torque LAND ROVER DEFENDER 1996 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 278 of 455

REAR SUSPENSION

1

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Anti-roll bar

- Strap nyloc nuts 30..............................................................................

- Ball link self lock nut 68........................................................................

- Castellated nut 40................................................................................

Top link to mounting bracket 176.....................................................................

Bottom link to axle 176.....................................................................................

Bottom link to chassis 176...............................................................................

Top link bracket to rear cross member 47......................................................

Shock absorber to axle 37 N............................................................................

Page 288 of 455

BRAKES

7

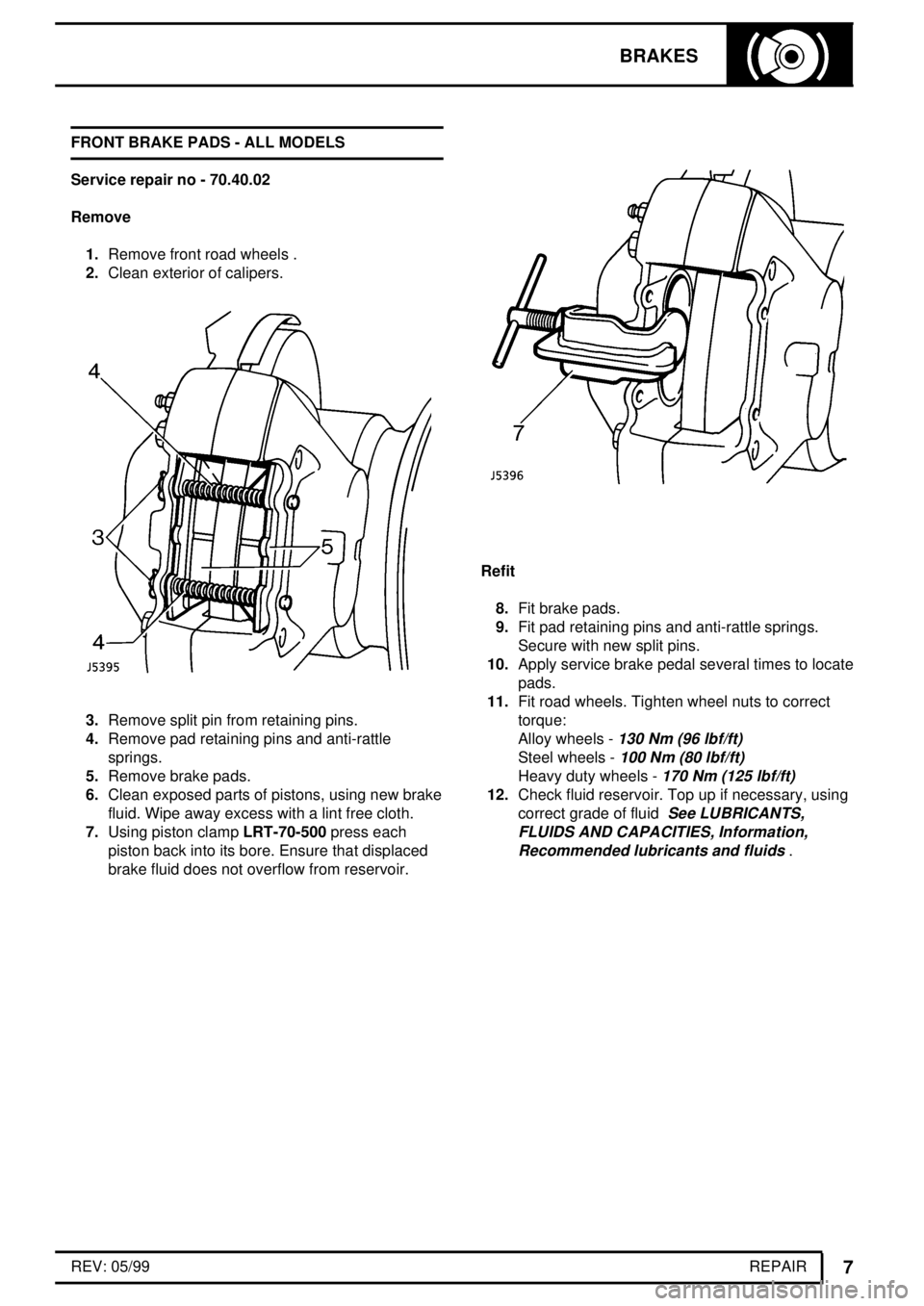

REPAIR REV: 05/99 FRONT BRAKE PADS - ALL MODELS

Service repair no - 70.40.02

Remove

1.Remove front road wheels .

2.Clean exterior of calipers.

3.Remove split pin from retaining pins.

4.Remove pad retaining pins and anti-rattle

springs.

5.Remove brake pads.

6.Clean exposed parts of pistons, using new brake

fluid. Wipe away excess with a lint free cloth.

7.Using piston clampLRT-70-500press each

piston back into its bore. Ensure that displaced

brake fluid does not overflow from reservoir.

Refit

8.Fit brake pads.

9.Fit pad retaining pins and anti-rattle springs.

Secure with new split pins.

10.Apply service brake pedal several times to locate

pads.

11.Fit road wheels. Tighten wheel nuts to correct

torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

12.Check fluid reservoir. Top up if necessary, using

correct grade of fluid

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended lubricants and fluids

.

