heater LAND ROVER DEFENDER 1996 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 129 of 455

26COOLING SYSTEM

4

REPAIRREV: 05/99 AUXILIARY MOUNTING BRACKET AND GASKET

Service repair no - 26.50.04

Remove

1.Disconnect battery.

2.Drain cooling system

See Adjustment, Drain

and refill cooling system

.

3.Remove radiator top hose.

4.Remove intercooler top hose.

5.Remove viscous fan unit.

See Viscous

coupling and fan

6.Remove fan cowl.See Fan cowl

7.Slacken power steering pump pulley retaining

bolts.

8.Remove drive belt.

See ELECTRICAL, Repair,

Auxiliary Drive belt

9.Unscrew 3 bolts and remove power steering

pump pulley.

10.Remove 4 bolts securing power steering pump

mounting bracket.

11.Lower pump and bracket. Do not disconnect fluid

pipes.

12.Remove generator.

See ELECTRICAL, Repair,

Generator

13.Unscrew retaining nut and remove drive belt

tensioner.

14.Release hose clip from bracket above water

pump.15.Disconnect bottom hose/heater return hose at

water pump and heater rail.

16.Disconnect by-pass hose from water pump and

thermostat housing.

17.Remove 5 bolts (one with nut) and single

retaining nut, securing auxiliary mounting

bracket to cylinder block.

18.Withdraw mounting bracket, complete with water

pump.

19.Remove gasket and clean mating faces.

Refit

20.Using 2 slave studs, fit new gasket.

NOTE: All fixing bolts and nuts should be

tightened to

25 Nm (18 lbf/ft)unless

otherwise stated.

21.Locate mounting bracket, complete with water

pump on slave studs and secure with 4 other

fixings.

22.Remove slave studs and fit remaining bolts/nuts.

23.Fit by-pass hose to thermostat housing and

water pump.

24.Fit bottom hose/heater return hose to water

pump and heater rail.

25.Fit heater hose clip to mounting bracket.

26.Fit drive belt tensioner. Tighten nut to

45 Nm (33

lbf/ft).

27.Fit generator.See ELECTRICAL, Repair,

Generator

Do not fit drive belt at this stage.

