service LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 543 of 667

77PANEL REPAIRS

18

SEALING AND CORROSION PROTECTION Seam Sealers

A heat cured, PVC Plastisol sealer is applied to joint

areas during factory assembly. This material is not

suitable for service use.

Carry out seam sealing after the application of primer

and before the surfacer and final paint coats. Ensure

that surfaces are first cleaned of all grease and oil.

Apply the sealer material to the joint as a bead, either

by hand or using an applicator gun. Where necessary,

brush sealer well into the joint and wipe smooth using

a cloth soaked with solvent such as Shell SBP3. This

will ensure an acceptable cosmetic finish.

Apply sealer to ALL accessible joints following repair

work. Be aware that damage to a vehicle can often

result in deflection to those areas of the body which

are remote from the impact. The sealers in these

areas can therefore be disturbed by subsequent

straightening and repair operations. Check joints in

the vicinity of the area undergoing repair for evidence

of cracked sealer, clean them out as required and

re-treat them with fresh sealer using the following

procedure:

Clean the affected joint or seam and

re-treat any exposed metal areas with a

suitable etch phosphate primer.

Treat affected area with an acid-etch

primer.

Apply appropriate seam sealer as

necessary.

Apply appropriate colour coat (and

underbody sealer as applicable).

Where joints are inaccessible following the

reassembly or fitment of components, ensure that a

paste-type sealer is applied to such joints. Certain

seams also become inaccessible after the completion

of panel repairs. In such instances the paint process

should be carried out and sealers applied before final

assembly.Provided access is adequate, apply the sealer to both

sides of the repair joint. Where access is limited to

one side only (e.g. box sections), inject the affected

box member with cavity wax.

CAUTION: ALWAYS deploy an extractor

unit to remove toxic fumes when using

oxy-acetylene equipment to remove panels

treated with wax and sealers.

The following Illustrations show the treatment areas

for Seam Sealing.

ProCarManuals.com

Page 553 of 667

77PANEL REPAIRS

28

SEALING AND CORROSION PROTECTION WATER LEAKS

Sealing charts in this section show those areas of the

bodyshell most likely to be affected by accident

damage and water leaks, and which could therefore

require re-treatment in repair. They do not show those

joint areas which only apply to factory assembly

operations and which are unlikely to be disturbed in

service (e.g. centre tunnel), or where the damage

would be so severe that the entire bodyshell would

normally be written off.

When water leakage occurs, always adopt a logical

approach to the problem using a combination of skill,

experience and intuition. Do not attempt to reach a

conclusion based only on visual evidence, such as

assuming that a leak emanates from the windscreen

because the footwell is wet. It will often be found that

the source of the leak is elsewhere. The correct

procedure will increase the chance of locating a leak,

however obscure it may seem.

Tools and Equipment

The following tools and equipment are recommended

for detection and rectification of water leaks:

1. Garden sprayer (hand-operated).

2. Wet/dry vacuum cleaner.

3. Dry absorbent cloths.

4. Battery torch.

5. Small mirror.

6. Weatherstrip locating tool.

7. Trim panel remover.

8. Small wooden or plastic wedges.

9. Dry compressed air supply.

10. Hot air blower.

11. Sealer applicators.

12. Ultrasonic leak detector.

During leak detection, the vehicle should be

considered in three basic sections:

The front interior space,

The rear passenger space (where

applicable), and

The rear loadspace or boot.Testing

From the information supplied by the customer it

should be possible for the bodyshop operator to locate

the starting point from which the leak may be

detected. After the area of the leak has been

identified, find the actual point of entry into the vehicle.

A simple and effective means initially is an ordinary

garden spray with provision for pressure and jet

adjustment. This will allow water to be directed in a jet

or turned into a fine spray. Use a mirror and a

battery-powered torch (NOT a mains voltage

inspection lamp) to see into dark corners.

The sequence of testing is particularly important. Start

at the lowest point and work slowly upwards, to avoid

testing in one area while masking the leak in another.

For example, if testing started at the level of the

windscreen, any water cascading into the plenum

chamber could leak through a bulkhead grommet and

into the footwells. Even at this point it could still be

wrongly assumed that the windscreen seal was at

fault.

Another important part of identifying a water leak is by

visual examination of door aperture seals, grommets

and weatherstrips for damage, deterioration or

misalignment, together with the fit of the door itself

against the seals.

Sealing

When the point of the leak has been detected,

proceed to rectify it using the following procedure:

1. Renew all door aperture seals and weatherstrips

which have suffered damage, misalignment or

deterioration.

2. Check all body seals to ensure that they are

correctly located on their mounting flanges/faces

using a locating tool if necessary.

3. Dry out body seams to be treated using

compressed air and/or a hot air blower as

necessary.

4. Apply sealant on the outside of the joint

wherever possible to ensure the exclusion of

water.

