torque LAND ROVER DEFENDER 1996 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 195 of 455

51REAR AXLE AND FINAL DRIVE

6

OVERHAUL

70.Press inner bearing cone onto drive pinion using,

LRT-51-502details 1 and 2 and press

LRT-99-002.

71.Position pinion and bearing in casing; omit

collapsable spacer at this stage.

72.Fit outer bearing cone onto pinion.

73.Fit coupling flange and plain washer and loosely

fit flange nut.

74.Tighten coupling flange locknut to remove

end-float from pinion.

75.Rotate pinion to settle bearings and slowly

tighten flange locknut. Use a spring balance to

obtain a torque resistance of 11 Kgf/cm (18

lbf/in) to rotate pinion.

Drive pinion markings

76.Check that serial number marked on pinion end

face matches that marked on crown wheel.

77.The markings on end face adjacent to serial

number are of no significance during servicing.

78.The figure marked on end face opposite to serial

number indicates, in thousandths of an inch,

deviation from nominal required to correctly set

pinion. A pinion marked plus (+) must be set

below nominal, a minus (-) pinion must be set

above nominal. An unmarked pinion must be set

at nominal.

79.The nominal setting dimension is represented by

setting gauge block18G191PorLRT-54-503,

which is referenced from pinion end face to

bottom radius of differential bearing bore. The

latter gauge is illustrated following instruction 85.

Drive pinion adjustment

80.Ensure that pinion end face is free of raised

burrs around etched markings.

81.Remove keep disc from magnetized base of dial

gauge tool18G191.

82.Place dial gauge and setting gauge18G191Por

LRT-54-503on a flat surface and zero dial

gauge stylus on to setting gauge.

Page 197 of 455

51REAR AXLE AND FINAL DRIVE

8

OVERHAUL 86.Before adjusting shim thickness, check pinion

face marking and if it has a plus (+) figure,

subtract that from shim thickness figure obtained

in previous instruction. Alternatively if pinion has

a minus (-) figure, add amount to shim thickness

figure.

87.Adjust shim thickness under pinion inner cup as

necessary, by amount determined in instructions

85 and 86.

88.Recheck pinion height setting instructions 82 to

84. If setting is correct, mean reading on dial

gauge will agree with figure marked on pinion

end face. For example, with an end face marking

of +3, dial gauge reading should indicate that

pinion is 0.003 in (0.0762 mm) below nominal.

89.When pinion setting is satisfactory, temporarily

remove pinion outer bearing.

90.Fit a new collapsable bearing spacer, flared end

outward, to drive pinion and refit outer bearing.

91.Fit pinion oil slinger.

92.Fit oil seal gasket.

93.Fit pinion oil seal, lipped side first, using general

purpose grease or, where available, a

molybdenum disulphide based grease on seal

lip, usingLRT-51-002to drift in seal.

94.Fit coupling flange and plain washer and loosely

fit a new flange nut. SecureLRT-51-003to

coupling flange, using slave fixings.

95.Alternately tighten flange nut and check drive

pinion resistance to rotation until following

figures are achieved, as applicable:

A.Assemblies re-using original pinion bearings:

17,3 to 34,5 kgf cm.

B.Assemblies with new pinion bearings: 34,5 to

46,0 kgf cm.

NOTE: Once the bearing spacer has

started to collapse the torque resistance

build-up is rapid, therefore check

frequently, using a spring balance, to ensure the

correct figures are not exceeded, otherwise a new

collapsable bearing spacer will be required.