Page 135 of 455

MANIFOLD AND EXHAUST SYSTEM

1

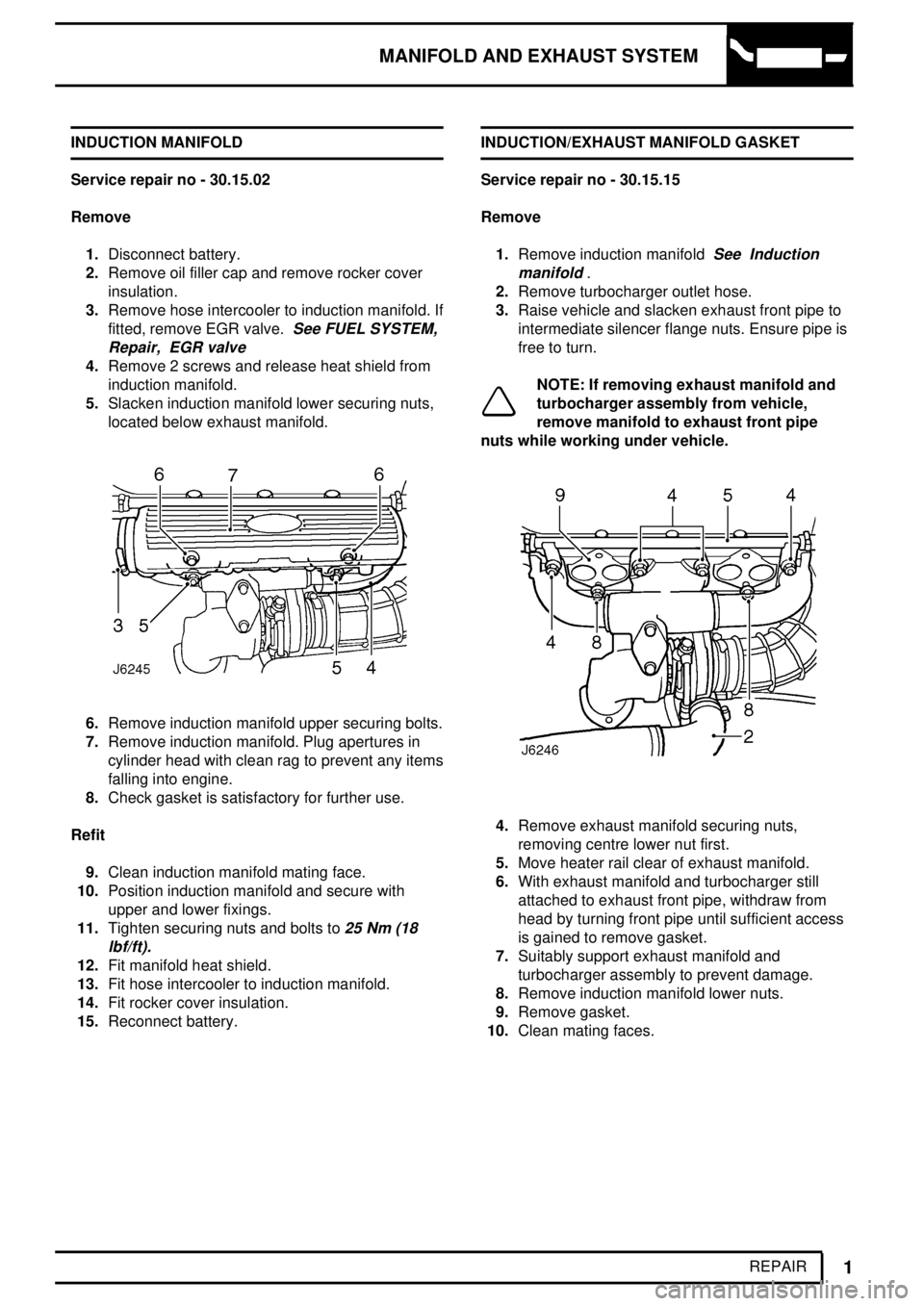

REPAIR INDUCTION MANIFOLD

Service repair no - 30.15.02

Remove

1.Disconnect battery.

2.Remove oil filler cap and remove rocker cover

insulation.

3.Remove hose intercooler to induction manifold. If

fitted, remove EGR valve.

See FUEL SYSTEM,

Repair, EGR valve

4.Remove 2 screws and release heat shield from

induction manifold.

5.Slacken induction manifold lower securing nuts,

located below exhaust manifold.

6.Remove induction manifold upper securing bolts.

7.Remove induction manifold. Plug apertures in

cylinder head with clean rag to prevent any items

falling into engine.

8.Check gasket is satisfactory for further use.

Refit

9.Clean induction manifold mating face.

10.Position induction manifold and secure with

upper and lower fixings.

11.Tighten securing nuts and bolts to

25 Nm (18

lbf/ft).

12.Fit manifold heat shield.

13.Fit hose intercooler to induction manifold.

14.Fit rocker cover insulation.

15.Reconnect battery.INDUCTION/EXHAUST MANIFOLD GASKET

Service repair no - 30.15.15

Remove

1.Remove induction manifold

See Induction

manifold

.

2.Remove turbocharger outlet hose.

3.Raise vehicle and slacken exhaust front pipe to

intermediate silencer flange nuts. Ensure pipe is

free to turn.

NOTE: If removing exhaust manifold and

turbocharger assembly from vehicle,

remove manifold to exhaust front pipe

nuts while working under vehicle.

4.Remove exhaust manifold securing nuts,

removing centre lower nut first.

5.Move heater rail clear of exhaust manifold.

6.With exhaust manifold and turbocharger still

attached to exhaust front pipe, withdraw from

head by turning front pipe until sufficient access

is gained to remove gasket.

7.Suitably support exhaust manifold and

turbocharger assembly to prevent damage.

8.Remove induction manifold lower nuts.

9.Remove gasket.

10.Clean mating faces.

Page 136 of 455

30MANIFOLD AND EXHAUST SYSTEM

2

REPAIR Refit

11.Fit new gasket over manifold studs.

