key battery LAND ROVER DEFENDER 1996 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 67 of 455

12ENGINE

8

REPAIR Refit

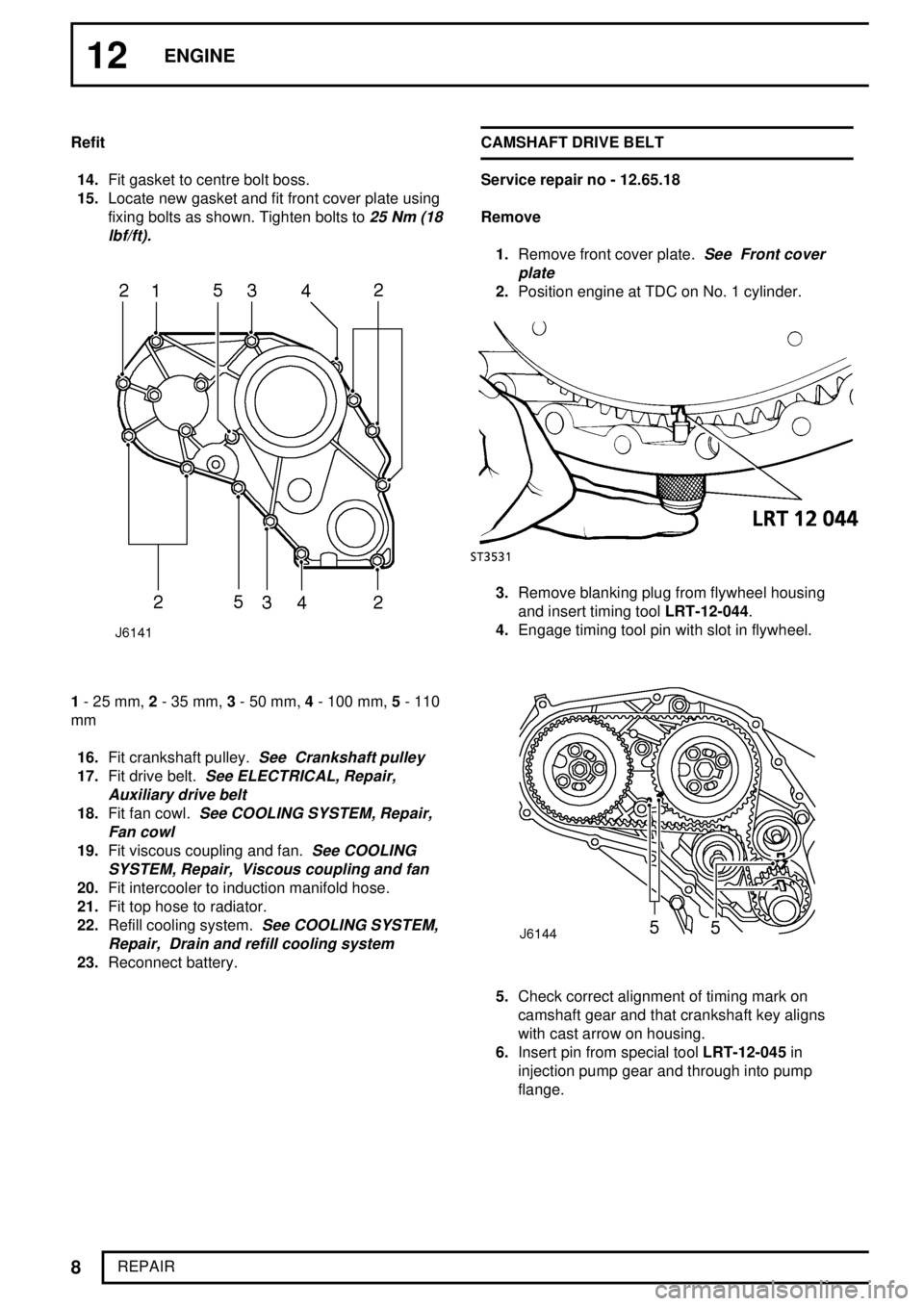

14.Fit gasket to centre bolt boss.

