wheel torque LAND ROVER DEFENDER 1996 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 263 of 455

STEERING

1

SPECIFICATIONS, TORQUE REV: 05/99 TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Ball joint nuts 40..............................................................................................

Clamp bolt nuts 9...........................................................................................

Steering column bracket nuts 22....................................................................

Steering wheel nut 43.....................................................................................

Tie bar to mounting nut 110.............................................................................

Universal joint pinch bolt 25............................................................................

PAS box

Adjuster locknut 60.................................................................................

Drop arm nut 176....................................................................................

Sector shaft cover to steering box 75.....................................................

Steering box to chassis 81.....................................................................

Steering box fluid pipes 14mm thread 15...............................................

Steering box fluid pipes 16mm thread 20...............................................

Tie bar 81...............................................................................................

PAS pump

High pressure fluid pipe 20.....................................................................

Power steering pump mounting 35.........................................................

Pulley bolts, power steering pump 10....................................................

Hose clamp 3........................................................................................

Front mounting plate bolts 9..................................................................

PAS reservoir

Hose clamp 3........................................................................................

* Torque values below are for all screws and bolts used except for those that are specified otherwise.

METRIC Nm

M5 6......................................................................................................

M6 9......................................................................................................

M8 25.....................................................................................................

M10 45...................................................................................................

M12 90...................................................................................................

M14 105..................................................................................................

M16 180..................................................................................................

UNC / UNF

1/4 9......................................................................................................

5/16 24...................................................................................................

3/8 39.....................................................................................................

7/16 78...................................................................................................

1/2 90.....................................................................................................

5/8 136....................................................................................................

Page 266 of 455

60FRONT SUSPENSION

2

REPAIRREV: 05/99

6.Remove fixings, radius arm to axle.

7.Lower radius arm front end to clear axle and

remove from vehicle.

8.Using suitable length of steel tubing, press out

flexible bushes.

Refit

9.Press in replacement bushes.

CAUTION: When pressing in new bushes

press on outer edge of bush and not

rubber inner.

10.Fit radius arm to axle mounting.

11.Fit track rod at ball joint.

12.Fit radius arm to chassis. Tighten bolts to

176

Nm (130 lbf/ft).

13.Fully tighten radius arm to axle fixings to197 Nm

(145 lbf/ft).

14.Fit road wheel, remove chassis stands and jack.

Tighten wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

FRONT SHOCK ABSORBER

Service repair no - 60.30.02.

Remove

1.Loosen road wheel retaining nuts.

2.Support chassis on stands and remove road

wheel.

3.Support axle weight with jack.

4.Remove shock absorber lower fixing and

withdraw cupwasher, rubber bush and seating

washer.

5.Remove four shock absorber bracket fixings.

6.Withdraw shock absorber and bracket assembly.

7.Withdraw lower seating washer, rubber bush and

cupwasher.

8.Remove fixings, shock absorber to mounting

bracket.

9.Withdraw mounting bracket.

10.Lift off top seating washer, rubber bush and

cupwasher.

Page 267 of 455

FRONT SUSPENSION

3

REPAIR REV: 05/99 Refit

11.Assemble shock absorber components.

12.Position shock absorber, complete with bracket

and secure with 4 fixings.

13.Secure shock absorber lower fixing.

14.Fit road wheel, remove chassis stands and jack.

Tighten wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

FRONT ROAD SPRING

Service repair no - 60.20.11.

Remove

1.Remove front shock absorber

See Front

shock absorber

.

CAUTION: Avoid over stretching brake

hoses. If necessary, loosen hose

connector locknuts to allow hoses to

follow axle.

2.Lower axle sufficient to free road spring.

3.Withdraw road spring.

4.Withdraw shock absorber bracket securing ring.

Refit

5.Fit shock absorber bracket retaining ring. Retain

in position with a nut.

6.Position road spring and raise axle.

7.Remove nut retaining securing ring.

8.Fit front shock absorber

See Front shock

absorber

.

Page 272 of 455

REAR SUSPENSION

1

REPAIR REV: 05/99 REAR ROAD SPRING

Service repair no - 64.20.01.

Remove

1.Loosen rear road wheel retaining nuts.

2.Support chassis on stands and remove wheels.

3.Support rear axle weight with jack.

4.Disconnect shock absorbers at one end.

5.Position coil spring compressor correctly on road

spring.