12.Loosely fit induction manifold lower nuts to

studs.

13.Fit exhaust manifold and secure with central

upper and lower nuts.

14.Locate heater rail to its correct position and

secure with outer exhaust manifold nuts.

15.Tighten all exhaust manifold nuts to

45 Nm (33

lbf/ft).

16.Tighten exhaust front pipe to intermediate

silencer nuts to

50 Nm (37 lbf/ft).

17.Fit turbocharger outlet pipe.

18.Fit induction manifold

See Induction manifold

.EXHAUST MANIFOLD/TURBOCHARGER

ASSEMBLY

Service repair no - 30.15.10

Remove

1.Remove induction manifold

See Induction

manifold

.

2.Disconnect turbocharger inlet hose.

3.Disconnect boost pressure pipe at turbocharger.

4.Remove intercooler bottom hose.

5.Place suitable container under engine and

disconnect turbocharger oil feed and return

pipes at cylinder block.

6.Remove 3 nuts securing exhaust front pipe to

manifold flange.

7.Remove 7 nuts and lift exhaust manifold and

turbocharger assembly from cylinder head.

8.Discard manifold gasket.

Refit

9.Fit new manifold gasket.

10.Position exhaust manifold assembly onto

location studs and secure to cylinder head.

Tighten nuts to

45 Nm (33 lbf/ft).

11.Secure exhaust front pipe to manifold flange.

Tighten fixings to

50 Nm (37 lbf/ft).

12.Reconnect turbocharger oil feed and return

pipes at cylinder block.

13.Fit intercooler bottom hose.

14.Fit boost pressure pipe at turbocharger.

15.Fit turbocharger inlet hose.

16.Fit induction manifold

See Induction manifold

.

Page 355 of 455

76CHASSIS AND BODY

34

REPAIRREV: 05/99 LOWER FASCIA PANEL (HEATER DUCT)

ASSEMBLY

Service repair no - 76.46.05

Remove

1.Disconnect battery.

2.Remove steering wheel

See STEERING,

Repair, Steering wheel

.

3.Remove steering column nacelle

See

STEERING, Repair, Steering column nacelle

.

4.Remove instrument panel

See INSTRUMENTS,

Repair, instrument panel

.

5.Release heater cable at control lever

See

HEATING AND VENTILATION, Repair, Heater

control cable - air distribution

.

6.Remove 2 screws, withdraw switch panel from

lower fascia and disconnect switch multi-plugs.

7.Prise out Land Rover decal and remove screw

securing grab handle to crash pad.

8.Remove lower screw and lift grab handle from

lower fascia panel.

9.On RH drive vehicles only, remove screw

securing LH side of finisher to wiper motor cover.

10.Remove 4 screws and remove both demister

vents from crash pad.

11.Remove 3 screws securing crash pad to fascia

bulkhead.

12.Remove crash pad.

13.Remove radio, if fitted.

14.Remove 2 trim studs securing radio housing to

trim panel. Remove radio housing.

