Bonnet release LAND ROVER DEFENDER 1996 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 65 of 455

12ENGINE

6

REPAIR 42.Raise engine, and locate front engine mountings

to chassis.

43.Remove gearbox support and lower engine.

44.Tighten front engine mounting to chassis fixings

to

45 Nm (33 lbf/ft).

45.Release chains from engine lifting brackets and

remove hoist.

46.Connect oil cooler pipes to oil filter adaptor.

47.Fit vacuum hose to brake servo adaptor.

48.Secure fuel feed pipe in retaining clip on air

cleaner bracket.

49.Fit fuel lift pump pipes.

50.Connect feed and spill return pipes to injector

pump.

51.If fitted, reconnect hand throttle cable to

mounting bracket and injector pump.

52.Fit outer cable adjusting nut into injector pump

mounting bracket.

53.Fit inner throttle cable to injector pump and

secure with clevis and split pin.

54.Secure bleed hose in retaining clips on front

timing cover.

55.Fit bleed hose to thermostat housing.

56.Connect inlet and outlet hoses to power steering

pump.

57.Fit down pipe to exhaust manifold and secure

with 3 nuts.

58.Connect starter motor battery and fuse box

leads.

59.If fitted, connect EGR valve multi-plug and

vacuum pipe.

60.Secure breather pipe clip to cylinder head.

61.Connect engine harness multi-plug.

62.Fit heater plug feed wire.

63.Connect electrical feed plug at rear of cylinder

head.

64.Fit heater hoses to cylinder head and heater

rails.

65.Fit feed pipe/hose to turbo-charger and

intercooler.

66.Fit rocker cover insulation.

67.Fit radiator assembly.

See COOLING SYSTEM,

Repair, Radiator

If applicable, fit air

conditioning condenser, compressor pipes and

heater matrix hoses.

See AIR CONDITIONING,

Repair, Condenser

68.Fit bonnet.

