drain bolt LAND ROVER DEFENDER 1996 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 216 of 455

FRONT AXLE AND FINAL DRIVE

5

OVERHAUL 38.Place retaining plate, joint washer and oil seal

over axle flange ready for assembly.

39.Fit swivel bearing housing to axle flange with 7

bolts. Tighten to

73 Nm (54 lbf/ft).

40.Grease and fit upper and lower swivel pin taper

roller bearings.

41.Position swivel pin housing over swivel bearing

housing.

42.Coat joint washer both sides with sealing

compound and position on lower swivel pin.

43.Loosely fit brake shield bracket plus lower swivel

pin with lug outboard to swivel pin housing.

44.Loosely fit top swivel pin plus existing shims and

brake hose bracket to swivel pin housing.

45.Apply Loctite 270 or equivalent to lower swivel

pin bolts.

78 Nm (58 lbf/ft),bend over lock tabs.

46.Tighten top swivel pin bolts to

78 Nm (58 lbf/ft).

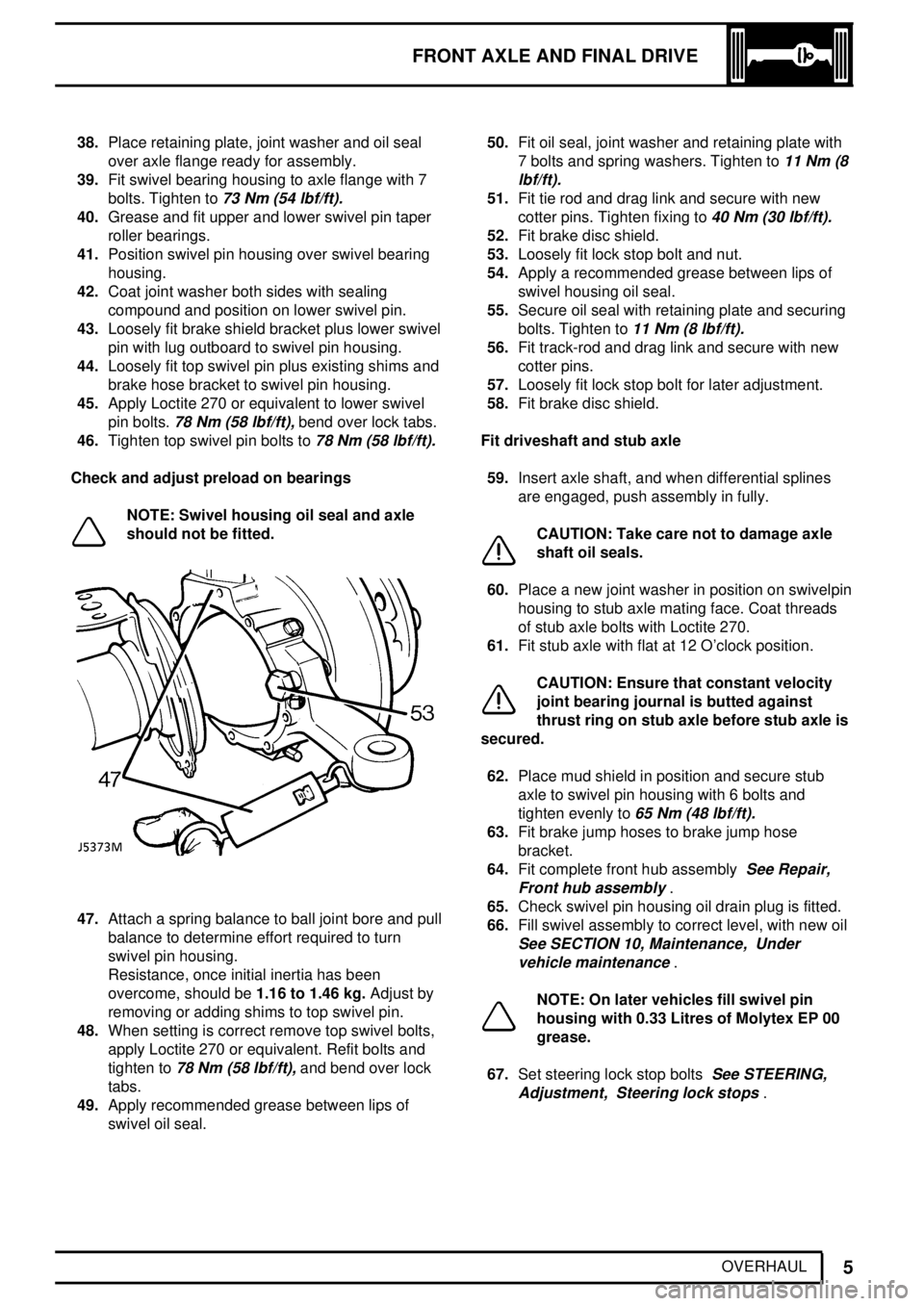

Check and adjust preload on bearings

NOTE: Swivel housing oil seal and axle

should not be fitted.