6.Compress spring evenly to facilitate removal.

7.Lower axle to free road spring from upper seat.

CAUTION: Avoid lowering axle further than

rear brake flexible hose will allow.

8.Remove spring retainer plate.

9.Withdraw road spring.

10.Collect spring seat.

Refit

11.Position spring seat on axle location.

12.Fit road spring into chassis location and, using a

turning motion, fit to spring seat.

13.Fit spring retainer plate. Tighten bolts to

14 Nm

(10 lbf/ft).

14.Secure shock absorber. Tighten fixing to37 Nm

(27 lbf/ft).

15.Fit road wheels, remove chassis stands and

jack. Tighten wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

REAR SHOCK ABSORBER

Service repair no - 64.30.02.

Remove

1.Loosen road wheel retaining nuts.

2.Support chassis on stands. Remove road wheel

and support rear axle weight with jack.

3.Remove fixings and withdraw shock absorber

from axle bracket.

4.Remove upper fixings.

5.Withdraw shock absorber.

6.If required, remove mounting bracket

7.If required, remove mounting rubbers.

Refit

8.Position shock absorber and fit upper fixings.

9.Secure shock absorber with lower fixings to axle

bracket. Tighten upper and lower fixings to

37

Nm (27 lbf/ft).

10.Fit road wheels, remove chassis stands and

jack. Tighten wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

Page 288 of 455

BRAKES

7

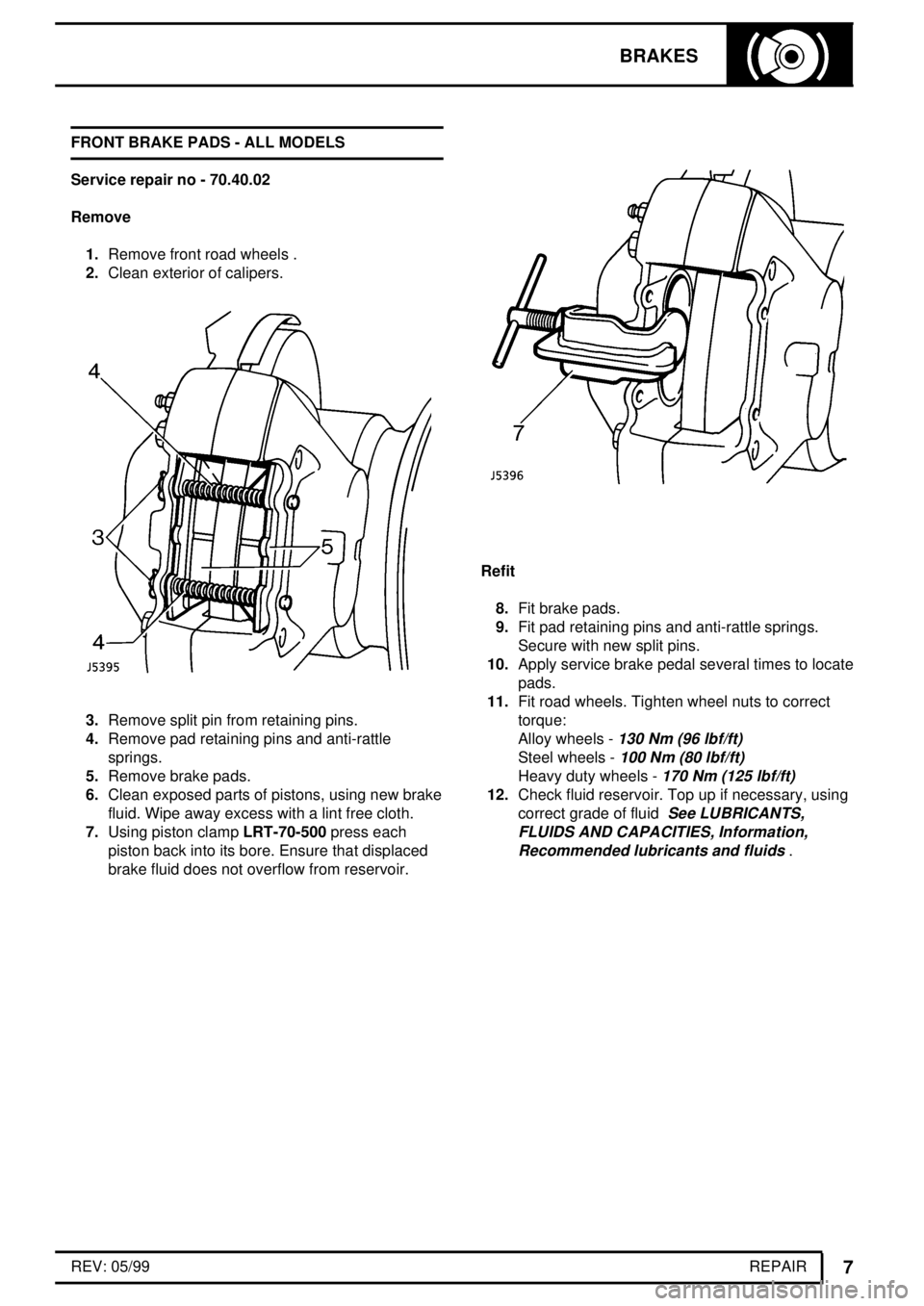

REPAIR REV: 05/99 FRONT BRAKE PADS - ALL MODELS

Service repair no - 70.40.02

Remove

1.Remove front road wheels .

2.Clean exterior of calipers.

3.Remove split pin from retaining pins.

4.Remove pad retaining pins and anti-rattle

springs.

5.Remove brake pads.

6.Clean exposed parts of pistons, using new brake

fluid. Wipe away excess with a lint free cloth.

7.Using piston clampLRT-70-500press each

piston back into its bore. Ensure that displaced

brake fluid does not overflow from reservoir.

Refit

8.Fit brake pads.

9.Fit pad retaining pins and anti-rattle springs.

Secure with new split pins.

10.Apply service brake pedal several times to locate

pads.

11.Fit road wheels. Tighten wheel nuts to correct

torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

12.Check fluid reservoir. Top up if necessary, using

correct grade of fluid

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended lubricants and fluids

.

