clock LAND ROVER DEFENDER 1996 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 38 of 455

07GENERAL FITTING REMINDERS

6

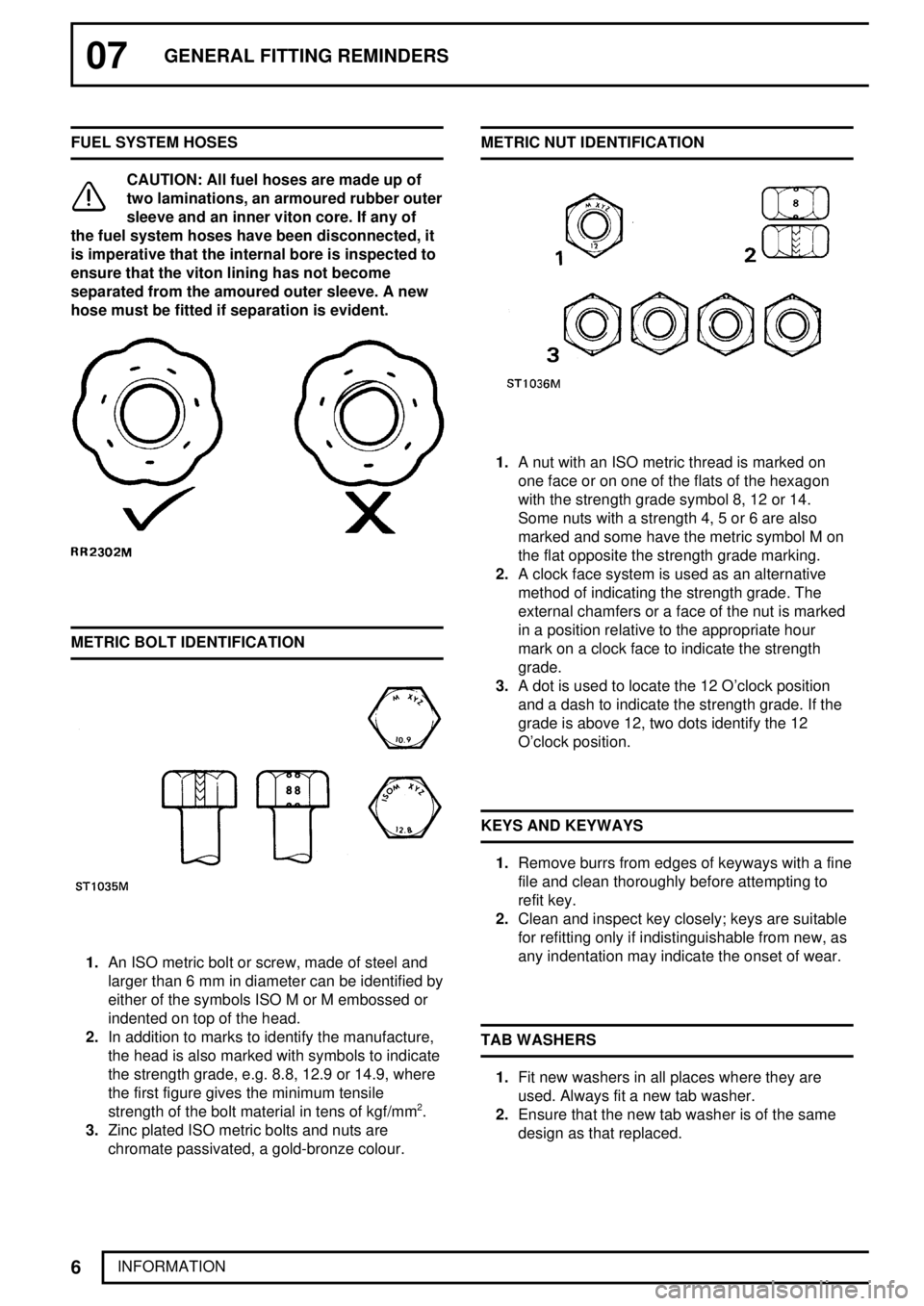

INFORMATION FUEL SYSTEM HOSES

CAUTION: All fuel hoses are made up of

two laminations, an armoured rubber outer

sleeve and an inner viton core. If any of

the fuel system hoses have been disconnected, it

is imperative that the internal bore is inspected to

ensure that the viton lining has not become

separated from the amoured outer sleeve. A new

hose must be fitted if separation is evident.

METRIC BOLT IDENTIFICATION

1.An ISO metric bolt or screw, made of steel and

larger than 6 mm in diameter can be identified by

either of the symbols ISO M or M embossed or

indented on top of the head.

2.In addition to marks to identify the manufacture,

the head is also marked with symbols to indicate

the strength grade, e.g. 8.8, 12.9 or 14.9, where

the first figure gives the minimum tensile

strength of the bolt material in tens of kgf/mm

2.

3.Zinc plated ISO metric bolts and nuts are

chromate passivated, a gold-bronze colour.METRIC NUT IDENTIFICATION

1.A nut with an ISO metric thread is marked on

one face or on one of the flats of the hexagon

with the strength grade symbol 8, 12 or 14.

Some nuts with a strength 4, 5 or 6 are also

marked and some have the metric symbol M on

the flat opposite the strength grade marking.

2.A clock face system is used as an alternative

method of indicating the strength grade. The

external chamfers or a face of the nut is marked

in a position relative to the appropriate hour

mark on a clock face to indicate the strength

grade.

3.A dot is used to locate the 12 O'clock position

and a dash to indicate the strength grade. If the

grade is above 12, two dots identify the 12

O'clock position.

KEYS AND KEYWAYS

1.Remove burrs from edges of keyways with a fine

file and clean thoroughly before attempting to

refit key.

2.Clean and inspect key closely; keys are suitable

for refitting only if indistinguishable from new, as

any indentation may indicate the onset of wear.

TAB WASHERS

1.Fit new washers in all places where they are

used. Always fit a new tab washer.

2.Ensure that the new tab washer is of the same

design as that replaced.

Page 44 of 455

MAINTENANCE

1

MAINTENANCE SERVICE SCHEDULE

The following section describes the items detailed in

the vehicle Service Schedule. Where required

instructions are given for carrying out the service

procedure, or a cross reference is given to the section

in the manual where the procedure may be found.

Service Maintenance Schedules are published

separately to reflect the needs and intervals for each

vehicle variant. Procedures in the Workshop Manual

must be used in conjunction with the Service

Schedule sheets.

