locating bore and remove any sharp

edges which may damage new oil seal.

5.Fit new seal.

6.Fit output flange and all other parts.

7.Add oil to correct level into gearbox

See

SECTION 10, Maintenance, Under vehicle

maintenance

.

Cover plate sealant leaking.

1.Drain oil and remove leaking cover plate.

2.Remove all traces of joint sealant from both joint

faces.

3.Degrease all components and apply a thin film of

Hylomar sealant, to both joint faces.

4.Apply thread sealant to bolts which come into

contact with gearbox oil.

5.Refit cover plate.

CAUTION: Care must be taken not to

overtighten fixings.Leak between main and transfer gearboxes.

1.Site vehicle onto a ramp .

2.Select neutral in transfer box and select 4th gear

in main gearbox.

3.Run engine at 2000 rpm with clutch/drive

engaged.

4.Observe joint between main and transfer boxes.

5.If oil leak is found establish if it is gear oil.

6.If so, leak is originating from transfer box.

7.Check two inner (main/transfer) bolts are oil

tight, as these holes are tapped into main

transfer case.

8.Remove transfer box to inspect mainshaft collar

seal track condition, and front face of transfer

case for porosity

See Repair, Transfer

gearbox

.

9.If these areas require servicing, transfer gearbox

input seal must also be renewed.

CAUTION: Avoid damaging new seal lip

and ensure seal is fitted flush with

machined face. Also ensure new seal is

not damaged when refitting transfer gearbox.

10.If red ATF type oil is seen leaking during

workshop test, investigate main gearbox for

cause of leak.

Detent plug or electrical switch leaks.

1.Detent plugs and electrical switches do not

usually leak. It must be noted that they fit into

open tapped holes in transfer case and therefore

should be considered when looking for source of

leak.

Page 173 of 455

TRANSFER GEARBOX

1

SPECIFICATIONS, TORQUE REV: 05/99 TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Transfer gearbox

Pinch bolt - operating arm to crank arm 9......................................................

End cover gear change housing 9.................................................................

Bottom cover to transfer case 25....................................................................

Front output housing to transfer case 25........................................................

Cross shaft housing to front output housing 25...............................................

Gear change housing 25.................................................................................

Pivot shaft to link arm 25.................................................................................

Connecting rod to adjustable clevis 25...........................................................

Anti-rotation plate intermediate shaft 25.........................................................

Front output housing cover 25........................................................................

Pivot bracket to extension housing 25............................................................

Finger housing to front output housing 25......................................................

Bearing housing to transfer case 25...............................................................

Brake drum to coupling flange 25...................................................................

Bearing housing cover to transfer gearbox 45................................................

Rear output speedometer housing to transfer gearbox 45..............................

Selector finger to cross shaft high/low 25.......................................................

Selector fork, high/low to shaft 25...................................................................

Transmission brake to speedometer housing 72............................................

Gate plate to grommet plate 9.......................................................................

Gearbox to transfer case 45...........................................................................

Oil drain plug 30..............................................................................................

Oil filler/level plug 30.......................................................................................

Differential case (front to rear) 60...................................................................

Output flanges 162...........................................................................................

Differential case rear stake nut 72..................................................................

Transfer breather 15.......................................................................................

Transfer box front drive flange to drive shaft 45..............................................

Transfer box rear drive flange to drive shaft 45..............................................

Transfer gearbox mounting brackets to chassis 30........................................

Mounting brackets to transfer gearbox 55......................................................

Mounting rubbers to mounting brackets 21.....................................................

Page 183 of 455

REAR AXLE AND FINAL DRIVE

1

REPAIR REAR AXLE

Service repair no - 51.25.01

Remove

WARNING: Remove and refit of axle

requires a further two persons to steady

the axle when lowering or repositioning

axle.

1.Drain brake system.

2.Support chassis rear.

3.Remove road wheels.

4.Support axle weight with hydraulic jack.

5.Disconnect shock absorbers.

6.Disconnect flexible brake hose at RH chassis

side member and breather hose at banjo

connection on axle casing.

7.Disconnect lower links at axle.8.Mark differential and propeller shaft flanges with

identification marks for assembly.

9.Remove 4 nuts and bolts, lower propeller shaft

and tie to one side.

10.Disconnect pivot bracket ball joint at axle

bracket.

11.Release bolts and remove coil spring retaining

plates.

12.Lower axle and remove road springs.

13.If applicable, remove anti-roll bar links at axle

See REAR SUSPENSION, Repair, anti-roll

bar

.

14.Remove axle assembly.

Page 189 of 455

REAR AXLE AND FINAL DRIVE

7

REPAIR DIFFERENTIAL ASSEMBLY - 90

Service repair no - 51.15.01

Remove

1.Using suitable container, drain axle oil.

2.Mark differential and propeller shaft flanges to

facilitate reassembly.

3.Remove 4 bolts and disconnect propeller shaft

from differential. Tie aside.

4.Remove 5 hub drive member bolts and withdraw

axle half shafts sufficiently to disengage from

differential unit.

5.Remove 10 nuts securing differential to axle

case.

6.Withdraw differential unit.

NOTE: The differential unit can only be

serviced as a complete assembly with

matching drive pinion. For advice ring

Land Rover Service Department.Refit

7.Ensure mating faces are clean and apply a bead

of RTV sealant to axle case.

8.Support differential unit and position on axle

casing.

9.Secure with self locking nuts and tighten to

40

Nm (30lbf/ft).

10.Align marks on flanges and secure propeller

shaft to differential. Tighten bolts to

48 Nm (35

lbf/ft).

11.Refit half shafts, using new drive member

gaskets. Tighten bolts to

65 Nm (48 lbf/ft).

12.Refill axle oil with approved lubricantSee

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended lubricants and

fluids

.

Page 213 of 455

54FRONT AXLE AND FINAL DRIVE

2

OVERHAUL FRONT STUB AXLE, CONSTANT VELOCITY JOINT

AND SWIVEL PIN HOUSING

Service repair no - 60.15.43.

Remove stub axle, axle shaft and constant

velocity joint.

1.Remove front hub assembly

See Repair, Front

hub assembly

.

2.Drain swivel pin housing and refit plug.

NOTE: On later vehicles the swivel pin

housing is filled with grease for life, the

level and drain plugs being deleted.

3.Remove 6 bolts retaining stub axle to swivel

housing.

4.Remove mud shield.

5.Remove stub axle and joint washer.

6.Wthdraw axle shaft and constant velocity joint

from axle casing.

Remove constant velocity joint from axle shaft

7.Hold axle shaft firmly in a soft jawed vice.

8.Using a soft mallet drive constant velocity joint

from shaft.

9.Remove circlip and collar from axle shaft.

Constant velocity joint

10.Mark positions of constant velocity joint, inner

and outer race and cage for reassembly.

11.Swivel cage and inner race to remove balls.