Page 357 of 455

76CHASSIS AND BODY

36

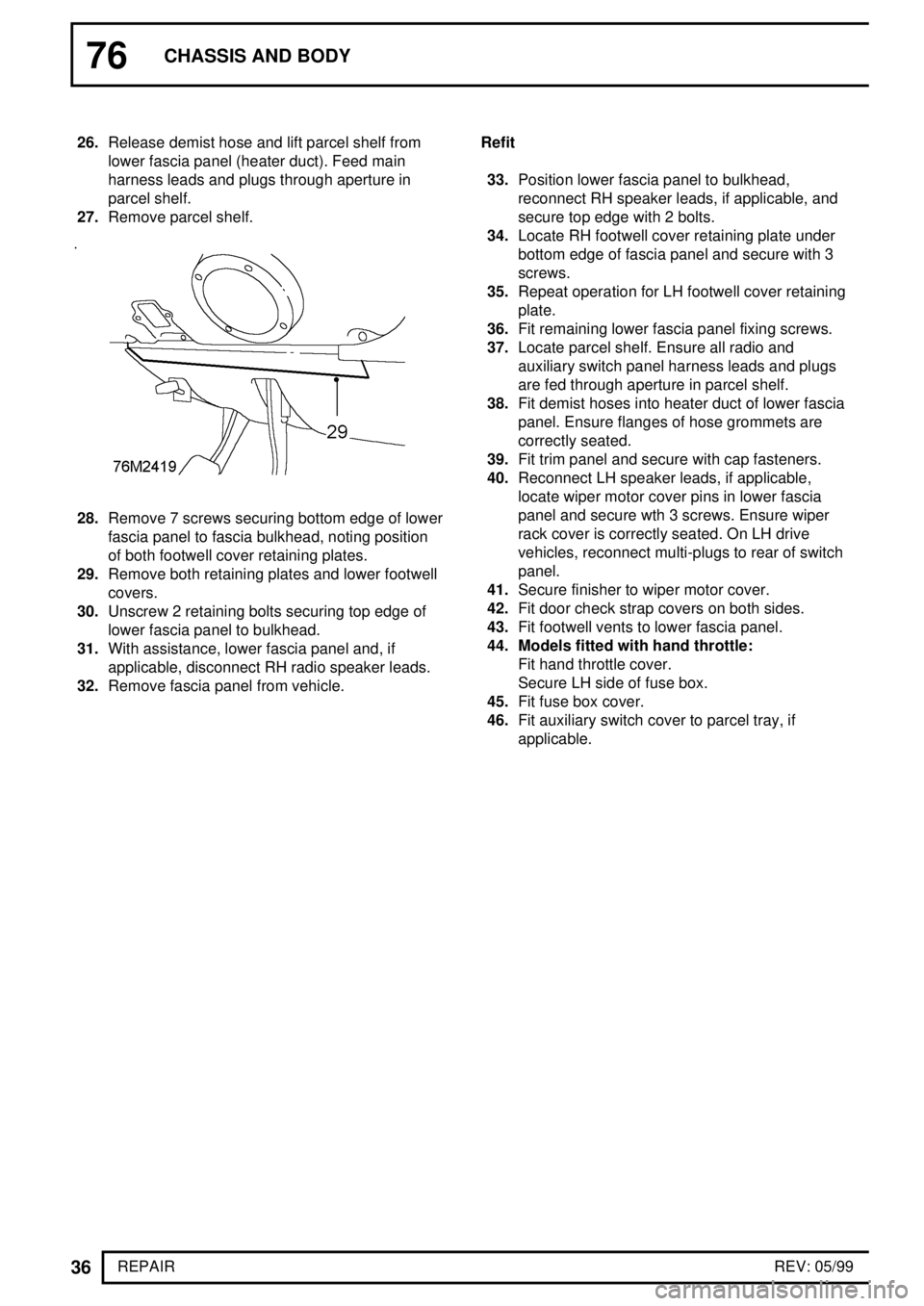

REPAIRREV: 05/99 26.Release demist hose and lift parcel shelf from

lower fascia panel (heater duct). Feed main

harness leads and plugs through aperture in

parcel shelf.

27.Remove parcel shelf.

28.Remove 7 screws securing bottom edge of lower

fascia panel to fascia bulkhead, noting position

of both footwell cover retaining plates.

29.Remove both retaining plates and lower footwell

covers.

30.Unscrew 2 retaining bolts securing top edge of

lower fascia panel to bulkhead.

31.With assistance, lower fascia panel and, if

applicable, disconnect RH radio speaker leads.

32.Remove fascia panel from vehicle.Refit

33.Position lower fascia panel to bulkhead,

reconnect RH speaker leads, if applicable, and

secure top edge with 2 bolts.

34.Locate RH footwell cover retaining plate under

bottom edge of fascia panel and secure with 3

screws.

35.Repeat operation for LH footwell cover retaining

plate.

36.Fit remaining lower fascia panel fixing screws.

37.Locate parcel shelf. Ensure all radio and

auxiliary switch panel harness leads and plugs

are fed through aperture in parcel shelf.