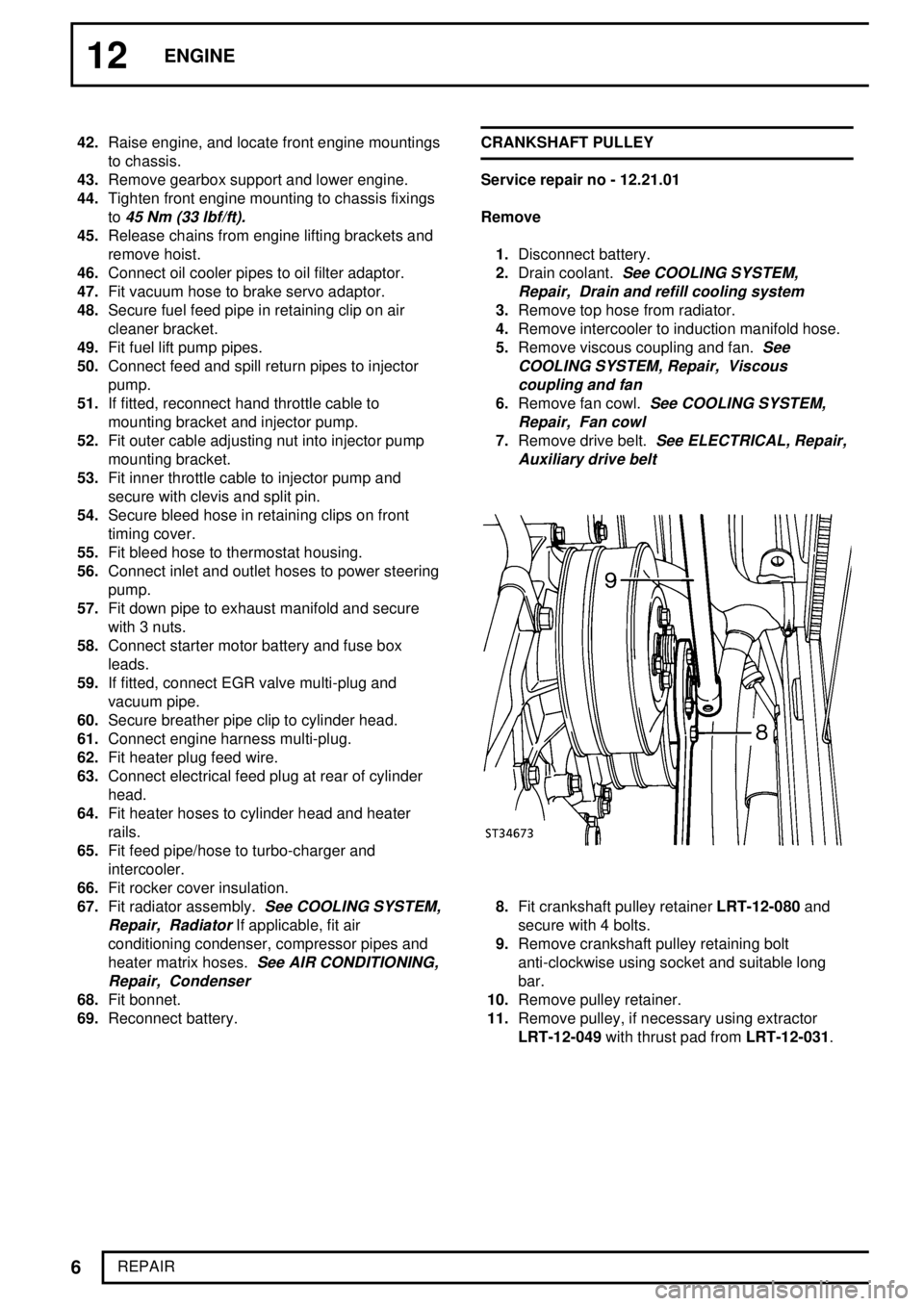

69.Reconnect battery.CRANKSHAFT PULLEY

Service repair no - 12.21.01

Remove

1.Disconnect battery.

2.Drain coolant.

See COOLING SYSTEM,

Repair, Drain and refill cooling system

3.Remove top hose from radiator.

4.Remove intercooler to induction manifold hose.

5.Remove viscous coupling and fan.

See

COOLING SYSTEM, Repair, Viscous

coupling and fan

6.Remove fan cowl.See COOLING SYSTEM,

Repair, Fan cowl

7.Remove drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

8.Fit crankshaft pulley retainerLRT-12-080and

secure with 4 bolts.

9.Remove crankshaft pulley retaining bolt

anti-clockwise using socket and suitable long

bar.

10.Remove pulley retainer.

11.Remove pulley, if necessary using extractor

LRT-12-049with thrust pad fromLRT-12-031.

Page 82 of 455

ENGINE

23

REPAIR

43.Check and adjust valve clearances.

See Adjustment, Valve clearances - check

and adjust

44.Fit rocker cover, ensuring oil seal is satisfactory

for continued use, and renew if necessary.

45.Secure rocker cover with special seal washers

and nuts. Tighten to

10 Nm (7 lbf/ft).

46.Fit rear engine lifting bracket, securing breather

pipe and multi-plug retaining clips. Tighten fixing

bolts to

25 Nm (18 lbf/ft).

47.Fit engine harness bracket to cylinder head.

48.Secure air cleaner mounting bracket to support

strut.

49.Connect heater hose to rear of cylinder head.

50.Position heater rail and connect hose from water

pump.

51.Fit exhaust manifold and turbocharger assembly.

See MANIFOLD AND EXHAUST SYSTEM,

Repair, Exhaust manifold

52.Fit induction manifold.See MANIFOLD AND

EXHAUST SYSTEM, Repair, Induction

manifold

53.Connect water temperature sensor lead.

54.Connect water pump hose at thermostat.

55.Fit bleed hose at thermostat.

56.Connect radiator top hose at thermostat.

57.Fit heater plugs.

See FUEL SYSTEM, Repair,

Heater plugs

58.Fit fuel injectors.See FUEL SYSTEM, Repair,

Fuel injectors

59.Fit crankcase ventilation valve and side breather

hose.

60.Fit air cleaner.

See FUEL SYSTEM, Repair,

Air cleaner

61.Refill cooling system.See COOLING SYSTEM,

Repair, Drain and refill cooling system

62.Fit bonnet.

