service LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 601 of 667

84WIPERS AND WASHERS

2

REPAIR

4.Remove 4 trim studs securing upper rear finisher

to body.

5.Release and remove upper rear finisher.

6.Position drain tin to collect any fluid spillage.

7.Disconnect washer tube from jet.

8.Remove nut securing washer jet to body.

9.Remove washer jet.

Refit

10.Fit washer jet to body and secure with nut.

11.Connect washer tube to jet.

12.Remove drain tin.

13.Fit upper rear finisher and secure with trim studs.

14.Fit both rear grab handles and secure with

screws.

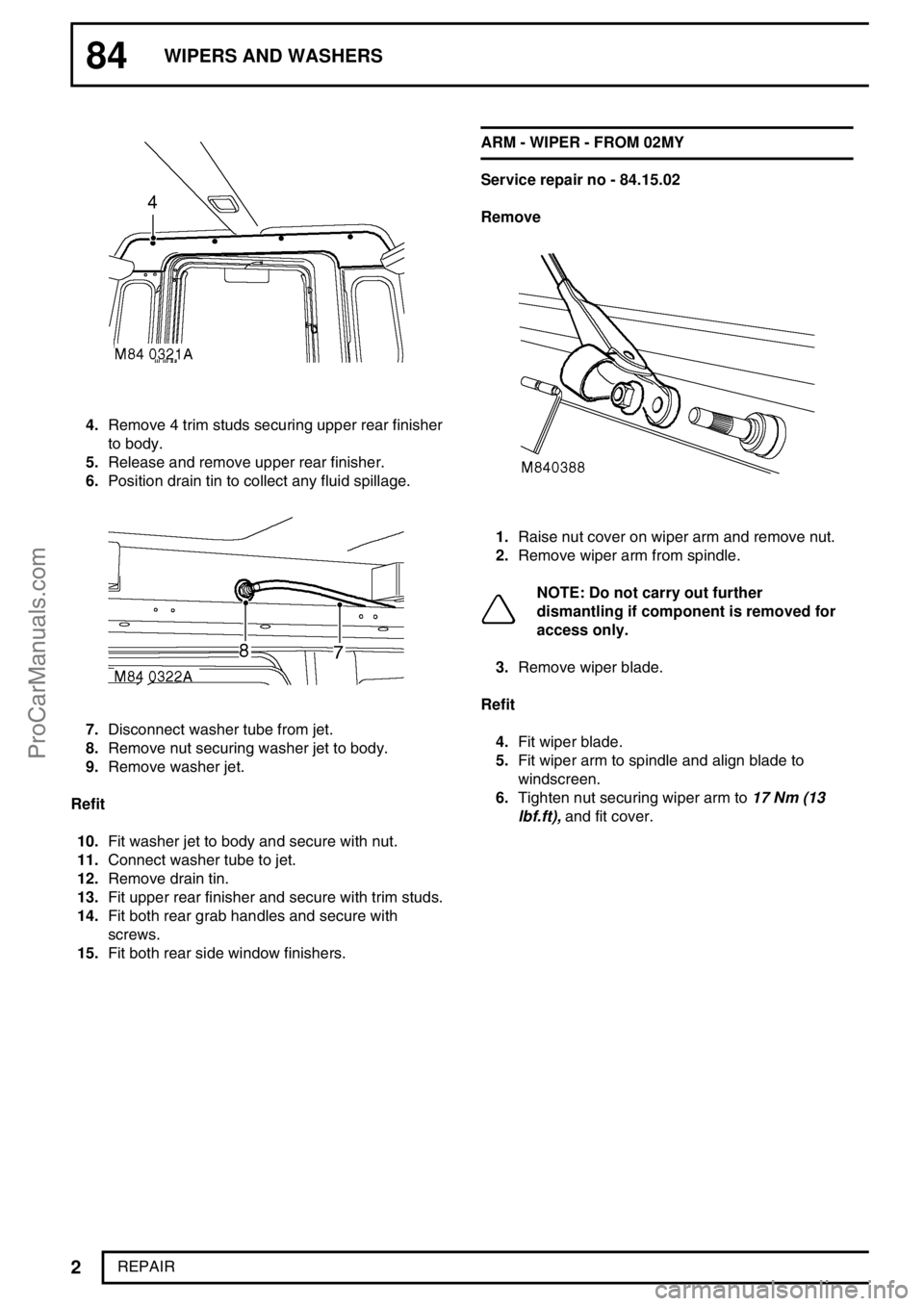

15.Fit both rear side window finishers.ARM - WIPER - FROM 02MY

Service repair no - 84.15.02

Remove

1.Raise nut cover on wiper arm and remove nut.