Service Maintenance Schedules are available from:

Land Rover Publications,

Character Mailing,

Heysham Road,

Bootle,

Merseyside, L70 1JL

VEHICLE INTERIOR

CHECK SEATS & BELTS

Check condition and security of seat belts, seat belt

mountings, seat belt buckles and operation of inertia

seat belts.

CHECK OPERATION OF LAMPS

Check operation of all lamps, horns and warning

indicators.

CHECK OPERATION OF WIPERS

Check operation of front/rear wipers and washers and

condition of wiper blades.CHECK OPERATION OF HANDBRAKE

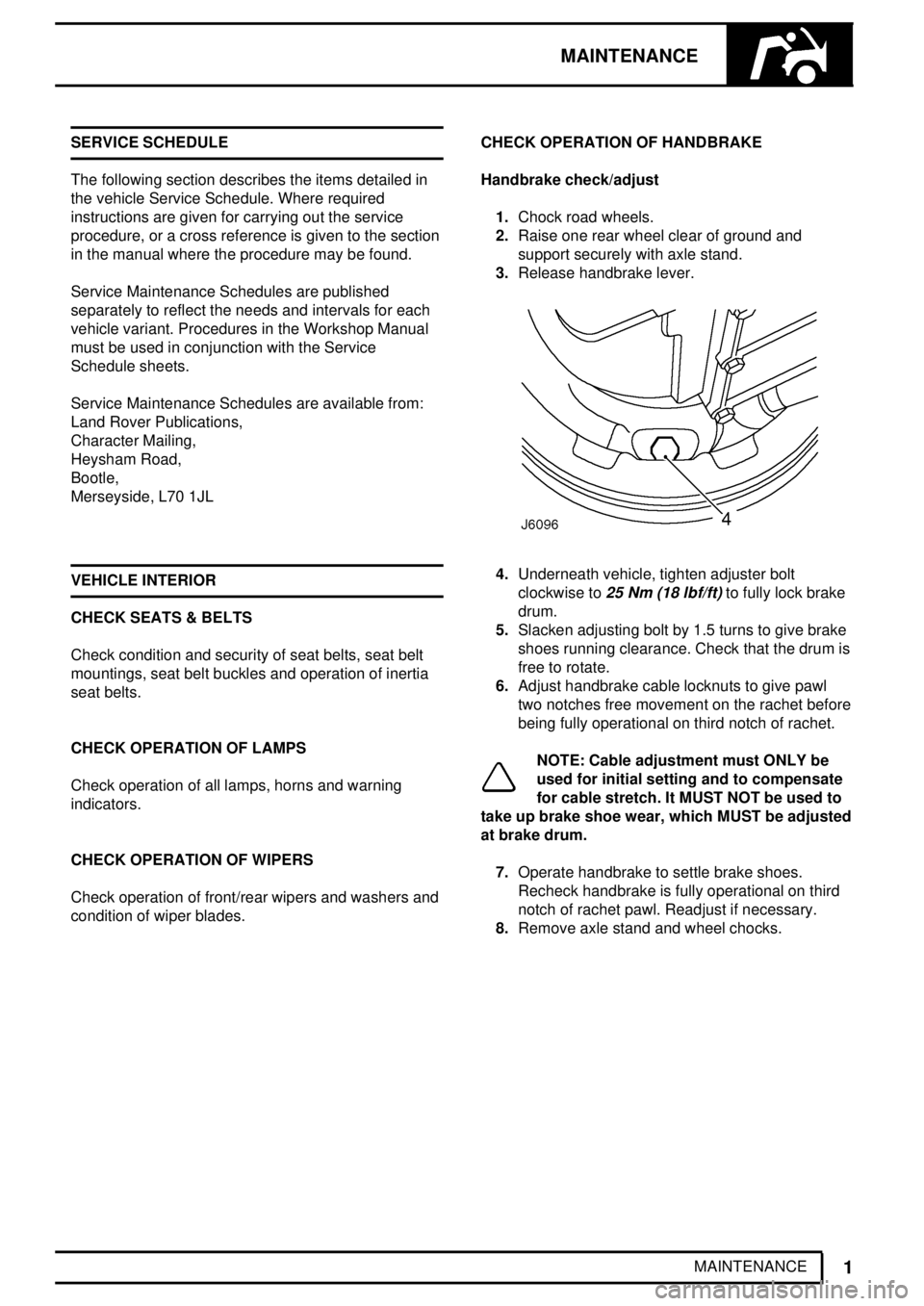

Handbrake check/adjust

1.Chock road wheels.

2.Raise one rear wheel clear of ground and

support securely with axle stand.

3.Release handbrake lever.

4.Underneath vehicle, tighten adjuster bolt

clockwise to

25 Nm (18 lbf/ft)to fully lock brake

drum.

5.Slacken adjusting bolt by 1.5 turns to give brake

shoes running clearance. Check that the drum is

free to rotate.

6.Adjust handbrake cable locknuts to give pawl

two notches free movement on the rachet before

being fully operational on third notch of rachet.

NOTE: Cable adjustment must ONLY be

used for initial setting and to compensate

for cable stretch. It MUST NOT be used to

take up brake shoe wear, which MUST be adjusted

at brake drum.

7.Operate handbrake to settle brake shoes.

Recheck handbrake is fully operational on third

notch of rachet pawl. Readjust if necessary.

8.Remove axle stand and wheel chocks.