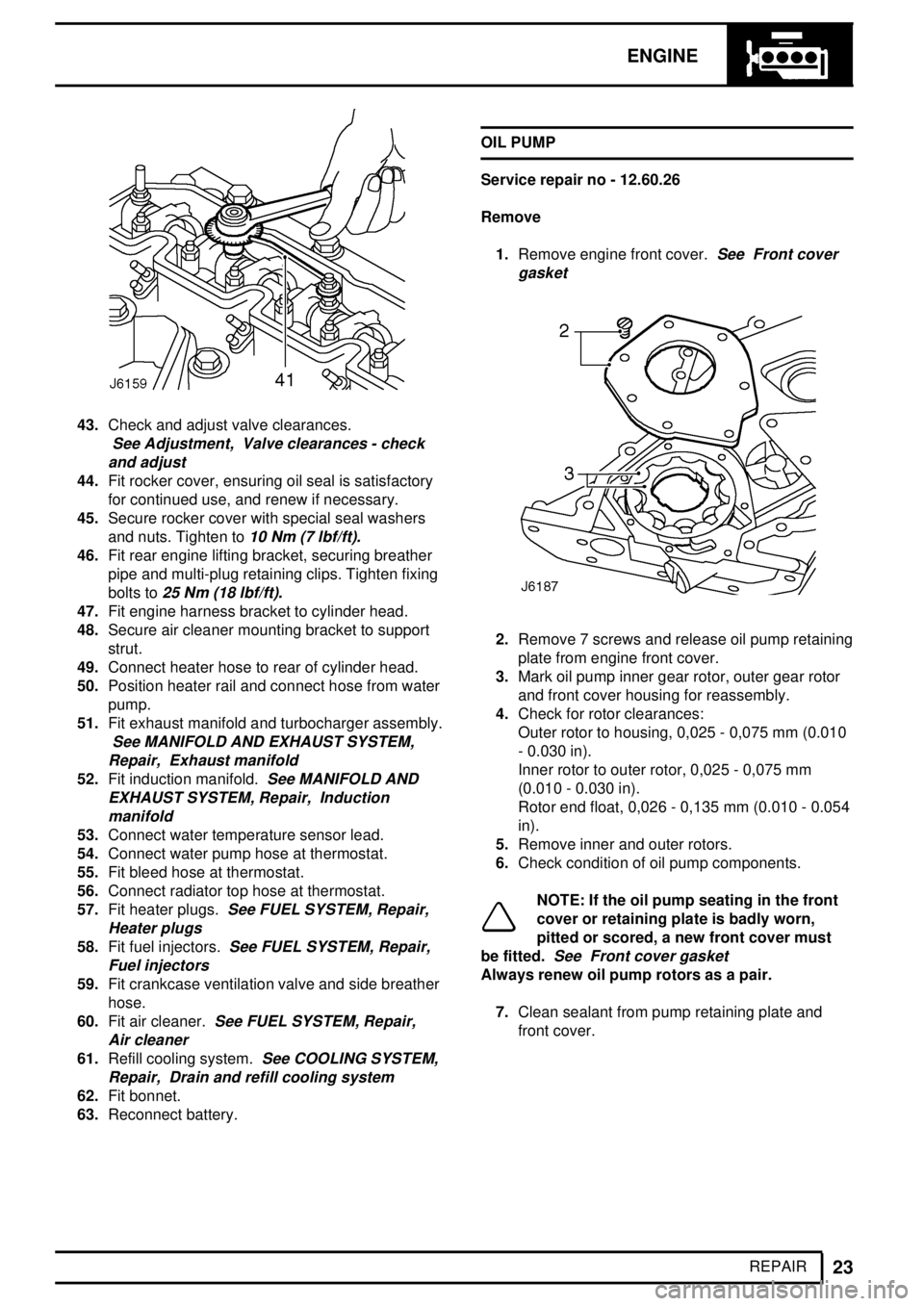

63.Reconnect battery.OIL PUMP

Service repair no - 12.60.26

Remove

1.Remove engine front cover.

See Front cover

gasket

2.Remove 7 screws and release oil pump retaining

plate from engine front cover.

3.Mark oil pump inner gear rotor, outer gear rotor

and front cover housing for reassembly.

4.Check for rotor clearances:

Outer rotor to housing, 0,025 - 0,075 mm (0.010

- 0.030 in).

Inner rotor to outer rotor, 0,025 - 0,075 mm

(0.010 - 0.030 in).

Rotor end float, 0,026 - 0,135 mm (0.010 - 0.054

in).

5.Remove inner and outer rotors.

6.Check condition of oil pump components.

NOTE: If the oil pump seating in the front

cover or retaining plate is badly worn,

pitted or scored, a new front cover must

be fitted.

See Front cover gasket

Always renew oil pump rotors as a pair.

7.Clean sealant from pump retaining plate and

front cover.

Page 114 of 455

19FUEL SYSTEM

12

REPAIR HEATER PLUG CONTROL UNIT

Service repair no - 19.60.33

Remove

1.Disconnect battery.

2.Remove screw securing control unit to bulkhead.