2.Remove wiper arm from spindle.

NOTE: Do not carry out further

dismantling if component is removed for

access only.

3.Remove wiper blade.

Refit

4.Fit wiper blade.

5.Fit wiper arm to spindle and align blade to

windscreen.

6.Tighten nut securing wiper arm to17 Nm (13

lbf.ft),and fit cover.

ProCarManuals.com

Page 602 of 667

WIPERS AND WASHERS

3

REPAIR WIPER MOTOR AND DRIVE RACK - FROM 02MY

Service repair no - 84.15.09

Remove

1.Disconnect battery negative lead.See

ELECTRICAL, Repair.

2.Remove wiper arms.See this Section.

3.Remove fascia console.See CHASSIS AND

BODY, Repair.

4.Remove air vent control knobs.

5.Remove 6 screws, remove fascia closing panel

and collect nut plate.

6.Move cover aside and loosen wiper motor drive

tube nut.

7.Remove 2 screws securing wiper motor, remove

retaining strap and mounting pad.

8.Disconnect multiplug from wiper motor.

9.Remove tube nut and remove wiper motor with

rack.

Refit

10.Lubricate wiper motor drive rack with grease.

11.Feed wiper motor rack into tube, connect

multiplug and fit but do not tighten tube nut.

12.Fit mounting pad and retaining strap, align wiper

motor and tighten screws.

13.Tighten wiper motor tube nut to8 Nm (6 lbf.ft)

and reposition nut cover.

14.Fit fascia closing panel.

ProCarManuals.com

Page 603 of 667

84WIPERS AND WASHERS

4

REPAIR 15.Fit nut plate and fit screws to secure nut plate

and closing panel.

16.Fit knobs to air vent control levers.

17.Fit fascia console.See CHASSIS AND BODY,

Repair.

18.Fit wiper arms.See this Section.

19.Connect battery negative lead.See

ELECTRICAL, Repair.WHEELBOX/DRIVE PIVOT - FROM 02MY

Service repair no - 84.15.25

Remove

1.Disconnect battery negative lead.See

ELECTRICAL, Repair.

2.Remove steering column nacelle.See

STEERING, Repair.

3.Remove wiper motor and drive rack.See this

Section.

4.Remove 2 screws and move heater fan switch

aside.

5.Remove 2 screws securing drivers side demister

duct.

6.Disconnect demister tube and remove duct.

7.Remove bolt and nut and bolt securing steering

column support bracket and remove bracket.

8.Remove 11 screws securing fascia support rail.

ProCarManuals.com

Page 604 of 667

WIPERS AND WASHERS

5

REPAIR

9.Remove cable ties securing washer tube to

windscreen wiper rack tube.

10.Loosen fully 4 nuts securing backplates to wheel

boxes and remove windscreen wiper rack tubes.

11.Remove seals from wheel box spindles.

12.Remove 2 nuts securing wheel boxes and

remove sealing washers.

13.Carefully pull fascia support rail from bulkhead

sufficiently to remove wheel boxes.

Refit

14.Loosen fully but do not remove nuts securing

wheel box back plates.

15.Grease wheel boxes.

16.Fit wheel boxes, fit sealing washers and tighten

nuts to5 Nm (3.7 lbf.ft).

17.Fit spindle seals.

18.Fit wiper rack tubes and tighten wheel box back

plate nuts sufficiently to hold tubes. Tighten

wheel box back plate nuts to6 Nm (4 lbf.ft)

after fitting windscreen wiper motor.

19.Align washer tube to rack tube and secure with

cable ties.

20.Align fascia support rail and secure with screws.