47.Attach a spring balance to ball joint bore and pull

balance to determine effort required to turn

swivel pin housing.

Resistance, once initial inertia has been

overcome, should be1.16 to 1.46 kg.Adjust by

removing or adding shims to top swivel pin.

48.When setting is correct remove top swivel bolts,

apply Loctite 270 or equivalent. Refit bolts and

tighten to

78 Nm (58 lbf/ft),and bend over lock

tabs.

49.Apply recommended grease between lips of

swivel oil seal.50.Fit oil seal, joint washer and retaining plate with

7 bolts and spring washers. Tighten to

11 Nm (8

lbf/ft).

51.Fit tie rod and drag link and secure with new

cotter pins. Tighten fixing to

40 Nm (30 lbf/ft).

52.Fit brake disc shield.

53.Loosely fit lock stop bolt and nut.

54.Apply a recommended grease between lips of

swivel housing oil seal.

55.Secure oil seal with retaining plate and securing

bolts. Tighten to

11 Nm (8 lbf/ft).

56.Fit track-rod and drag link and secure with new

cotter pins.

57.Loosely fit lock stop bolt for later adjustment.

58.Fit brake disc shield.

Fit driveshaft and stub axle

59.Insert axle shaft, and when differential splines

are engaged, push assembly in fully.

CAUTION: Take care not to damage axle

shaft oil seals.

60.Place a new joint washer in position on swivelpin

housing to stub axle mating face. Coat threads

of stub axle bolts with Loctite 270.

61.Fit stub axle with flat at 12 O'clock position.

CAUTION: Ensure that constant velocity

joint bearing journal is butted against

thrust ring on stub axle before stub axle is

secured.

62.Place mud shield in position and secure stub

axle to swivel pin housing with 6 bolts and

tighten evenly to

65 Nm (48 lbf/ft).

63.Fit brake jump hoses to brake jump hose

bracket.

64.Fit complete front hub assembly

See Repair,

Front hub assembly

.

65.Check swivel pin housing oil drain plug is fitted.

66.Fill swivel assembly to correct level, with new oil

See SECTION 10, Maintenance, Under

vehicle maintenance

.

NOTE: On later vehicles fill swivel pin

housing with 0.33 Litres of Molytex EP 00

grease.

67.Set steering lock stop bolts

See STEERING,

Adjustment, Steering lock stops

.

Page 241 of 455

57STEERING

4

REPAIR POWER STEERING BOX

Service repair no - 57.10.01

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

remove and refit procedures are required, it may

be necessary to remove the undertray

See

CHASSIS AND BODY, Repair, Front undertray

.

General precautions

·Whenever any part of system, is removed or

disconnected, utmost cleanliness must be

observed.

·Disconnected ports and hoses must be

plugged to prevent ingress of dirt. If metal

sediment is found in system, establish cause,

rectify and flush system.

·Do not start engine until reservoir is full as

pump will be damaged.

·Metric pipe fittings are used with 'O' ring pipe

ends on fittings to steering box.

·Follow normal 'O' ring replacement procedure

whenever pipes are disconnected.

·Ensure compatible metric components when

fitting replacement pipes.

CAUTION: After refitting steering linkage

parts follow correct procedure to ensure

that road wheels, steering box and

steering wheel are correctly positioned relative to

each other when in straight ahead condition.

NOTE: When drag link is disconnected

from steering box, travel available at

steering wheel to each full lock is not

equal.

Remove

1.Site vehicle on level surface.

2.Apply park brake, chock rear wheels, raise

vehicle and locate axle stands. Alternatively,

raise vehicle on a hoist.

3.Remove road wheel.

4.Remove panhard rod

See FRONT

SUSPENSION, Repair, Panhard rod

.

5.Disconnect steering damper from drag link.