15.Locate new gasket and fit front cover plate using

fixing bolts as shown. Tighten bolts to

25 Nm (18

lbf/ft).

1- 25 mm,2- 35 mm,3- 50 mm,4- 100 mm,5- 110

mm

16.Fit crankshaft pulley.

See Crankshaft pulley

17.Fit drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

18.Fit fan cowl.See COOLING SYSTEM, Repair,

Fan cowl

19.Fit viscous coupling and fan.See COOLING

SYSTEM, Repair, Viscous coupling and fan

20.Fit intercooler to induction manifold hose.

21.Fit top hose to radiator.

22.Refill cooling system.

See COOLING SYSTEM,

Repair, Drain and refill cooling system

23.Reconnect battery.CAMSHAFT DRIVE BELT

Service repair no - 12.65.18

Remove

1.Remove front cover plate.

See Front cover

plate

2.Position engine at TDC on No. 1 cylinder.

3.Remove blanking plug from flywheel housing

and insert timing toolLRT-12-044.

4.Engage timing tool pin with slot in flywheel.

5.Check correct alignment of timing mark on

camshaft gear and that crankshaft key aligns

with cast arrow on housing.

6.Insert pin from special toolLRT-12-045in

injection pump gear and through into pump

flange.

Page 414 of 455

86ELECTRICAL

2

DESCRIPTION AND OPERATION VEHICLE IMMOBILISATION AND ALARM SYSTEM

A sophisticated engine immobilisation and anti-theft

alarm system is offered on the Land Rover Defender

300 Tdi vehicle range, which incorporates the

following features:

Perimeter protection

This part of the alarm system protects side doors,

bonnet and rear door against unauthorised entry -

alarm sounding if any one of these apertures is

opened without alarm first being disarmed.

Interior protection

Also known as volumetric protection, this part of the

system protects space inside the vehicle. Once

armed, the alarm will sound if a door is opened, or if

movement is detected inside the vehicle.

Engine immobilisation

The engine is immobilised electronically whenever the

alarm system is armed. Even if the alarm has not

been armed, engine immobilisation will occur

automatically thirty seconds after the driver's door is

opened, or five minutes after the starter switch is

turned to position '0'.

ALARM SYSTEM COMPONENTS

Electronic control unit (ECU)

The ECU is the alarm system brain and controls all

vehicle immobilisation and alarm functions. It

responds to the inputs received, by supplying suitable

outputs to indicate status of the alarm system or

activating relevant warning devices. unit is located

under fascia behind instrument binnacle.

Handset and key

The handset is the primary source of control for the

alarm system i.e. it arms and disarms the alarm

components. The key can be used to override engine

immoblisation if the handset is lost or fails to operate,

seeEngine immobilisation override.The handset battery should last for approximately

three years dependent upon use. The following

symptoms will be noticed when the battery requires

replacement:

1.The handset will only work every other operation

while disarming.

2.The direction indicator lamps will not flash when

the alarm is disarmed.

For battery replacement procedure, seeHandset

Battery.

Passive coil

The passive coil is fitted on the starter switch and

activates a receiving coil in the handset, causing it to

automatically transmit a remobilisation signal to the

ECU.

Aerial

The aerial is integral within the alarm system harness

and supplies the ECU with the signal received from

handset.

Immobilisation spider

The immobilisation spider provides an interface

between ECU and immobilised areas of the vehicle.

This is installed in a sealed (safe) box inside the

vehicle battery box.

Digital diesel shut-off valve - 97 MY

When fitted, the digital diesel shut-off valve

immobilises the fuel injection pump by preventing

power reaching the fuel shut-off solenoid,

See

Immobilisation and alarm system circuit diagram -

with DDS

.

