light LAND ROVER DEFENDER 1996 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 424 of 455

86ELECTRICAL

12

DESCRIPTION AND OPERATION VEHICLE ALARM SYSTEM BUILT-IN TEST

NOTE: The handset should be detached

from the key to allow perimetric testing of

the alarm system. The system will

automatically switch to volumetric testing if the

handset is in close proximity to the starter switch.

The built-in test procedure can be accessed providing

the following conditions exist:

Alarm disarmed.

Ignition 'off'.

Doors unlocked.

Bonnet closed.

With assistance, the test mode can be entered by

completing the following instructions within 5 seconds:

1.Open bonnet.

2.Turn starter switch 'on'.

3.Open driver's door (far enough to activate door

switch).

4.Turn starter switch 'off'.

5.Turn starter switch 'on'.

If the test mode has been correctly accessed, the

alarm sounder/horn will operate briefly and the

anti-theft alarm indicator and direction indicator lamps

will flash.

Perimetric tests

The anti-theft alarm indicator light and direction

indicator lamps will flash when:

1.Door switches are activated.

2.The bonnet is opened.

3.Key switches are activated.Volumetric tests

Press the LH (unlock) button or move the handset

close to the starter switch to disable perimetric testing

and enable volumetric testing. If movement is

detected within the vehicle by the ultrasonic sensor

the anti-theft alarm indicator and direction indicator

lamps will illuminate.

NOTE: Exit the anti-theft alarm built-in test

by turning the starter switch to the 'off'

position.

If the previously described conditions are not achieved

during the built-in test procedure, this would indicate a

fault in the alarm system. Before undertaking detailed

fault diagnosis procedures, first make visual checks of

components such as a faulty door switch or blown

alarm system fuse.

Page 426 of 455

ELECTRICAL

1

REPAIR ELECTRICAL PRECAUTIONS

The following guidelines are intended to ensure the

safety of the operator whilst preventing damage to

electrical and electronic components fitted to the

vehicle.

Polarity

Never reverse connect the vehicle battery and always

observe the correct polarity when connecting test

equipment.

High voltage circuits

WARNING: Before commencing work on

an ignition system, all high tension

terminals, adaptors and diagnostic

equipment for testing should be inspected to

ensure that they are adequately insulated and

shielded to prevent accidental personal contacts

and minimize the risk of shock. Wearers of

surgically implanted pacemaker devices should

not be in close proximity to ignition circuits or

diagnostic equipment.

Whenever disconnecting live high tension circuits

always use insulated pliers and never allow the open

end of a high tension lead to come into contact with

other components particularly electronic control units.

Exercise caution when measuring the voltage on the

coil terminals while the engine is running, since, high

voltage spikes can occur on these terminals.

Connectors and harness

Always ensure that these items are dry and oil free

before disconnecting and connecting test equipment.

Never force connectors apart either by using tools or

by pulling on the wiring harness. Always ensure

locking tabs are disengaged before removal and note

orientation to enable correct reconnection. Ensure that

any protective covers and substances are replaced if

disturbed. Having confirmed a component to be faulty

switch-off the ignition and disconnect the battery.

Remove the component and support the disconnected

harness. When replacing the component keep oily

hands away from electrical connection areas and

push connectors home until any locking tabs fully

engage.Battery disconnecting

Before disconnecting the battery, switch off all

electrical equipment.

Battery charging

Recharge the battery out of the vehicle and keep the

top well ventilated. While being charged or

discharged, and for approximately 15 minutes

afterwards, batteries emit hydrogen gas which is

flammable. Always ensure any battery charging area

is well ventilated and that every precaution is taken to

avoid naked flames and sparks.

GENERAL PRECAUTIONS

Switch-off ignition prior to making any connection or

disconnection in the system as electrical surge

caused by disconnecting 'live' connections can

damage electronic components.

Ensure hands and work surfaces are clean and free of

grease, swarf, etc. as grease collects dirt which can

cause tracking or high-resistance contacts.

When handling printed circuit boards, treat them as

you would a disc - hold by the edges only.

