LAND ROVER DEFENDER 1996 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 381 of 455

82AIR CONDITIONING

6

ADJUSTMENT SYSTEM TEST

1.Place the vehicle in a ventilated, shaded area

free from excessive draught, with the doors and

windows open.

2.Check that the surface of the condenser is not

restricted with dirt, leaves, flies, etc. Do not

neglect to check the surface between the

condenser and the radiator. Clean as necessary.

3.Switch on the ignition and the air conditioner air

flow control. Check that the blower is operating

efficiently at low, medium and high speeds.

Switch off the blower and the ignition.

4.Check that the evaporator condensate drain

tubes are open and clear.

5.Check the tension of the compressor driving belt,

and adjust if necessary.

6.Inspect all connections for the presence of

refrigerant oil. If oil is evident, check for leaks,

and repair as necessary.

NOTE: The compressor oil is soluble in

Refrigerant R134a and is deposited when

the refrigerant evaporates from a leak.

7.Start the engine.

8.Set the temperature controls to cold and switch

the air conditioner blower control on and off

several times, checking that the magnetic clutch

on the compressor engages and releases each

time.

9.With the temperature control at maximum

cooling and the blower control at high speed,

warm up the engine and fast idle at 1000

rev/min.

10.Repeat at 1800 rev/min.

11.Gradually increase the engine speed to the high

range and check the sight glass at intervals.

12.Check for frosting on the service valves.

13.Check the high pressure hoses and connections

by hand for varying temperature. Low

temperature indicates a restriction or blockage at

that point.

14.Switch off the air conditioning blower and stop

the engine.

15.If the air conditioning equipment is still not

satisfactory, carry out a pressure test as

previously described in this section.PRECAUTIONS IN HANDLING REFRIGERANT

LINES

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

1.When disconnecting any hose or pipe

connection the system must be discharged of all

pressure. Proceed cautiously, regardless of

gauge readings. Open connections slowly,

keeping hands and face well clear, so that no

injury occurs if there is liquid in the line. If

pressure is noticed, allow it to bleed off slowly.

2.Lines, flexible end connections and components

must be capped immediately they are opened to

prevent the entrance of moisture and dirt.

3.Any dirt or grease on fittings must be wiped off

with a clean alcohol dampened cloth. Do not use

chlorinated solvents such as trichloroethylene. If

dirt, grease or moisture cannot be removed from

inside the hoses, they must be replaced with

new hoses.

4.All replacement components and flexible end

connections must be sealed, and only opened

immediately prior to making the connection.

5.Ensure the components are at room temperature

before uncapping, to prevent condensation of

moisture from the air that enters.

6.Components must not remain uncapped for

longer than 15 minutes. In the event of delay, the

caps must be fitted.

7.Receiver/driers must never be left uncapped as

they contain Silica Gel crystals which will absorb

moisture from the atmosphere. A receiver/ drier

left uncapped must not be used, fit a new unit.

8.The compressor shaft must not be rotated until

the system is entirely assembled and contains a

charge of refrigerant.

9.A new compressor contains an initial charge of

refrigerant oil. The compressor also contains a

holding charge of gas when received which

should be retained by leaving the seals in place

until the pipes are re-connected.

10.The receiver/drier should be the last component

connected to the system to ensure optimum

dehydration and maximum moisture protection of

the system.

Page 382 of 455

AIR CONDITIONING

7

ADJUSTMENT 11.All precautions must be taken to prevent

damage to fittings and connections. Slight

damage could cause a leak with the high

pressures used in the system.

12.Always use two wrenches of the correct size,

one on each fitting when releasing and

tightening refrigeration unions.

13.Joints and 'O' rings should be coated with

refrigeration oil to aid correct seating. Fittings

which are not lubricated with refrigerant oil are

almost certain to leak.

14.All lines must be free of kinks. The efficiency of

the system is reduced by a single kink or

restriction.

15.Flexible hoses should not be bent to a radius

less than 90mm radius.

16.Flexible hoses should not be within 100mm of

the exhaust manifold.

17.Completed assemblies must be checked for

refrigeration lines touching metal panels. Any

direct contact of lines and panels transmits noise

and must be eliminated.PERIODIC MAINTENANCE

Routine servicing, apart from visual checks, is not

necessary. The visual inspections are as follows:

Condenser

With a water hose or air line, clean the fins of the

condenser to remove flies, leaves, etc. Check the pipe

connections for signs of oil leakage.

Compressor

Check pipe connections for signs of oil leakage.

Check flexible hoses for swelling. Examine the

compressor belt for tightness and condition.