Page 416 of 455

86ELECTRICAL

4

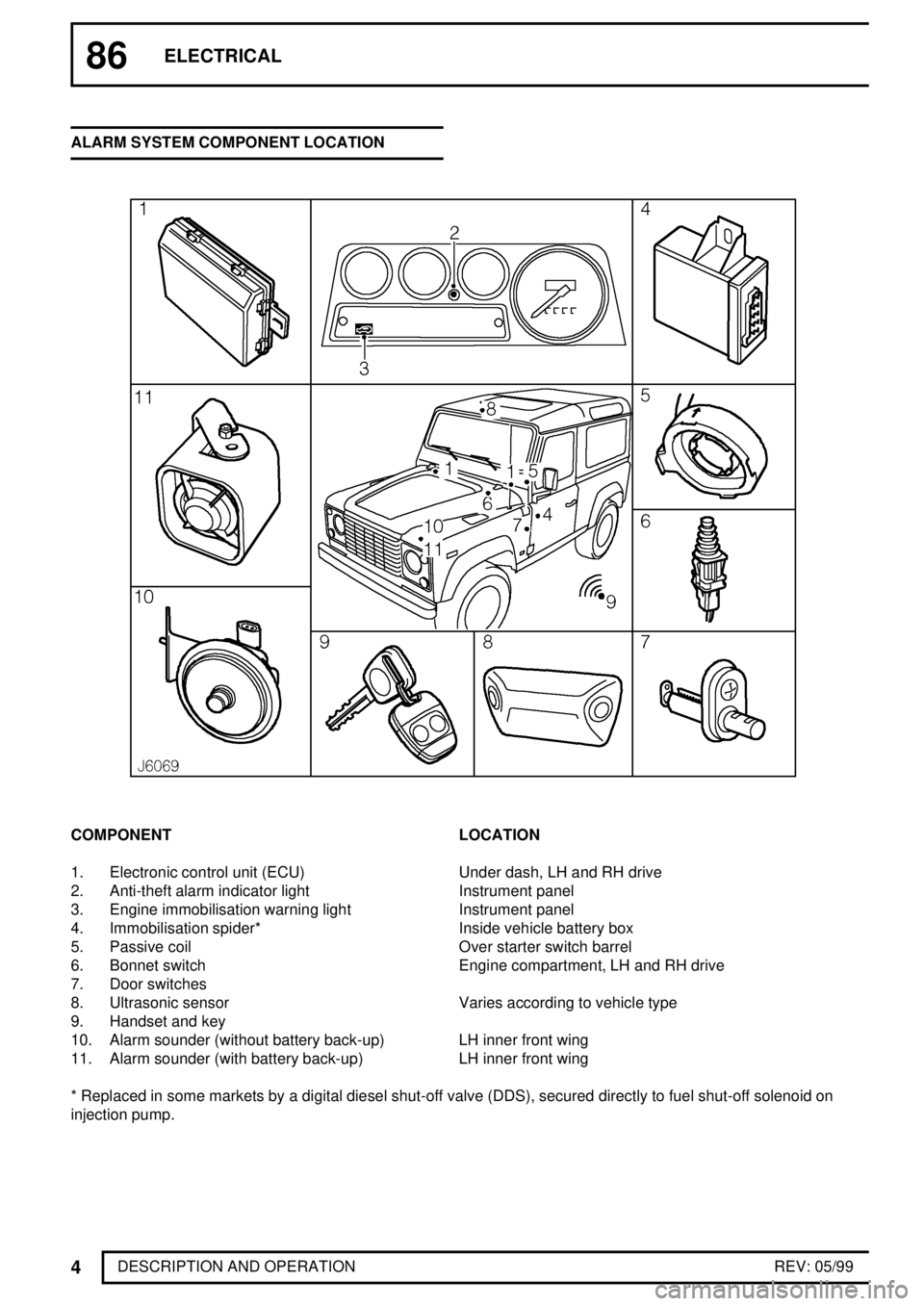

DESCRIPTION AND OPERATION REV: 05/99 ALARM SYSTEM COMPONENT LOCATION

COMPONENT LOCATION

1. Electronic control unit (ECU) Under dash, LH and RH drive

2. Anti-theft alarm indicator light Instrument panel

3. Engine immobilisation warning light Instrument panel

4. Immobilisation spider* Inside vehicle battery box

5. Passive coil Over starter switch barrel

6. Bonnet switch Engine compartment, LH and RH drive

7. Door switches

8. Ultrasonic sensor Varies according to vehicle type

9. Handset and key

10. Alarm sounder (without battery back-up) LH inner front wing

11. Alarm sounder (with battery back-up) LH inner front wing

* Replaced in some markets by a digital diesel shut-off valve (DDS), secured directly to fuel shut-off solenoid on

injection pump.