Page 198 of 455

REAR AXLE AND FINAL DRIVE

9

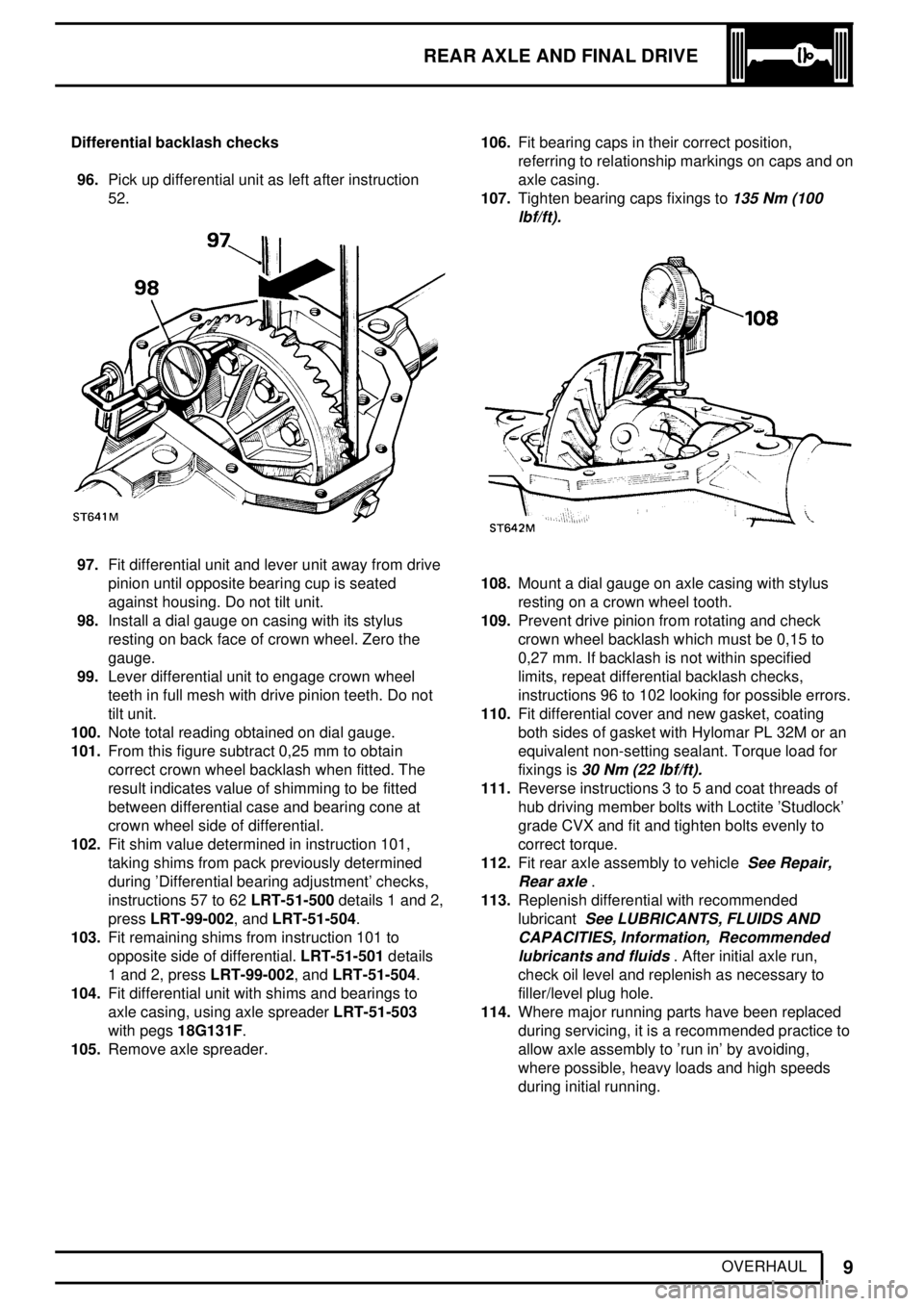

OVERHAUL Differential backlash checks

96.Pick up differential unit as left after instruction

52.

97.Fit differential unit and lever unit away from drive

pinion until opposite bearing cup is seated

against housing. Do not tilt unit.

98.Install a dial gauge on casing with its stylus

resting on back face of crown wheel. Zero the

gauge.

99.Lever differential unit to engage crown wheel

teeth in full mesh with drive pinion teeth. Do not

tilt unit.

100.Note total reading obtained on dial gauge.

101.From this figure subtract 0,25 mm to obtain

correct crown wheel backlash when fitted. The

result indicates value of shimming to be fitted

between differential case and bearing cone at

crown wheel side of differential.

102.Fit shim value determined in instruction 101,

taking shims from pack previously determined

during 'Differential bearing adjustment' checks,

instructions 57 to 62LRT-51-500details 1 and 2,

pressLRT-99-002, andLRT-51-504.

103.Fit remaining shims from instruction 101 to

opposite side of differential.LRT-51-501details

1 and 2, pressLRT-99-002, andLRT-51-504.

104.Fit differential unit with shims and bearings to

axle casing, using axle spreaderLRT-51-503

with pegs18G131F.

105.Remove axle spreader.106.Fit bearing caps in their correct position,

referring to relationship markings on caps and on

axle casing.

107.Tighten bearing caps fixings to

135 Nm (100

lbf/ft).