38.Fit demist hoses into heater duct of lower fascia

panel. Ensure flanges of hose grommets are

correctly seated.

39.Fit trim panel and secure with cap fasteners.

40.Reconnect LH speaker leads, if applicable,

locate wiper motor cover pins in lower fascia

panel and secure wth 3 screws. Ensure wiper

rack cover is correctly seated. On LH drive

vehicles, reconnect multi-plugs to rear of switch

panel.

41.Secure finisher to wiper motor cover.

42.Fit door check strap covers on both sides.

43.Fit footwell vents to lower fascia panel.

44. Models fitted with hand throttle:

Fit hand throttle cover.

Secure LH side of fuse box.

45.Fit fuse box cover.

46.Fit auxiliary switch cover to parcel tray, if

applicable.

Page 358 of 455

CHASSIS AND BODY

37

REPAIR REV: 05/9947.Connect leads and plugs to auxiliary switches

and clock.

48.Secure switch panel to lower fascia panel and

switch cover.

49.Position radio housing, if applicable, and feed

radio multi- plug, aerial and speaker leads from

switch cover to radio housing.

50.Secure radio housing to trim panel.

51.Fit radio connections and secure radio in

housing.

52.Fit crash pad to fascia bulkhead.

53.Fit demister vents in crash pad.

54.Fit grab handle to lower fascia panel and secure

to crash pad. Refit Land Rover decal.

55.Connect multi-plugs to rear screen, hazard and

interior lamp switches and fit switch panel to

fascia panel.

56.Fit heater control cable

See HEATING AND

VENTILATION, Repair, Heater control cable -

air distribution

.

57.Fit instrument panel

See INSTRUMENTS,

Repair, instrument panel

.

58.Fit steering column nacelle

See STEERING,

Repair, Steering column nacelle

.

59.Fit steering wheel

See STEERING, Repair,

Steering wheel

.

60.Reconnect battery.FRONT UNDERTRAY

Service repair no - 76.11.81 - Front undertray

Service repair no - 76.11.85 - Acoustic pad

Remove

1.Raise vehicle on ramp.

2.Position support under chassis front

crossmember.

3.Lower ramp to give clearance between axle and

undertray.

4.Remove 4 nuts, disconnect propeller shaft from

front axle, and move aside.

5.Remove 2 bolts securing undertray to chassis

front crossmember.

6.Remove nut securing undertray to bump stop

front fixing bolt on both sides.

7.Remove 2 bolts securing sides of undertray to

rear undertray.

8.Pull front undertray forwards to release flanges

from rear undertray.

9.Lower undertray to clear steering box etc. and

manouvre rearwards over axle.

10.Remove front undertray.

11.If necessary, remove 8 fasteners to release

acoustic pad from undertray.

Page 361 of 455

HEATING AND VENTILATION

1

DESCRIPTION AND OPERATION HEATING AND VENTILATION SYSTEM

Description

The heating and ventilation system is standard on all

models. Air conditioning is an optional system which

provides fully integrated climate control for the vehicle

interior.The heater assembly, comprising a matrix housed in a

distribution unit and a variable speed blower motor, is

located on one side of the engine compartment and

attached directly to the fascia bulkhead.

The heating controls are positioned on the outside of

the instrument binnacle and cable linked to

mechanical flaps in the distribution unit.

Heater assembly

1.Heater distribution unit

2.Fixings, heater to fascia bulkhead

3.Heater matrix

4.Blower motor housing

5.Circlip, impeller to blower motor

6.Impeller

7.Resistor unit and harness connector8.Fixings, blower motor mounting plate

9.Mounting plate, blower motor

10.Blower motor

11.Fixings, blower motor to mounting bracket

12.Temperature flap, air flow to heater matrix

13.Air flap, air supply to plenum chamber (heater

duct)

Page 362 of 455

80HEATING AND VENTILATION

2

DESCRIPTION AND OPERATION HEATER OPERATION

The heater matrix (3), located in the distribution unit

(1), see J6341, is connected to the engine cooling

system. As water is circulated continuously through

the matrix, a selection of heated or ambient air is

controlled by two flaps within the distribution unit. The

temperature flap (12) controls the amount of ambient

air to the heater matrix, air being suppliedthrough a ducted vent on top of the vehicle front wing

to the blower motor (volute) housing (4). The blower

motor (10) can be used to boost the air flow into the

distribution unit. The air flap (13) controls the supply of

heated or ambient air from the heater unit into a

plenum chamber integeral with the vehicle fascia. Two

flaps in the plenum chamber (heater duct) distribute

the air flow to either the footwell vents or windscreen

demister vents as shown.

