drain bolt LAND ROVER DEFENDER 1996 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 106 of 455

19FUEL SYSTEM

4

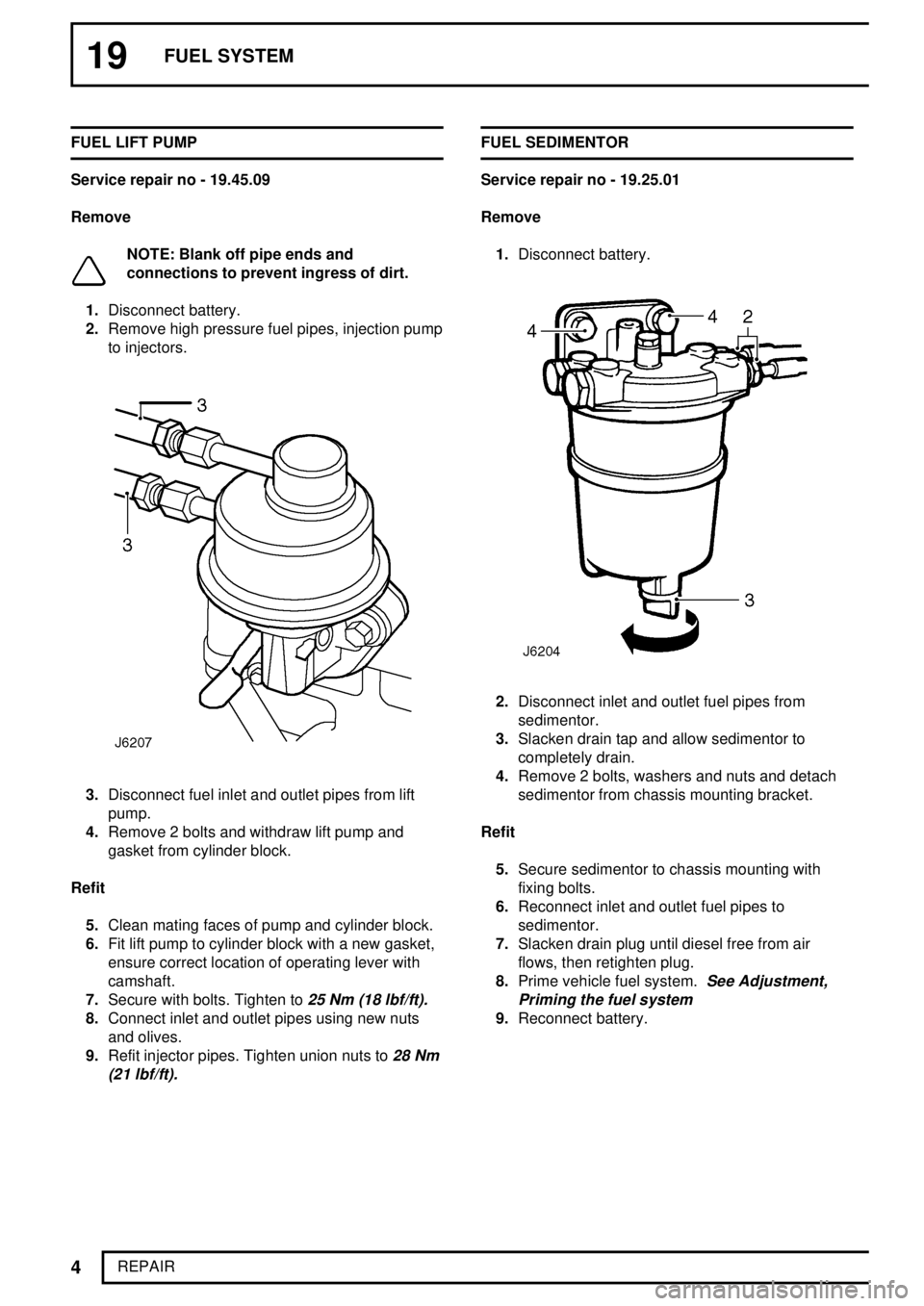

REPAIR FUEL LIFT PUMP

Service repair no - 19.45.09

Remove

NOTE: Blank off pipe ends and

connections to prevent ingress of dirt.

1.Disconnect battery.

2.Remove high pressure fuel pipes, injection pump

to injectors.

3.Disconnect fuel inlet and outlet pipes from lift

pump.

4.Remove 2 bolts and withdraw lift pump and

gasket from cylinder block.

Refit

5.Clean mating faces of pump and cylinder block.

6.Fit lift pump to cylinder block with a new gasket,

ensure correct location of operating lever with

camshaft.

7.Secure with bolts. Tighten to

25 Nm (18 lbf/ft).

8.Connect inlet and outlet pipes using new nuts

and olives.

9.Refit injector pipes. Tighten union nuts to

28 Nm

(21 lbf/ft).

FUEL SEDIMENTOR

Service repair no - 19.25.01

Remove

1.Disconnect battery.

2.Disconnect inlet and outlet fuel pipes from

sedimentor.

3.Slacken drain tap and allow sedimentor to

completely drain.

4.Remove 2 bolts, washers and nuts and detach

sedimentor from chassis mounting bracket.

Refit

5.Secure sedimentor to chassis mounting with

fixing bolts.

6.Reconnect inlet and outlet fuel pipes to

sedimentor.

7.Slacken drain plug until diesel free from air

flows, then retighten plug.

8.Prime vehicle fuel system.

See Adjustment,

Priming the fuel system

9.Reconnect battery.