Sight glass

Examine the sight glass for bubbles with the system

operating. Check connections for leakage.

Evaporator

Examine the refrigeration connections at the unit.

Page 383 of 455

AIR CONDITIONING

1

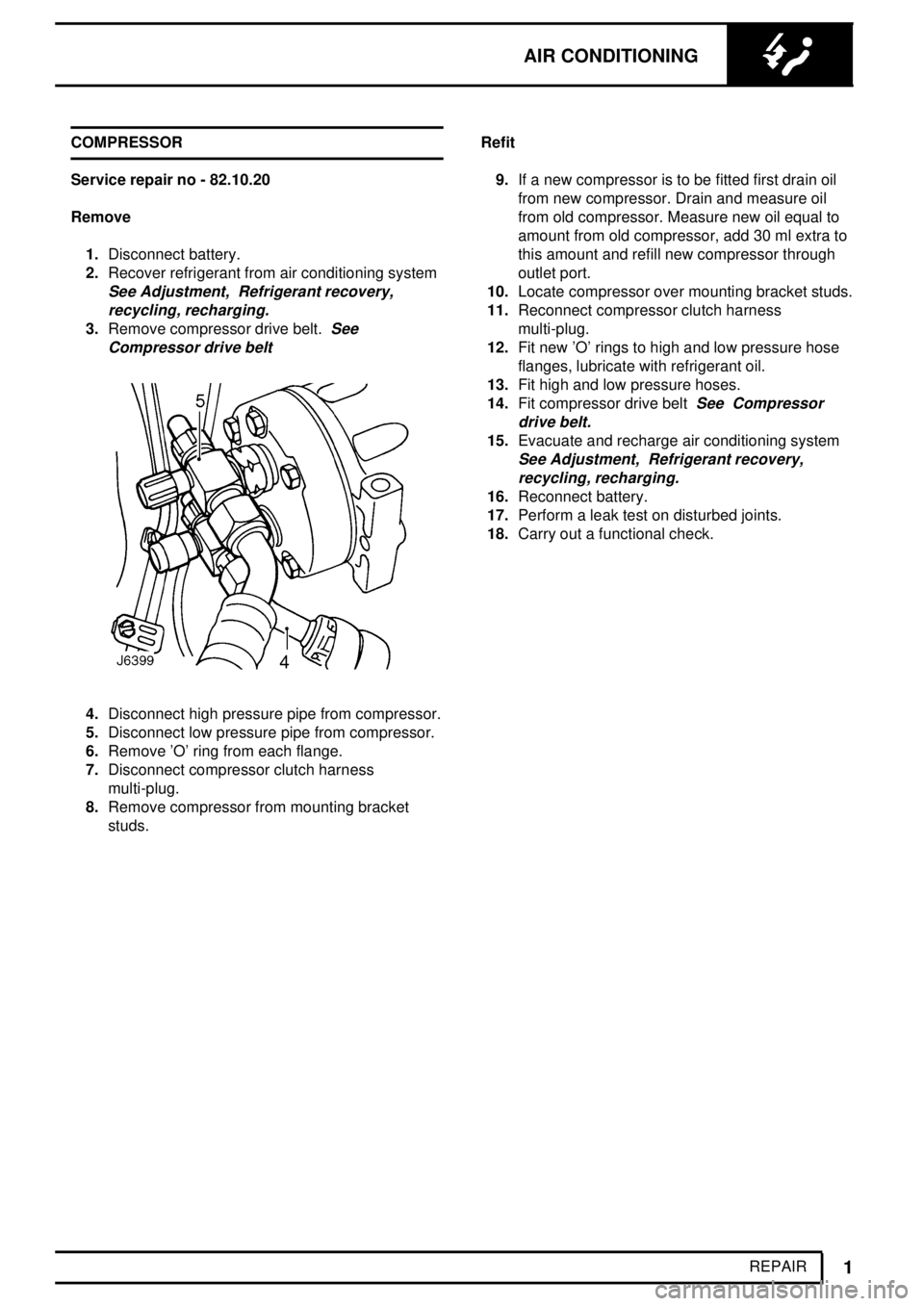

REPAIR COMPRESSOR

Service repair no - 82.10.20

Remove

1.Disconnect battery.

2.Recover refrigerant from air conditioning system

See Adjustment, Refrigerant recovery,

recycling, recharging.

3.Remove compressor drive belt.See

Compressor drive belt

4.Disconnect high pressure pipe from compressor.

5.Disconnect low pressure pipe from compressor.

6.Remove 'O' ring from each flange.

7.Disconnect compressor clutch harness

multi-plug.