HEATER CONTROLS

1. Temperature control

Move the lever downwards to increase air

temperature or up to decrease air temperature.

2. Air distribution control

Lever fully up - windscreen vents only.

Lever midway - footwell and windscreen vents.

Lever fully down - footwell vents.3. Blower motor fan speed control

Move the lever progressively downwards to increase

fan speed. With the control at '0' the fan is switched

off and the volume of air entering the passenger

compartment is solely dependent on ram air when the

vehicle is moving.

Page 364 of 455

HEATING AND VENTILATION

1

REPAIR HEATER UNIT

Service repair no - 80.20.01

Remove

1.Remove bonnet and disconnect battery.

2.Remove radiator bottom hose at radiator union

and drain cooling system

See COOLING

SYSTEM, Repair, Drain and refill cooling

system

.

3.Slacken clips and remove heater hoses at

heater box unions.

4.Remove outer cable securing clips.

5.Slacken trunnions and remove control cables

from heater vent flap levers.

6.Remove heater wiring harness securing loop.

7.Disconnect harness multi-plug.

8.Remove interior bulkhead trim.

9.Remove lower nuts and bolts securing the

heater unit to the bulkhead.

10.Slacken heater unit upper retaining bolts.

11.Manoeuvre heater unit, complete with blower

motor, clear of air inlet duct and remove from

engine compartment.

12.If existing heater unit is to be refitted, remove

sealing rubber.

For heater matrix removal

See Heater matrix.

For blower motor removal

See Blower motor.

Refit

13.Smear a new heater unit sealing rubber with a

suitable impact adhesive and fit to heater.

14.Manoevre heater unit into position in engine

compartment, fit blower motor to air inlet duct

and locate upper fixing bolts.

15.Loosely fit heater unit lower fixing bolts.

16.Fully tighten upper fixing bolts.

17.Fully tighten lower fixings and refit interior

bulkhead trim.

18.Secure wiring harness and reconnect multi-plug.

19.Fit control cables to vent flap trunnions and

secure with outer cable clips.

20.Connect heater hoses.

21.Fit radiator bottom hose and refill cooling system

See COOLING SYSTEM, Repair, Drain and

refill cooling system

.

22.Fit bonnet and reconnect battery.