Page 421 of 455

ELECTRICAL

9

DESCRIPTION AND OPERATION IMMOBILISATION AND ALARM SYSTEM CIRCUIT

DIAGRAM

1.Anti-theft alarm indicator light (LED)

2.Engine immobilisation warning light

3.Alarm system fuse - 15 amp

4.Alarm sounder relay

5.Under bonnet lighting fuse

6.Alarm sounder (without battery back-up)

7.Alarm system fuse - 5 amp (position 20)

8.Electronic control unit (ECU)

9.Bonnet switch

10.Alarm sounder protection fuse - 20 amp

(position 10)

11.Starter switch

12.Under bonnet ignition fuse

13.Driver's door switch

14.Vehicle horn switch

15.Vehicle horn

16.Passive coil

17.Starter switch relay

18.Front passenger door switch

19.Hazard warning light fuse - 15 amp (position 1)

20.Ultrasonic sensor

21.Interior lamp and horn fuse - 20 amp (position 3)

22.Alarm sounder (with battery back-up)

23.LH direction indicator lamps

24.RH direction indicator lamps

25.Interior lamp

26.Immobilisation spider

27.Rear side doors and rear door switches

28.Diagnostic connector

29.Diagnostic fuse - 7.5 amp

30.Starter solenoid

31.Fuel switch-off solenoid (injection pump)

32.Generator

33.AerialKey to cable colours

B-Black

G-Green

K-Pink

LG-Light Green

N-Brown

O-Orange

P-Purple

R-Red

S-Slate

U-Blue

W-White

Y-Yellow

The last letter of a colour code denotes the tracer

colour

Page 423 of 455

ELECTRICAL

11

DESCRIPTION AND OPERATION IMMOBILISATION AND ALARM SYSTEM CIRCUIT

DIAGRAM - WITH DDS

1.Anti-theft alarm indicator light (LED)

2.Engine immobilisation warning light

3.Alarm system fuse - 15 amp

4.Alarm sounder relay

5.Under bonnet lighting fuse

6.Alarm sounder (without battery back-up)

7.Alarm system fuse - 5 amp (position 20)

8.Electronic control unit (ECU)

9.Bonnet switch

10.Alarm sounder protection fuse - 20 amp

(position 10)

11.Starter switch

12.Under bonnet ignition fuse

13.Driver's door switch

14.Vehicle horn switch

15.Vehicle horn

16.Passive coil

17.Starter switch relay

18.Front passenger door switch

19.Hazard warning light fuse - 15 amp (position 1)

20.Ultrasonic sensor

21.Interior lamp and horn fuse - 20 amp (position 3)

22.Alarm sounder (with battery back-up)

23.LH direction indicator lamps

24.RH direction indicator lamps

25.Interior lamp

26.Digital diesel shut-off valve (DDS)

27.Rear side doors and rear door switches

28.Diagnostic connector

29.Diagnostic fuse - 7.5 amp

30.Starter solenoid

31.Fuel shut-off solenoid (injection pump)

32.Generator

33.AerialKey to cable colours

B-Black

G-Green

K-Pink

LG-Light Green

N-Brown

O-Orange

P-Purple

R-Red

S-Slate

U-Blue

W-White

Y-Yellow

The last letter of a colour code denotes the tracer

colour

Page 427 of 455

86ELECTRICAL

2

REPAIR BATTERY

Service repair no - 86.15.01

NOTE: If the vehicle is fitted with a battery

backed-up alarm sounder, disconnecting

the vehicle battery will cause the alarm to

sound unless the following procedure is followed:

1.Remove LH front seat cushion.

2.Release retaining clip and remove battery

access cover.

3.Slacken battery negative lead clamp bolt.

4.Turn starter switch 'on'.

5.Turn starter switch 'off' and remove key.

6.Disconnect battery WITHIN 15 SECONDS.