Page 107 of 455

FUEL SYSTEM

5

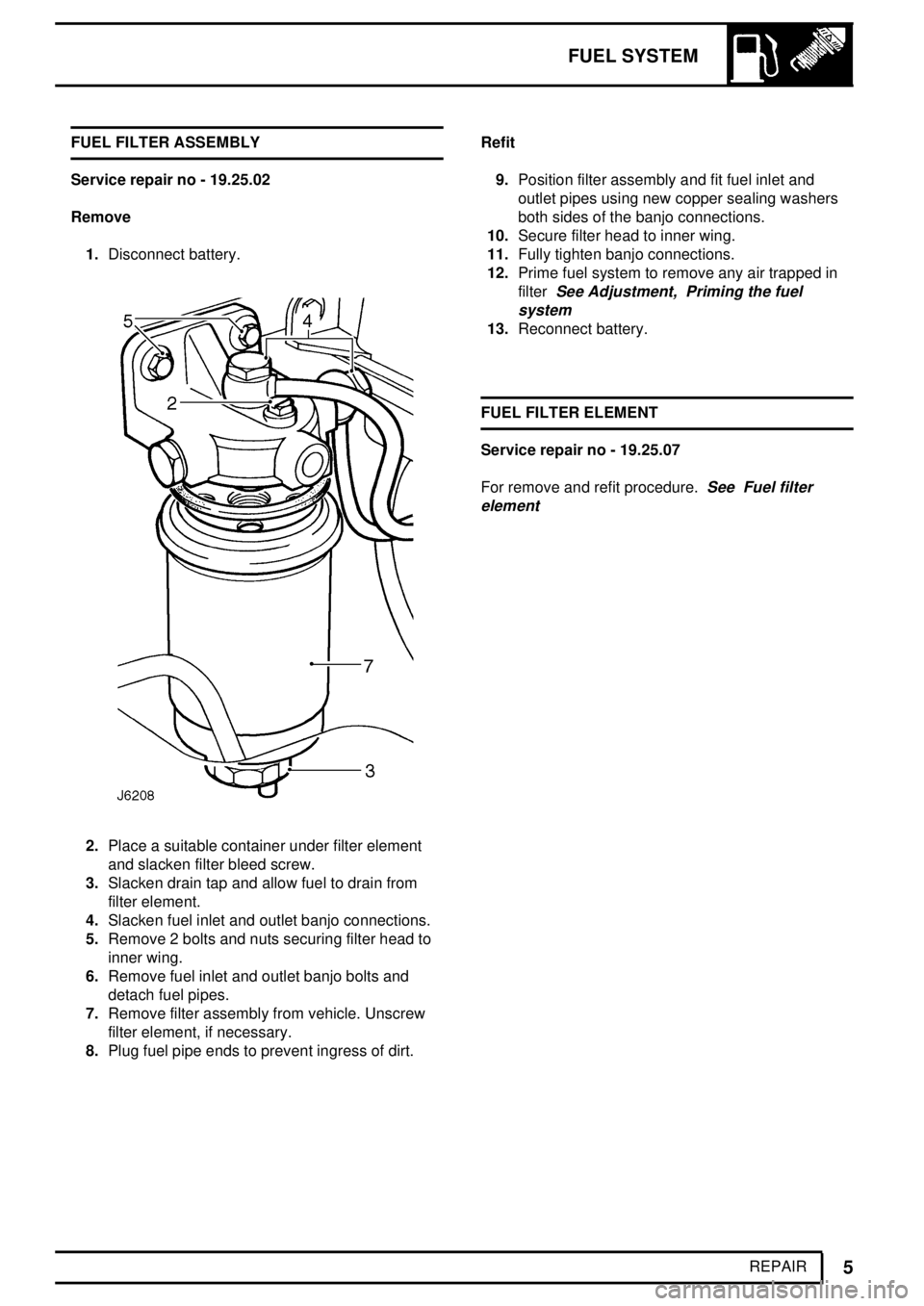

REPAIR FUEL FILTER ASSEMBLY

Service repair no - 19.25.02

Remove

1.Disconnect battery.

2.Place a suitable container under filter element

and slacken filter bleed screw.

3.Slacken drain tap and allow fuel to drain from

filter element.

4.Slacken fuel inlet and outlet banjo connections.

5.Remove 2 bolts and nuts securing filter head to

inner wing.

6.Remove fuel inlet and outlet banjo bolts and

detach fuel pipes.

7.Remove filter assembly from vehicle. Unscrew

filter element, if necessary.

8.Plug fuel pipe ends to prevent ingress of dirt.Refit

9.Position filter assembly and fit fuel inlet and

outlet pipes using new copper sealing washers

both sides of the banjo connections.

10.Secure filter head to inner wing.

11.Fully tighten banjo connections.

12.Prime fuel system to remove any air trapped in

filter

See Adjustment, Priming the fuel

system

13.Reconnect battery.

FUEL FILTER ELEMENT

Service repair no - 19.25.07

For remove and refit procedure.