Page 365 of 455

80HEATING AND VENTILATION

2

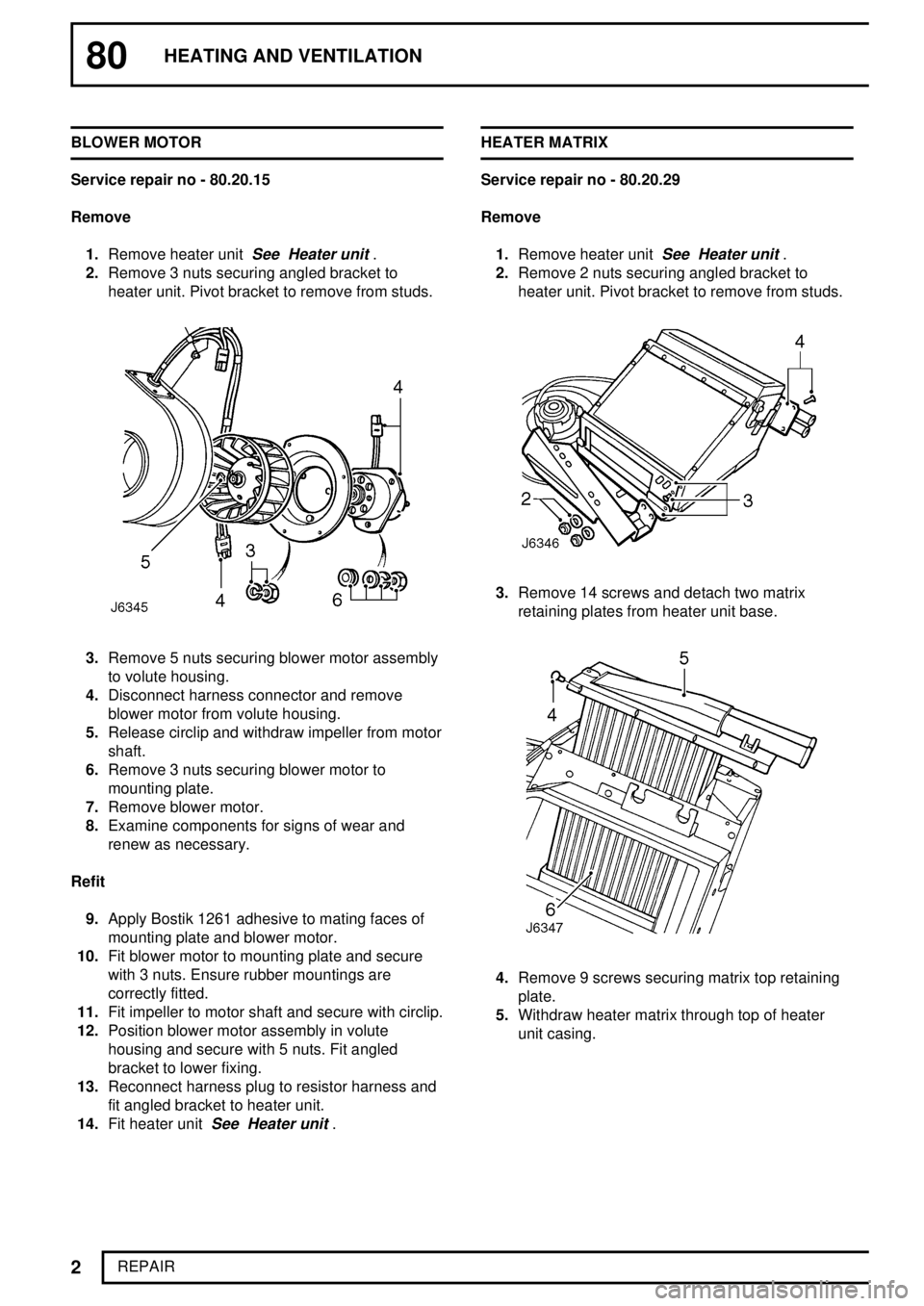

REPAIR BLOWER MOTOR

Service repair no - 80.20.15

Remove

1.Remove heater unit

See Heater unit.

2.Remove 3 nuts securing angled bracket to

heater unit. Pivot bracket to remove from studs.

3.Remove 5 nuts securing blower motor assembly

to volute housing.

4.Disconnect harness connector and remove

blower motor from volute housing.

5.Release circlip and withdraw impeller from motor

shaft.

6.Remove 3 nuts securing blower motor to

mounting plate.

7.Remove blower motor.

8.Examine components for signs of wear and

renew as necessary.

Refit

9.Apply Bostik 1261 adhesive to mating faces of

mounting plate and blower motor.

10.Fit blower motor to mounting plate and secure

with 3 nuts. Ensure rubber mountings are

correctly fitted.

11.Fit impeller to motor shaft and secure with circlip.

12.Position blower motor assembly in volute

housing and secure with 5 nuts. Fit angled

bracket to lower fixing.

13.Reconnect harness plug to resistor harness and

fit angled bracket to heater unit.

14.Fit heater unit

See Heater unit.HEATER MATRIX

Service repair no - 80.20.29

Remove

1.Remove heater unit

See Heater unit.

2.Remove 2 nuts securing angled bracket to

heater unit. Pivot bracket to remove from studs.

3.Remove 14 screws and detach two matrix

retaining plates from heater unit base.

4.Remove 9 screws securing matrix top retaining

plate.

5.Withdraw heater matrix through top of heater

unit casing.