8.Remove compressor from mounting bracket

studs.Refit

9.If a new compressor is to be fitted first drain oil

from new compressor. Drain and measure oil

from old compressor. Measure new oil equal to

amount from old compressor, add 30 ml extra to

this amount and refill new compressor through

outlet port.

10.Locate compressor over mounting bracket studs.

11.Reconnect compressor clutch harness

multi-plug.

12.Fit new 'O' rings to high and low pressure hose

flanges, lubricate with refrigerant oil.

13.Fit high and low pressure hoses.

14.Fit compressor drive belt

See Compressor

drive belt.

15.Evacuate and recharge air conditioning system

See Adjustment, Refrigerant recovery,

recycling, recharging.

16.Reconnect battery.

17.Perform a leak test on disturbed joints.

18.Carry out a functional check.

Page 384 of 455

82AIR CONDITIONING

2

REPAIR COMPRESSOR DRIVE BELT

Service repair no - 82.10.02

Remove

1.Disconnect battery.

2.Remove auxiliary drive belt

See ELECTRICAL,

Repair, Auxiliary drive belt.

3.Remove 3 nuts securing drive belt guard to

compressor retaining studs.

4.Slacken 3 belt tensioner retaining bolts.

5.Remove compressor drive belt. Mark direction

on belt if refitting.Refit

6.Fit compressor drive belt.

7.Fit drive belt guard.

8.Fit torque meter to centre of tensioner, apply and

hold a torque of

35 Nm (26 lbf/ft).

9.Tighten tensioner retaining bolts.

10.Rotate crankshaft 2 full turns.

11.Reapply and hold a torque of

35 Nm (26 lbf/ft)

to tensioner, then fully slacken and retighten

tensioner retaining bolts to

25 Nm (18 lbf/ft).

12.Fit auxiliary drive beltSee ELECTRICAL,

Repair, Auxiliary drive belt.

13.Reconnect battery.