See Fuel filter

element

Page 108 of 455

19FUEL SYSTEM

6

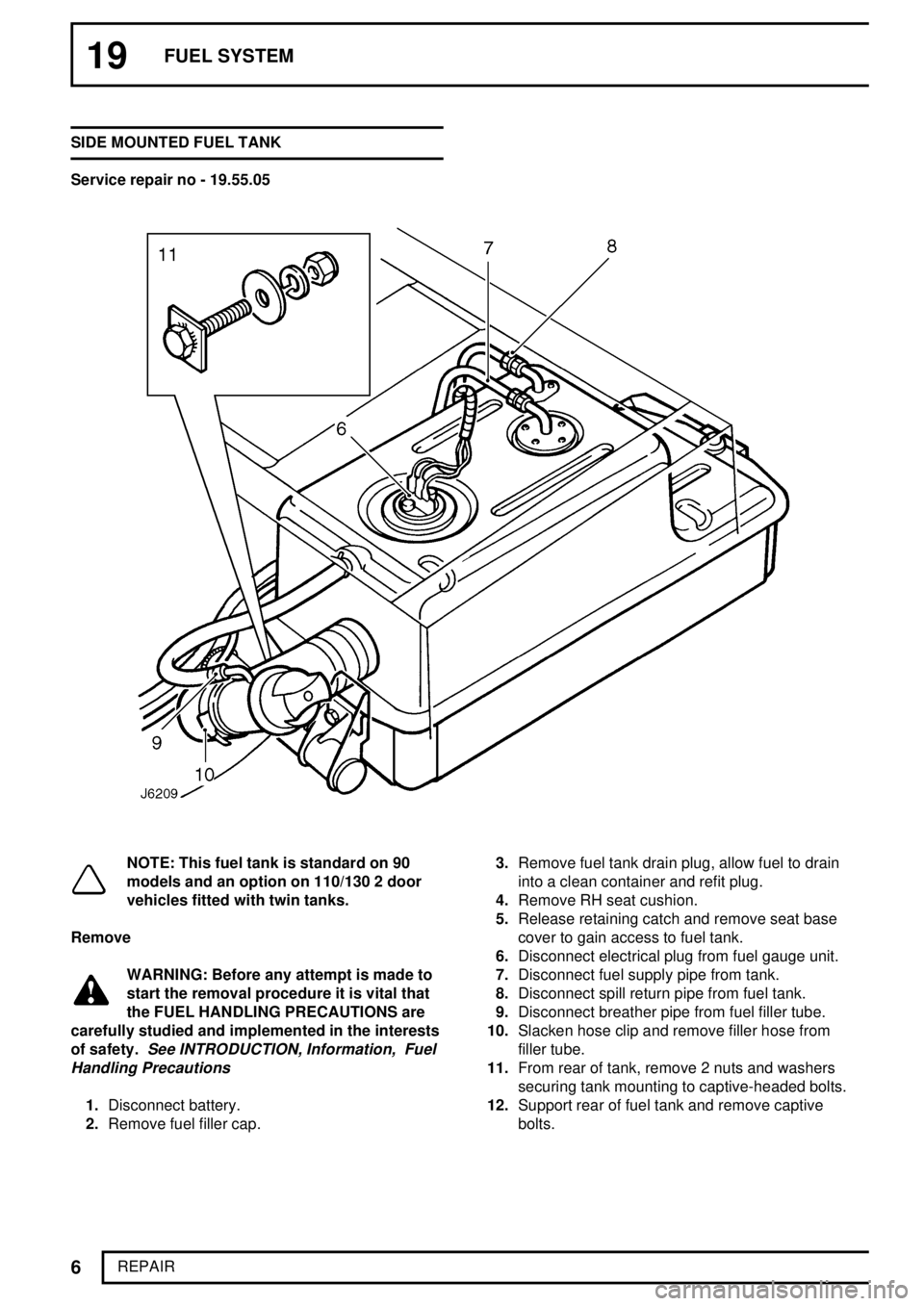

REPAIR SIDE MOUNTED FUEL TANK

Service repair no - 19.55.05

NOTE: This fuel tank is standard on 90

models and an option on 110/130 2 door

vehicles fitted with twin tanks.

Remove

WARNING: Before any attempt is made to

start the removal procedure it is vital that

the FUEL HANDLING PRECAUTIONS are

carefully studied and implemented in the interests

of safety.

See INTRODUCTION, Information, Fuel

Handling Precautions

1.Disconnect battery.

2.Remove fuel filler cap.3.Remove fuel tank drain plug, allow fuel to drain

into a clean container and refit plug.

4.Remove RH seat cushion.

5.Release retaining catch and remove seat base

cover to gain access to fuel tank.

6.Disconnect electrical plug from fuel gauge unit.

7.Disconnect fuel supply pipe from tank.

8.Disconnect spill return pipe from fuel tank.

9.Disconnect breather pipe from fuel filler tube.

10.Slacken hose clip and remove filler hose from

filler tube.

11.From rear of tank, remove 2 nuts and washers

securing tank mounting to captive-headed bolts.

12.Support rear of fuel tank and remove captive

bolts.