Prior to commencing a test, and periodically during a

test, touch a good earth, for instance, a cigar lighter

socket, to discharge body static as some electronic

components are vulnerable to static electricity.

Page 428 of 455

ELECTRICAL

3

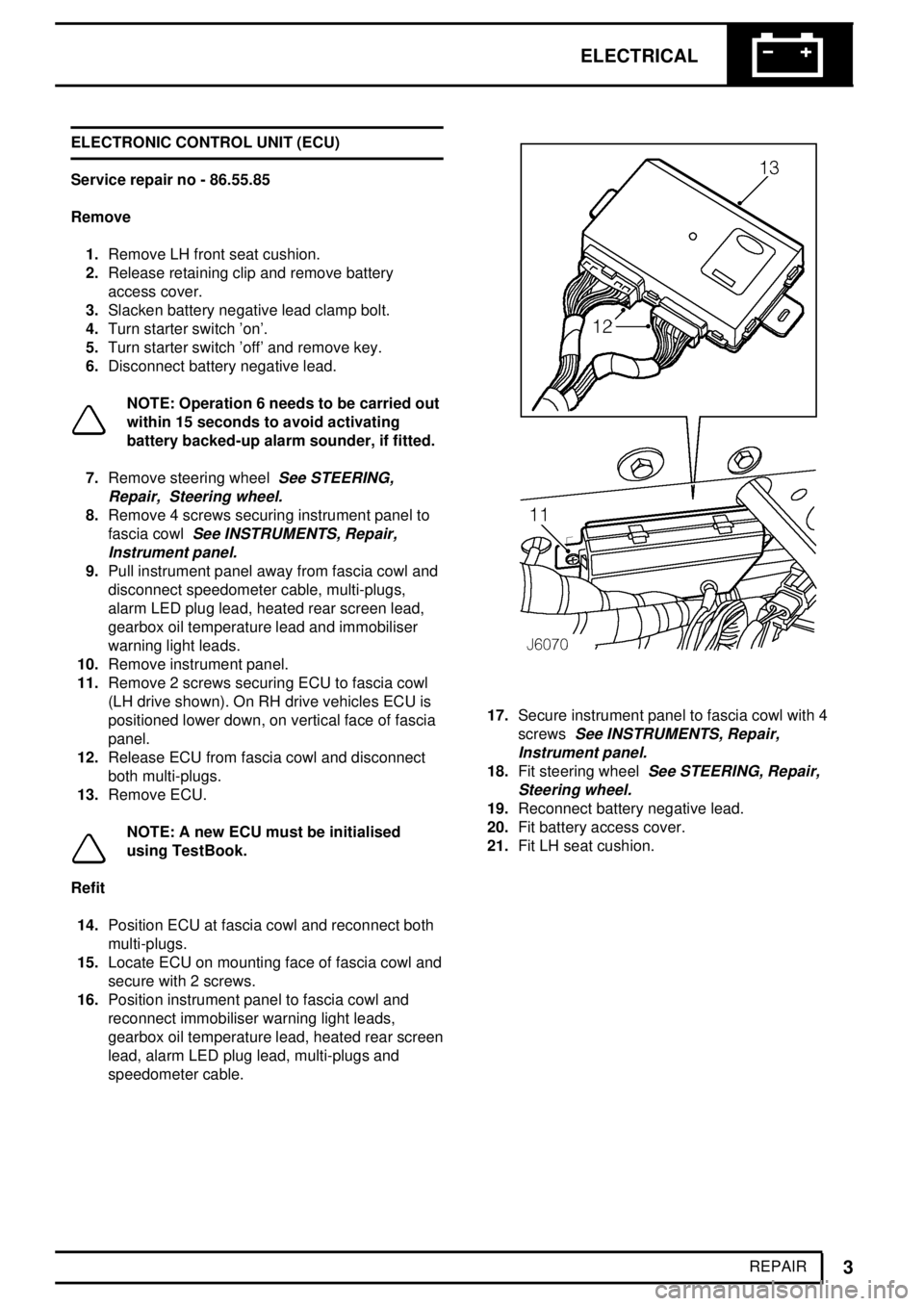

REPAIR ELECTRONIC CONTROL UNIT (ECU)

Service repair no - 86.55.85

Remove

1.Remove LH front seat cushion.