Page 385 of 455

AIR CONDITIONING

3

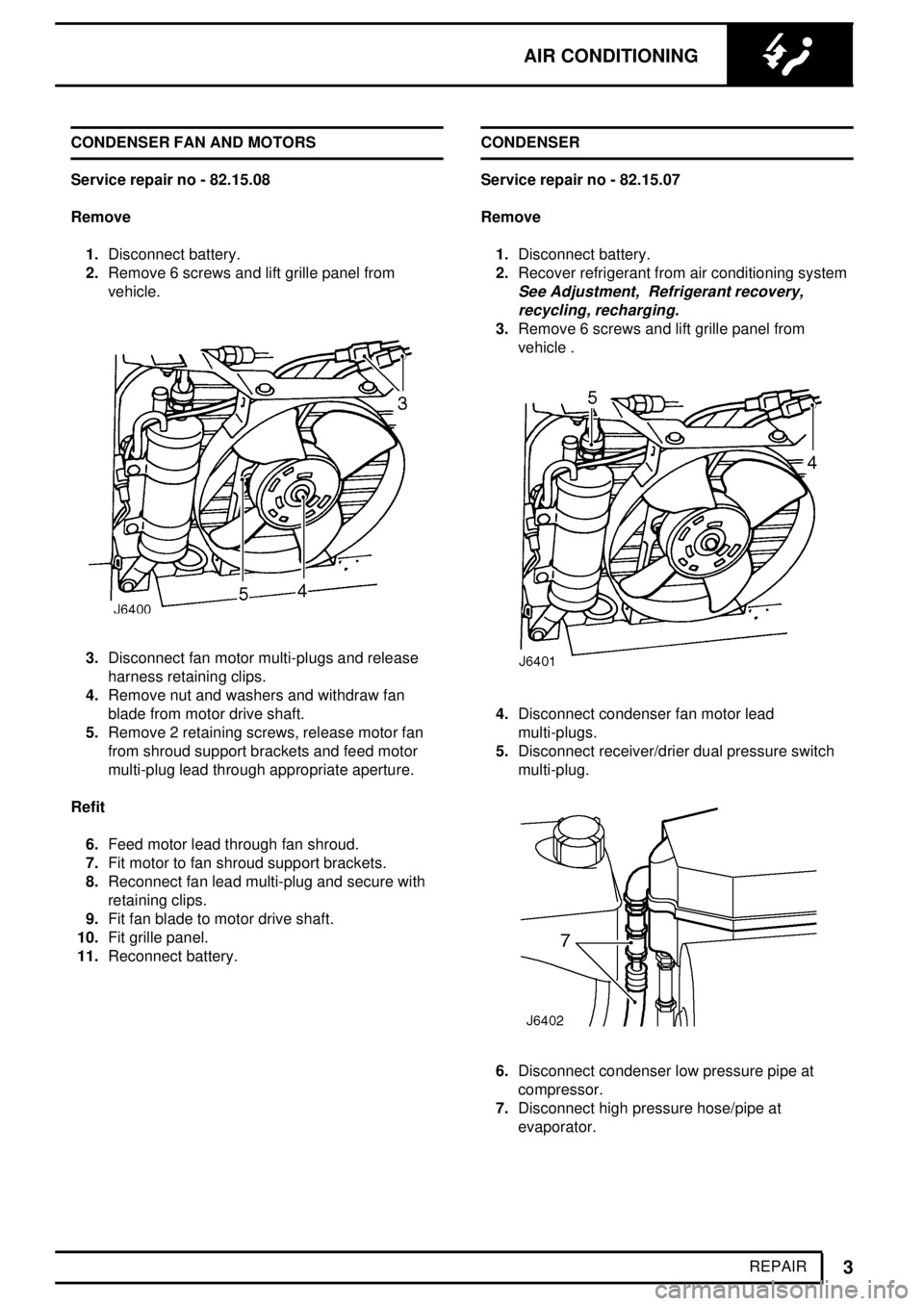

REPAIR CONDENSER FAN AND MOTORS

Service repair no - 82.15.08

Remove

1.Disconnect battery.

2.Remove 6 screws and lift grille panel from

vehicle.

3.Disconnect fan motor multi-plugs and release

harness retaining clips.

4.Remove nut and washers and withdraw fan

blade from motor drive shaft.

5.Remove 2 retaining screws, release motor fan

from shroud support brackets and feed motor

multi-plug lead through appropriate aperture.

Refit

6.Feed motor lead through fan shroud.

7.Fit motor to fan shroud support brackets.

8.Reconnect fan lead multi-plug and secure with

retaining clips.

9.Fit fan blade to motor drive shaft.

10.Fit grille panel.

11.Reconnect battery.CONDENSER

Service repair no - 82.15.07

Remove

1.Disconnect battery.

2.Recover refrigerant from air conditioning system

See Adjustment, Refrigerant recovery,

recycling, recharging.

3.Remove 6 screws and lift grille panel from

vehicle .

4.Disconnect condenser fan motor lead

multi-plugs.

5.Disconnect receiver/drier dual pressure switch

multi-plug.

6.Disconnect condenser low pressure pipe at

compressor.

7.Disconnect high pressure hose/pipe at

evaporator.