Page 109 of 455

FUEL SYSTEM

7

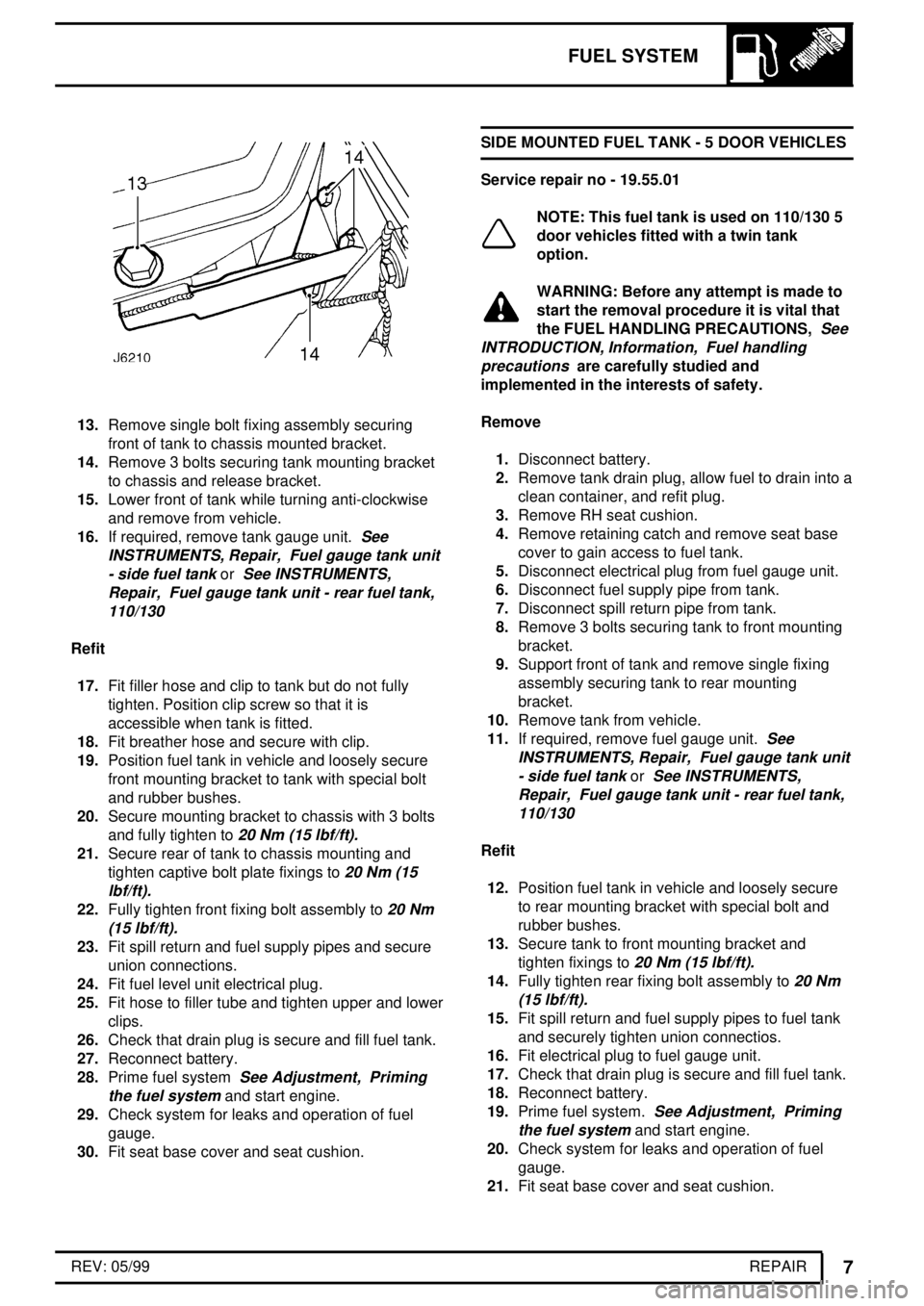

REPAIR REV: 05/99

13.Remove single bolt fixing assembly securing

front of tank to chassis mounted bracket.

14.Remove 3 bolts securing tank mounting bracket

to chassis and release bracket.

15.Lower front of tank while turning anti-clockwise

and remove from vehicle.

16.If required, remove tank gauge unit.

See

INSTRUMENTS, Repair, Fuel gauge tank unit

- side fuel tank

orSee INSTRUMENTS,

Repair, Fuel gauge tank unit - rear fuel tank,

110/130

Refit

17.Fit filler hose and clip to tank but do not fully

tighten. Position clip screw so that it is

accessible when tank is fitted.

18.Fit breather hose and secure with clip.

19.Position fuel tank in vehicle and loosely secure

front mounting bracket to tank with special bolt

and rubber bushes.

20.Secure mounting bracket to chassis with 3 bolts

and fully tighten to

20 Nm (15 lbf/ft).

21.Secure rear of tank to chassis mounting and

tighten captive bolt plate fixings to

20 Nm (15

lbf/ft).

22.Fully tighten front fixing bolt assembly to20 Nm

(15 lbf/ft).

23.Fit spill return and fuel supply pipes and secure

union connections.

24.Fit fuel level unit electrical plug.

25.Fit hose to filler tube and tighten upper and lower

clips.

26.Check that drain plug is secure and fill fuel tank.

27.Reconnect battery.

28.Prime fuel system

See Adjustment, Priming

the fuel system

and start engine.

29.Check system for leaks and operation of fuel

gauge.

30.Fit seat base cover and seat cushion.SIDE MOUNTED FUEL TANK - 5 DOOR VEHICLES

Service repair no - 19.55.01

NOTE: This fuel tank is used on 110/130 5

door vehicles fitted with a twin tank

option.

WARNING: Before any attempt is made to

start the removal procedure it is vital that

the FUEL HANDLING PRECAUTIONS,

See

INTRODUCTION, Information, Fuel handling

precautions

are carefully studied and

implemented in the interests of safety.

Remove

1.Disconnect battery.

2.Remove tank drain plug, allow fuel to drain into a

clean container, and refit plug.

3.Remove RH seat cushion.

4.Remove retaining catch and remove seat base

cover to gain access to fuel tank.

5.Disconnect electrical plug from fuel gauge unit.

6.Disconnect fuel supply pipe from tank.

7.Disconnect spill return pipe from tank.

8.Remove 3 bolts securing tank to front mounting

bracket.

9.Support front of tank and remove single fixing

assembly securing tank to rear mounting

bracket.

10.Remove tank from vehicle.

11.If required, remove fuel gauge unit.