Page 289 of 455

70BRAKES

8

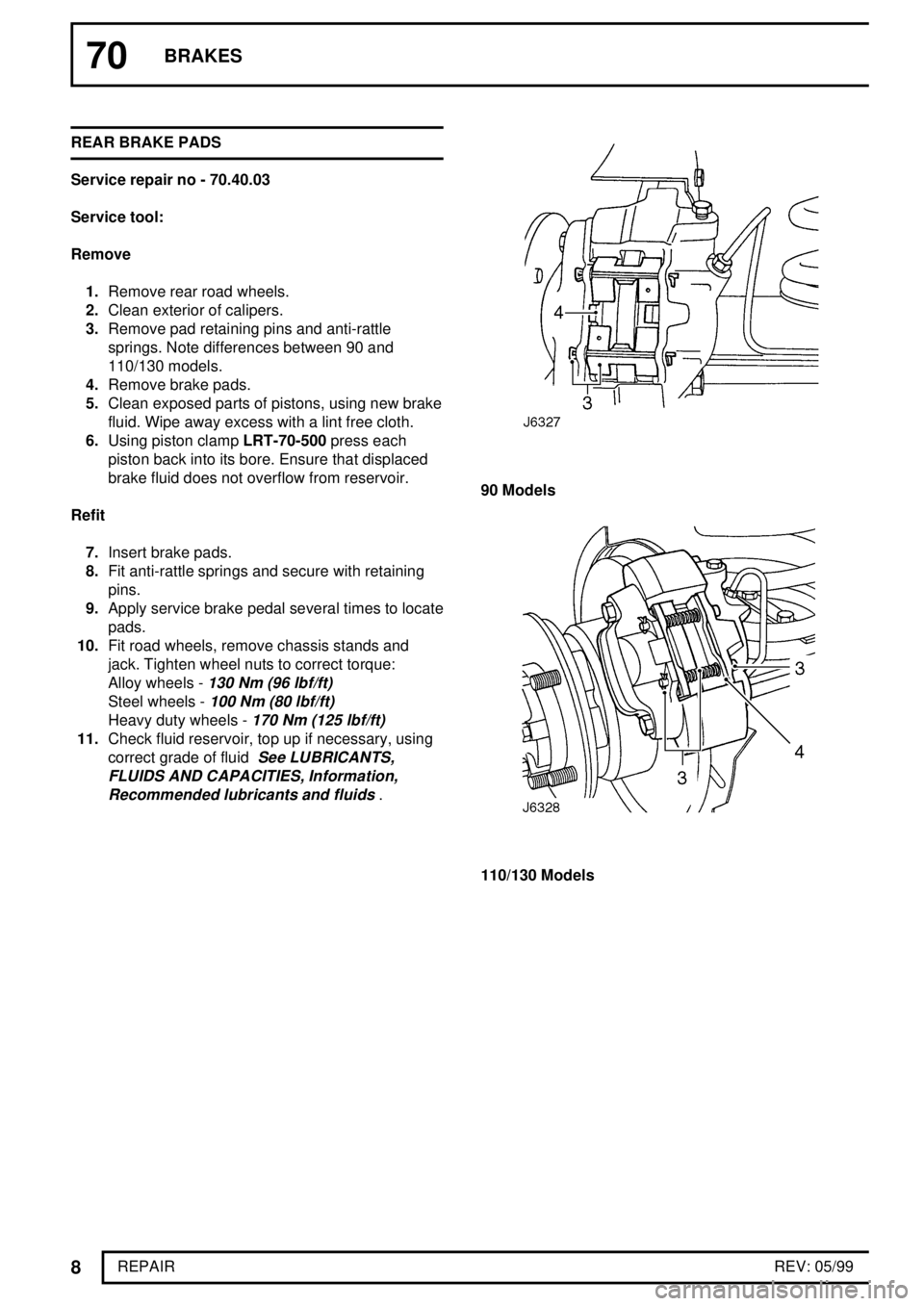

REPAIRREV: 05/99 REAR BRAKE PADS

Service repair no - 70.40.03

Service tool:

Remove

1.Remove rear road wheels.

2.Clean exterior of calipers.

3.Remove pad retaining pins and anti-rattle

springs. Note differences between 90 and

110/130 models.

4.Remove brake pads.

5.Clean exposed parts of pistons, using new brake

fluid. Wipe away excess with a lint free cloth.

6.Using piston clampLRT-70-500press each

piston back into its bore. Ensure that displaced

brake fluid does not overflow from reservoir.

Refit

7.Insert brake pads.

8.Fit anti-rattle springs and secure with retaining

pins.

9.Apply service brake pedal several times to locate

pads.

10.Fit road wheels, remove chassis stands and

jack. Tighten wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

11.Check fluid reservoir, top up if necessary, using

correct grade of fluid

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended lubricants and fluids

.

90 Models

110/130 Models

Page 292 of 455

BRAKES

11

REPAIR REV: 05/99 Assemble outboard pistons

13.Coat new fluid seal with brake fluid. Ease seal

into groove in bore using only fingers, ensuring it

is properly seated. Fluid seal and groove are not

same in section, so when seal is seated it feels

raised to touch at edge furthest away from

mouth of bore.

14.Coat appropriate piston with brake fluid. Insert it

squarely into bore by hand only. Do not tilt piston

during insertion, leave approximately 8mm

projecting from bore.

15.Coat new wiper seal with brake fluid and fit to

new seal retainer. Slide assembly, seal first, over

protruding piston and into bore recess. Use

piston clamp to press home seal retainer and

piston.

Mounting inboard pistons

16.Clamp outboard pistons and carry out same

procedure for removing and fitting outboard

pistons and seals, instructions 8 to 15.

Fit calipers and pads

17.Fit caliper, tighten bolts evenly to

82 Nm (60

lbf/ft).

18.Connect brake flexible hoses to caliper. Tighten

to

15 Nm (11 lbf/ft).

19.Remove hose clamps.

20.Insert pads. Fit pins and springs, secure using

new split pin.

21.Bleed brake system

See Brake System Bleed

.

22.Press brake pedal firmly several times to locate

friction pads.