Page 386 of 455

82AIR CONDITIONING

4

REPAIR

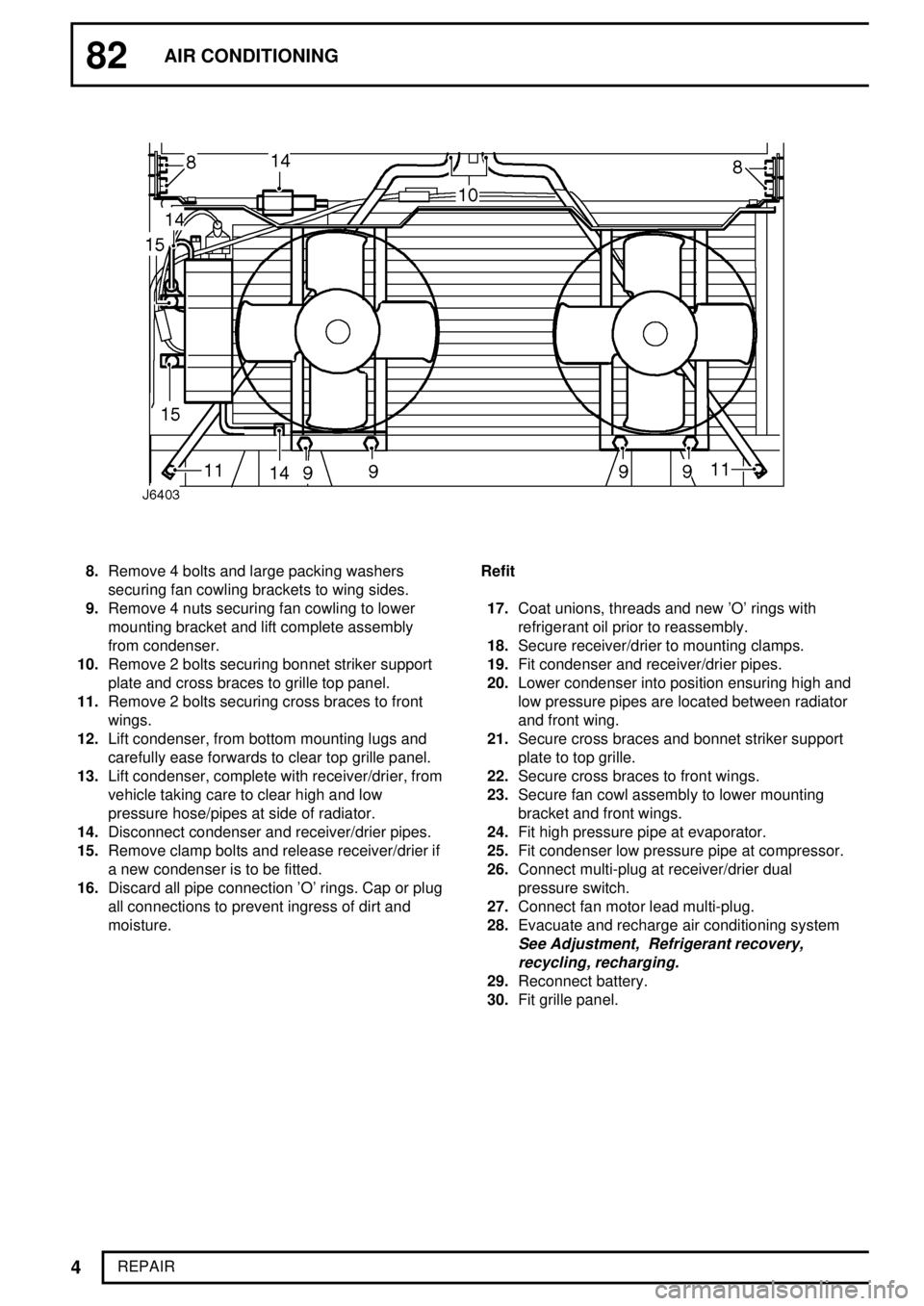

8.Remove 4 bolts and large packing washers

securing fan cowling brackets to wing sides.

9.Remove 4 nuts securing fan cowling to lower

mounting bracket and lift complete assembly

from condenser.

10.Remove 2 bolts securing bonnet striker support

plate and cross braces to grille top panel.

11.Remove 2 bolts securing cross braces to front

wings.

12.Lift condenser, from bottom mounting lugs and

carefully ease forwards to clear top grille panel.

13.Lift condenser, complete with receiver/drier, from

vehicle taking care to clear high and low

pressure hose/pipes at side of radiator.

14.Disconnect condenser and receiver/drier pipes.

15.Remove clamp bolts and release receiver/drier if

a new condenser is to be fitted.

16.Discard all pipe connection 'O' rings. Cap or plug

all connections to prevent ingress of dirt and

moisture.Refit

17.Coat unions, threads and new 'O' rings with

refrigerant oil prior to reassembly.

18.Secure receiver/drier to mounting clamps.

19.Fit condenser and receiver/drier pipes.

20.Lower condenser into position ensuring high and

low pressure pipes are located between radiator

and front wing.

21.Secure cross braces and bonnet striker support

plate to top grille.

22.Secure cross braces to front wings.

23.Secure fan cowl assembly to lower mounting

bracket and front wings.

24.Fit high pressure pipe at evaporator.

25.Fit condenser low pressure pipe at compressor.

26.Connect multi-plug at receiver/drier dual

pressure switch.

27.Connect fan motor lead multi-plug.

28.Evacuate and recharge air conditioning system

See Adjustment, Refrigerant recovery,

recycling, recharging.

29.Reconnect battery.

30.Fit grille panel.