See

INSTRUMENTS, Repair, Fuel gauge tank unit

- side fuel tank

orSee INSTRUMENTS,

Repair, Fuel gauge tank unit - rear fuel tank,

110/130

Refit

12.Position fuel tank in vehicle and loosely secure

to rear mounting bracket with special bolt and

rubber bushes.

13.Secure tank to front mounting bracket and

tighten fixings to

20 Nm (15 lbf/ft).

14.Fully tighten rear fixing bolt assembly to20 Nm

(15 lbf/ft).

15.Fit spill return and fuel supply pipes to fuel tank

and securely tighten union connectios.

16.Fit electrical plug to fuel gauge unit.

17.Check that drain plug is secure and fill fuel tank.

18.Reconnect battery.

19.Prime fuel system.

See Adjustment, Priming

the fuel system

and start engine.

20.Check system for leaks and operation of fuel

gauge.

21.Fit seat base cover and seat cushion.

Page 111 of 455

FUEL SYSTEM

9

REPAIR REV: 05/99

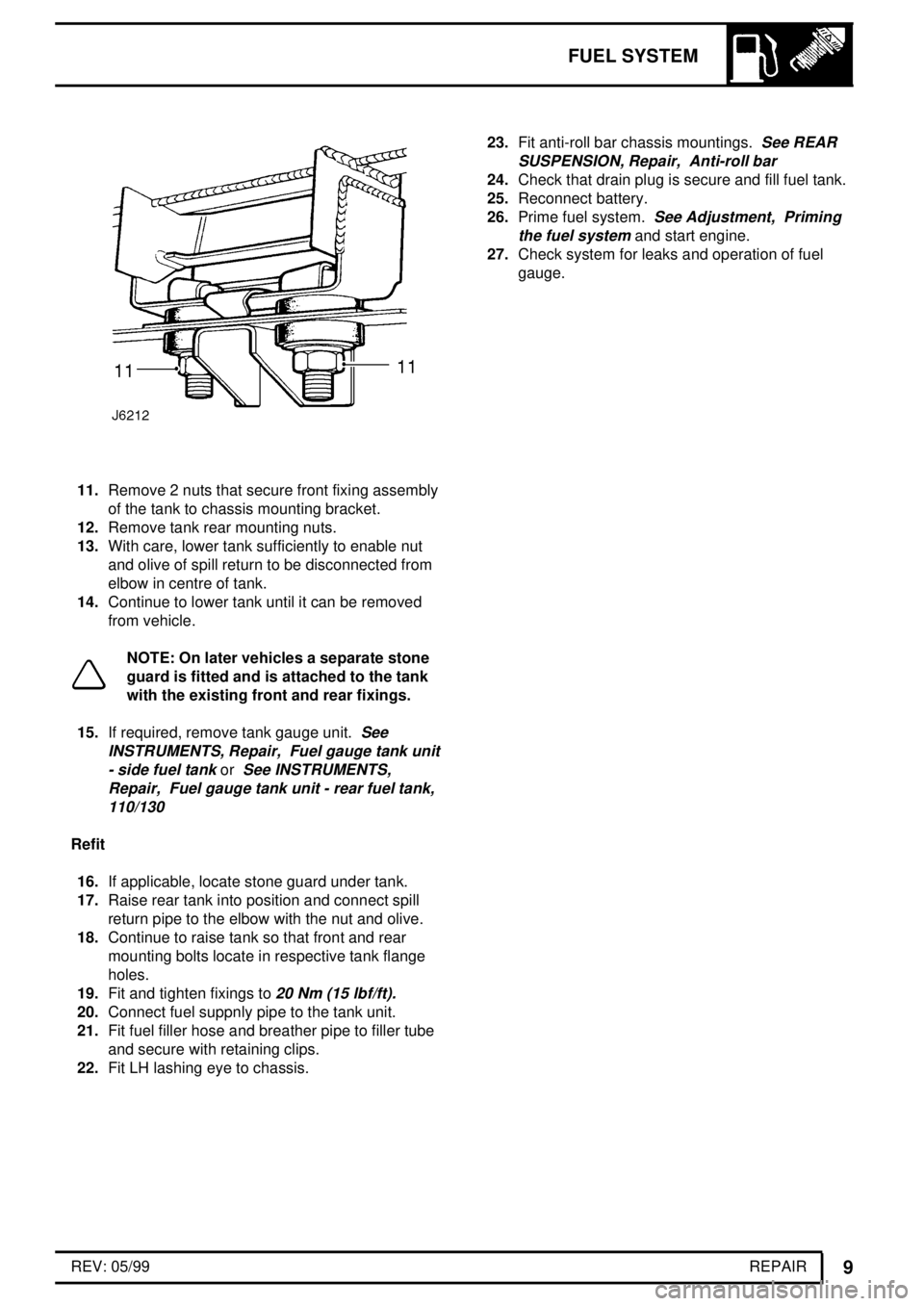

11.Remove 2 nuts that secure front fixing assembly

of the tank to chassis mounting bracket.

12.Remove tank rear mounting nuts.

13.With care, lower tank sufficiently to enable nut

and olive of spill return to be disconnected from

elbow in centre of tank.

14.Continue to lower tank until it can be removed

from vehicle.

NOTE: On later vehicles a separate stone

guard is fitted and is attached to the tank

with the existing front and rear fixings.

15.If required, remove tank gauge unit.

See

INSTRUMENTS, Repair, Fuel gauge tank unit

- side fuel tank

orSee INSTRUMENTS,

Repair, Fuel gauge tank unit - rear fuel tank,

110/130

Refit

16.If applicable, locate stone guard under tank.