6.Disconnect drag link from drop arm, see J6305

on opposite page, using a suitable extractor.

7.Slacken, but do not remove nut securing tie bar

to mounting arm.8.Remove 2 bolts securing tie bar to steering box

and move aside.

9.Remove filler cap from power steering fluid

reservoir.

10.Position suitable container under steering box.

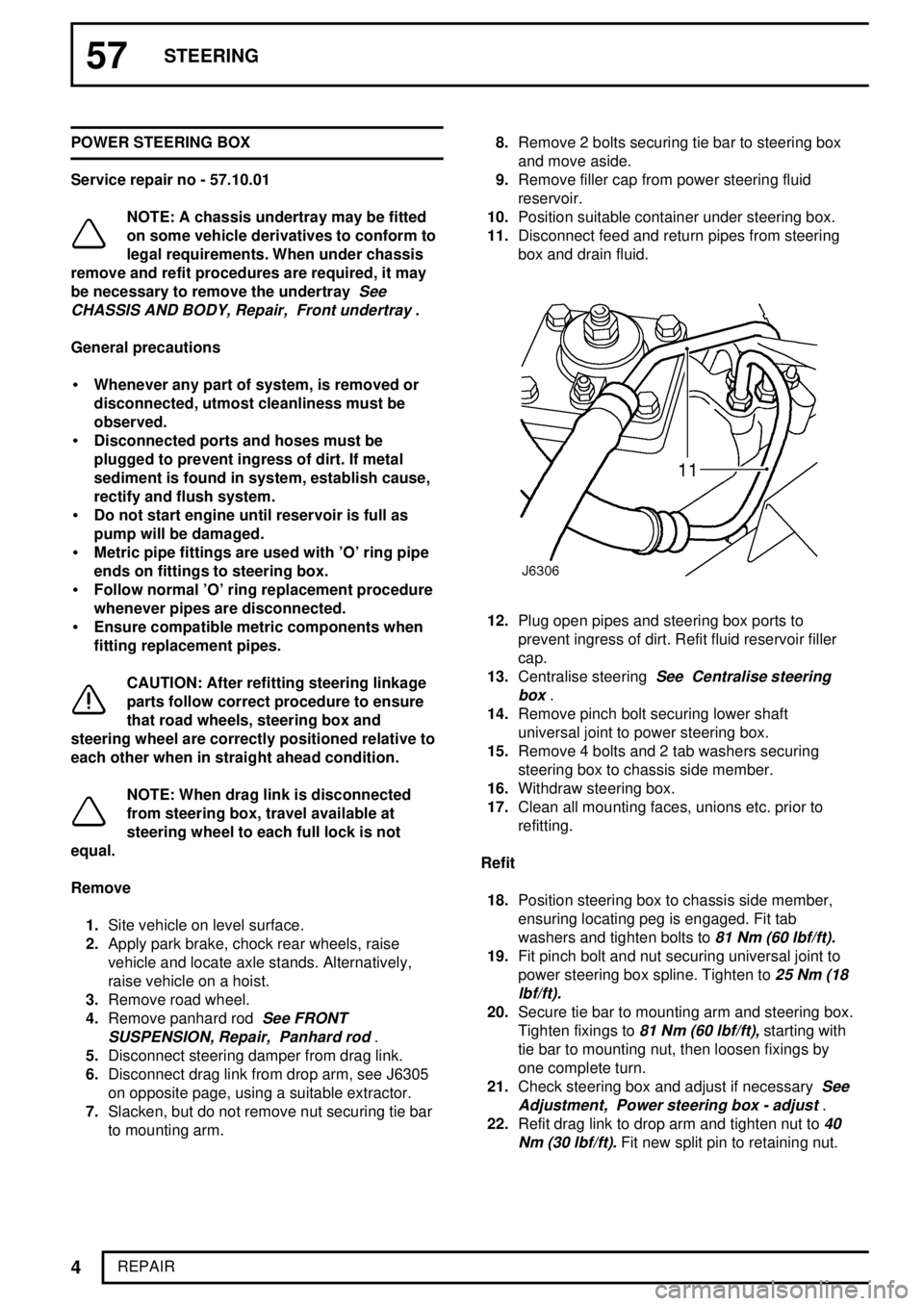

11.Disconnect feed and return pipes from steering

box and drain fluid.

12.Plug open pipes and steering box ports to

prevent ingress of dirt. Refit fluid reservoir filler

cap.