23.Fit road wheels, remove axle stands. Finally

tighten road wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

24.Road test vehicle. Note that new friction pads

require 'bedding-in', this may take several

hundred miles before brakes are at maximum

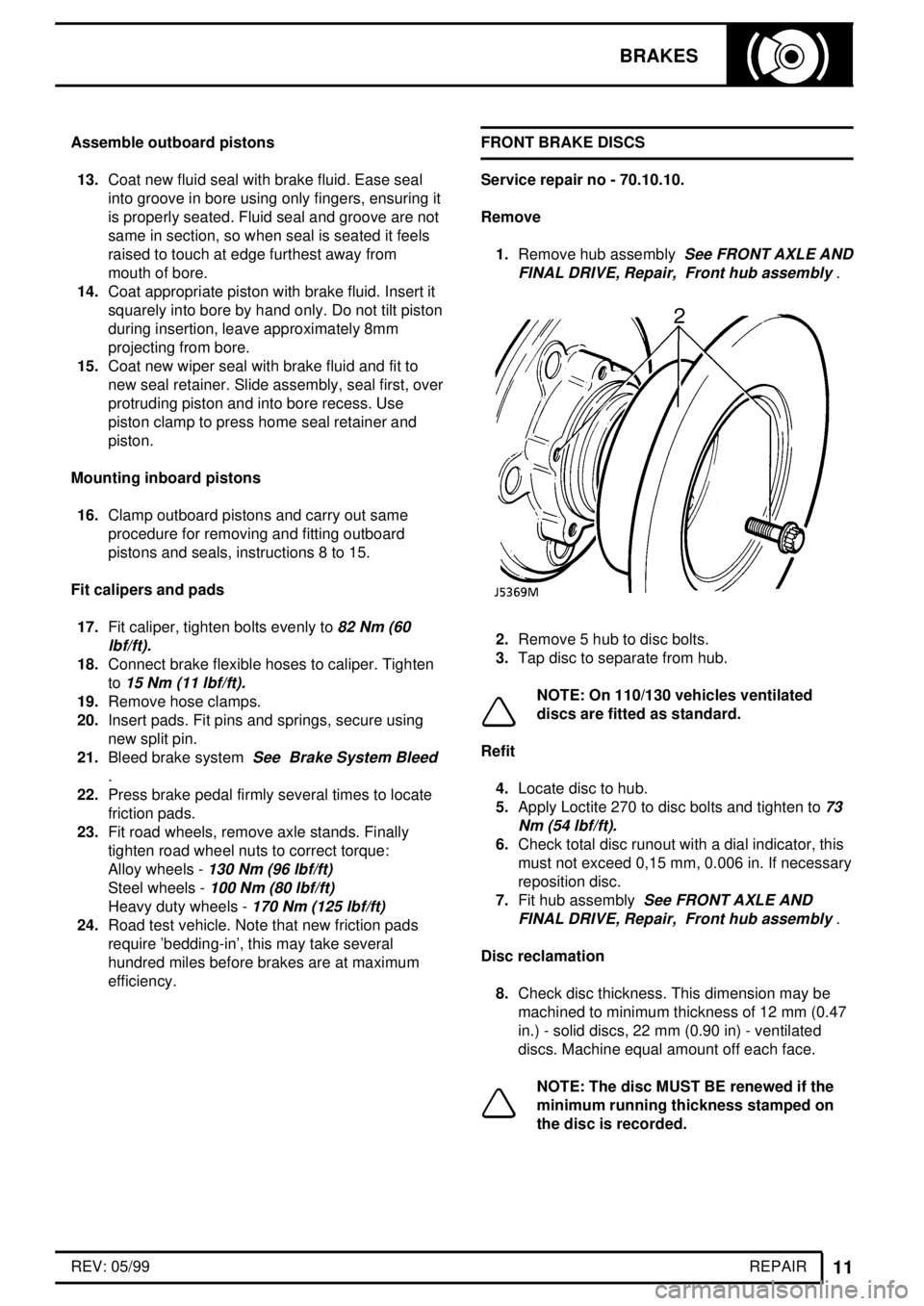

efficiency.FRONT BRAKE DISCS

Service repair no - 70.10.10.