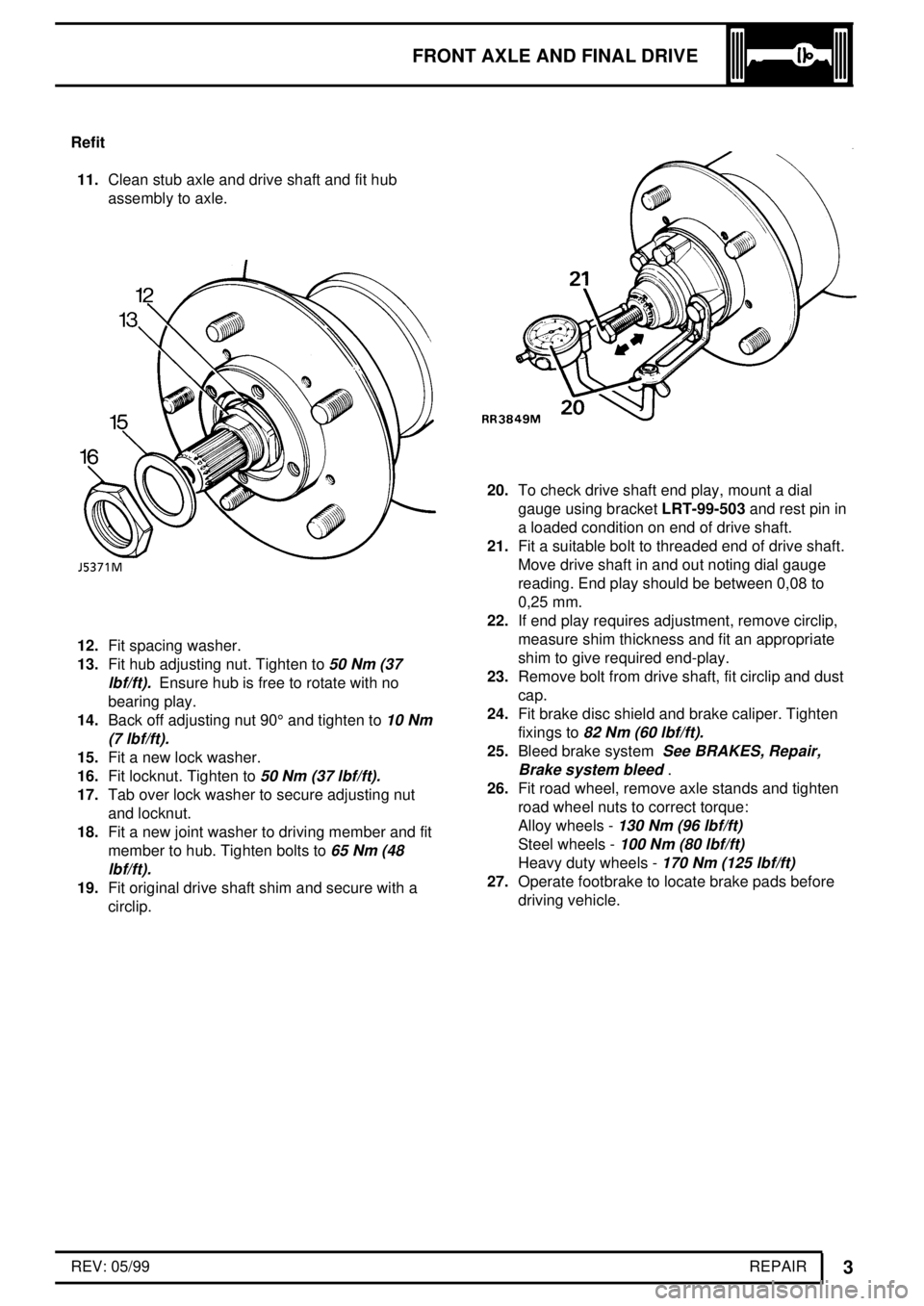

108.Mount a dial gauge on axle casing with stylus

resting on a crown wheel tooth.

109.Prevent drive pinion from rotating and check

crown wheel backlash which must be 0,15 to

0,27 mm. If backlash is not within specified

limits, repeat differential backlash checks,

instructions 96 to 102 looking for possible errors.