13.Centralise steering

See Centralise steering

box

.

14.Remove pinch bolt securing lower shaft

universal joint to power steering box.

15.Remove 4 bolts and 2 tab washers securing

steering box to chassis side member.

16.Withdraw steering box.

17.Clean all mounting faces, unions etc. prior to

refitting.

Refit

18.Position steering box to chassis side member,

ensuring locating peg is engaged. Fit tab

washers and tighten bolts to

81 Nm (60 lbf/ft).

19.Fit pinch bolt and nut securing universal joint to

power steering box spline. Tighten to

25 Nm (18

lbf/ft).

20.Secure tie bar to mounting arm and steering box.

Tighten fixings to

81 Nm (60 lbf/ft),starting with

tie bar to mounting nut, then loosen fixings by

one complete turn.

21.Check steering box and adjust if necessary

See

Adjustment, Power steering box - adjust

.

22.Refit drag link to drop arm and tighten nut to

40

Nm (30 lbf/ft).

Fit new split pin to retaining nut.

Page 243 of 455

57STEERING

6

REPAIR POWER STEERING SYSTEM - BLEED

Service repair no - 57.15.02

1.Check that fluid level is at maximum level

See

MAINTENANCE , Under bonnet maintenance.

2.Run engine to normal operating temperature.

3.Recheck reservoir fluid level, top up if necessary

NOTE: During operations 4 to 6, maintain

maximum fluid level in reservoir. Do not

increase engine speed or move steering

wheel.