2.Release retaining clip and remove battery

access cover.

3.Slacken battery negative lead clamp bolt.

4.Turn starter switch 'on'.

5.Turn starter switch 'off' and remove key.

6.Disconnect battery negative lead.

NOTE: Operation 6 needs to be carried out

within 15 seconds to avoid activating

battery backed-up alarm sounder, if fitted.

7.Remove steering wheel

See STEERING,

Repair, Steering wheel.

8.Remove 4 screws securing instrument panel to

fascia cowl

See INSTRUMENTS, Repair,

Instrument panel.

9.Pull instrument panel away from fascia cowl and

disconnect speedometer cable, multi-plugs,

alarm LED plug lead, heated rear screen lead,

gearbox oil temperature lead and immobiliser

warning light leads.

10.Remove instrument panel.

11.Remove 2 screws securing ECU to fascia cowl

(LH drive shown). On RH drive vehicles ECU is

positioned lower down, on vertical face of fascia

panel.

12.Release ECU from fascia cowl and disconnect

both multi-plugs.

13.Remove ECU.

NOTE: A new ECU must be initialised

using TestBook.

Refit

14.Position ECU at fascia cowl and reconnect both

multi-plugs.

15.Locate ECU on mounting face of fascia cowl and

secure with 2 screws.

16.Position instrument panel to fascia cowl and

reconnect immobiliser warning light leads,

gearbox oil temperature lead, heated rear screen

lead, alarm LED plug lead, multi-plugs and

speedometer cable.

17.Secure instrument panel to fascia cowl with 4

screws

See INSTRUMENTS, Repair,

Instrument panel.

18.Fit steering wheelSee STEERING, Repair,

Steering wheel.

19.Reconnect battery negative lead.

20.Fit battery access cover.

21.Fit LH seat cushion.