110.Fit differential cover and new gasket, coating

both sides of gasket with Hylomar PL 32M or an

equivalent non-setting sealant. Torque load for

fixings is

30 Nm (22 lbf/ft).

111.Reverse instructions 3 to 5 and coat threads of

hub driving member bolts with Loctite 'Studlock'

grade CVX and fit and tighten bolts evenly to

correct torque.

112.Fit rear axle assembly to vehicle

See Repair,

Rear axle

.

113.Replenish differential with recommended

lubricant

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

lubricants and fluids

. After initial axle run,

check oil level and replenish as necessary to

filler/level plug hole.

114.Where major running parts have been replaced

during servicing, it is a recommended practice to

allow axle assembly to 'run in' by avoiding,

where possible, heavy loads and high speeds

during initial running.

Page 205 of 455

REAR AXLE AND FINAL DRIVE

1

SPECIFICATIONS, TORQUE REV: 05/99 TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

REAR AXLE

Pinion housing to axle case 41.......................................................................

Crown wheel to differential case 58................................................................

Differential bearing cap to pinion housing 90..................................................

Differential drive flange to drive shaft 47.........................................................

Bevel pinion nut 129........................................................................................

Lower link to axle 176......................................................................................

Pivot bracket ball joint to axle 176...................................................................

Page 209 of 455

FRONT AXLE AND FINAL DRIVE

1

REPAIR REV: 05/99 FRONT AXLE ASSEMBLY

Service repair no - 54.10.01

Remove

WARNING: Remove and refit of axle

requires a further two persons to steady

axle when lowering or repositioning axle.

1.Support chassis front.

2.Remove road wheels.

3.Support axle weight with hydraulic jack.

4.Remove radius arms to chassis frame nuts.

5.Disconnect steering damper from track rod.

Using a extractor remove track rod links from

swivel pin arms.

6.Remove four nuts and bolts securing radius

arms to axle bracket.

7.Remove radius arms.

8.Remove bolts securing brake hose brackets .

Refit bolts to prevent oil leakage.

9.Remove bolts from brake calipers and tie to one

side.

10.Remove nuts and washers securing shock

absorbers to axle.

11.Disconnect drag link from swivel pin housing

arm.

12.Remove two nuts and bolts securing panhard

rod to axle bracket. Lift rod clear of axle.

13.Mark for reassembly drive shaft flanges.

Remove four nuts and bolts, tie propeller shaft to

one side.

14.Release axle ventilation pipe banjo and lower

axle assembly. Remove road springs.

15.Disconnect anti-roll bar link

See FRONT

SUSPENSION, Repair, Anti-roll bar ball

.

16.Remove axle assembly.

Refit

17.Position axle under vehicle, supporting left side

of axle, and fit anti-roll bar links

See FRONT

SUSPENSION, Repair, Anti-roll bar links

.

18.Fit propeller shaft. Tighten bolts to

47 Nm (35

lbf/ft).

19.Fit panhard rod to axle bracket. Tighten bolts to

88 Nm (65 lbf/ft).

20.Fit drag link to swivel pin arm. Tighten fixings to

40 Nm (30 lbf/ft).

21.Fit shock absorbers to axle.

22.Fit brake calipers. Tighten bolts to

82 Nm (60

lbf/ft).

23.Tighten upper swivel pin bolts to78 Nm (58

lbf/ft).

24.Fit radius arms to axle brackets. Tighten bolts to

197 Nm (145 lbf/ft).

25.Fit steering damper to track rod.

26.Fit radius arms to chassis side member. Tighten

fixings to

197 Nm (145 lbf/ft).

27.Tighten track rod end to40 Nm (30 lbf/ft)and fit

new split pin.