Page 52 of 455

MAINTENANCE

9

MAINTENANCE REV: 05/99 UNDER VEHICLE MAINTENANCE

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

maintenance, or remove and refit procedures are

required, it may be necessary to remove the

undertray and/or integral access panels

See

CHASSIS AND BODY, Repair, Front undertray

or

See CHASSIS AND BODY, Repair, Rear undertray

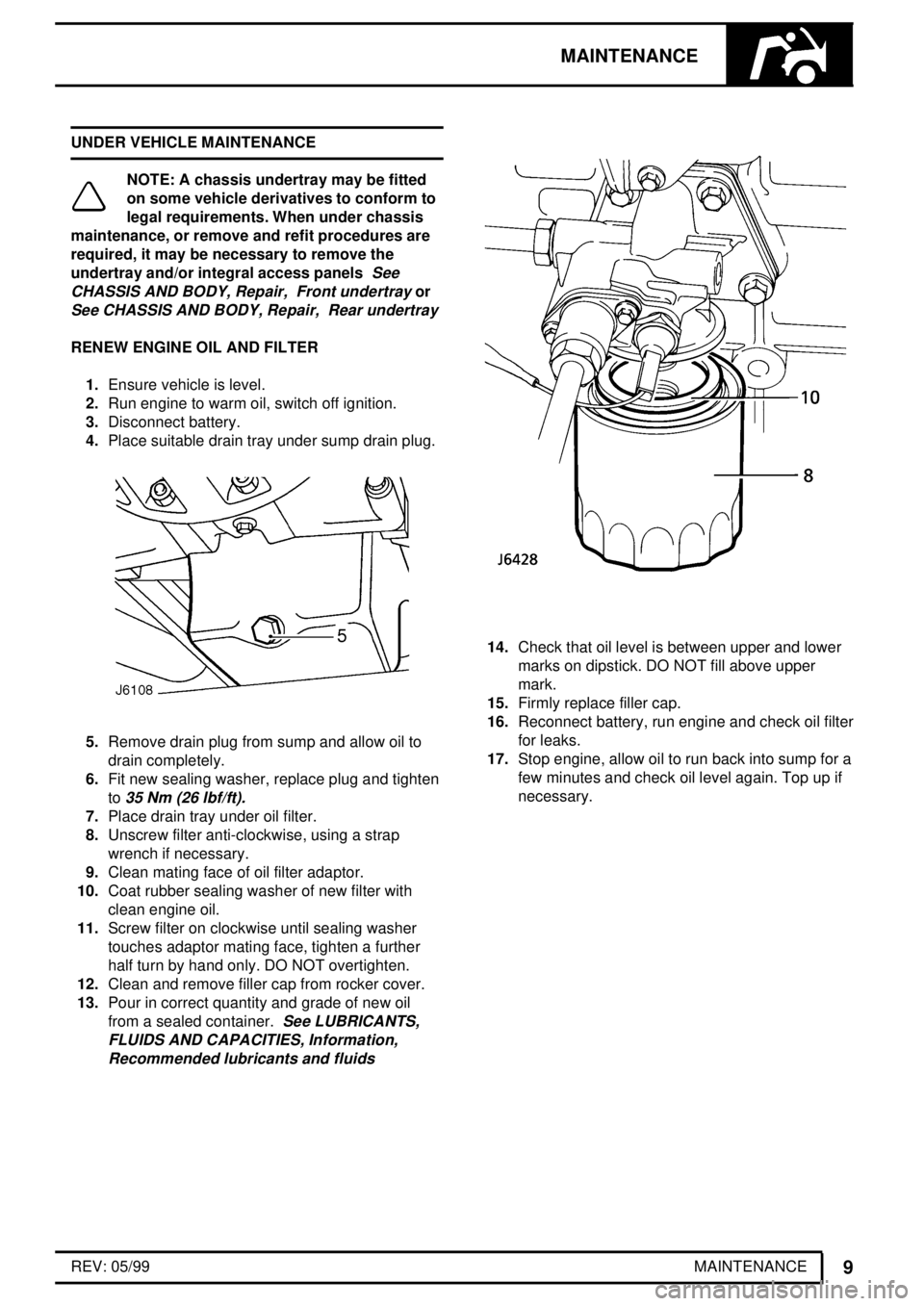

RENEW ENGINE OIL AND FILTER

1.Ensure vehicle is level.

2.Run engine to warm oil, switch off ignition.

3.Disconnect battery.

4.Place suitable drain tray under sump drain plug.

5.Remove drain plug from sump and allow oil to

drain completely.

6.Fit new sealing washer, replace plug and tighten

to

35 Nm (26 lbf/ft).

7.Place drain tray under oil filter.

8.Unscrew filter anti-clockwise, using a strap

wrench if necessary.

9.Clean mating face of oil filter adaptor.

10.Coat rubber sealing washer of new filter with

clean engine oil.

11.Screw filter on clockwise until sealing washer

touches adaptor mating face, tighten a further

half turn by hand only. DO NOT overtighten.

12.Clean and remove filler cap from rocker cover.

13.Pour in correct quantity and grade of new oil

from a sealed container.

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended lubricants and fluids

14.Check that oil level is between upper and lower

marks on dipstick. DO NOT fill above upper

mark.

15.Firmly replace filler cap.

16.Reconnect battery, run engine and check oil filter

for leaks.

17.Stop engine, allow oil to run back into sump for a

few minutes and check oil level again. Top up if

necessary.