Page 429 of 455

86ELECTRICAL

4

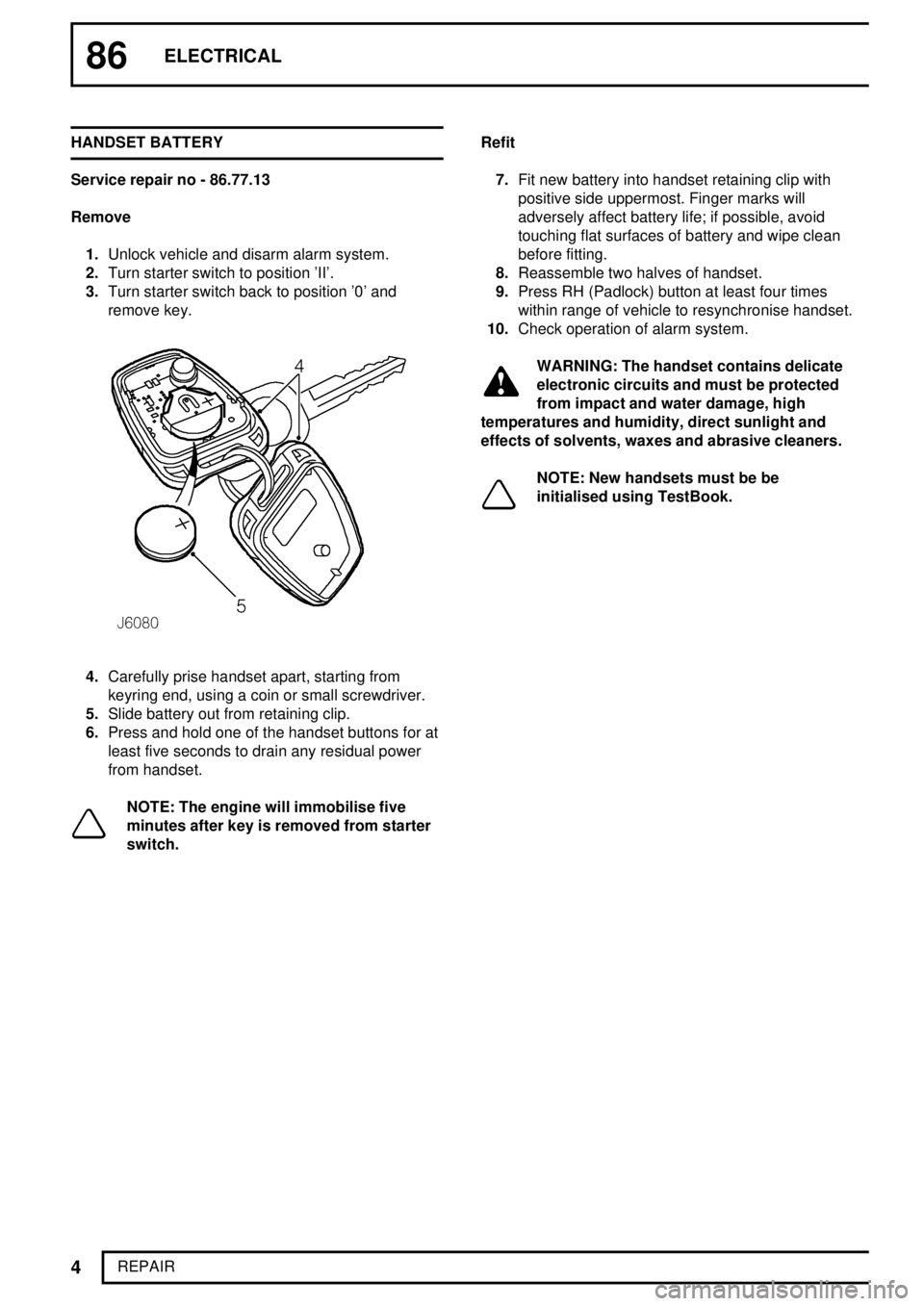

REPAIR HANDSET BATTERY

Service repair no - 86.77.13

Remove

1.Unlock vehicle and disarm alarm system.

2.Turn starter switch to position 'II'.

3.Turn starter switch back to position '0' and

remove key.

4.Carefully prise handset apart, starting from

keyring end, using a coin or small screwdriver.

5.Slide battery out from retaining clip.

6.Press and hold one of the handset buttons for at

least five seconds to drain any residual power

from handset.

NOTE: The engine will immobilise five

minutes after key is removed from starter

switch.Refit

7.Fit new battery into handset retaining clip with

positive side uppermost. Finger marks will

adversely affect battery life; if possible, avoid

touching flat surfaces of battery and wipe clean

before fitting.

8.Reassemble two halves of handset.

9.Press RH (Padlock) button at least four times

within range of vehicle to resynchronise handset.

10.Check operation of alarm system.

WARNING: The handset contains delicate

electronic circuits and must be protected

from impact and water damage, high

temperatures and humidity, direct sunlight and

effects of solvents, waxes and abrasive cleaners.

NOTE: New handsets must be be

initialised using TestBook.

Page 430 of 455

ELECTRICAL

5

REPAIR PASSIVE COIL

Service repair no - 86.77.35

Remove

1.Remove LH front seat cushion.

2.Release retaining clip and remove battery

access cover.

3.Slacken battery negative lead clamp bolt.

4.Turn starter switch 'on'.

5.Turn starter switch 'off' and remove key.

6.Disconnect battery negative lead.

NOTE: Operation 6 needs to be carried out

within 15 seconds to avoid activating

battery backed-up alarm sounder, if fitted.

7.Remove steering wheel

See STEERING,

Repair, Steering wheel.

8.Remove 4 screws securing instrument panel to

fascia cowl

See INSTRUMENTS, Repair,

Instrument panel.

9.Pull instrument panel away from fascia and

disconnect speedometer cable, multi-plugs,

alarm LED plug lead, heated rear screen lead,

gearbox oil temperature lead and immobiliser

warning light leads.

10.Remove instrument panel.