3.Disconnect multi-plug and release control unit.

Refit

4.Fit harness multi-plug to control unit.

5.Secure control unit to bulkhead.

6.Reconnect battery.AIR CLEANER

Service repair no - 19.10.01

Remove

1.Slacken hose clip and detach outlet hose.

2.Release clips and open air cleaner retaining

straps.

3.Lift up air cleaner, slacken hose clip and detach

inlet hose.

4.Remove air cleaner.

Refit

5.Position air cleaner and connect inlet hose.

6.Close air cleaner retaining straps and secure

lock clips.

7.Connect outlet hose.

NOTE: If an EGR fuel system is fitted,

ensure the modulator valve vacuum spill

pipe is secure in the outlet hose.

AIR CLEANER ELEMENT

Service repair no - 19.10.10

For remove and refit procedure.

See SECTION 10,

Maintenance, Under bonnet maintenance

Page 353 of 455

76CHASSIS AND BODY

32

REPAIR BONNET LOCK

Service repair no - 76.16.21

Remove

1.Open bonnet.

2.Mark position of guide plate and lock to bonnet

platform.

3.Remove 8 screws securing grille.

4.Remove grille.

5.Remove 2 bolts securing guide plate and lock.

6.Remove guide plate.

7.Release spring securing lock to bonnet platform.

8.Slacken clamping bolt securing bonnet release

cable.

9.Remove lock.

Refit

10.Fit spring between lock and bonnet platform.

11.Position lock and guide plate to bonnet platform

and nip up bolts.

12.Position guide plate and lock to position marks

and tighten bolts to

10 Nm (7 lbf/ft).

13.Fit cable to lock and tighten clamping bolt.

14.Check operation of release cable and adjust if

necessary.

15.Fit grille and tighten securing screws.

16.Close bonnet.BONNET RELEASE CABLE

Service repair no - 76.16.29

Remove

1.Open bonnet.

2.Remove 8 screws securing grille.

3.Remove grille.

4.Slacken clamping bolt securing bonnet release

cable.

5.Remove cable from lock.

6.Release cable from clip on underside of bonnet

platform.

7.Feed cable through valance and collect

grommet.

8.Release cable from clip fixed to wheelarch under

expansion tank.

9.Loosen clamping nut securing bonnet release

handle to mounting bracket.

10.Remove bonnet release handle from mounting

bracket.

11.Withdraw cable through bulkhead.

Refit

12.Feed cable through bulkhead and fit bonnet

release handle to mounting bracket. Tighten

clamping nut.

13.Route cable behind expansion tank and fit to

securing clip.

14.Feed cable through valance.

15.Fit grommet between cable and valance.

16.Fit cable to securing clip on underside of bonnet

platform.

Page 354 of 455

CHASSIS AND BODY

33

REPAIR 17.Fit cable to lock and tighten clamping bolt.

18.Check operation of release cable and bonnet

lock and adjust if necessary.

19.Fit grille and tighten screws.

20.Close bonnet.