Page 387 of 455

AIR CONDITIONING

5

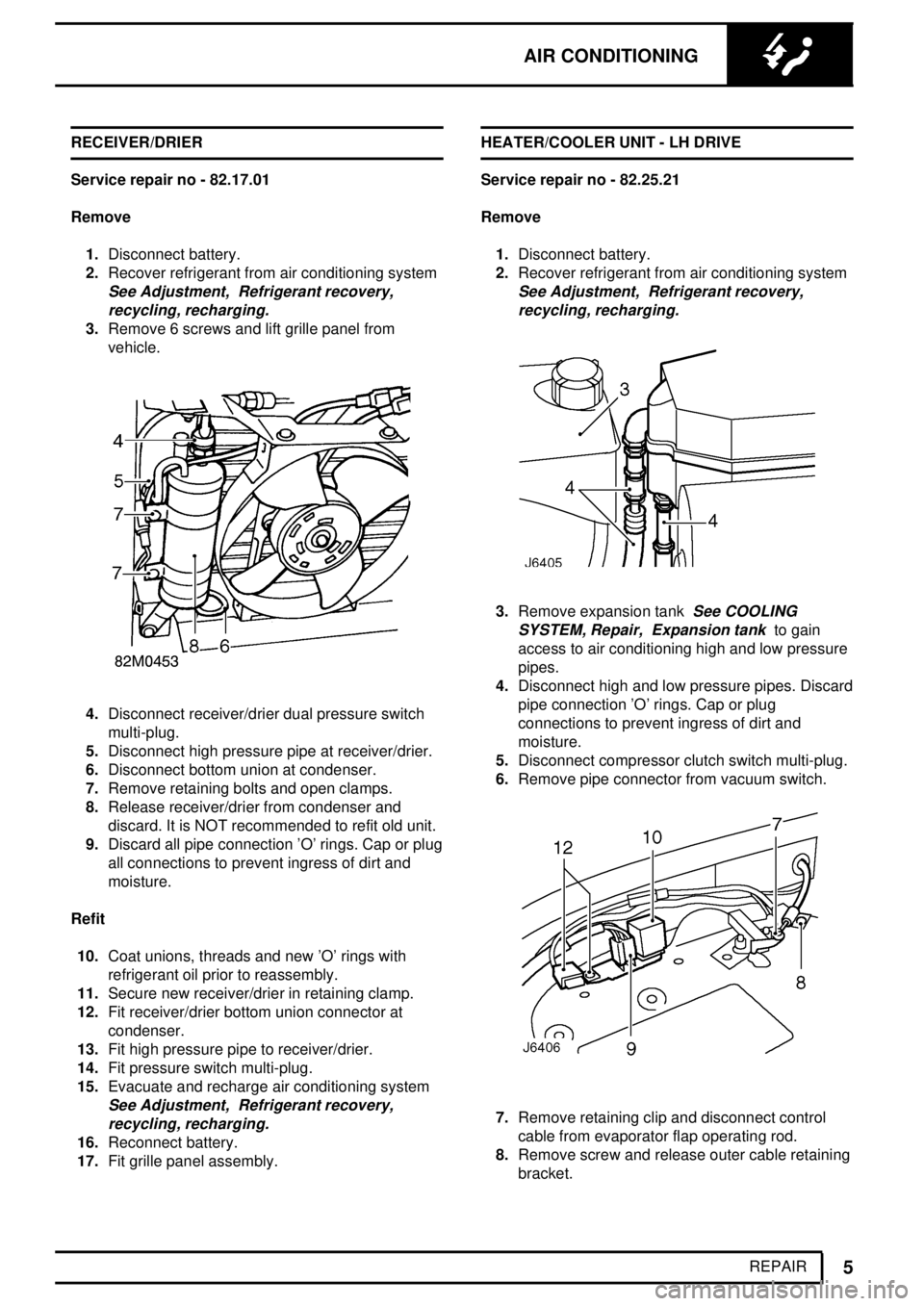

REPAIR RECEIVER/DRIER

Service repair no - 82.17.01

Remove

1.Disconnect battery.

2.Recover refrigerant from air conditioning system

See Adjustment, Refrigerant recovery,

recycling, recharging.

3.Remove 6 screws and lift grille panel from

vehicle.

4.Disconnect receiver/drier dual pressure switch

multi-plug.

5.Disconnect high pressure pipe at receiver/drier.

6.Disconnect bottom union at condenser.

7.Remove retaining bolts and open clamps.

8.Release receiver/drier from condenser and

discard. It is NOT recommended to refit old unit.

9.Discard all pipe connection 'O' rings. Cap or plug

all connections to prevent ingress of dirt and

moisture.

Refit

10.Coat unions, threads and new 'O' rings with

refrigerant oil prior to reassembly.

11.Secure new receiver/drier in retaining clamp.

12.Fit receiver/drier bottom union connector at

condenser.

13.Fit high pressure pipe to receiver/drier.

14.Fit pressure switch multi-plug.

15.Evacuate and recharge air conditioning system

See Adjustment, Refrigerant recovery,

recycling, recharging.

16.Reconnect battery.

17.Fit grille panel assembly.HEATER/COOLER UNIT - LH DRIVE

Service repair no - 82.25.21

Remove

1.Disconnect battery.

2.Recover refrigerant from air conditioning system

See Adjustment, Refrigerant recovery,

recycling, recharging.

3.Remove expansion tankSee COOLING

SYSTEM, Repair, Expansion tank

to gain

access to air conditioning high and low pressure

pipes.