If alarm is accidentally activated, ensure sounder is

connected and silence by turning the starter switch to

position 'II'.Remove

WARNING: During battery removal or

before carrying out any repairs or

maintenance to electrical components

always disconnect negative lead first. If positive

lead is disconnected with negative lead in place,

accidental contact of a wrench to any grounded

metal part could cause a severe spark, possibly

resulting in personal injury. Upon installation of

battery always connect positive lead first.

1.Remove LH front seat cushion.

2.Release retaining clip and remove battery

access cover.

3.Disconnect both battery leads, negative first.

4.Slacken securing nuts and move battery clamp,

with 'J' bolts aside.

5.Remove battery.

NOTE: Coat battery clamps and terminals

with petroleum jelly before refitting.

Refit

6.Position battery and secure with clamp. Ensure

'J' bolts are hooked correctly under retaining

brackets on base of battery box.

7.Reconnect battery leads, positive lead first.

8.Fit battery access cover.

9.Fit seat cushion.

Page 428 of 455

ELECTRICAL

3

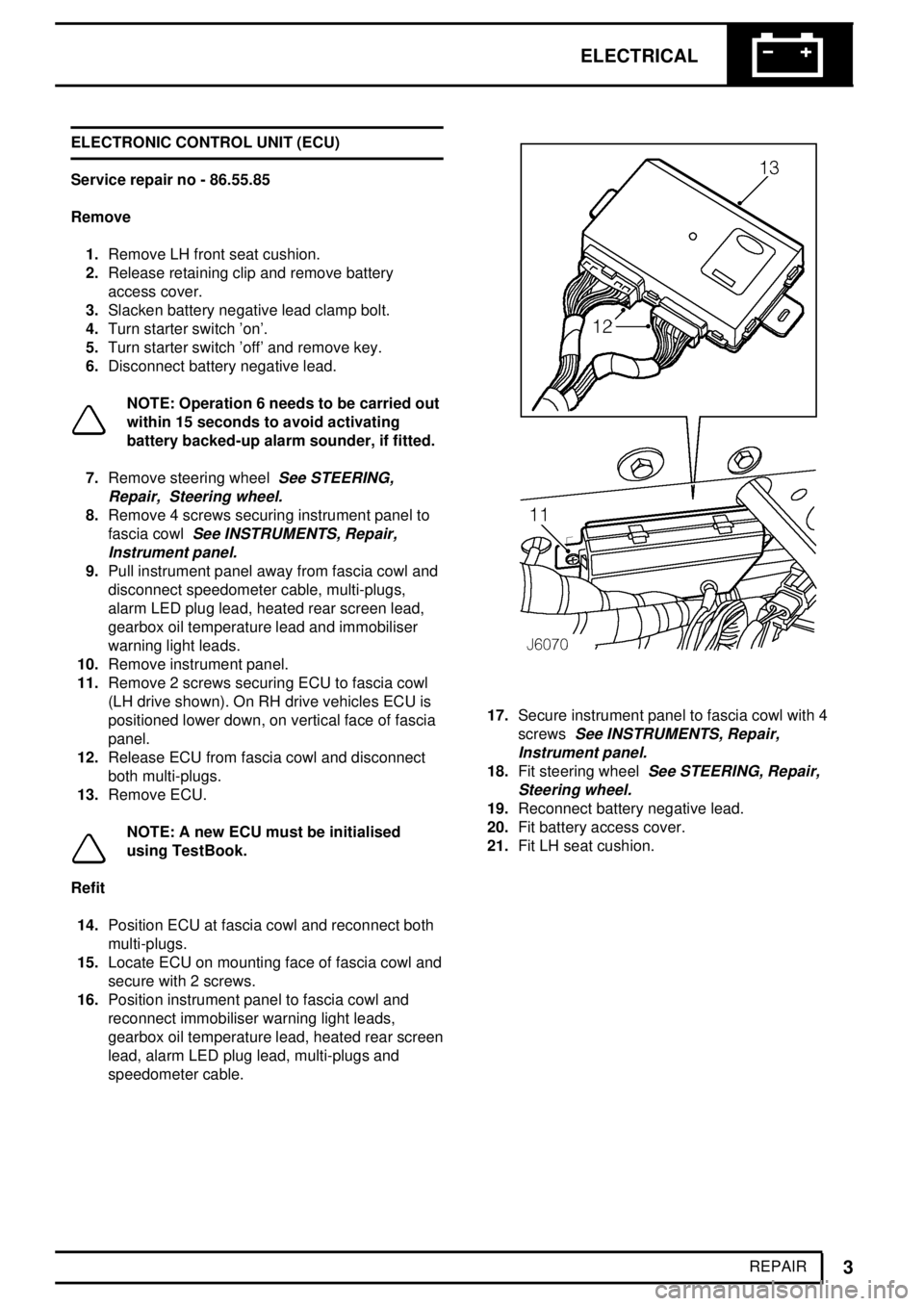

REPAIR ELECTRONIC CONTROL UNIT (ECU)

Service repair no - 86.55.85

Remove

1.Remove LH front seat cushion.

2.Release retaining clip and remove battery

access cover.

3.Slacken battery negative lead clamp bolt.

4.Turn starter switch 'on'.

5.Turn starter switch 'off' and remove key.