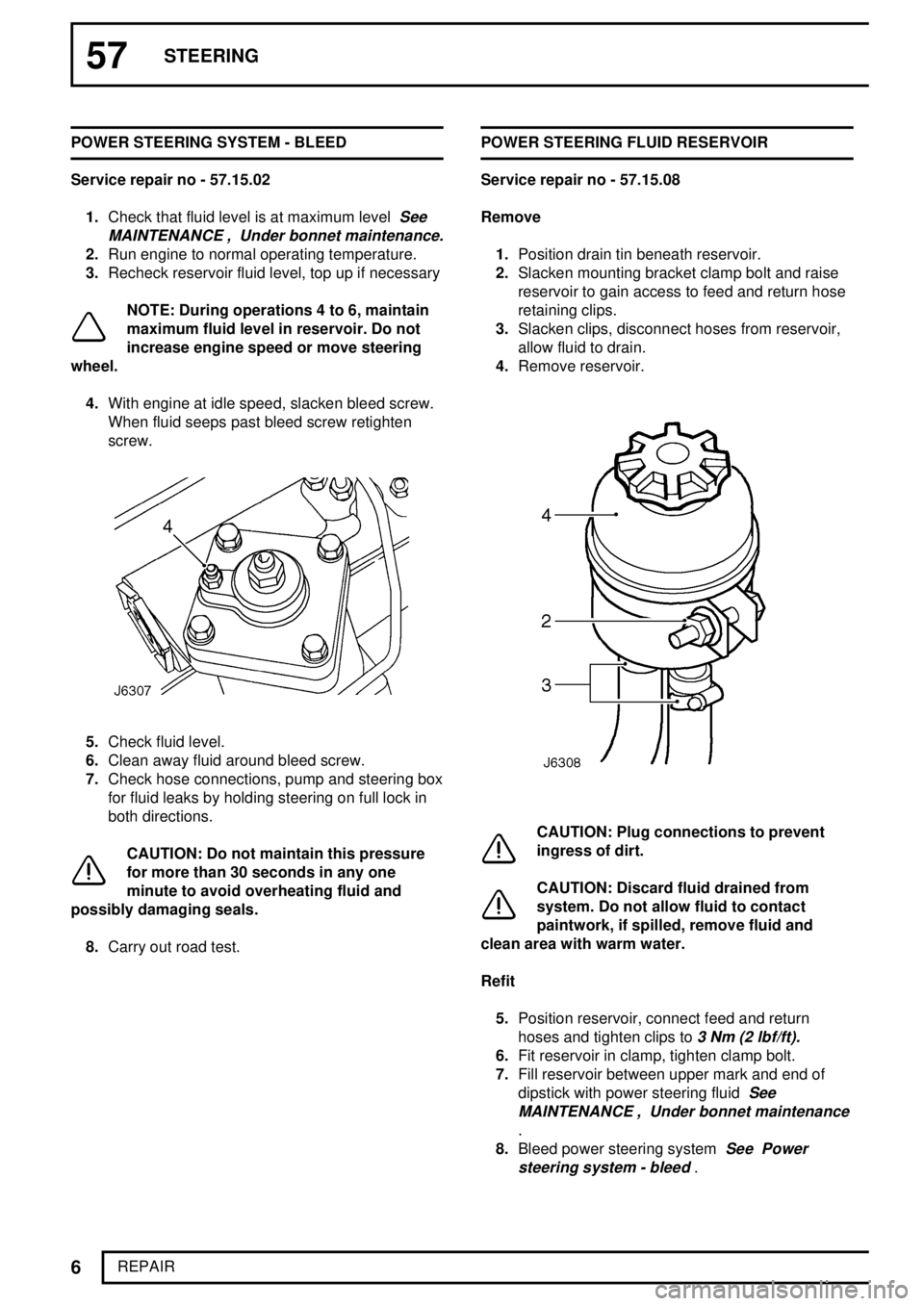

4.With engine at idle speed, slacken bleed screw.

When fluid seeps past bleed screw retighten

screw.

5.Check fluid level.

6.Clean away fluid around bleed screw.

7.Check hose connections, pump and steering box

for fluid leaks by holding steering on full lock in

both directions.

CAUTION: Do not maintain this pressure

for more than 30 seconds in any one

minute to avoid overheating fluid and

possibly damaging seals.

8.Carry out road test.POWER STEERING FLUID RESERVOIR

Service repair no - 57.15.08

Remove

1.Position drain tin beneath reservoir.

2.Slacken mounting bracket clamp bolt and raise

reservoir to gain access to feed and return hose

retaining clips.

3.Slacken clips, disconnect hoses from reservoir,

allow fluid to drain.

4.Remove reservoir.

CAUTION: Plug connections to prevent

ingress of dirt.

CAUTION: Discard fluid drained from

system. Do not allow fluid to contact

paintwork, if spilled, remove fluid and

clean area with warm water.

Refit

5.Position reservoir, connect feed and return

hoses and tighten clips to

3 Nm (2 lbf/ft).

6.Fit reservoir in clamp, tighten clamp bolt.

7.Fill reservoir between upper mark and end of

dipstick with power steering fluid

See

MAINTENANCE , Under bonnet maintenance

.

8.Bleed power steering system

See Power

steering system - bleed

.

Page 244 of 455

STEERING

7

REPAIR POWER STEERING PUMP

Service repair no - 57.20.14

Remove

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

remove and refit procedures are required, it may

be necessary to remove the undertray

See

CHASSIS AND BODY, Repair, Front undertray

.

1.Disconnect battery.

2.Remove viscous fan unit

See COOLING

SYSTEM, Repair, Viscous coupling and fan

.

3.Restrain steering pump pulley, slacken but do

not remove 3 bolts securing pulley.

4.Remove drive belt

See ELECTRICAL, Repair,

Auxiliary drive belt

.

5.Remove bolts and remove pulley.

6.Position suitable container beneath steering

pump.

7.Slacken retaining clip and disconnect return

hose from steering pump.

8.Disconnect high pressure pipe from steering

pump.

9.Allow steering fluid to drain into container.

CAUTION: Plug all connections to prevent

ingress of dirt.

10.Remove 4 bolts securing steering pump bracket

to engine auxiliary mounting bracket.

11.Remove pump and bracket assembly.

12.Remove 3 bolts and detach mounting bracket

from pump.

Refit

13.Fit mounting bracket to replacement steering

pump. Tighten bolts to

9 Nm (7 lbf/ft).

14.Fit pump and bracket to auxiliary mounting

bracket. Tighten bolts to

35 Nm (26 lbf/ft).

15.Connect high pressure feed pipe to steering

pump and tighten to

20 Nm (15 lbf/ft).

16.Connect return hose to steering pump. Tighten

retaining clip to

3 Nm (2 lbf/ft).

17.Position pulley to steering pump, coat threads of

bolts with Loctite 242; fit but do not fully tighten

bolts.

18.Fit drive belt

See ELECTRICAL, Repair,

Auxiliary drive belt

.

19.Restrain steering pump pulley, tighten bolts to

10

Nm (7lbf/ft).

20.Fit viscous fan unitSee COOLING SYSTEM,

Repair, Viscous coupling and fan

.