28.Remove chassis supports, fit road wheels and

tighten to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

Page 211 of 455

FRONT AXLE AND FINAL DRIVE

3

REPAIR REV: 05/99 Refit

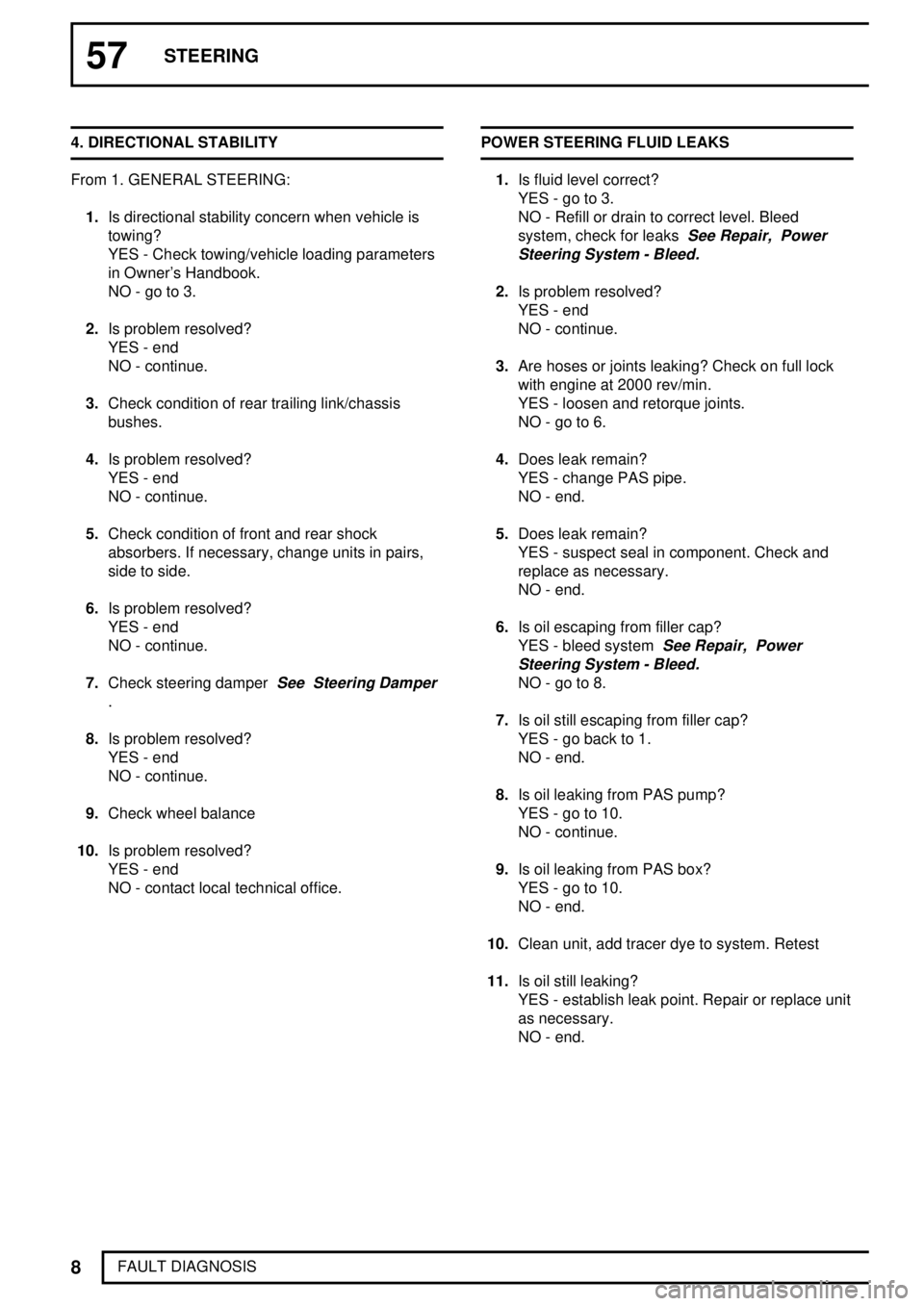

11.Clean stub axle and drive shaft and fit hub

assembly to axle.

12.Fit spacing washer.

13.Fit hub adjusting nut. Tighten to

50 Nm (37

lbf/ft).

Ensure hub is free to rotate with no

bearing play.

14.Back off adjusting nut 90°and tighten to

10 Nm

(7 lbf/ft).

15.Fit a new lock washer.

16.Fit locknut. Tighten to

50 Nm (37 lbf/ft).

17.Tab over lock washer to secure adjusting nut

and locknut.

18.Fit a new joint washer to driving member and fit

member to hub. Tighten bolts to

65 Nm (48

lbf/ft).

19.Fit original drive shaft shim and secure with a

circlip.

20.To check drive shaft end play, mount a dial

gauge using bracketLRT-99-503and rest pin in

a loaded condition on end of drive shaft.

21.Fit a suitable bolt to threaded end of drive shaft.

Move drive shaft in and out noting dial gauge

reading. End play should be between 0,08 to

0,25 mm.

22.If end play requires adjustment, remove circlip,

measure shim thickness and fit an appropriate

shim to give required end-play.

23.Remove bolt from drive shaft, fit circlip and dust

cap.