21.Fit steering column support bracket and tighten

bolt and nut and bolt to45 Nm (33 lbf.ft).

22.Fit demister duct to tube, align relay bracket and

secure duct with screws.

23.Position heater fan switch and secure with

screws.

24.Fit wiper motor and drive rack.See this

Section.

25.Fit steering column nacelle.See STEERING,

Repair.

26.Connect battery negative lead.See

ELECTRICAL, Repair.RELAY - WIPER DELAY - FROM 02MY

Service repair no - 84.15.37

Remove

1.Disconnect battery negative lead.See

ELECTRICAL, Repair.

2.Remove 4 screws securing instrument pack and

release pack from fascia.

3.Disconnect 2 multiplugs from warning lamp

panel.

4.Disconnect instrument pack multiplug from main

harness.

5.Remove instrument pack.

ProCarManuals.com

Page 605 of 667

84WIPERS AND WASHERS

6

REPAIR

6.Identify and remove relay.

Refit

7.Fit relay.

8.Position instrument pack and connect multiplugs.

9.Fit instrument pack to fascia and secure with

screws.

10.Connect battery negative lead.See

ELECTRICAL, Repair.MOTOR - WIPER - TAIL DOOR - FROM 02MY

Service repair no - 84.35.12

Remove

1.Remove spare wheel from tail door.

2.Raise nut cover, remove nut and release wiper

arm.

3.Remove nut and collect washer securing wiper

motor to tail door.

4.Open tail door.

5.Remove tail door trim casing.See CHASSIS

AND BODY, Repair.

6.Remove bolt securing door locking solenoid to

tail door.

7.Pivot both assemblies and withdraw wiper motor

from tail door.

8.Disconnect multiplugs from wiper motor.

9.Remove wiper motor assembly.

ProCarManuals.com

Page 606 of 667

WIPERS AND WASHERS

7

REPAIR

NOTE: Do not carry out further

dismantling if component is removed for

access only.

10.Remove 2 bolts securing wiper motor to

mounting bracket, remove bracket.

Refit

11.Fit mounting bracket to motor and tighten bolts

to10 Nm (7 lbf.ft).

12.Fit motor spindle to rear door, connect multiplugs

and push motor fully home. Align motor

mounting bracket with solenoid mounting

bracket, fit bolt and tighten to10 Nm ( 7 lbf.ft ).

13.Fit rear door trim casing.See CHASSIS AND

BODY, Repair.

14.Fit washer and nut to rear wiper assembly,

tighten nut to3 Nm (2.2 lbf.ft).

15.Fit wiper arm to spindle, align blade to glass and

tighten nut to17 Nm (13 lbf.ft).

16.Close nut cover.

17.Fit spare wheel and tighten nuts to45 Nm (33

lbf.ft).RELAY - TAIL DOOR WIPER - FROM 02MY

Service repair no - 84.35.38

Remove

1.Remove tail door trim casing.See CHASSIS

AND BODY, Repair.

2.Remove rear wiper motor relay.

Refit

3.Fit relay.

4.Fit tail door trim casing.See CHASSIS AND

BODY, Repair.

ProCarManuals.com

Page 634 of 667

ELECTRICAL

25

DESCRIPTION AND OPERATION Electric window lift is a new feature for 02MY. The electric windows are only available on the front driver and

passenger doors. Rear passenger doors retain the manual window lift regulator mechanism.

The window lift system comprises a window motor in each front door, two window lift switches located in the fascia

switch panel and a relay, located adjacent to the passenger compartment fusebox. The windows are only

operative when the ignition switch is in position II.

Each window lift motor is located in the door, behind the trim casing. The motor and regulator form a handed

assembly and are not available separately as serviceable items.

The window lift relay receives a permanent battery feed via fusible links 1 and 3 in the under seat fuse box. The

relay coil has one side connected to earth with the other side receiving a feed from the ignition switch position II.

When the ignition is in position II, the relay is energised and battery voltage is supplied to each of the window lift

switches. On vehicles with heated seats, the relay is shared with the heated seat circuit.

Each switch has two wires to its applicable motor. When the switch is operated in either the up or down position,

one wire is supplied with a feed and the other is connected to earth as applicable for the selection made.