11.Remove 7 screws securing upper and lower

halves of nacelle to steering column mounting

bracket

See STEERING, Repair, Steering

column nacelle.

12.Release multi-switch gaiters from both sides of

nacelle.

13.Remove nacelle upper and lower halves from

steering column; collect blanking grommet from

RH side.

14.Disconnect multi-plug and remove passive coil

from starter switch.

Refit

15.Feed passive coil plug lead into fascia cowl area

and reconnect multi-plug .

16.Fit coil on starter switch.

17.Position nacelle upper and lower halves to

steering column mounting bracket and secure

with 7 screws. Do not fully tighten screws at this

stage

See STEERING, Repair, Steering

column nacelle.

18.Check that passive coil is still fitted correctly on

starter switch.

19.Check fit of nacelle at starter switch and steering

column and fully tighten fixing screws.

20.Fit multi-switch gaiters to both sides of nacelle

and check that blanking grommet is located.

21.Position instrument panel to fascia cowl area

and reconnect immobiliser warning light leads,

gearbox oil temperature lead, heated rear screen

lead, alarm LED plug lead, main harness multi-

plugs and speedometer.

22.Secure instrument panel to fascia cowl with 4

screws

See INSTRUMENTS, Repair,

Instrument panel.

23.Fit steering wheelSee STEERING, Repair,

Steering wheel.

24.Reconnect battery negative lead.

25.Fit battery access cover.

26.Fit LH seat cushion.

27.Test immobilisation and alarm system.