24.Fit brake disc shield and brake caliper. Tighten

fixings to

82 Nm (60 lbf/ft).

25.Bleed brake systemSee BRAKES, Repair,

Brake system bleed

.

26.Fit road wheel, remove axle stands and tighten

road wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

27.Operate footbrake to locate brake pads before

driving vehicle.

Page 217 of 455

FRONT AXLE AND FINAL DRIVE

1

SPECIFICATIONS, TORQUE REV: 05/99 TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

FRONT AXLE

Hub driving member to hub 65*.......................................................................

Brake disc to hub 73.......................................................................................

Stub axle to swivel pin housing 65*.................................................................

Brake caliper to swivel pin housing 82............................................................

Upper swivel pin to swivel pin housing 78*.....................................................

Lower swivel pin to swivel pin housing 78*.....................................................

Oil seal retainer to swivel pin housing 11........................................................

Swivel bearing housing to axle case 73*.........................................................

Pinion housing to axle case 41.......................................................................

Crown wheel to differential housing 58...........................................................

Differential bearing cap to pinion housing 90..................................................

Differential drive flange to drive shaft 47.........................................................

Mudshield to bracket lower swivel pin 11........................................................

Bevel pinion nut 130........................................................................................

Draglink to hub arm 40....................................................................................

Panhard rod to axle bracket 88.......................................................................

Radius arm to axle 190....................................................................................

Radius arm to chassis side member 190.........................................................

NOTE: * These bolts to be coated with Loctite 270 prior to assembly.

Page 227 of 455

STEERING

5

FAULT DIAGNOSIS REV: 05/99 Symptom :-

Steering excessively light/sensitive. Excessive

freeplay at steering wheel.

1.Are steering box adjustments correct?

NO -

See Adjustment, Power Steering Box.

WARNING: Adjustments of steering box

should not be required while in warranty

period. If box is within warranty, it must be

returned to manufacturer. No attempt must be

made to introduce backlash.

YES - Suspect worn panhard rod or radius arm

bushes. Check condition of ball joints and the

lower steering column shaft universal joints for

wear

See Repair, Lower Steering Shaft and

Universal Joints

.

Symptom :-

Steering vibration, road wheel shimmy - wobble.

Vibration through the steering linkage powerful

enough to induce high frequency oscillation of the

steering wheel, is generally caused by out of balance

road wheels. However there are a number of other

possible causes of this symptom which if severe, may

be described as shimmy or wobble. Regardless of the

terminology used by the owner/driver to describe the

symptoms, the following diagnostic checks should be

carried out in the order presented.

1.Check the tyres and balance of the road wheels

See GENERAL SPECIFICATION DATA,

Information, Wheels and Tyres

,See

WHEELS AND TYRES, Fault diagnosis, Fault

- Symptoms See WHEELS AND TYRES,

Repair, Wheel Balancing .

2.Check the steering hydraulic damper function

See Steering Damper.

3.Check steering column universal joints for wear

and correct alignment

See Repair, Lower

Steering Shaft and Universal Joints

.4.Check steering linkage ball joints for wear,

correct alignment and security, including steering

box and tie rod

See Steering Linkage Inspect

.

5.Check all front suspension rubbers for wear.

Check all fixing torques, including radius arm

bushes, panhard rod and anti-roll bar

See

FRONT SUSPENSION, Repair, Panhard Rod

,

See FRONT SUSPENSION, Repair, Radius

Arm

,See FRONT SUSPENSION, Repair,

Anti-Roll Bar

,See FRONT SUSPENSION,

Repair, Front Shock Absorber

.

6.Fit new radius arm bushes using NTC 6781. Fit

new nuts, bolts and washers.

7.If problem persists fit damper kit STC 288 - 90,

STC 290 - 110/130 (2 off front) and STC 289 -

90, STC 291 - 110 levelled, STC 292 - 110

unlevelled, STC 293 - 130 (2 off rear). Road test

vehicle.

8.Check the power steering box adjustments and

operation

See Overhaul, Power Steering Box.

9.Check the hub bearing end floats and determine

the condition of the hub bearings as applicable

See FRONT AXLE AND FINAL DRIVE, Repair,

Front Hub Assembly

.

10.Check the resistance and condition of the

swivels

See FRONT AXLE AND FINAL DRIVE,

Description and operation, Description

.

If problem is not diagnosed: Repeat checks

starting at 1.