Each motor has thermal cut-out protection. If the window reaches the top or bottom limit of its travel or an object

obstructs the window, the thermal cut-out will sense the increased load on the motor and cut the power supply to

the motor brush contacts.

The cut-out time is between 3.5 to 5.0 seconds, with a time to restart of between 1 to 10 seconds. These figures

are based on an ambient temperature of 20°C (68°F) and a voltage of 13.5V.

ProCarManuals.com

Page 638 of 667

ELECTRICAL

1

ADJUSTMENT HEADLAMPS - ALIGN BEAM

Service repair no - 86.40.17

Check

1.Align suitable beam setting equipment to

headlamp.

2.Ensure headlamp height adjustment switch set

to’O’and headlamps switch on.

Headlamp setting = 1.2% below horizontal and

parallel.

Adjust

3.Align beam setting equipment to 2nd headlamp

and adjust 2nd lamp as necessary.

4.Switch off headlamps.

5.Remove beamsetter.SOLENOID/MOTOR - FRONT DOOR - ADJUST

Service repair no - 86.26.21

Adjust

1.Remove door trim casing.See CHASSIS AND

BODY, Repair.

M86 5629

2.Carefully peel back plastic sheet to expose

mechanism.

3.Release clip and detach solenoid link from latch.

M86 5630

4.Ensure sill button is fully raised.

5.Fully extend solenoid actuator then lower 3.5

mm +/- 1.00 mm.

6.Whilst holding actuator in this position, adjust

length of link, until link pin is aligned with hole in

latch lever.

7.Connect link and secure with clip.

8.Secure plastic sheet.

9.Fit door trim casing.See CHASSIS AND

BODY, Repair.

ProCarManuals.com

Page 640 of 667

ELECTRICAL

1

REPAIR BELT - AUXILLARY DRIVE

Service repair no - 86.10.03

Remove

1.Remove cooling fan.See COOLING SYSTEM,

Repair.

2.Release drive belt tensioner using a 15 mm ring

spanner and release belt from pulleys.

Refit

3.Clean drive belt pulley grooves and ensure

grooves are not damaged.

4.Fit new drive belt around pulleys, ensure belt is

correctly aligned in pulley grooves.

5.With assistance, hold tensioner fully clockwise

and fit drive belt around remaining pulley.

6.Fit cooling fan.See COOLING SYSTEM,

Repair.HARNESS - INJECTORS

Service repair no - 86.70.22

Remove

1.Remove camshaft cover gasket.See ENGINE ,

Repair.2.Disconnect engine harness from injector

harness.

3.Disconnect multiplugs from injectors.

4.Release injector harness from camshaft carrier

and remove harness.

Refit

5.Fit new’O’rings to injector harness connector.

6.Position harness and locate connector to

camshaft carrier.

7.Connect injector and engine harness multiplugs.

8.Fit camshaft cover gasket.See ENGINE ,

Repair.