6.Disconnect battery negative lead.

NOTE: Operation 6 needs to be carried out

within 15 seconds to avoid activating

battery backed-up alarm sounder, if fitted.

7.Remove steering wheel

See STEERING,

Repair, Steering wheel.

8.Remove 4 screws securing instrument panel to

fascia cowl

See INSTRUMENTS, Repair,

Instrument panel.

9.Pull instrument panel away from fascia cowl and

disconnect speedometer cable, multi-plugs,

alarm LED plug lead, heated rear screen lead,

gearbox oil temperature lead and immobiliser

warning light leads.

10.Remove instrument panel.

11.Remove 2 screws securing ECU to fascia cowl

(LH drive shown). On RH drive vehicles ECU is

positioned lower down, on vertical face of fascia

panel.

12.Release ECU from fascia cowl and disconnect

both multi-plugs.

13.Remove ECU.

NOTE: A new ECU must be initialised

using TestBook.

Refit

14.Position ECU at fascia cowl and reconnect both

multi-plugs.

15.Locate ECU on mounting face of fascia cowl and

secure with 2 screws.

16.Position instrument panel to fascia cowl and

reconnect immobiliser warning light leads,

gearbox oil temperature lead, heated rear screen

lead, alarm LED plug lead, multi-plugs and

speedometer cable.

17.Secure instrument panel to fascia cowl with 4

screws

See INSTRUMENTS, Repair,

Instrument panel.

18.Fit steering wheelSee STEERING, Repair,

Steering wheel.

19.Reconnect battery negative lead.

20.Fit battery access cover.

21.Fit LH seat cushion.