Page 386 of 455

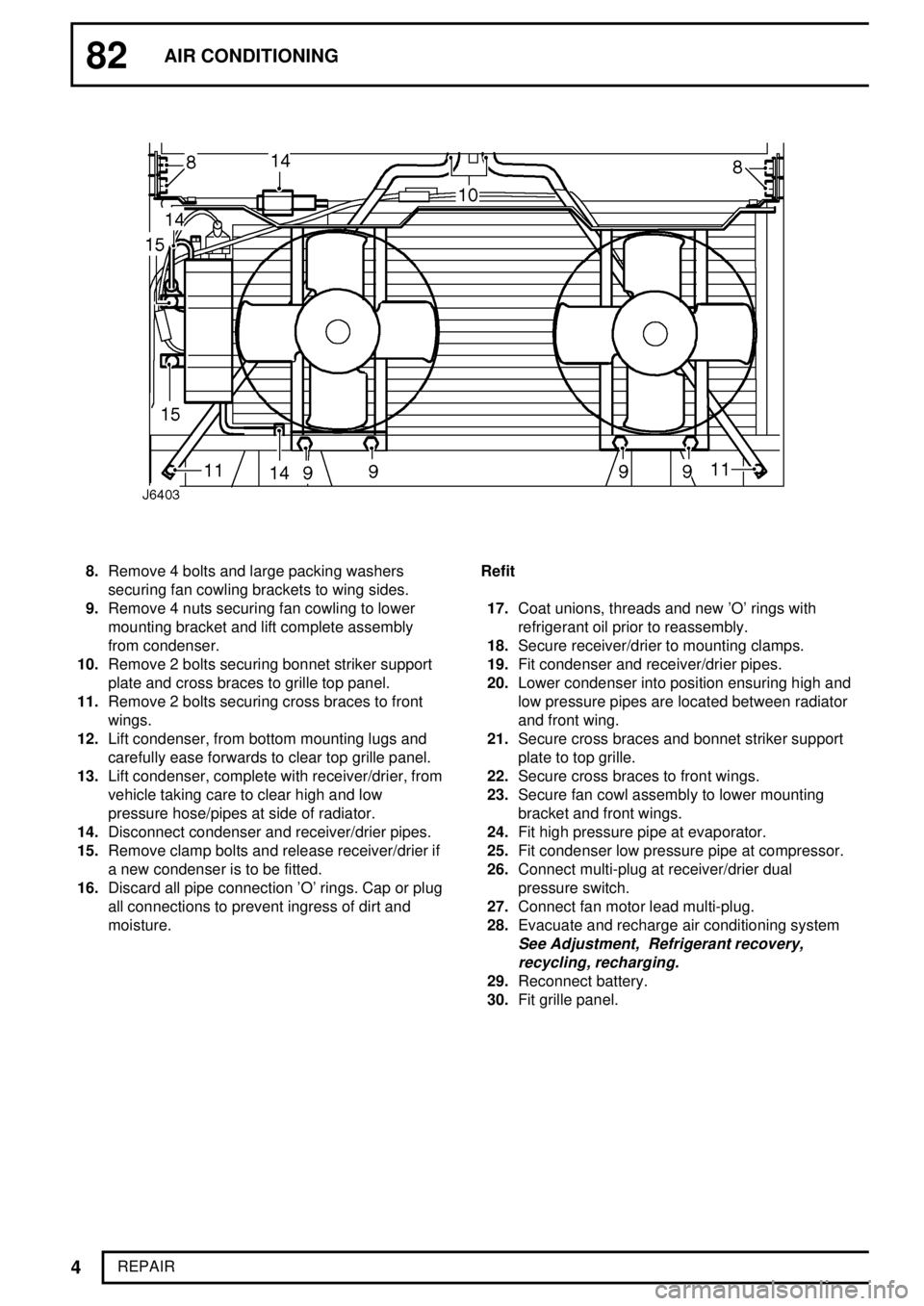

82AIR CONDITIONING

4

REPAIR

8.Remove 4 bolts and large packing washers

securing fan cowling brackets to wing sides.

9.Remove 4 nuts securing fan cowling to lower

mounting bracket and lift complete assembly

from condenser.

10.Remove 2 bolts securing bonnet striker support

plate and cross braces to grille top panel.

11.Remove 2 bolts securing cross braces to front

wings.

12.Lift condenser, from bottom mounting lugs and

carefully ease forwards to clear top grille panel.

13.Lift condenser, complete with receiver/drier, from

vehicle taking care to clear high and low

pressure hose/pipes at side of radiator.

14.Disconnect condenser and receiver/drier pipes.

15.Remove clamp bolts and release receiver/drier if

a new condenser is to be fitted.

16.Discard all pipe connection 'O' rings. Cap or plug

all connections to prevent ingress of dirt and

moisture.Refit

17.Coat unions, threads and new 'O' rings with

refrigerant oil prior to reassembly.

18.Secure receiver/drier to mounting clamps.

19.Fit condenser and receiver/drier pipes.

20.Lower condenser into position ensuring high and

low pressure pipes are located between radiator

and front wing.

21.Secure cross braces and bonnet striker support

plate to top grille.

22.Secure cross braces to front wings.

23.Secure fan cowl assembly to lower mounting

bracket and front wings.

24.Fit high pressure pipe at evaporator.

25.Fit condenser low pressure pipe at compressor.

26.Connect multi-plug at receiver/drier dual

pressure switch.

27.Connect fan motor lead multi-plug.

28.Evacuate and recharge air conditioning system

See Adjustment, Refrigerant recovery,

recycling, recharging.

29.Reconnect battery.

30.Fit grille panel.