Page 434 of 455

ELECTRICAL

9

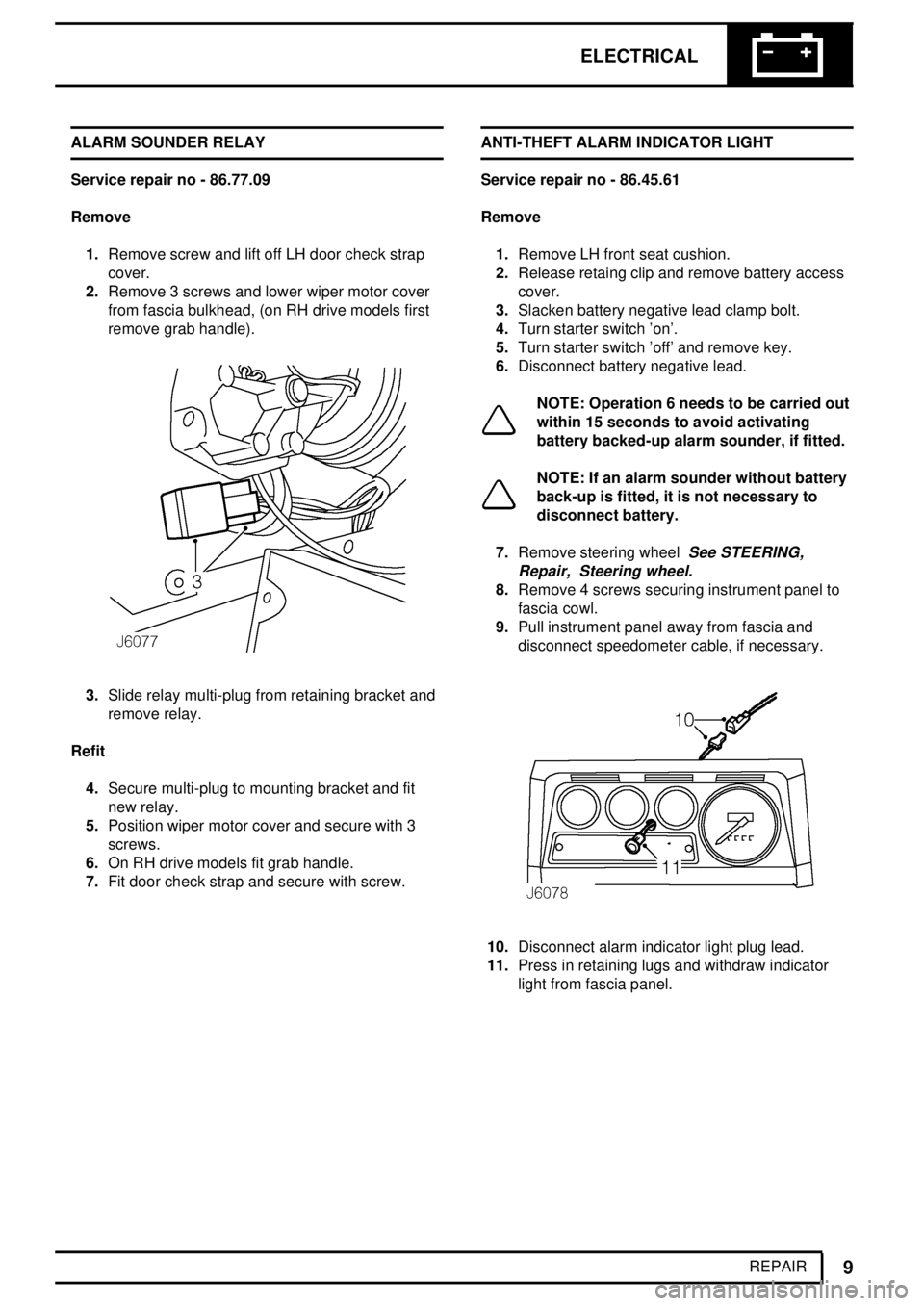

REPAIR ALARM SOUNDER RELAY

Service repair no - 86.77.09

Remove

1.Remove screw and lift off LH door check strap

cover.

2.Remove 3 screws and lower wiper motor cover

from fascia bulkhead, (on RH drive models first

remove grab handle).

3.Slide relay multi-plug from retaining bracket and

remove relay.

Refit

4.Secure multi-plug to mounting bracket and fit

new relay.

5.Position wiper motor cover and secure with 3

screws.

6.On RH drive models fit grab handle.

7.Fit door check strap and secure with screw.ANTI-THEFT ALARM INDICATOR LIGHT

Service repair no - 86.45.61

Remove

1.Remove LH front seat cushion.

2.Release retaing clip and remove battery access

cover.

3.Slacken battery negative lead clamp bolt.

4.Turn starter switch 'on'.

5.Turn starter switch 'off' and remove key.

6.Disconnect battery negative lead.

NOTE: Operation 6 needs to be carried out

within 15 seconds to avoid activating

battery backed-up alarm sounder, if fitted.

NOTE: If an alarm sounder without battery

back-up is fitted, it is not necessary to

disconnect battery.

7.Remove steering wheel

See STEERING,

Repair, Steering wheel.

8.Remove 4 screws securing instrument panel to

fascia cowl.

9.Pull instrument panel away from fascia and

disconnect speedometer cable, if necessary.

10.Disconnect alarm indicator light plug lead.

11.Press in retaining lugs and withdraw indicator

light from fascia panel.

Page 435 of 455

86ELECTRICAL

10

REPAIR Refit

12.Fit alarm indicator light into fascia panel and

reconnect plug lead.

13.Reconnect speedometer cable and fit instrument

panel to fascia cowl.

14.Fit steering wheel

See STEERING, Repair,

Steering wheel.

15.Reconnect battery negative lead.

16.Fit battery access cover.

17.Fit LH seat cushion.ALARM SYSTEM FUSE

Service repair no - 86.77.04

Remove

1.Remove LH front seat cushion.

2.Release retaining clip and remove battery

access cover.

3.Slacken battery negative lead clamp bolt.

4.Turn starter switch 'on'.

5.Turn starter switch 'off' and remove key.

6.Disconnect battery negative lead.

NOTE: Operation 6 needs to be carried out

within 15 seconds to avoid activating

battery backed-up alarm sounder, if fitted.

NOTE: If an alarm sounder without battery

back-up is fitted, it is not necessary to

disconnect battery.

7.Remove steering wheel

See STEERING,

Repair, Steering wheel.

8.Remove 4 screws securing instrument panel to

fascia cowl

See INSTRUMENTS, Repair,

Instrument panel.