Remove

1.Remove hub assembly

See FRONT AXLE AND

FINAL DRIVE, Repair, Front hub assembly

.

2.Remove 5 hub to disc bolts.

3.Tap disc to separate from hub.

NOTE: On 110/130 vehicles ventilated

discs are fitted as standard.

Refit

4.Locate disc to hub.

5.Apply Loctite 270 to disc bolts and tighten to

73

Nm (54 lbf/ft).

6.Check total disc runout with a dial indicator, this

must not exceed 0,15 mm, 0.006 in. If necessary

reposition disc.

7.Fit hub assembly

See FRONT AXLE AND

FINAL DRIVE, Repair, Front hub assembly

.

Disc reclamation

8.Check disc thickness. This dimension may be

machined to minimum thickness of 12 mm (0.47

in.) - solid discs, 22 mm (0.90 in) - ventilated

discs. Machine equal amount off each face.

NOTE: The disc MUST BE renewed if the

minimum running thickness stamped on

the disc is recorded.

Page 295 of 455

70BRAKES

14

REPAIRREV: 05/99 15.Coat a new wiper seal with brake fluid and fit to

new seal retainer. Slide assembly, seal first, over

protruding piston into bore recess.

16.Using special toolLRT-70-500- piston clamp,

press home seal retainer and piston.

Mounting inboard piston

17.Carry out same procedure as for removing and

fitting outboard piston and seals, instructions 8 to

16.

Fit calipers and pads to vehicle

18.Fit caliper to axle, tighten 2 bolts evenly to

82

Nm (60 lbf/ft).

19.Connect brake pipe to caliper. Tighten to15 Nm

(11 lbf/ft).

20.Remove clamp from flexible brake hose.

21.Insert pads and retaining springs, secure in

position with new retaining pins and spread ends

or fit new split pins, depending on vehicle model.

Note correct position of retaining springs on 90

models.

22.Bleed brake system

See Brake System Bleed.

23.Press brake pedal firmly several times to locate

pads.

24.Fit road wheels, remove axle stands. Finally

tighten road wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

25.Road test vehicle. Note new brake pads require

'bedding-in', for several hundred miles before

brakes are at maximum efficiency.REAR BRAKE DISC

Service repair no - 70.10.11.

Remove

1.Remove rear hub assembly

See REAR AXLE

AND FINAL DRIVE, Repair, Rear hub

assembly

.

2.Remove disc bolts.

3.Remove disc from rear hub.

Refit

4.Fit disc to rear hub.

5.Fit disc bolts. Tighten to

73 Nm (54 lbf/ft).

6.Check total disc run out, this must not exceed

0,15 mm (0.006 in). If necessary reposition disc.

7.Fit rear hub assembly

See REAR AXLE AND

FINAL DRIVE, Repair, Rear Hub Assembly

.

Disc reclamation

8.Check disc thickness. This dimension may be

machined to minimum thickness of 12 mm.

Machine equal amounts off each face.

NOTE: The brake disc MUST BE renewed if

the minimum running thickness stamped

on the disc is recorded.

Page 312 of 455

74WHEELS AND TYRES

6

REPAIRREV: 05/99 WHEELS

Remove

WARNING: The parking brake acts on

transmission, not rear wheels, and may

not hold vehicle when jacking unless

following procedure is used. If one front wheel

and one rear wheel is raised no vehicle holding or

braking effect is possible. Wheels MUST be

chocked in all circumstances.

Apply parking brake, select a gear in main

gearbox and engage low gear in transfer box.

1.Loosen 5 wheel nuts.

2.Using a suitable trolley jack, raise vehicle and

place on axle stands

See INTRODUCTION,

Information, Jacking

.