Page 59 of 455

ENGINE

1

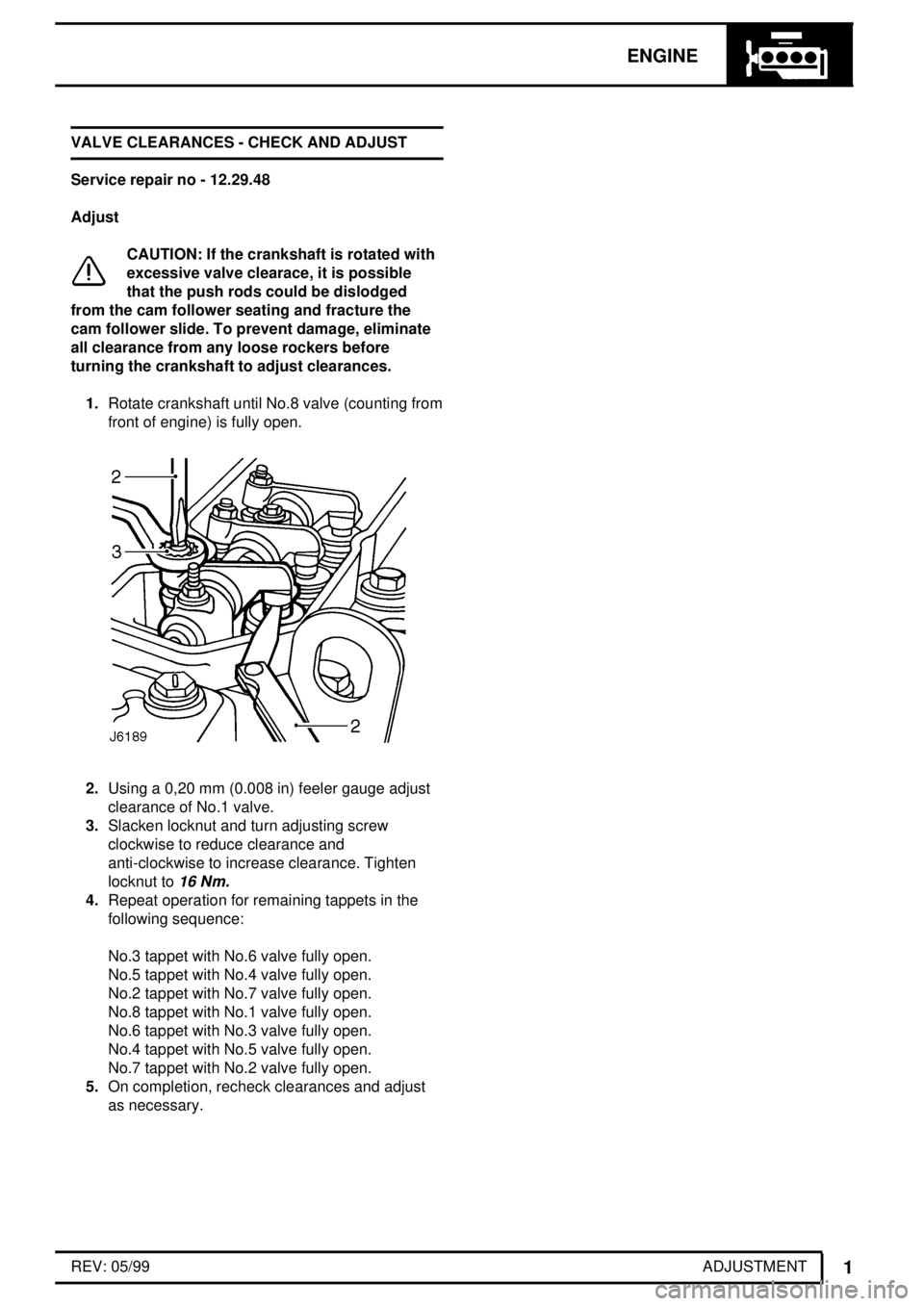

ADJUSTMENT REV: 05/99 VALVE CLEARANCES - CHECK AND ADJUST

Service repair no - 12.29.48

Adjust

CAUTION: If the crankshaft is rotated with

excessive valve clearace, it is possible

that the push rods could be dislodged

from the cam follower seating and fracture the

cam follower slide. To prevent damage, eliminate

all clearance from any loose rockers before

turning the crankshaft to adjust clearances.

1.Rotate crankshaft until No.8 valve (counting from

front of engine) is fully open.

2.Using a 0,20 mm (0.008 in) feeler gauge adjust

clearance of No.1 valve.

3.Slacken locknut and turn adjusting screw

clockwise to reduce clearance and

anti-clockwise to increase clearance. Tighten

locknut to

16 Nm.

4.Repeat operation for remaining tappets in the

following sequence:

No.3 tappet with No.6 valve fully open.

No.5 tappet with No.4 valve fully open.

No.2 tappet with No.7 valve fully open.

No.8 tappet with No.1 valve fully open.

No.6 tappet with No.3 valve fully open.

No.4 tappet with No.5 valve fully open.

No.7 tappet with No.2 valve fully open.

5.On completion, recheck clearances and adjust

as necessary.

Page 65 of 455

12ENGINE

6

REPAIR 42.Raise engine, and locate front engine mountings

to chassis.

43.Remove gearbox support and lower engine.

44.Tighten front engine mounting to chassis fixings

to

45 Nm (33 lbf/ft).

45.Release chains from engine lifting brackets and

remove hoist.

46.Connect oil cooler pipes to oil filter adaptor.

47.Fit vacuum hose to brake servo adaptor.

48.Secure fuel feed pipe in retaining clip on air

cleaner bracket.

49.Fit fuel lift pump pipes.

50.Connect feed and spill return pipes to injector

pump.

51.If fitted, reconnect hand throttle cable to

mounting bracket and injector pump.

52.Fit outer cable adjusting nut into injector pump

mounting bracket.

53.Fit inner throttle cable to injector pump and

secure with clevis and split pin.

54.Secure bleed hose in retaining clips on front

timing cover.

55.Fit bleed hose to thermostat housing.

56.Connect inlet and outlet hoses to power steering

pump.

57.Fit down pipe to exhaust manifold and secure

with 3 nuts.

58.Connect starter motor battery and fuse box

leads.

59.If fitted, connect EGR valve multi-plug and

vacuum pipe.

60.Secure breather pipe clip to cylinder head.

61.Connect engine harness multi-plug.

62.Fit heater plug feed wire.

63.Connect electrical feed plug at rear of cylinder

head.

64.Fit heater hoses to cylinder head and heater

rails.

65.Fit feed pipe/hose to turbo-charger and

intercooler.

66.Fit rocker cover insulation.

67.Fit radiator assembly.

See COOLING SYSTEM,

Repair, Radiator

If applicable, fit air

conditioning condenser, compressor pipes and

heater matrix hoses.

See AIR CONDITIONING,

Repair, Condenser

68.Fit bonnet.