Page 429 of 455

86ELECTRICAL

4

REPAIR HANDSET BATTERY

Service repair no - 86.77.13

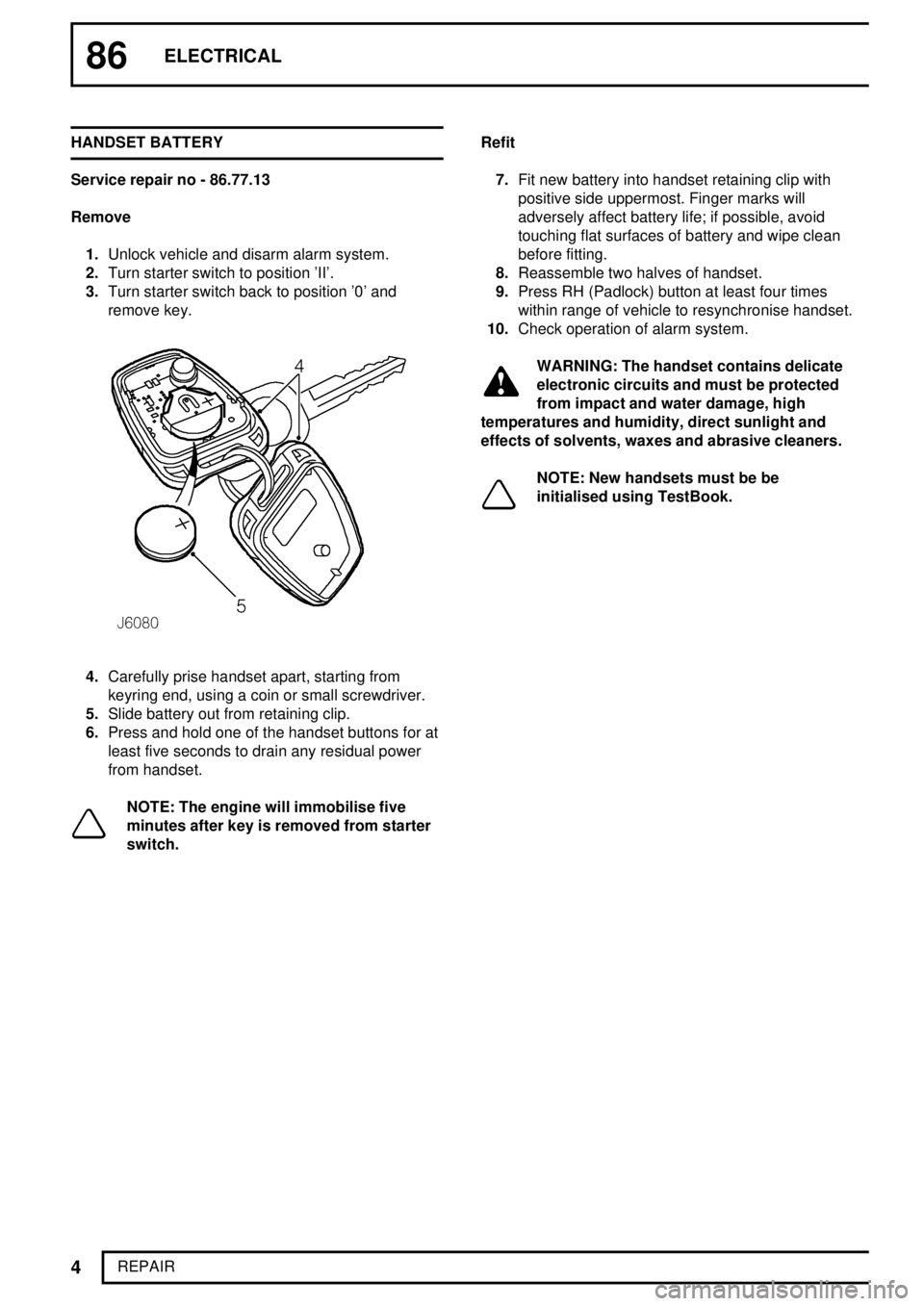

Remove

1.Unlock vehicle and disarm alarm system.

2.Turn starter switch to position 'II'.

3.Turn starter switch back to position '0' and

remove key.

4.Carefully prise handset apart, starting from

keyring end, using a coin or small screwdriver.

5.Slide battery out from retaining clip.

6.Press and hold one of the handset buttons for at

least five seconds to drain any residual power

from handset.

NOTE: The engine will immobilise five

minutes after key is removed from starter

switch.Refit

7.Fit new battery into handset retaining clip with

positive side uppermost. Finger marks will

adversely affect battery life; if possible, avoid

touching flat surfaces of battery and wipe clean

before fitting.

8.Reassemble two halves of handset.

9.Press RH (Padlock) button at least four times

within range of vehicle to resynchronise handset.

10.Check operation of alarm system.

WARNING: The handset contains delicate

electronic circuits and must be protected

from impact and water damage, high

temperatures and humidity, direct sunlight and

effects of solvents, waxes and abrasive cleaners.

NOTE: New handsets must be be

initialised using TestBook.

Page 430 of 455

ELECTRICAL

5

REPAIR PASSIVE COIL

Service repair no - 86.77.35

Remove

1.Remove LH front seat cushion.

2.Release retaining clip and remove battery

access cover.

3.Slacken battery negative lead clamp bolt.

4.Turn starter switch 'on'.

5.Turn starter switch 'off' and remove key.

6.Disconnect battery negative lead.