Page 432 of 455

ELECTRICAL

7

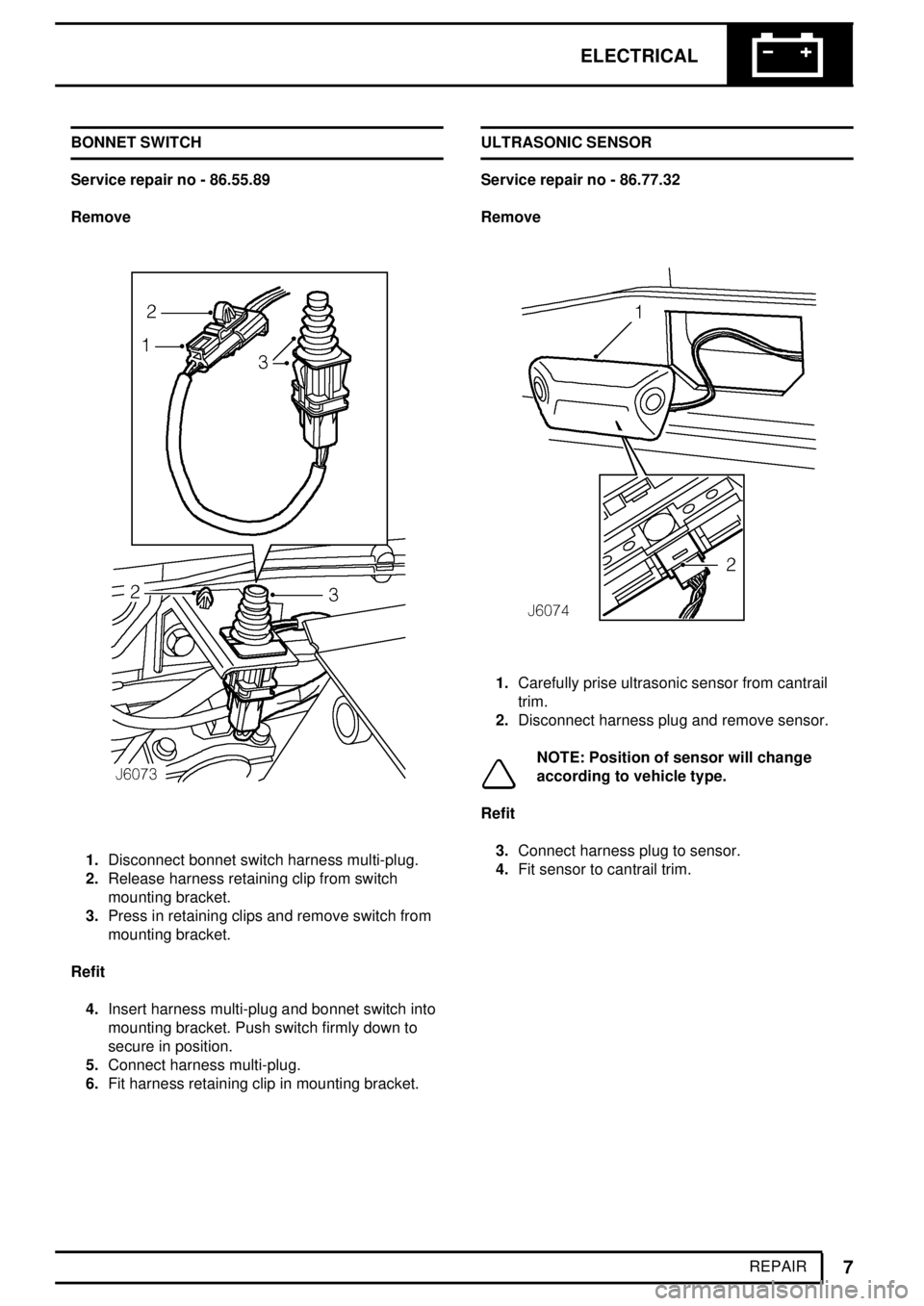

REPAIR BONNET SWITCH

Service repair no - 86.55.89

Remove

1.Disconnect bonnet switch harness multi-plug.

2.Release harness retaining clip from switch

mounting bracket.

3.Press in retaining clips and remove switch from

mounting bracket.

Refit

4.Insert harness multi-plug and bonnet switch into

mounting bracket. Push switch firmly down to

secure in position.

5.Connect harness multi-plug.

6.Fit harness retaining clip in mounting bracket.ULTRASONIC SENSOR

Service repair no - 86.77.32

Remove

1.Carefully prise ultrasonic sensor from cantrail

trim.

2.Disconnect harness plug and remove sensor.

NOTE: Position of sensor will change

according to vehicle type.

Refit

3.Connect harness plug to sensor.

4.Fit sensor to cantrail trim.