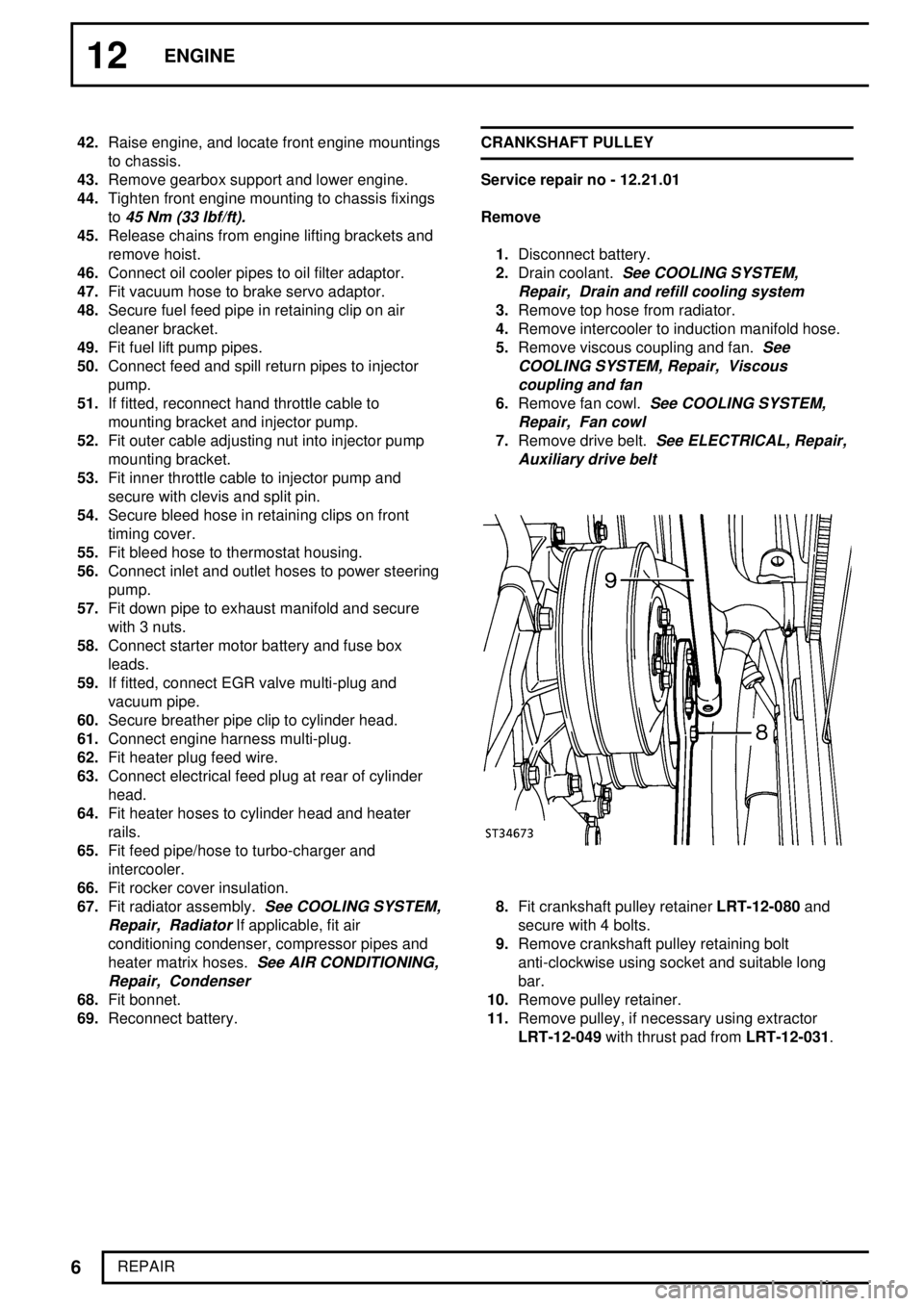

69.Reconnect battery.CRANKSHAFT PULLEY

Service repair no - 12.21.01

Remove

1.Disconnect battery.

2.Drain coolant.

See COOLING SYSTEM,

Repair, Drain and refill cooling system

3.Remove top hose from radiator.

4.Remove intercooler to induction manifold hose.

5.Remove viscous coupling and fan.

See

COOLING SYSTEM, Repair, Viscous

coupling and fan

6.Remove fan cowl.See COOLING SYSTEM,

Repair, Fan cowl

7.Remove drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

8.Fit crankshaft pulley retainerLRT-12-080and

secure with 4 bolts.

9.Remove crankshaft pulley retaining bolt

anti-clockwise using socket and suitable long

bar.

10.Remove pulley retainer.

11.Remove pulley, if necessary using extractor

LRT-12-049with thrust pad fromLRT-12-031.

Page 69 of 455

12ENGINE

10

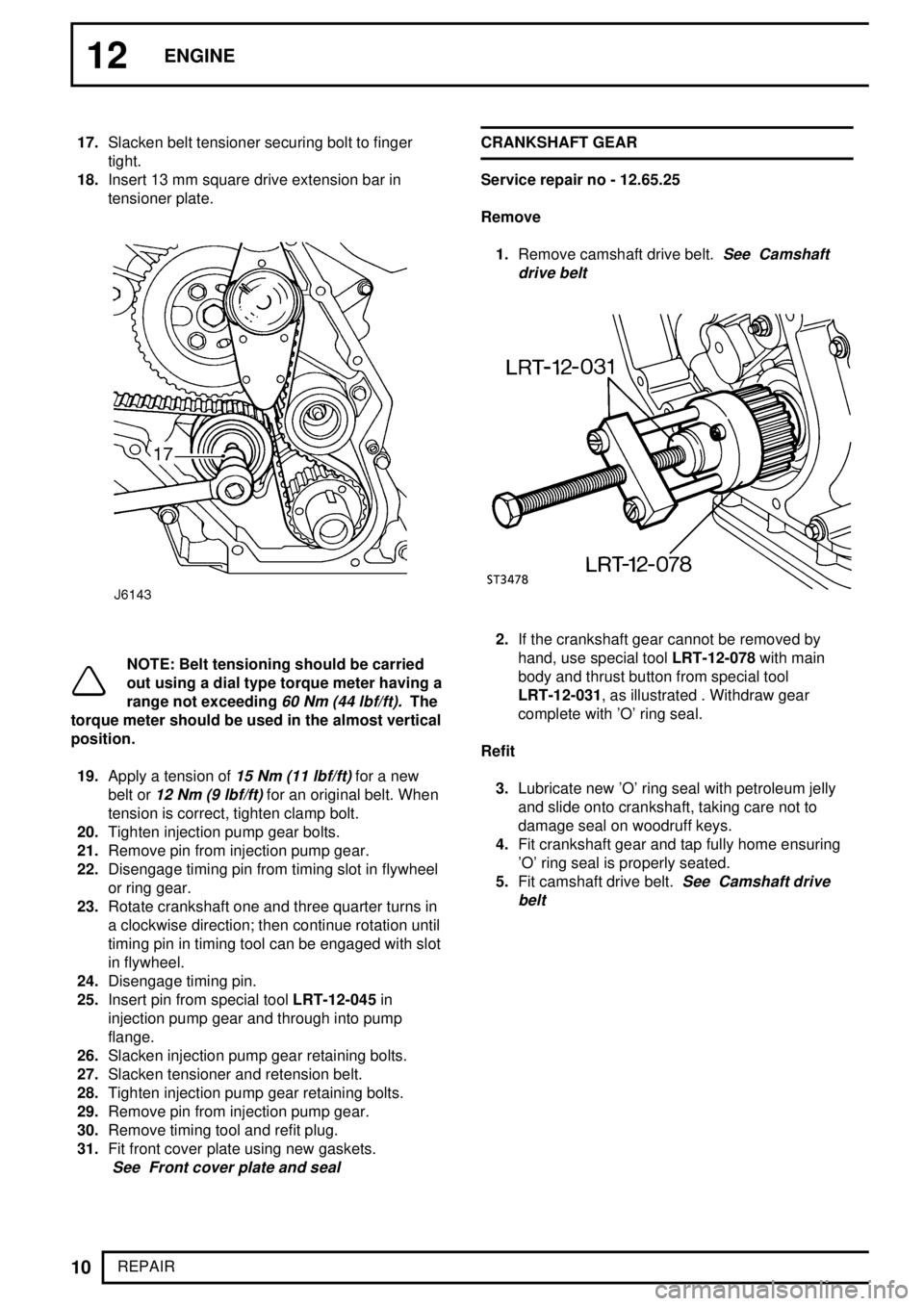

REPAIR 17.Slacken belt tensioner securing bolt to finger

tight.