11.Carry out a full steering geometry check

See

GENERAL SPECIFICATION DATA,

Information, Steering

.

Page 230 of 455

57STEERING

8

FAULT DIAGNOSIS 4. DIRECTIONAL STABILITY

From 1. GENERAL STEERING:

1.Is directional stability concern when vehicle is

towing?

YES - Check towing/vehicle loading parameters

in Owner's Handbook.

NO - go to 3.

2.Is problem resolved?

YES - end

NO - continue.

3.Check condition of rear trailing link/chassis

bushes.

4.Is problem resolved?

YES - end

NO - continue.

5.Check condition of front and rear shock

absorbers. If necessary, change units in pairs,

side to side.

6.Is problem resolved?

YES - end

NO - continue.

7.Check steering damper

See Steering Damper

.

8.Is problem resolved?

YES - end

NO - continue.

9.Check wheel balance

10.Is problem resolved?

YES - end

NO - contact local technical office.POWER STEERING FLUID LEAKS

1.Is fluid level correct?

YES - go to 3.

NO - Refill or drain to correct level. Bleed

system, check for leaks

See Repair, Power

Steering System - Bleed.

2.Is problem resolved?

YES - end

NO - continue.

3.Are hoses or joints leaking? Check on full lock

with engine at 2000 rev/min.

YES - loosen and retorque joints.

NO - go to 6.

4.Does leak remain?

YES - change PAS pipe.

NO - end.

5.Does leak remain?

YES - suspect seal in component. Check and

replace as necessary.

NO - end.

6.Is oil escaping from filler cap?

YES - bleed system

See Repair, Power

Steering System - Bleed.

NO - go to 8.

7.Is oil still escaping from filler cap?

YES - go back to 1.

NO - end.

8.Is oil leaking from PAS pump?

YES - go to 10.

NO - continue.

9.Is oil leaking from PAS box?

YES - go to 10.

NO - end.

10.Clean unit, add tracer dye to system. Retest

11.Is oil still leaking?

YES - establish leak point. Repair or replace unit

as necessary.

NO - end.

Page 233 of 455

STEERING

11

FAULT DIAGNOSIS STIFF STEERING CHECKLIST

NOTE: Having completed visual checks

and steering assessment and confirmed

that vehicle steering load is incorrect carry

out the following procedure in order shown.

Steering wheel 'torque to turn' loads

1.Raise vehicle so both front wheels free.

2.With engine off, centralise steering wheel, and

remove steering wheel decal. Using torque

wrench on column nut, check torque required to

turn the steering wheel one turn in each

direction.

3.Record readings obtained in each direction.

Reading should be

4.40 Nm (3.5 lbf/ft).

NOTE: If figures are in excess of that

specified carry out steering box tie bar

reset below. If figures are as specified

See

Visual Check and Basic Adjustments

.

Steering box tie bar reset

1.Loosen the tie bar fixings one complete turn.

2.Drive vehicle carefully a short distance (within

the dealership) applying full lock in both

directions in order to settle steering components.

Drive vehicle over speed bumps and include

harsh braking if possible.

WARNING: Do not drive on public

highway.

3.Near end of operation 2. ensure vehicle is driven

in a straight line on level ground and halted.

4.Tighten panhard rod mounting arm nut to

110

Nm (81 lbf/ft).

5.Tighten the 2 fixings, tie bar to steering box, to

81 Nm (60 lbf/ft).

6.Recheck steering wheel torque to turn. If torque

reading is still greater than specified, carry out

steering shaft universal joint lubrication.Lower steering shaft universal joint lubrication

1.Check lower steering shaft is correctly phased

See Repair, Lower Steering Shaft and

Universal Joints

.

2.Lubricate universal joints with an anti-seizure

type penetrating spray. Work the joints to ensure

full penetration of the spray by driving vehicle

and steering from lock to lock.

3.If steering stiffness still persists carry out swivel

pin preload setting.

Swivel pin preload setting

1.The swivel pin preload setting must be checked

and set

See FRONT AXLE AND FINAL DRIVE,

Overhaul, Front Stub Axle, Constant Velocity

Joint and Swivel Pin Housing

.

Note that a pull load of 1.16 - 1.46 kg is required

after the axle shaft and swivel housing seal have

been removed.

Steering box adjustment

1.Check steering box adjustment

See

Adjustment, Power Steering Box

.

Steering damper check

1.Check condition of steering damper

See

Steering Damper

.