Page 289 of 455

70BRAKES

8

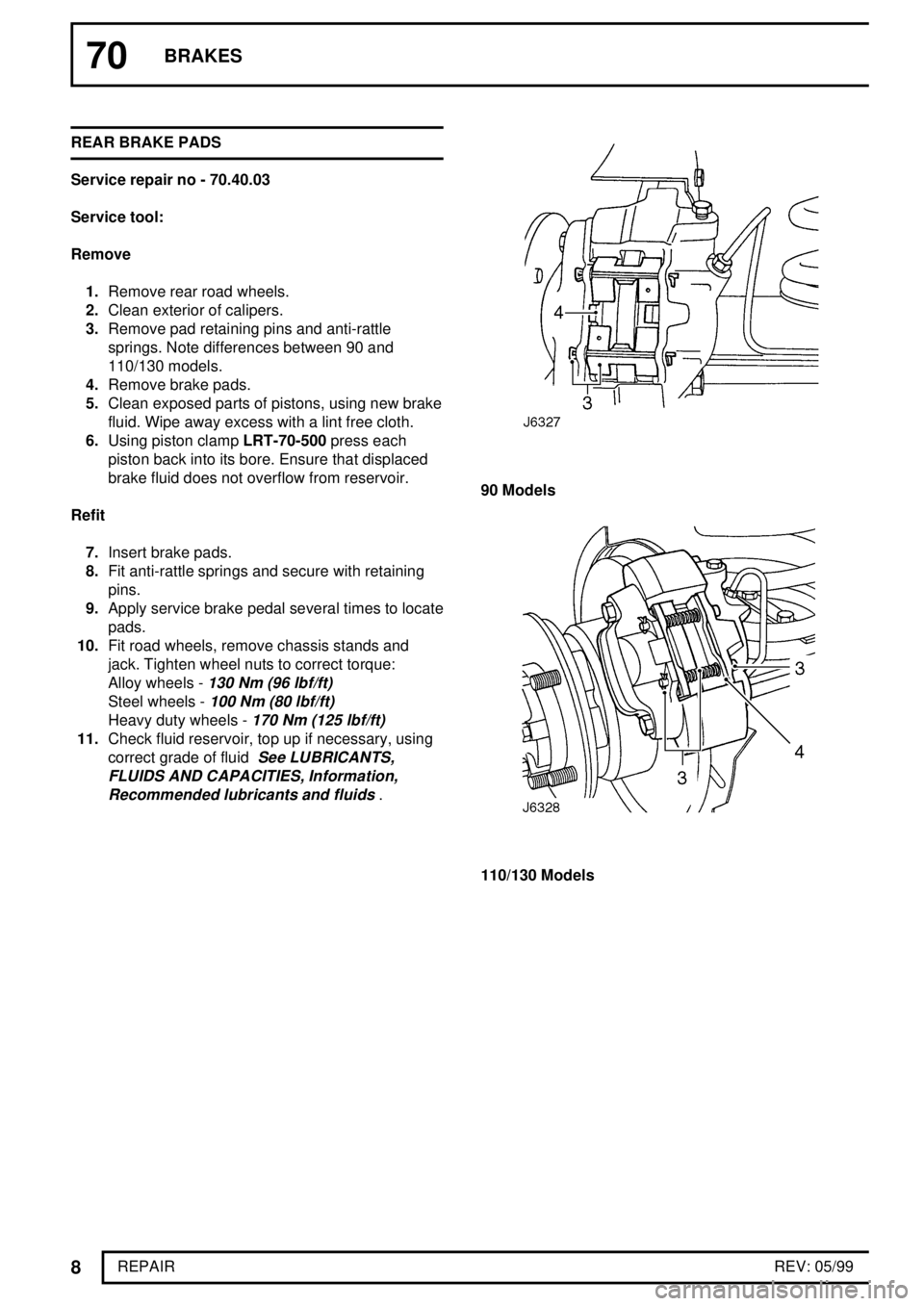

REPAIRREV: 05/99 REAR BRAKE PADS

Service repair no - 70.40.03

Service tool:

Remove

1.Remove rear road wheels.

2.Clean exterior of calipers.

3.Remove pad retaining pins and anti-rattle

springs. Note differences between 90 and

110/130 models.

4.Remove brake pads.

5.Clean exposed parts of pistons, using new brake

fluid. Wipe away excess with a lint free cloth.

6.Using piston clampLRT-70-500press each

piston back into its bore. Ensure that displaced

brake fluid does not overflow from reservoir.

Refit

7.Insert brake pads.

8.Fit anti-rattle springs and secure with retaining

pins.

9.Apply service brake pedal several times to locate

pads.

10.Fit road wheels, remove chassis stands and

jack. Tighten wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

11.Check fluid reservoir, top up if necessary, using

correct grade of fluid

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended lubricants and fluids

.

90 Models

110/130 Models

Page 292 of 455

BRAKES

11

REPAIR REV: 05/99 Assemble outboard pistons

13.Coat new fluid seal with brake fluid. Ease seal

into groove in bore using only fingers, ensuring it

is properly seated. Fluid seal and groove are not

same in section, so when seal is seated it feels

raised to touch at edge furthest away from

mouth of bore.

14.Coat appropriate piston with brake fluid. Insert it

squarely into bore by hand only. Do not tilt piston

during insertion, leave approximately 8mm

projecting from bore.

15.Coat new wiper seal with brake fluid and fit to

new seal retainer. Slide assembly, seal first, over

protruding piston and into bore recess. Use

piston clamp to press home seal retainer and

piston.

Mounting inboard pistons

16.Clamp outboard pistons and carry out same

procedure for removing and fitting outboard

pistons and seals, instructions 8 to 15.

Fit calipers and pads

17.Fit caliper, tighten bolts evenly to

82 Nm (60

lbf/ft).

18.Connect brake flexible hoses to caliper. Tighten

to

15 Nm (11 lbf/ft).

19.Remove hose clamps.

20.Insert pads. Fit pins and springs, secure using

new split pin.

21.Bleed brake system

See Brake System Bleed

.

22.Press brake pedal firmly several times to locate

friction pads.