17.Raise rear tank into position and connect spill

return pipe to the elbow with the nut and olive.

18.Continue to raise tank so that front and rear

mounting bolts locate in respective tank flange

holes.

19.Fit and tighten fixings to

20 Nm (15 lbf/ft).

20.Connect fuel suppnly pipe to the tank unit.

21.Fit fuel filler hose and breather pipe to filler tube

and secure with retaining clips.

22.Fit LH lashing eye to chassis.23.Fit anti-roll bar chassis mountings.

See REAR

SUSPENSION, Repair, Anti-roll bar

24.Check that drain plug is secure and fill fuel tank.

25.Reconnect battery.

26.Prime fuel system.

See Adjustment, Priming

the fuel system

and start engine.

27.Check system for leaks and operation of fuel

gauge.

Page 117 of 455

FUEL SYSTEM

15

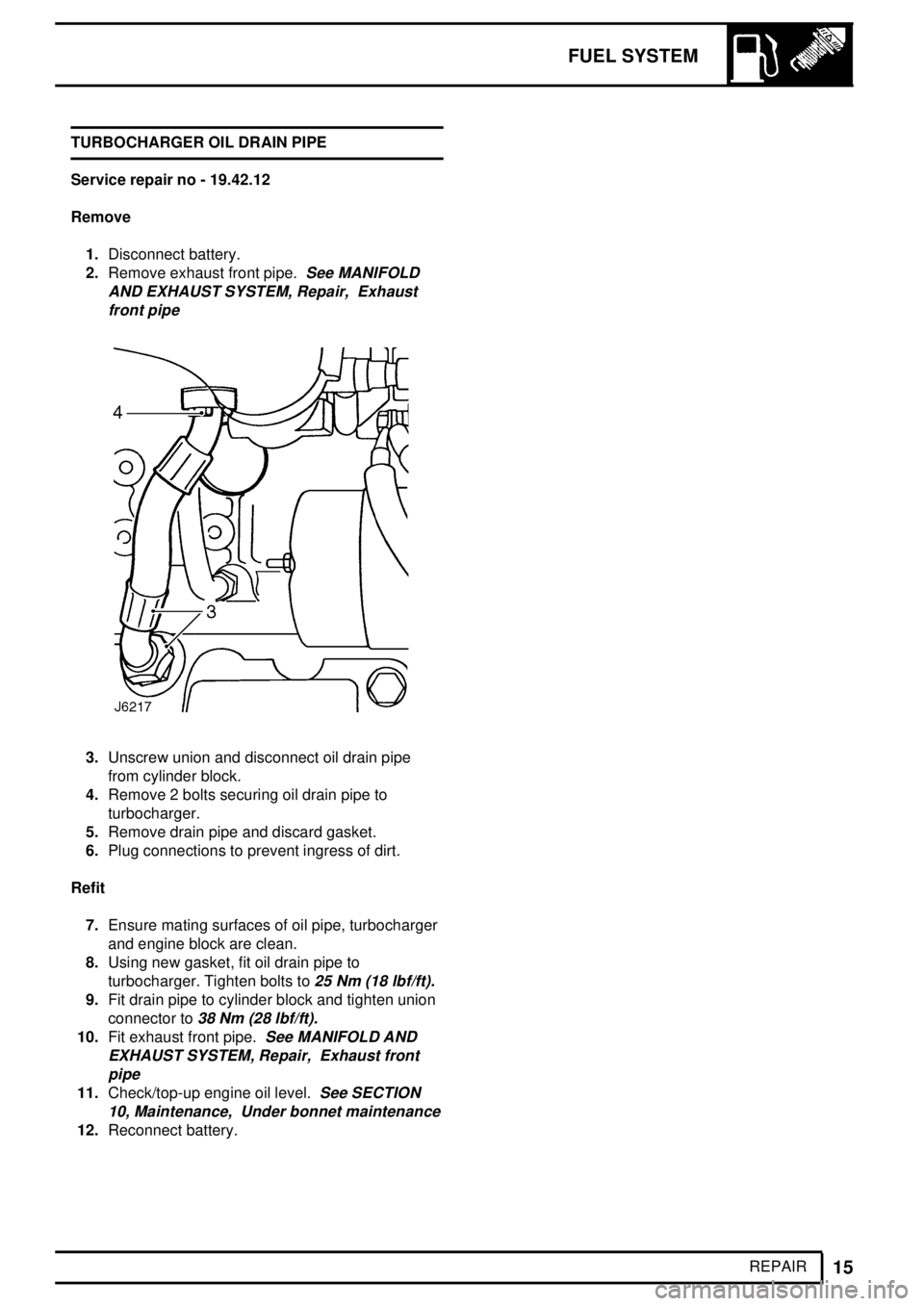

REPAIR TURBOCHARGER OIL DRAIN PIPE

Service repair no - 19.42.12

Remove

1.Disconnect battery.

2.Remove exhaust front pipe.

See MANIFOLD

AND EXHAUST SYSTEM, Repair, Exhaust

front pipe

3.Unscrew union and disconnect oil drain pipe

from cylinder block.

4.Remove 2 bolts securing oil drain pipe to

turbocharger.

5.Remove drain pipe and discard gasket.

6.Plug connections to prevent ingress of dirt.

Refit

7.Ensure mating surfaces of oil pipe, turbocharger

and engine block are clean.