3.Remove wheel nuts and carefully withdraw

wheel over studs.

Refit

4.Ensure that retaining studs and nuts are clean.

5.Alloy wheels: Lightly coat wheel mounting spigot

face with a suitable anti-seize compound to

minimise possibility of adhesion between wheel

and spigot face.

6.Refit wheel taking care not to damage stud

threads. (Do not apply oil).

7.Fit wheel nuts and turn by hand for at least three

full threads before using any form of wheel

wrench.

8.Tighten nuts as much as possible using a

suitable wrench.

9.Lower vehicle and finally tighten nuts to correct

torque sequence shown.

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

Page 377 of 455

82AIR CONDITIONING

2

ADJUSTMENT SERVICING PRECAUTIONS

Care must be taken when handling refrigeration

system components. Units must not be lifted by their

hoses, pipes or capillary lines. Hoses and lines must

not be subjected to any twist or stress. Ensure that

hoses are positioned in their correct run before fully

tightening the couplings, and ensure that all clips and

supports are used. Torque wrenches of the correct

type must be used when tightening refrigerant

connections to the stated value. An additional spanner

must be used to hold the union to prevent twisting of

the pipe.

Before connecting any hose or pipe ensure that

refrigerant oil is applied to the seat of the new '0' ring

but not to the threads.

Check the oil trap for the amount of oil lost.

All protective plugs on components must be left in

place until immediately prior to connection.

The receiver/drier contains desiccant which absorbs

moisture. It must be positively sealed at all times.

CAUTION: Whenever the refrigerant

system is opened, the receiver/drier must

be renewed immediately before evacuating

and recharging the system.

Use alcohol and a clean cloth to clean dirty

connections.

Ensure that all new parts fitted are marked for use

withR134a.

Refrigerant oil

Use the approved refrigerant lubricating oil - Nippon

Denso ND-OIL 8.

CAUTION: Do not use any other type of

refrigerant oil.

Refrigerant oil easily absorbs water and must not be

stored for long periods. Do not pour unused oil back

into the container.

When renewing system components, add the

following quantities of refrigerant oil:

Condenser 40ml..........................................................

Evaporator 80ml..........................................................

Pipe or hose 20ml........................................................

Receiver/drier 20ml......................................................Total quantity of refrigerant oil in system = 140ml

A new compressor is sealed and pressurised with

Nitrogen gas, slowly release the sealing cap, gas

pressure should be heard to release as the seal is

broken.

NOTE: A new compressor should always

have its sealing caps in place and these

must not be removed until immediately

prior to fitting

A new compressor is supplied with an oil fill of 140ml.

A calculated quantity of oil must be drained from a

new compressor before fitting.

To calculate the quantity of oil to be drained:

1.Remove sealing plugs from the OLD

compressor.

2.Invert compressor and gravity drain oil into

measuring cylinder. Rotating the compressor

clutch plate will assist complete draining.

3.Note the quantity of oil drained (Yml).

4.Calculate the quantity (Qml) of oil to be drained

from the NEW compressor using the following

formula:

Xml - (Yml + 20ml) = Qml

Rapid refrigerant discharge

When the air conditioning system is involved in

accident damage and the circuit is punctured, the

refrigerant is discharged rapidly. The rapid discharge

of refrigerant will also result in the loss of most of the

oil from the system. The compressor must be

removed and all the remaining oil in the compressor

drained and refilled as follows:

1.Gravity drain all the oil, assist by rotating the

clutch plate (not the pulley).

2.Refill the compressor with 90ml of new

refrigerant oil.

3.Plug the inlet and outlet ports.

Servicing Equipment

The following equipment is required for full servicing

of the air conditioning system.

Recovery, recycling and charging station

Leak detector

Thermometer +20°C to -60°C

Safety goggles and gloves

Page 384 of 455

82AIR CONDITIONING

2

REPAIR COMPRESSOR DRIVE BELT

Service repair no - 82.10.02

Remove

1.Disconnect battery.