23.Fit road wheels, remove axle stands. Finally

tighten road wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

24.Road test vehicle. Note that new friction pads

require 'bedding-in', this may take several

hundred miles before brakes are at maximum

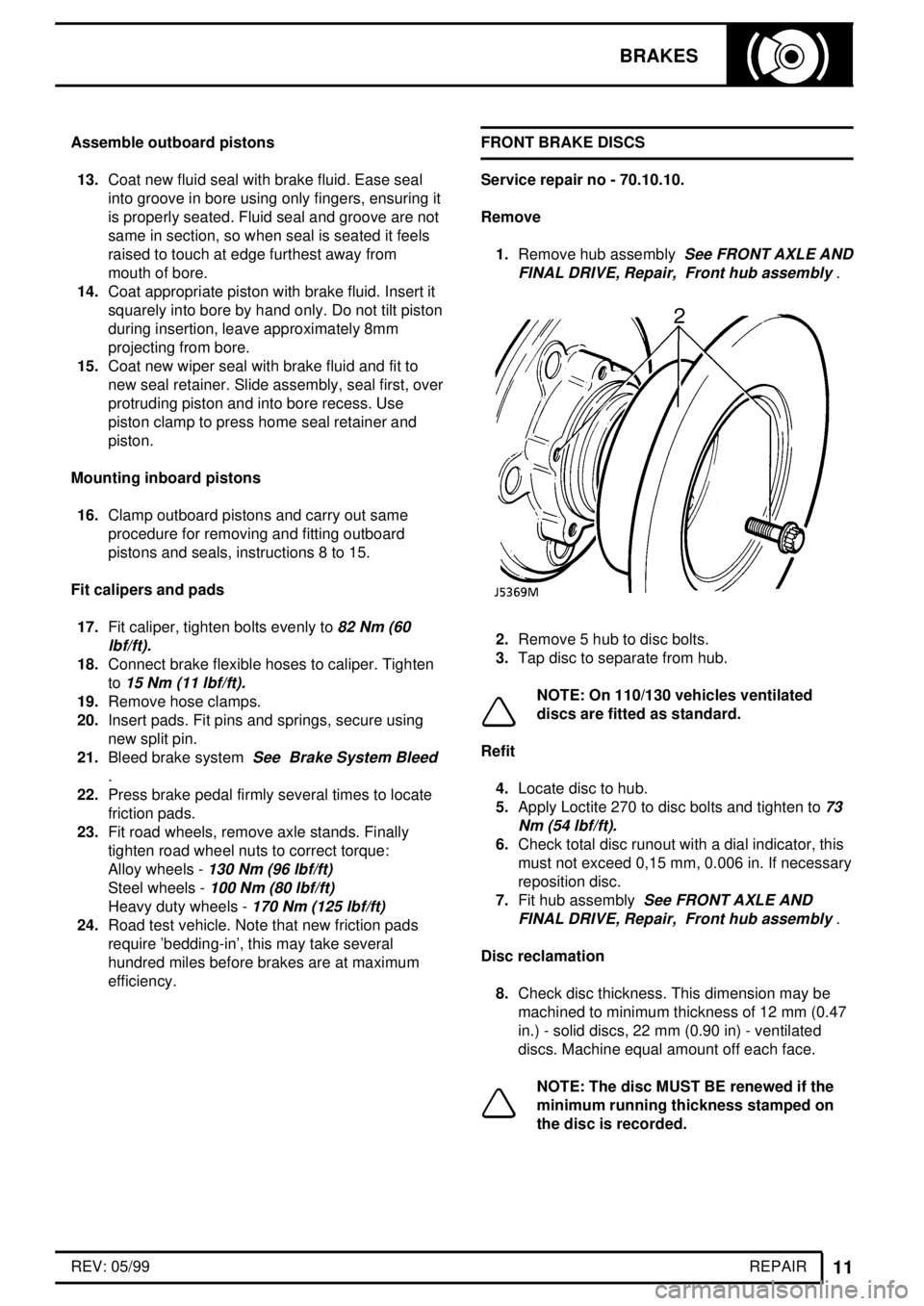

efficiency.FRONT BRAKE DISCS

Service repair no - 70.10.10.

Remove

1.Remove hub assembly

See FRONT AXLE AND

FINAL DRIVE, Repair, Front hub assembly

.

2.Remove 5 hub to disc bolts.

3.Tap disc to separate from hub.

NOTE: On 110/130 vehicles ventilated

discs are fitted as standard.

Refit

4.Locate disc to hub.

5.Apply Loctite 270 to disc bolts and tighten to

73

Nm (54 lbf/ft).

6.Check total disc runout with a dial indicator, this

must not exceed 0,15 mm, 0.006 in. If necessary

reposition disc.

7.Fit hub assembly

See FRONT AXLE AND

FINAL DRIVE, Repair, Front hub assembly

.

Disc reclamation

8.Check disc thickness. This dimension may be

machined to minimum thickness of 12 mm (0.47

in.) - solid discs, 22 mm (0.90 in) - ventilated

discs. Machine equal amount off each face.