9.Pull instrument panel away from fascia and

disconnect speedometer cable, main harness

multi-plugs, alarm LED plug lead, heated rear

screen leads, gearbox oil temperature lead and

immobiliser warning light lead.

10.Remove instrument panel.

11.Remove alarm system 15 amp (blue) fuse from

holder located behind starter switch.

Page 436 of 455

ELECTRICAL

11

REPAIR REV: 05/99 Refit

12.Fit new fuse.

13.Position instrument panel to fascia cowl area

and reconnect immobiliser warning light leads,

gearbox oil temperature lead, heated rear screen

leads, alarm LED plug lead, main harness

multi-plugs and speedometer cable,

14.Secure instrument panel to fascia cowl with 4

screws

See INSTRUMENTS, Repair,

Instrument panel.

15.Fit steering wheelSee STEERING, Repair,

Steering wheel.

16.Reconnect battery negative lead.

17.Fit battery access cover.

18.Fit LH front seat cushion.GENERATOR

Service repair no - 86.10.02

Remove

1.Disconnect battery.

2.Remove drive belt

See Auxiliary drive belt.

3.Unscrew 3 fixings, remove heat shield from rear

of generator, and disconnect electrical leads

from generator.

4.Remove generator bottom fixing bolt.

5.Remove long through bolt from top fixing and lift

generator from engine.

Refit

6.Fit generator to engine mounting bracket and

secure with top and bottom fixing bolts.

7.Connect electrical leads.

8.Fit heat shield.

9.Fit drive belt

See Auxiliary drive belt; Refit.

10.Reconnect battery.

Page 443 of 455

86ELECTRICAL

18

REPAIR REVERSE LAMP SWITCH

Service repair no - 37.27.01

Remove

The reverse lamp switch is located on the LH side of

the gearbox extension housing and is accessible from

underneath the vehicle.

1.Place vehicle on suitable ramp.

2.Disconnect reverse lamp switch lead multi-plug

from harness connector.

3.Unscrew switch from extension housing.

Refit

4.Fit new switch to gearbox extension housing.

Tighten to

25 Nm (18 lbf/ft).

5.Fit lamp switch lead multi-plug to harness

connector.

6.Check operation of lamp switch.WARNING LAMP ASSEMBLY

Service repair no - 86.45.60 - Warning lamp

assembly

Service repair no - 86.45.61 - Warning lamp bulb

renewal

Remove

1.Disconnect battery.

2.Remove 2 screws and withdraw warning light

assembly from instrument panel.

3.Remove multi-plug to give access to warning

lamp bulbs.

4.Twist bulb holder and pull it from its socket.

5.Pull bulb from holder.

Refit

6.Fit new bulb and refit holder.

7.Fit multi-plug.

8.Fit warning lamp assembly to instrument panel

9.Reconnect battery.