2.Remove auxiliary drive belt

See ELECTRICAL,

Repair, Auxiliary drive belt.

3.Remove 3 nuts securing drive belt guard to

compressor retaining studs.

4.Slacken 3 belt tensioner retaining bolts.

5.Remove compressor drive belt. Mark direction

on belt if refitting.Refit

6.Fit compressor drive belt.

7.Fit drive belt guard.

8.Fit torque meter to centre of tensioner, apply and

hold a torque of

35 Nm (26 lbf/ft).

9.Tighten tensioner retaining bolts.

10.Rotate crankshaft 2 full turns.

11.Reapply and hold a torque of

35 Nm (26 lbf/ft)

to tensioner, then fully slacken and retighten

tensioner retaining bolts to

25 Nm (18 lbf/ft).

12.Fit auxiliary drive beltSee ELECTRICAL,

Repair, Auxiliary drive belt.

13.Reconnect battery.

Page 407 of 455

WIPERS AND WASHERS

7

REPAIR Refit

NOTE: During reassembly all fixings

related to wiper motor and wheelboxes are

finger tightened only, until all components

are correctly aligned.

12.Fit wheelboxes to bulkhead and secure with

retaining nuts and washers.

13.Fit drive rack tubes to wheelboxes.

14.Apply grease to drive rack and wheelboxes.

15.Align wiper motor and mounting pad, secure with

retaining strap and tighten drive tube nut.

16.Fully tighten wheelbox back plate nuts.

17.Fully tighten both wheelbox spindle nuts.

18.Fit wiper arm adaptors and secure with grub

screw.

19.Before refitting panels fit wiper blades, connect

multi-plug and earth lead, reconnect battery and

check wiper operation.

20.If satisfactory, secure steering column upper and

lower fixings and tighten to correct torque.

21.Fit ventilator grille panel, fascia crash pad,

instrument housing and all other components

removed to gain access to wiper motor and

wheelboxes.

Page 409 of 455

WIPERS AND WASHERS

9

REPAIR 13.Fit wheelboxes to bulkhead.

14.Fit drive tubes to wheelboxes.

15.Feed drive rack through tubes until fully seated

in both wheelboxes.

16.Secure drive tube nut to wiper motor.

17.Fit wiper motor strap and earth lead.

18.When all components are correctly aligned, fully

tighten wheelboxes nuts to secure drive tubes.

Tighten wheelbox to bulkhead nuts.

19.Fully tighten drive tube nut to wiper motor and

motor strap screws.

20.Connect multiplug to wiper motor and earth lead

to strap tag.

21.Fit spacer, where used, early vehicles only.

22.Fit wiper arm adaptors.

23.Reconnect battery and check operation of wiper

motor and drive assembly and wheelboxes.

24.Disconnect battery.

25.Fit steering column upper and lower supports.

Tighten fixings to correct torque.

26.Fit demister vent top duct.

27.Secure RH demister vent and hose.

28.Fit LH and RH demister vents to ducts.

29.Fit centre and LH fascia top crash rail support

brackets.

30.Fit all other components removed to gain access

to wiper motor and wheelboxes.

31.Reconnect battery, check wiper motor operation

again and adjust wiper arms, if necessary.REAR WIPER MOTOR

Service repair no - 84.35.12

Remove

1.With assistance, unscrew 3 retaining nuts and

remove spare wheel from rear door mounting

studs.

2.Lift wiper arm end cap to gain access to securing

nut.

3.Remove nut and withdraw wiper arm from drive

spindle.

4.Remove retaining nut, plain washer and rubber

washer securing wiper motor drive spindle to

door.

5.Remove 2 screws and remove cover from wiper

motor mounting bracket.

6.Disconnect wiper motor harness multi-plug.

7.Remove bolt, with rubber washer, and detach

wiper motor, complete with mounting bracket,

from rear door.