ProCarManuals.com

Page 641 of 667

86ELECTRICAL

2

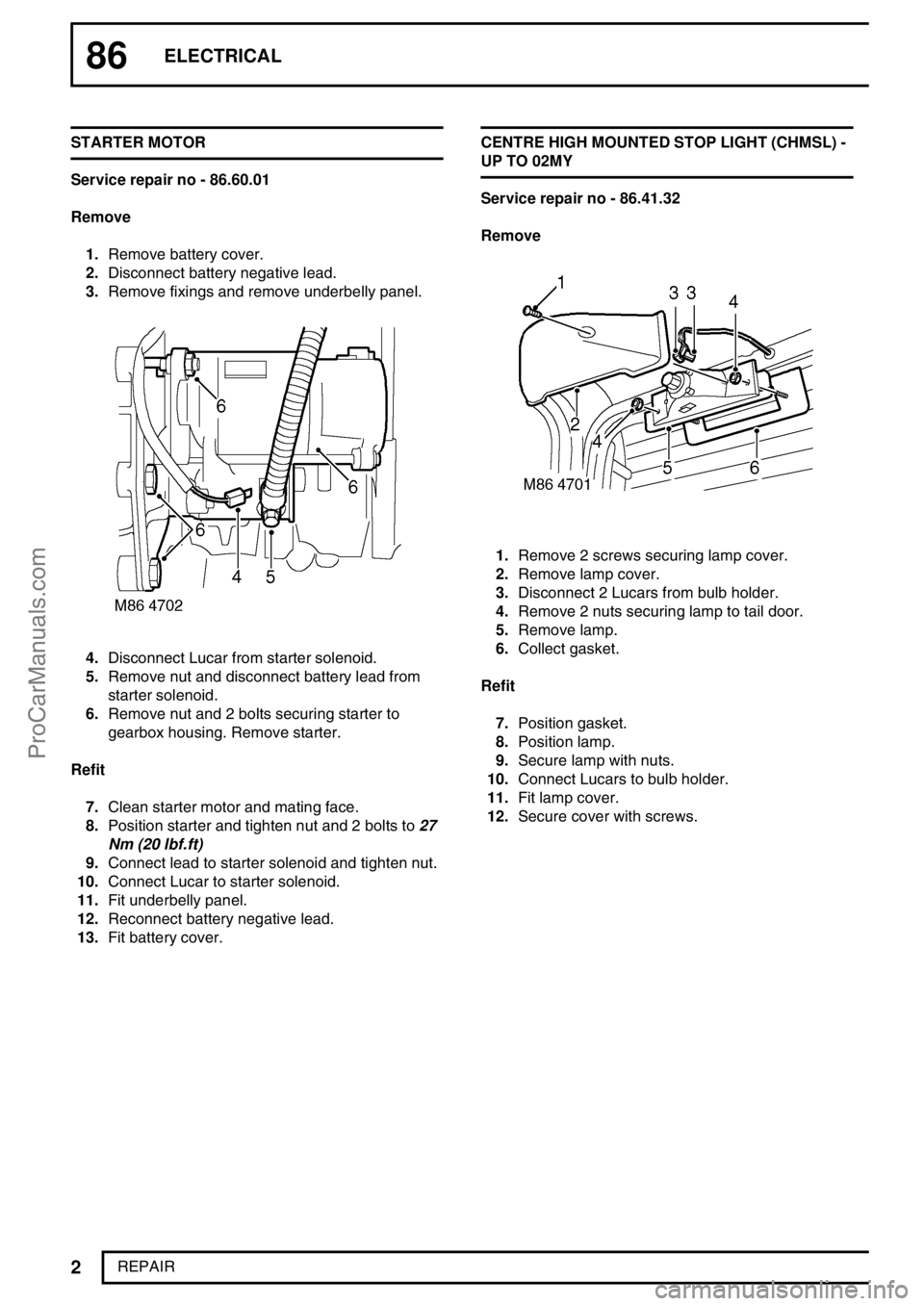

REPAIR STARTER MOTOR

Service repair no - 86.60.01

Remove

1.Remove battery cover.

2.Disconnect battery negative lead.

3.Remove fixings and remove underbelly panel.

4.Disconnect Lucar from starter solenoid.

5.Remove nut and disconnect battery lead from

starter solenoid.

6.Remove nut and 2 bolts securing starter to

gearbox housing. Remove starter.

Refit

7.Clean starter motor and mating face.

8.Position starter and tighten nut and 2 bolts to27

Nm (20 lbf.ft)

9.Connect lead to starter solenoid and tighten nut.

10.Connect Lucar to starter solenoid.

11.Fit underbelly panel.

12.Reconnect battery negative lead.

13.Fit battery cover.CENTRE HIGH MOUNTED STOP LIGHT (CHMSL) -

UP TO 02MY

Service repair no - 86.41.32

Remove

1.Remove 2 screws securing lamp cover.

2.Remove lamp cover.

3.Disconnect 2 Lucars from bulb holder.

4.Remove 2 nuts securing lamp to tail door.

5.Remove lamp.

6.Collect gasket.

Refit

7.Position gasket.

8.Position lamp.

9.Secure lamp with nuts.

10.Connect Lucars to bulb holder.

11.Fit lamp cover.

12.Secure cover with screws.

ProCarManuals.com