18.Insert 13 mm square drive extension bar in

tensioner plate.

NOTE: Belt tensioning should be carried

out using a dial type torque meter having a

range not exceeding

60 Nm (44 lbf/ft).The

torque meter should be used in the almost vertical

position.

19.Apply a tension of

15 Nm (11 lbf/ft)for a new

belt or

12 Nm (9 lbf/ft)for an original belt. When

tension is correct, tighten clamp bolt.

20.Tighten injection pump gear bolts.

21.Remove pin from injection pump gear.

22.Disengage timing pin from timing slot in flywheel

or ring gear.

23.Rotate crankshaft one and three quarter turns in

a clockwise direction; then continue rotation until

timing pin in timing tool can be engaged with slot

in flywheel.

24.Disengage timing pin.

25.Insert pin from special toolLRT-12-045in

injection pump gear and through into pump

flange.

26.Slacken injection pump gear retaining bolts.

27.Slacken tensioner and retension belt.

28.Tighten injection pump gear retaining bolts.

29.Remove pin from injection pump gear.

30.Remove timing tool and refit plug.

31.Fit front cover plate using new gaskets.

See Front cover plate and seal

CRANKSHAFT GEAR

Service repair no - 12.65.25

Remove

1.Remove camshaft drive belt.

See Camshaft

drive belt

2.If the crankshaft gear cannot be removed by

hand, use special toolLRT-12-078with main

body and thrust button from special tool

LRT-12-031, as illustrated . Withdraw gear

complete with 'O' ring seal.

Refit

3.Lubricate new 'O' ring seal with petroleum jelly

and slide onto crankshaft, taking care not to

damage seal on woodruff keys.

4.Fit crankshaft gear and tap fully home ensuring

'O' ring seal is properly seated.

5.Fit camshaft drive belt.

See Camshaft drive

belt

Page 78 of 455

ENGINE

19

REPAIR OIL FILTER

Service repair no - 12.60.01

Remove

1.Place drain tray under oil filter.

2.Unscrew filter anti-clockwise, using a strap

wrench, if necessary.

Refit

3.Clean mating face of oil filter adaptor.

4.Coat rubber sealing ring of new filter with clean

engine oil.

5.Screw on filter until sealing ring touches

machined face, then tighten a further half turn by

hand only. DO NOT over tighten.OIL TEMPERATURE CONTROL VALVE

Service repair no - 12.60.69

Remove

1.Clean adaptor housing.

2.Disconnect oil cooler feed pipe from thermostat

extension housing and plug to prevent ingress of

dirt.

3.Remove 2 bolts and carefully withdraw

thermostat extension housing (1) complete with

'O' ring seal (2), thermostat (3), 2 washers (4)

and spring (5).

4.Inspect all parts and renew as necessary.

Refit

5.Fit thermostat to extension housing ensuring pin

locates in hole.

6.Fit two washers and spring to thermostat.

7.Fit a new 'O' ring to extension housing.

8.Insert spring into adaptor and secure extension

housing to adaptor. Tighten bolts to

9Nm(7

lbf/ft).

Page 99 of 455

19FUEL SYSTEM

2

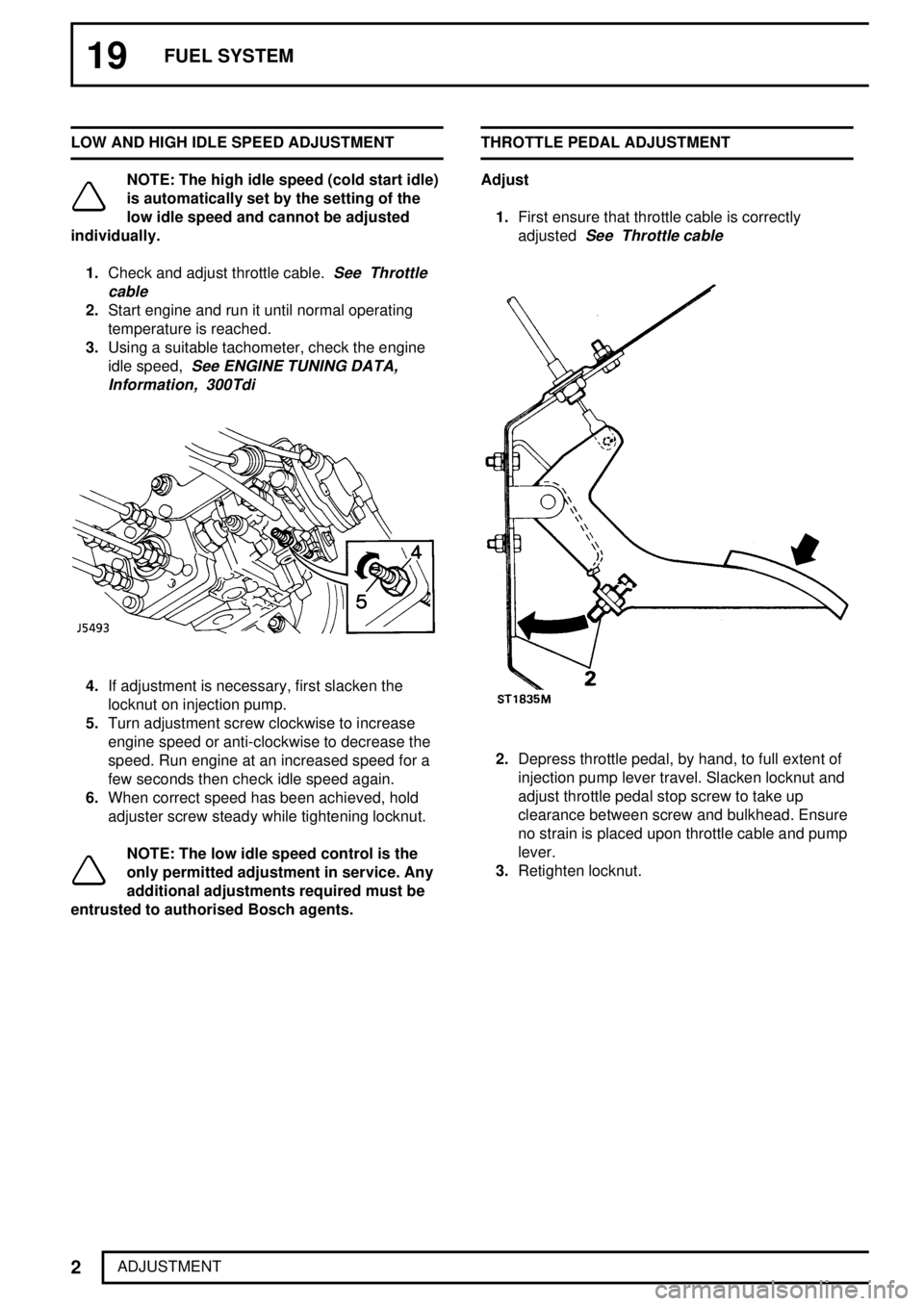

ADJUSTMENT LOW AND HIGH IDLE SPEED ADJUSTMENT

NOTE: The high idle speed (cold start idle)