4.Disconnect high and low pressure pipes. Discard

pipe connection 'O' rings. Cap or plug

connections to prevent ingress of dirt and

moisture.

5.Disconnect compressor clutch switch multi-plug.

6.Remove pipe connector from vacuum switch.

7.Remove retaining clip and disconnect control

cable from evaporator flap operating rod.

8.Remove screw and release outer cable retaining

bracket.

Page 388 of 455

82AIR CONDITIONING

6

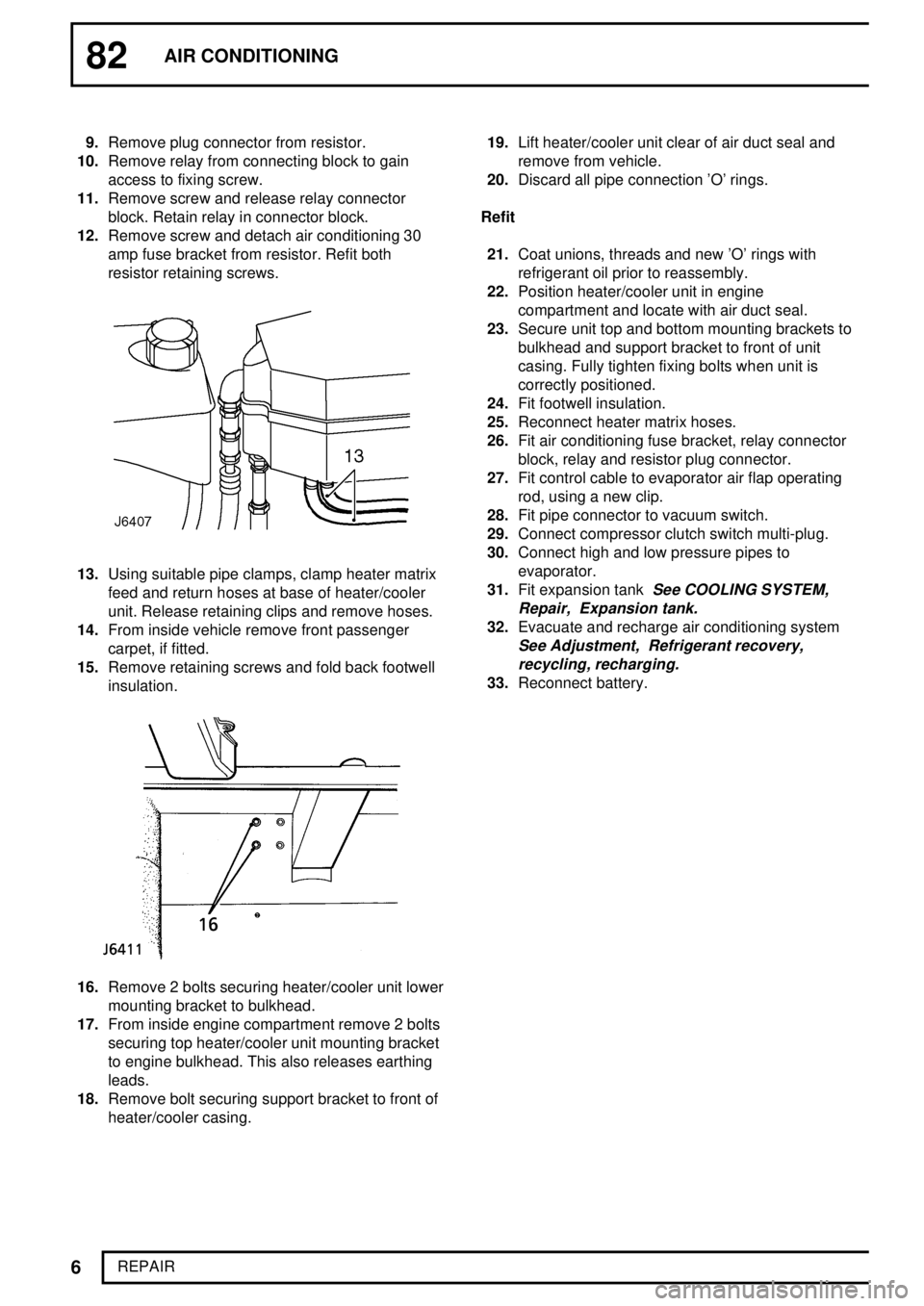

REPAIR 9.Remove plug connector from resistor.

10.Remove relay from connecting block to gain

access to fixing screw.

11.Remove screw and release relay connector

block. Retain relay in connector block.

12.Remove screw and detach air conditioning 30

amp fuse bracket from resistor. Refit both

resistor retaining screws.