21.Bleed power steering system

See Power

steering system - bleed

.

POWER STEERING PUMP DRIVE BELT

Service repair no - 57.20.02

NOTE: For details of drive belt remove and

refit

See ELECTRICAL, Repair, Auxiliary

drive belt

.

Page 254 of 455

STEERING

1

OVERHAUL POWER STEERING BOX - ADWEST

Service repair no - 57.10.07

Overhaul

NOTE: Overhaul of steering box should

not be carried out during the warranty

period.

WARNING: Wear safety glasses while

removing and refitting circlips and

retaining ring.

CAUTION: Absolute cleanliness is

essential when overhauling power steering

box.

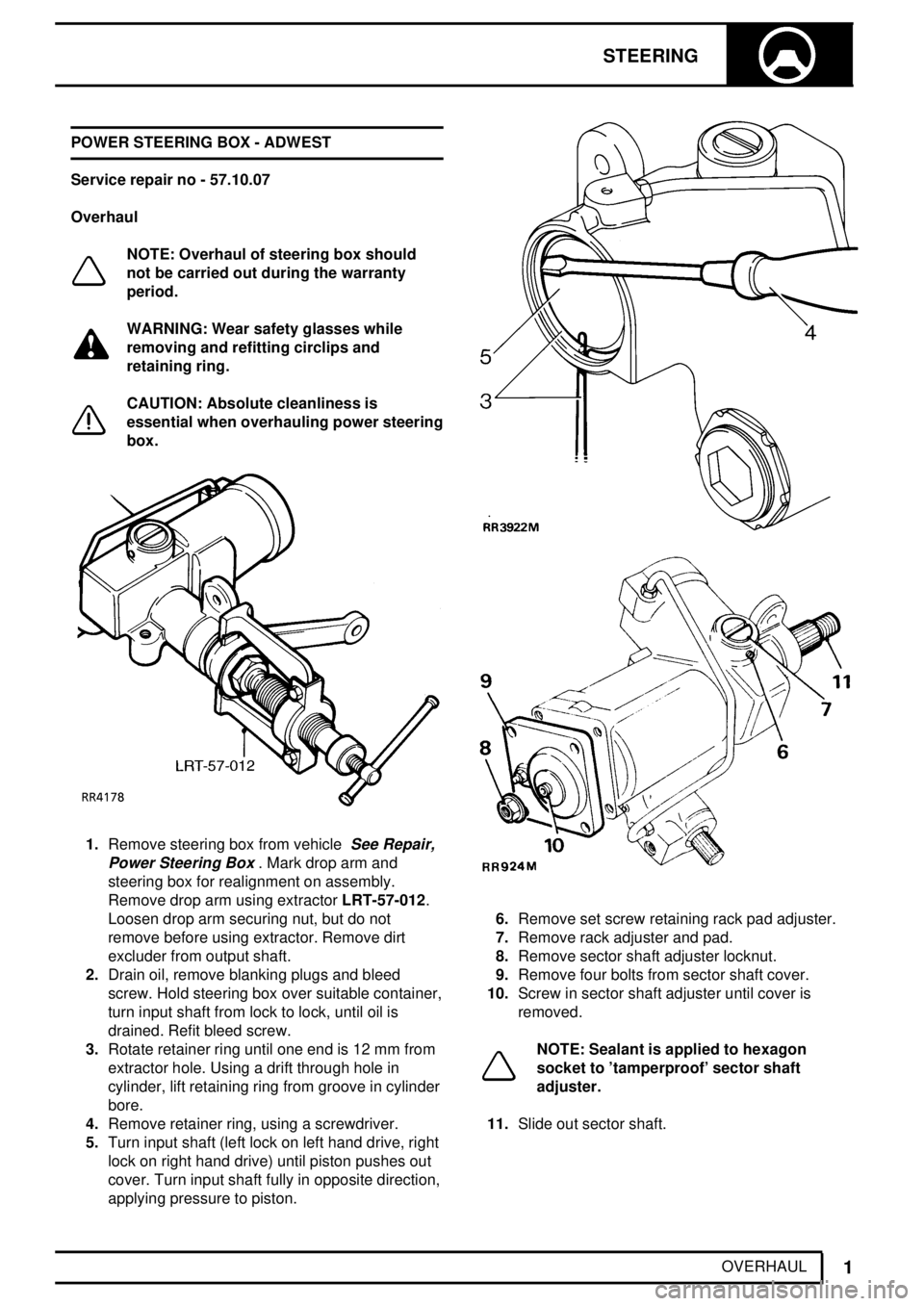

1.Remove steering box from vehicleSee Repair,

Power Steering Box

. Mark drop arm and

steering box for realignment on assembly.