is automatically set by the setting of the

low idle speed and cannot be adjusted

individually.

1.Check and adjust throttle cable.

See Throttle

cable

2.Start engine and run it until normal operating

temperature is reached.

3.Using a suitable tachometer, check the engine

idle speed,

See ENGINE TUNING DATA,

Information, 300Tdi

4.If adjustment is necessary, first slacken the

locknut on injection pump.

5.Turn adjustment screw clockwise to increase

engine speed or anti-clockwise to decrease the

speed. Run engine at an increased speed for a

few seconds then check idle speed again.

6.When correct speed has been achieved, hold

adjuster screw steady while tightening locknut.

NOTE: The low idle speed control is the

only permitted adjustment in service. Any

additional adjustments required must be

entrusted to authorised Bosch agents.THROTTLE PEDAL ADJUSTMENT

Adjust

1.First ensure that throttle cable is correctly

adjusted

See Throttle cable

2.Depress throttle pedal, by hand, to full extent of

injection pump lever travel. Slacken locknut and

adjust throttle pedal stop screw to take up

clearance between screw and bulkhead. Ensure

no strain is placed upon throttle cable and pump

lever.

3.Retighten locknut.

Page 100 of 455

FUEL SYSTEM

3

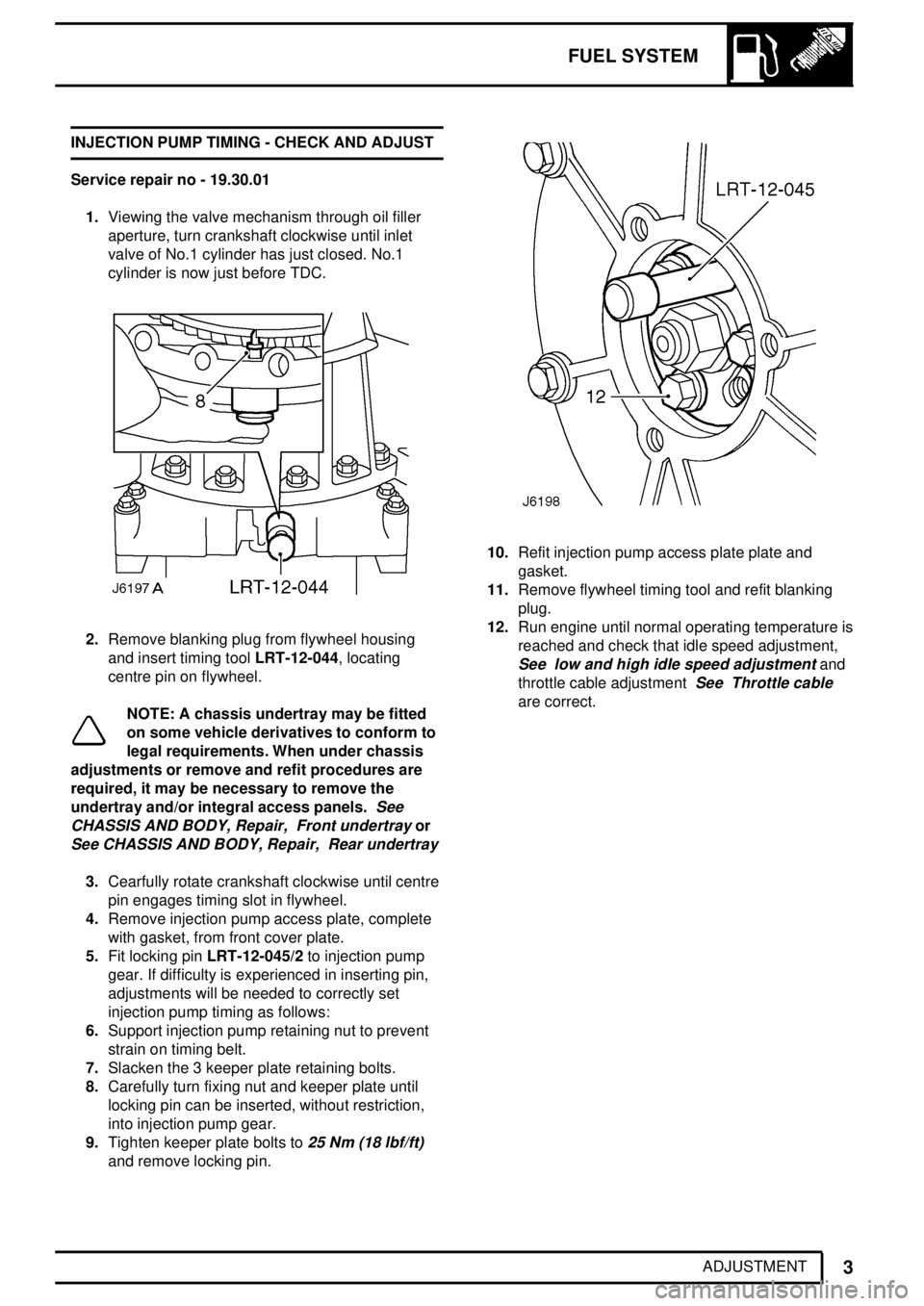

ADJUSTMENT INJECTION PUMP TIMING - CHECK AND ADJUST

Service repair no - 19.30.01

1.Viewing the valve mechanism through oil filler

aperture, turn crankshaft clockwise until inlet

valve of No.1 cylinder has just closed. No.1

cylinder is now just before TDC.

2.Remove blanking plug from flywheel housing

and insert timing toolLRT-12-044, locating

centre pin on flywheel.