NOTE: Operation 6 needs to be carried out

within 15 seconds to avoid activating

battery backed-up alarm sounder, if fitted.

7.Remove steering wheel

See STEERING,

Repair, Steering wheel.

8.Remove 4 screws securing instrument panel to

fascia cowl

See INSTRUMENTS, Repair,

Instrument panel.

9.Pull instrument panel away from fascia and

disconnect speedometer cable, multi-plugs,

alarm LED plug lead, heated rear screen lead,

gearbox oil temperature lead and immobiliser

warning light leads.

10.Remove instrument panel.

11.Remove 7 screws securing upper and lower

halves of nacelle to steering column mounting

bracket

See STEERING, Repair, Steering

column nacelle.

12.Release multi-switch gaiters from both sides of

nacelle.

13.Remove nacelle upper and lower halves from

steering column; collect blanking grommet from

RH side.

14.Disconnect multi-plug and remove passive coil

from starter switch.

Refit

15.Feed passive coil plug lead into fascia cowl area

and reconnect multi-plug .

16.Fit coil on starter switch.

17.Position nacelle upper and lower halves to

steering column mounting bracket and secure

with 7 screws. Do not fully tighten screws at this

stage

See STEERING, Repair, Steering

column nacelle.

18.Check that passive coil is still fitted correctly on

starter switch.

19.Check fit of nacelle at starter switch and steering

column and fully tighten fixing screws.

20.Fit multi-switch gaiters to both sides of nacelle

and check that blanking grommet is located.

21.Position instrument panel to fascia cowl area

and reconnect immobiliser warning light leads,

gearbox oil temperature lead, heated rear screen

lead, alarm LED plug lead, main harness multi-

plugs and speedometer.

22.Secure instrument panel to fascia cowl with 4

screws

See INSTRUMENTS, Repair,

Instrument panel.

23.Fit steering wheelSee STEERING, Repair,

Steering wheel.

24.Reconnect battery negative lead.

25.Fit battery access cover.

26.Fit LH seat cushion.

27.Test immobilisation and alarm system.

Page 431 of 455

86ELECTRICAL

6

REPAIR IMMOBILISATION SPIDER

Service repair no - 86.77.03

Remove

1.Remove LH front seat cushion.

2.Release retaining clip and remove battery

access cover.

3.Slacken battery lead clamp bolts.

4.Turn starter switch 'on'.

5.Turn starter switch 'off' and remove key.

6.Disconnect battery leads.

NOTE: Operation 6 needs to be carried out

within 15 seconds to avoid activating

battery backed-up alarm sounder, if fitted.

7.Remove battery clamp and 'J' bolts.

8.Remove 4 nuts securing immobilisation spider

housing box to fixing studs on front face of

battery box.

9.Remove grommet securing spider harness to

corner face of battery box.

10.Carefully pull harness into battery box, lift spider

housing box and place on front edge of seat

base.

11.Using a suitable sheet to protect inside of

vehicle, grind heads off 6 monobolts securing lid

to spider box housing.

12.Detach lid from housing and disconnect spider

harness plug.

13.Unscrew two nuts and remove immobilisation

spider from lid studs.

NOTE: If spider box lid and/or sealing

gasket is damaged during operation 11 a

new lid will need to be fitted.

NOTE: A new immobilisation spider must

be initialised using TestBook.

Refit

14.Fit immobilisation spider onto lid studs and

secure with retaining nuts.

15.Reconnect harness plug to spider and ensure it

fully 'clicks' home.

16.Position lid and spider assembly into box

housing so that harness plug is furst away from

harness entry.

17.Secure lid to spider box housing with monobolts.

18.Refit harness grommet into spider box, if

disturbed on removal procedures, and ensure

harness covering is fully inserted through

grommet to make water tight seal.

19.Push excess harnes cable through corner face

of battery box and fit grommet.

20.Fit spider housing box to fixing studs and secure

with four nuts.

21.Fit 'J' bolts and clamp to secure battery,

22.Reconnect battery leads.

23.Fit battery access cover.

24.Fit LH seat cushion.

25.Test immobilisation and alarm system.