Page 445 of 455

86ELECTRICAL

20

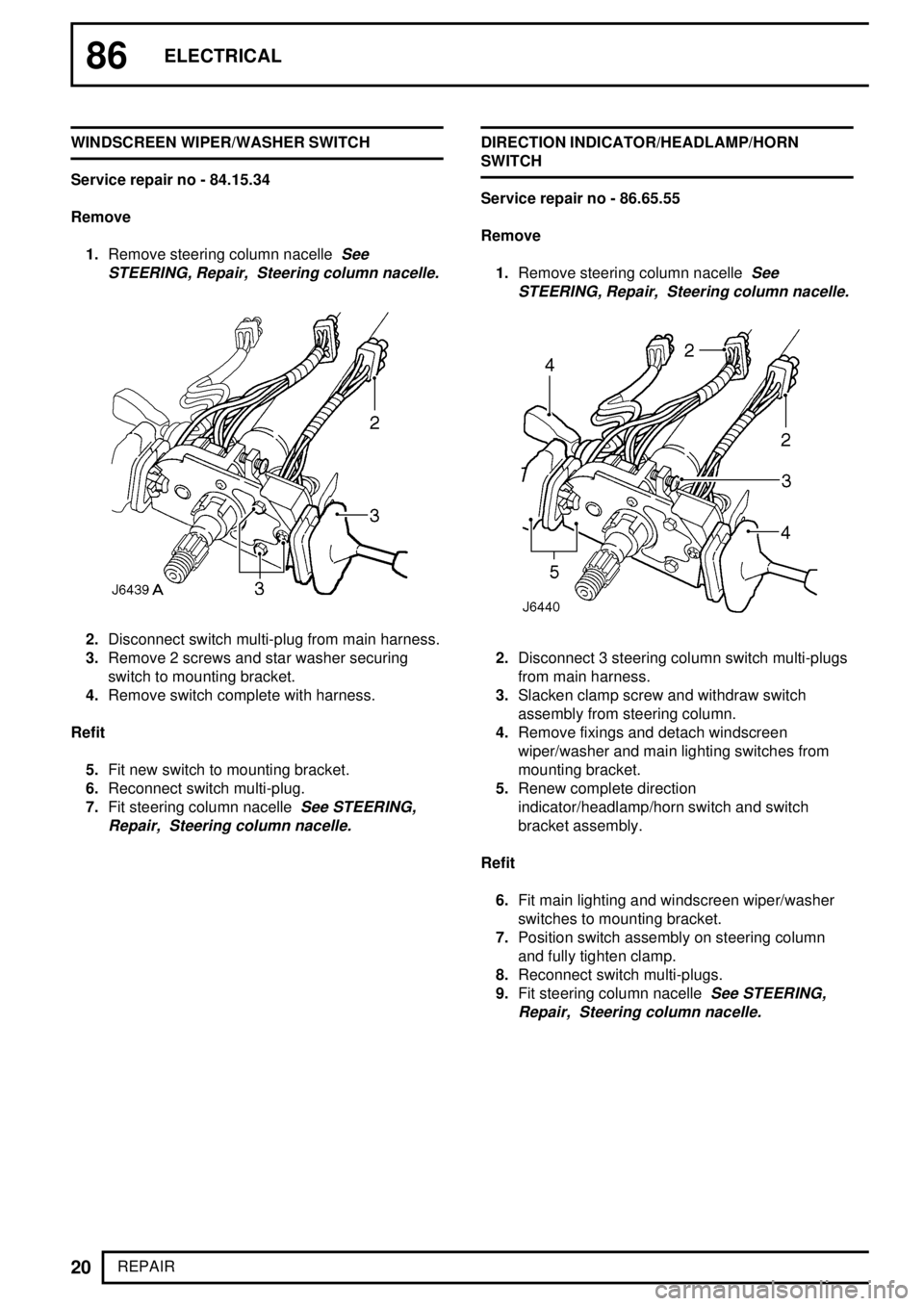

REPAIR WINDSCREEN WIPER/WASHER SWITCH

Service repair no - 84.15.34

Remove

1.Remove steering column nacelle

See

STEERING, Repair, Steering column nacelle.

2.Disconnect switch multi-plug from main harness.

3.Remove 2 screws and star washer securing

switch to mounting bracket.

4.Remove switch complete with harness.

Refit

5.Fit new switch to mounting bracket.

6.Reconnect switch multi-plug.

7.Fit steering column nacelle

See STEERING,

Repair, Steering column nacelle.

DIRECTION INDICATOR/HEADLAMP/HORN

SWITCH

Service repair no - 86.65.55

Remove

1.Remove steering column nacelle

See

STEERING, Repair, Steering column nacelle.

2.Disconnect 3 steering column switch multi-plugs

from main harness.

3.Slacken clamp screw and withdraw switch

assembly from steering column.

4.Remove fixings and detach windscreen

wiper/washer and main lighting switches from

mounting bracket.

5.Renew complete direction

indicator/headlamp/horn switch and switch

bracket assembly.

Refit

6.Fit main lighting and windscreen wiper/washer

switches to mounting bracket.

7.Position switch assembly on steering column

and fully tighten clamp.

8.Reconnect switch multi-plugs.

9.Fit steering column nacelle

See STEERING,

Repair, Steering column nacelle.