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

adjustments or remove and refit procedures are

required, it may be necessary to remove the

undertray and/or integral access panels.

See

CHASSIS AND BODY, Repair, Front undertray

or

See CHASSIS AND BODY, Repair, Rear undertray

3.Cearfully rotate crankshaft clockwise until centre

pin engages timing slot in flywheel.

4.Remove injection pump access plate, complete

with gasket, from front cover plate.

5.Fit locking pinLRT-12-045/2to injection pump

gear. If difficulty is experienced in inserting pin,

adjustments will be needed to correctly set

injection pump timing as follows:

6.Support injection pump retaining nut to prevent

strain on timing belt.

7.Slacken the 3 keeper plate retaining bolts.

8.Carefully turn fixing nut and keeper plate until

locking pin can be inserted, without restriction,

into injection pump gear.

9.Tighten keeper plate bolts to

25 Nm (18 lbf/ft)

and remove locking pin.

10.Refit injection pump access plate plate and

gasket.

11.Remove flywheel timing tool and refit blanking

plug.

12.Run engine until normal operating temperature is

reached and check that idle speed adjustment,

See low and high idle speed adjustmentand

throttle cable adjustment

See Throttle cable

are correct.

Page 103 of 455

FUEL SYSTEM

1

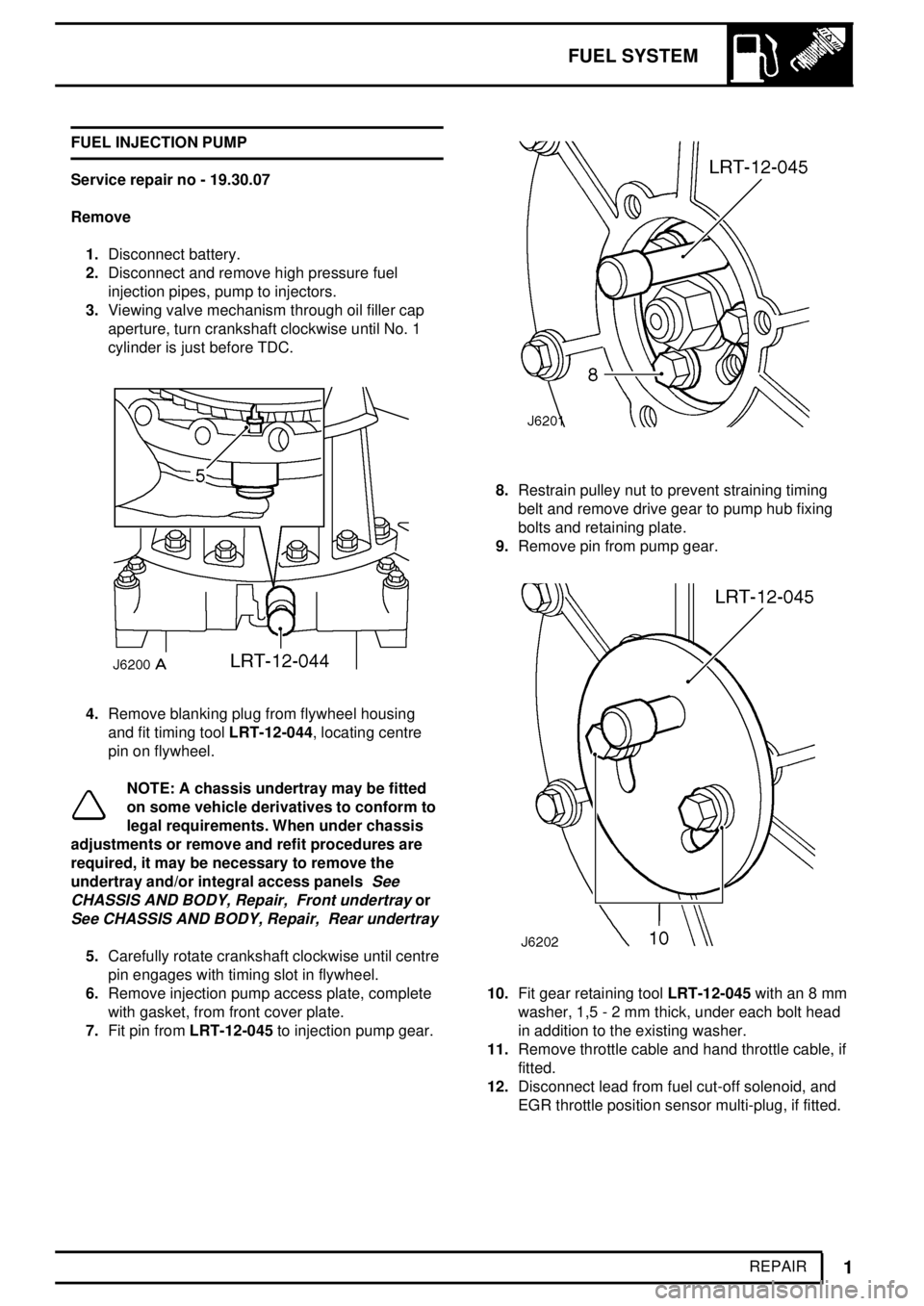

REPAIR FUEL INJECTION PUMP

Service repair no - 19.30.07

Remove

1.Disconnect battery.

2.Disconnect and remove high pressure fuel

injection pipes, pump to injectors.

3.Viewing valve mechanism through oil filler cap

aperture, turn crankshaft clockwise until No. 1

cylinder is just before TDC.

4.Remove blanking plug from flywheel housing

and fit timing toolLRT-12-044, locating centre

pin on flywheel.

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

adjustments or remove and refit procedures are

required, it may be necessary to remove the

undertray and/or integral access panels

See

CHASSIS AND BODY, Repair, Front undertray

or

See CHASSIS AND BODY, Repair, Rear undertray

5.Carefully rotate crankshaft clockwise until centre

pin engages with timing slot in flywheel.

6.Remove injection pump access plate, complete

with gasket, from front cover plate.

7.Fit pin fromLRT-12-045to injection pump gear.

8.Restrain pulley nut to prevent straining timing

belt and remove drive gear to pump hub fixing

bolts and retaining plate.

9.Remove pin from pump gear.

10.Fit gear retaining toolLRT-12-045with an 8 mm

washer, 1,5 - 2 mm thick, under each bolt head

in addition to the existing washer.

11.Remove throttle cable and hand throttle cable, if

fitted.

12.Disconnect lead from fuel cut-off solenoid, and

EGR throttle position sensor multi-plug, if fitted.