8.Using new gasket, fit oil drain pipe to

turbocharger. Tighten bolts to

25 Nm (18 lbf/ft).

9.Fit drain pipe to cylinder block and tighten union

connector to

38 Nm (28 lbf/ft).

10.Fit exhaust front pipe.See MANIFOLD AND

EXHAUST SYSTEM, Repair, Exhaust front

pipe

11.Check/top-up engine oil level.See SECTION

10, Maintenance, Under bonnet maintenance

12.Reconnect battery.

Page 127 of 455

26COOLING SYSTEM

2

REPAIR FAN COWL

Service repair no - 26.25.11

Remove

1.Disconnect battery.

2.Drain coolant.

See Adjustment, Drain and

refill cooling system.

3.Slacken retaining clips and remove radiator top

hose.

4.Slacken retaining clip and remove top hose from

intercooler.

NOTE: On vehicles fitted with EGR system,

remove complete intercooler top hose

assembly.

5.Remove viscous coupling and fan

See Viscous coupling and fan.

6.Remove 2 nuts securing top of fan cowl.

7.Release expansion tank hose from clips at base

of fan cowl.

8.Lift and remove cowl .

NOTE: On vehicles fitted with air

conditioning, it will be necessary to

remove the cowl and viscous fan unit

together to enable clearance of the compressor.Refit

9.Position fan cowl.

10.Fit viscous fan unit.

See Viscous coupling

and fan

11.Fit expansion tank hose into fan cowl clips.

12.Secure top of fan cowl to radiator top cover.

13.Fit intercooler top hose.

14.Fit radiator top hose.

15.Refill cooling system.

See Adjustment, Drain

and refill cooling system

16.Reconnect battery.

FAN PULLEY

Service repair no - 26.25.04.

Remove

1.Disconnect battery.

2.Remove viscous fan unit.

See Viscous

coupling and fan

3.Remove drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

4.Unscrew 4 bolts and remove pulley from adaptor

boss.

Refit

5.Fit fan pulley to adaptor boss. Tighten bolts to

25

Nm (18 lbf/ft).

6.Fit drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

7.Fit viscous fan unit.See Viscous coupling

and fan

8.Reconnect battery.

Page 128 of 455

COOLING SYSTEM

3

REPAIR WATER PUMP

Service repair no - 26.50.01

Remove

1.Disconnect battery.

2.Drain cooling system.

See Adjustment, Drain

and refill cooling system

3.Remove radiator top hose.

4.Remove intercooler top hose.

5.Slacken water pump and power steering pump

pulley retaining bolts.

6.Remove drive belt.

See ELECTRICAL, Repair,

Auxiliary drive belt

7.Unscrew flange nut and remove belt tensioner.

8.Remove oil filler cap and remove rocker cover

insulation.

9.Slacken retaining clip and disconnect hose at

heater rail.

10.Unscrew 3 bolts and remove water pump pulley.

11.Unscrew 3 bolts and remove power steering

pump pulley.

12.Remove 8 bolts securing water pump, noting

location of 3 through bolts into cylinder block.

13.Withdraw pump and gasket from auxiliary

mounting bracket.

14.Clean all gasket material from mating faces.

Refit

15.Using new gasket, fit water pump to mounting

bracket. Tighten bolts to

25 Nm (18 lbf/ft).

16.Fit power steering pump pulley.

17.Fit water pump pulley. Tighten bolts of both

pulleys to

25 Nm (18 lbf/ft).

18.Fit drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

19.Fit hose at heater rail.

20.Fit rocker cover insulation and oil filler cap.

21.Fit drive belt tensioner. Tighten retaining nut to

45 Nm (33 lbf/ft).

22.Fit intercooler top hose.

23.Fit radiator top hose.

24.Refill cooling system.

See Adjustment, Drain

and refill cooling system

25.Reconnect battery.

Page 129 of 455

26COOLING SYSTEM

4

REPAIRREV: 05/99 AUXILIARY MOUNTING BRACKET AND GASKET

Service repair no - 26.50.04

Remove

1.Disconnect battery.

2.Drain cooling system

See Adjustment, Drain

and refill cooling system

.

3.Remove radiator top hose.

4.Remove intercooler top hose.

5.Remove viscous fan unit.

See Viscous

coupling and fan

6.Remove fan cowl.See Fan cowl

7.Slacken power steering pump pulley retaining

bolts.

8.Remove drive belt.

See ELECTRICAL, Repair,

Auxiliary Drive belt

9.Unscrew 3 bolts and remove power steering

pump pulley.

10.Remove 4 bolts securing power steering pump

mounting bracket.

11.Lower pump and bracket. Do not disconnect fluid

pipes.

12.Remove generator.

See ELECTRICAL, Repair,

Generator

13.Unscrew retaining nut and remove drive belt

tensioner.

14.Release hose clip from bracket above water

pump.15.Disconnect bottom hose/heater return hose at

water pump and heater rail.

16.Disconnect by-pass hose from water pump and

thermostat housing.

17.Remove 5 bolts (one with nut) and single

retaining nut, securing auxiliary mounting

bracket to cylinder block.

18.Withdraw mounting bracket, complete with water

pump.

19.Remove gasket and clean mating faces.

Refit

20.Using 2 slave studs, fit new gasket.

NOTE: All fixing bolts and nuts should be

tightened to

25 Nm (18 lbf/ft)unless

otherwise stated.

21.Locate mounting bracket, complete with water

pump on slave studs and secure with 4 other

fixings.

22.Remove slave studs and fit remaining bolts/nuts.

23.Fit by-pass hose to thermostat housing and

water pump.

24.Fit bottom hose/heater return hose to water

pump and heater rail.