13.Using suitable pipe clamps, clamp heater matrix

feed and return hoses at base of heater/cooler

unit. Release retaining clips and remove hoses.

14.From inside vehicle remove front passenger

carpet, if fitted.

15.Remove retaining screws and fold back footwell

insulation.

16.Remove 2 bolts securing heater/cooler unit lower

mounting bracket to bulkhead.

17.From inside engine compartment remove 2 bolts

securing top heater/cooler unit mounting bracket

to engine bulkhead. This also releases earthing

leads.

18.Remove bolt securing support bracket to front of

heater/cooler casing.19.Lift heater/cooler unit clear of air duct seal and

remove from vehicle.

20.Discard all pipe connection 'O' rings.

Refit

21.Coat unions, threads and new 'O' rings with

refrigerant oil prior to reassembly.

22.Position heater/cooler unit in engine

compartment and locate with air duct seal.

23.Secure unit top and bottom mounting brackets to

bulkhead and support bracket to front of unit

casing. Fully tighten fixing bolts when unit is

correctly positioned.

24.Fit footwell insulation.

25.Reconnect heater matrix hoses.

26.Fit air conditioning fuse bracket, relay connector

block, relay and resistor plug connector.

27.Fit control cable to evaporator air flap operating

rod, using a new clip.

28.Fit pipe connector to vacuum switch.

29.Connect compressor clutch switch multi-plug.

30.Connect high and low pressure pipes to

evaporator.

31.Fit expansion tank

See COOLING SYSTEM,

Repair, Expansion tank.

32.Evacuate and recharge air conditioning system

See Adjustment, Refrigerant recovery,

recycling, recharging.

33.Reconnect battery.

Page 389 of 455

AIR CONDITIONING

7

REPAIR EVAPORATOR - LH DRIVE

Service repair no - 82.25.20

Remove

1.Remove heater/cooler unit

See Heater/cooler

unit.

2.Suitably support unit on a bench to prevent

damage to heater matrix pipes.

3.Release 3 nuts and remove mounting bracket

from underneath unit casing.

4.Remove 7 screws securing outlet duct to

heater/cooler unit.

5.Carefully break sealing compound around edge

of duct and pull ducting from unit.

6.Remove 15 screws located around cover seam.

Break sealing compound from unit body and top

cover.

7.Remove 4 screws and 4 nuts from top of cover.

8.From front of unit remove 2 screws adjacent to

low pressure pipe moulding.

9.At side of unit remove 2 screws adjacent to air

intake aperture.

10.Lift off top cover, release grommet and feed

blower motor wiring and air control flap rod

through respective apertures. Note thermostat

temperature probe which is inserted in

evaporator matrix through top cover.

11.Lift support plate and insulation pad from heater

matrix.

12.From bottom of unit casing, remove 3 screws

adjacent to dump valve outlet, and screws next

to heater matrix pipes.

Page 390 of 455

82AIR CONDITIONING

8

REPAIR

13.Remove all other fixings securing evaporator

and heater matrix support frame to unit casing.

14.Lift evaporator and heater matrices, complete

with support frame assembly, clear of casing.

Retain heater matrix pipe seal pad.

15.Remove 4 screws securing evaporator matrix to

support frame.

16.Withdraw evaporator matrix, complete with

expansion valve, from support frame.

17.Clean sealing compound from all joints of main

casing, top cover and outlet duct.

NOTE: The evaporator matrix is supplied

complete with the expansion valve.

However, a faulty expansion valve can be

serviced separately,

See Expansion valve.

Refit

18.Fit evaporator matrix in support frame.

19.Fit evaporator, heater matrix and support frame

assembly in casing. Ensure studs for lower

mounting bracket are located through bottom of

casing.

20.Apply mastic sealant around heater matrix pipes

to seal pipe apertures in casing. Fit seal pad

over pipes.

21.Fit 3 bottom fixings to secure to secure base of

support frame.

22.Fit all other fixings to secure support frame

assembly.

23.Locate heater matrix insulation pad and cover

plate.

24.Apply sealng compound around top edge of

main casing.

25.Feed blower motor wiring through top cover and

fit grommet.

26.Fit top cover to casing. Ensure thermostat

temperature probe is inserted in top of

evaporator. Apply mastic sealant to air flap

operating rod aperture.

27.Apply sealing compound to joint face of blower

motor outlet duct.

28.Locate duct over blower motor outlet and secure

to casing.

29.Secure lower mounting bracket to retaining studs

on base of main casing.

30.Fit heater/cooler unit assembly in engine

compartment

See Heater/cooler unit.