Remove drop arm using extractorLRT-57-012.

Loosen drop arm securing nut, but do not

remove before using extractor. Remove dirt

excluder from output shaft.

2.Drain oil, remove blanking plugs and bleed

screw. Hold steering box over suitable container,

turn input shaft from lock to lock, until oil is

drained. Refit bleed screw.

3.Rotate retainer ring until one end is 12 mm from

extractor hole. Using a drift through hole in

cylinder, lift retaining ring from groove in cylinder

bore.

4.Remove retainer ring, using a screwdriver.

5.Turn input shaft (left lock on left hand drive, right

lock on right hand drive) until piston pushes out

cover. Turn input shaft fully in opposite direction,

applying pressure to piston.

6.Remove set screw retaining rack pad adjuster.

7.Remove rack adjuster and pad.

8.Remove sector shaft adjuster locknut.

9.Remove four bolts from sector shaft cover.

10.Screw in sector shaft adjuster until cover is

removed.

NOTE: Sealant is applied to hexagon

socket to 'tamperproof' sector shaft

adjuster.

11.Slide out sector shaft.

Page 360 of 455

CHASSIS AND BODY

39

REPAIR ACCESS PANEL - FRONT UNDERTRAY

Service repair no - 76.11.85 - Access panel

Service repair no - 76.11.83 - Acoustic pad

The access panel is provided in the front undertray to

enable fitment of the wading plug into the engine

timing cover.

Remove

1.Raise vehicle on ramp.

2.Remove 5 bolts securing access panel to front

undertray.

3.Remove access panel.

4.If necessary, remove 5 fasteners and release

acoustic pad from access panel.

Refit

5.If applicable, fit acoustic pad to access panel.

6.Fit access panel to front undertray, Tighten

fixings to

14 Nm (10 lbf/ft).

7.Lower ramp.ACCESS PANEL - REAR UNDERTRAY

Service repair no - 76.11.84

The access panel is provided in the rear undertray to

enable fitment of the wading plug or timing tool

LRT-12-044in the flywheel housing, and access to

the engine oil sump drain plug.

Remove

1.Raise vehicle on ramp.

2.Rotate access panel anti-clockwise to release

locking flanges.

3.Remove access panel from undertray.

Refit

4.Locate access panel flanges in undertray

apertures.

5.Rotate panel clockwise to secure in undertray.

6.Lower ramp.

Page 364 of 455

HEATING AND VENTILATION

1

REPAIR HEATER UNIT

Service repair no - 80.20.01

Remove

1.Remove bonnet and disconnect battery.

2.Remove radiator bottom hose at radiator union

and drain cooling system

See COOLING

SYSTEM, Repair, Drain and refill cooling

system

.

3.Slacken clips and remove heater hoses at

heater box unions.

4.Remove outer cable securing clips.

5.Slacken trunnions and remove control cables

from heater vent flap levers.

6.Remove heater wiring harness securing loop.

7.Disconnect harness multi-plug.

8.Remove interior bulkhead trim.

9.Remove lower nuts and bolts securing the

heater unit to the bulkhead.

10.Slacken heater unit upper retaining bolts.

11.Manoeuvre heater unit, complete with blower

motor, clear of air inlet duct and remove from

engine compartment.

12.If existing heater unit is to be refitted, remove

sealing rubber.

For heater matrix removal

See Heater matrix.

For blower motor removal

See Blower motor.

Refit

13.Smear a new heater unit sealing rubber with a

suitable impact adhesive and fit to heater.

14.Manoevre heater unit into position in engine

compartment, fit blower motor to air inlet duct

and locate upper fixing bolts.

15.Loosely fit heater unit lower fixing bolts.

16.Fully tighten upper fixing bolts.

17.Fully tighten lower fixings and refit interior

bulkhead trim.

18.Secure wiring harness and reconnect multi-plug.

19.Fit control cables to vent flap trunnions and

secure with outer cable clips.

20.Connect heater hoses.

21.Fit radiator bottom hose and refill cooling system

See COOLING SYSTEM, Repair, Drain and

refill cooling system

.

22.Fit bonnet and reconnect battery.