NOTE: The disc MUST BE renewed if the

minimum running thickness stamped on

the disc is recorded.

Page 295 of 455

70BRAKES

14

REPAIRREV: 05/99 15.Coat a new wiper seal with brake fluid and fit to

new seal retainer. Slide assembly, seal first, over

protruding piston into bore recess.

16.Using special toolLRT-70-500- piston clamp,

press home seal retainer and piston.

Mounting inboard piston

17.Carry out same procedure as for removing and

fitting outboard piston and seals, instructions 8 to

16.

Fit calipers and pads to vehicle

18.Fit caliper to axle, tighten 2 bolts evenly to

82

Nm (60 lbf/ft).

19.Connect brake pipe to caliper. Tighten to15 Nm

(11 lbf/ft).

20.Remove clamp from flexible brake hose.

21.Insert pads and retaining springs, secure in

position with new retaining pins and spread ends

or fit new split pins, depending on vehicle model.

Note correct position of retaining springs on 90

models.

22.Bleed brake system

See Brake System Bleed.

23.Press brake pedal firmly several times to locate

pads.

24.Fit road wheels, remove axle stands. Finally

tighten road wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

25.Road test vehicle. Note new brake pads require

'bedding-in', for several hundred miles before

brakes are at maximum efficiency.REAR BRAKE DISC

Service repair no - 70.10.11.

Remove

1.Remove rear hub assembly

See REAR AXLE

AND FINAL DRIVE, Repair, Rear hub

assembly

.

2.Remove disc bolts.

3.Remove disc from rear hub.

Refit

4.Fit disc to rear hub.

5.Fit disc bolts. Tighten to

73 Nm (54 lbf/ft).

6.Check total disc run out, this must not exceed

0,15 mm (0.006 in). If necessary reposition disc.

7.Fit rear hub assembly

See REAR AXLE AND

FINAL DRIVE, Repair, Rear Hub Assembly

.

Disc reclamation

8.Check disc thickness. This dimension may be

machined to minimum thickness of 12 mm.

Machine equal amounts off each face.

NOTE: The brake disc MUST BE renewed if

the minimum running thickness stamped

on the disc is recorded.

Page 312 of 455

74WHEELS AND TYRES

6

REPAIRREV: 05/99 WHEELS

Remove

WARNING: The parking brake acts on

transmission, not rear wheels, and may

not hold vehicle when jacking unless

following procedure is used. If one front wheel

and one rear wheel is raised no vehicle holding or

braking effect is possible. Wheels MUST be

chocked in all circumstances.

Apply parking brake, select a gear in main

gearbox and engage low gear in transfer box.

1.Loosen 5 wheel nuts.

2.Using a suitable trolley jack, raise vehicle and

place on axle stands

See INTRODUCTION,

Information, Jacking

.

3.Remove wheel nuts and carefully withdraw

wheel over studs.

Refit

4.Ensure that retaining studs and nuts are clean.

5.Alloy wheels: Lightly coat wheel mounting spigot

face with a suitable anti-seize compound to

minimise possibility of adhesion between wheel

and spigot face.

6.Refit wheel taking care not to damage stud

threads. (Do not apply oil).

7.Fit wheel nuts and turn by hand for at least three

full threads before using any form of wheel

wrench.

8.Tighten nuts as much as possible using a

suitable wrench.

9.Lower vehicle and finally tighten nuts to correct

torque sequence shown.

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

Page 407 of 455

WIPERS AND WASHERS

7

REPAIR Refit

NOTE: During reassembly all fixings

related to wiper motor and wheelboxes are

finger tightened only, until all components

are correctly aligned.

12.Fit wheelboxes to bulkhead and secure with

retaining nuts and washers.

13.Fit drive rack tubes to wheelboxes.

14.Apply grease to drive rack and wheelboxes.

15.Align wiper motor and mounting pad, secure with

retaining strap and tighten drive tube nut.

16.Fully tighten wheelbox back plate nuts.

17.Fully tighten both wheelbox spindle nuts.

18.Fit wiper arm adaptors and secure with grub

screw.

19.Before refitting panels fit wiper blades, connect

multi-plug and earth lead, reconnect battery and

check wiper operation.

20.If satisfactory, secure steering column upper and

lower fixings and tighten to correct torque.

21.Fit ventilator grille panel, fascia crash pad,

instrument housing and all other components

removed to gain access to wiper motor and

wheelboxes.