25.Fit heater hose clip to mounting bracket.

26.Fit drive belt tensioner. Tighten nut to

45 Nm (33

lbf/ft).

27.Fit generator.See ELECTRICAL, Repair,

Generator

Do not fit drive belt at this stage.

Page 130 of 455

COOLING SYSTEM

5

REPAIR 28.Secure steering pump and bracket to auxiliary

mounting bracket.

29.Fit steering pump pulley.

30.Fit drive belt

See ELECTRICAL, Repair,

Auxiliary drive belt

.

31.Fit fan cowl

See Fan cowl.

32.Fit viscous fan unit

See Viscous coupling and

fan

.

33.Fit intercooler top hose.

34.Fit radiator top hose.

35.Refill cooling system.

See Adjustment, Drain

and refill cooling system

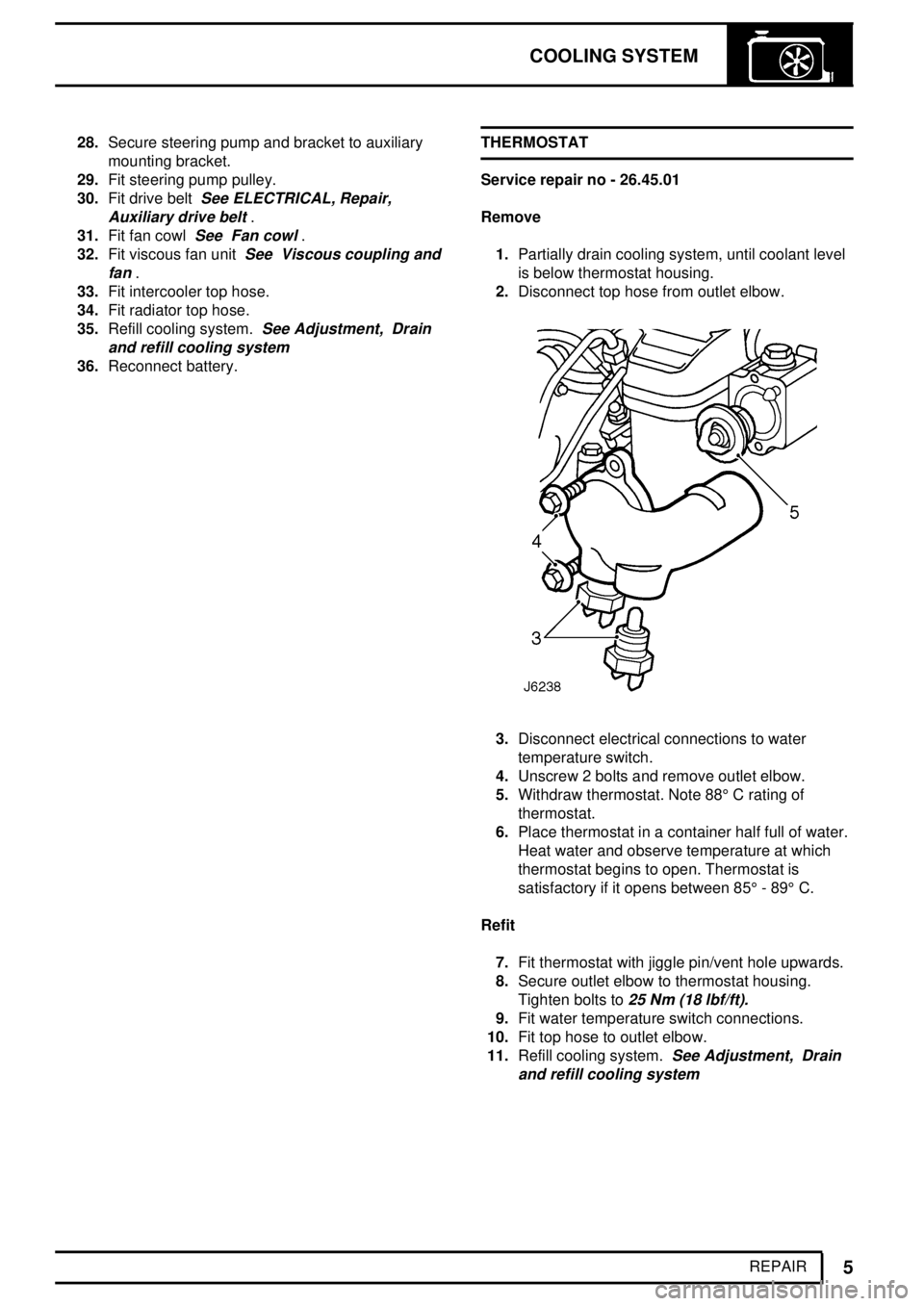

36.Reconnect battery.THERMOSTAT

Service repair no - 26.45.01

Remove

1.Partially drain cooling system, until coolant level

is below thermostat housing.

2.Disconnect top hose from outlet elbow.

3.Disconnect electrical connections to water

temperature switch.

4.Unscrew 2 bolts and remove outlet elbow.

5.Withdraw thermostat. Note 88°C rating of

thermostat.

6.Place thermostat in a container half full of water.

Heat water and observe temperature at which

thermostat begins to open. Thermostat is

satisfactory if it opens between 85°-89°C.

Refit

7.Fit thermostat with jiggle pin/vent hole upwards.

8.Secure outlet elbow to thermostat housing.

Tighten bolts to

25 Nm (18 lbf/ft).

9.Fit water temperature switch connections.

10.Fit top hose to outlet elbow.

11.Refill cooling system.

See Adjustment, Drain

and refill cooling system