5. When rectifying leaks between a screen glass

and its weatherstrip (or in the case of direct

glazing, between the glass and bodywork), avoid

removing the glass if possible. Apply the

approved material either at the glass to

weatherstrip or glass to body.

ProCarManuals.com

Page 554 of 667

PANEL REPAIRS

1

PANELS SERVICEABLE PANELS

Front end panels

1.Bonnet

2.Hinges

3.Bulkhead assembly

ProCarManuals.com

Page 580 of 667

PANEL REPAIRS

1

PAINT PAINT PROCEDURES

Replacement Panels

Service panels are supplied with a cathodic primer

coating as part of the panel protection, and in

compliance with the vehicle’s Corrosion Warranty

where applicable.DO NOT remove this primer

before paint refinishing. In the event of localised

surface damage or imperfections, ensure that the

minimum of primer is removed during rectification

work for effective repair.

Rectify damage by panel beating or straightening. To

remove corrosion or paint runs on outer surfaces,

abrade primer coat in the affected area as necessary

using the following procedure:

1. Clean the panel using a solvent wipe.

2. Treat exposed areas of metal with an etch

phosphate process.

3. Re-treat the affected area using either a

separate acid-etch primer and two-pack

surfacer, or an integrated etch primer/filler.

Bolted Panels

Before fitting bolt-on panels, ensure that all mating

and adjacent surfaces on the vehicle and replacement

panel are free from damage and distortion. Rectify if

necessary as described in this section, and apply

preformed strip sealer where specified.Welded Panels

1. Remove primer from the immediate vicinity of

new and existing panel flanges, cleaning to

bright metal finish.

2. On joints to be spot welded, apply weld-through

zinc rich primer to joint faces of both flanges.

Make spot welds while primer is still wet or

according to the manufacturer’s instructions.

3. Dress accessible weld seams.

4. Clean panel using solvent wipe.

5. Treat bare metal with an etch phosphate

process.

6. Re-treat repaired areas.

NOTE: It is not satisfactory to use

weld-through, zinc rich primers in

conjunction with MIG welding.

Sectioned Panels

When replacing part or sectioned panels, the basic

procedure is the same as for welded panels described

above, with the following variations:

1. Remove primer from both new and existing joint

faces, cleaning to a bright metal finish.

2. Where an overlap joint with the existing panel is

to be spot welded, apply weld-through, zinc rich

primer to both joint faces and spot weld while the

primer is still wet or according to the

manufacturer’s instructions.

3. MIG weld joints where applicable.

4. Clean the panel with a solvent wipe.

5. Treat bare metal areas using an etch phosphate

process.

6. Re-prime affected areas as necessary as for

rectifying transit damage.See this section.

7. Treat the inner faces of lap or butt joints with a

suitable cavity wax.See Sealing and Corrosion

Protection.

ProCarManuals.com

Page 584 of 667

AIR CONDITIONING

1

ADJUSTMENT REFRIGERANT RECOVERY, RECYCLING,

RECHARGING

Service repair no - 82.30.02

WARNING: The air conditioning system is

charged with a high pressure, potentially

toxic refrigerant. Repairs or servicing must

only be carried out by an operator familiar with

both the vehicle system and the charging and

testing equipment.

WARNING: All operations must be carried

out in a well ventillated area away from

open flame and heat sources.

WARNING: Wear eye and hand safety

protection.

CAUTION: Overcharging air conditioning

system will cause excessive head

pressure.

An air conditioning portable Refrigerant Recovery

Recycling Recharging Station for use with R134a

refrigerant incorporates all the features necessary to

recover R134a refrigerant from the air conditioning

system; to filter and remove moisture; to evacuate and

recharge with the reclaimed refrigerant. The unit can

also be used for performance testing and air

conditioning system analysis.

The operator must adhere to the equipment

manufacturer’s instructions.

Refrigerant Recovery

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

NOTE: Operate the refrigerant station in

accordance with the manufacturers

instructions.

5.Turn Process switch to correct position.

6.Turn Main switch to’ON’.

7.Allow station to recover refrigerant from system.8.Close valves on refrigerant station.

9.Turn Main switch to’OFF’.

10.Close valves on connectors.

11.Disconnect high and low pressure hoses from

connectors.

12.Fit dust caps to connectors.

13.Open tap at rear of station to drain refrigerant oil

recovered from system.

14.Measure and record quantity of refrigerant oil

recovered from system.

15.Close tap at rear of station.

Evacuation

CAUTION: Whenever the refrigerant

system is opened, the receiver/drier must

be renewed immediately before evacuating

and recharging the system.

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

5.Turn Process switch to correct position.

6.Turn Main switch to’ON’.

7.Allow station to evacuate system.

NOTE: If the vacuum reading is below

700mmHg after 15 minutes, suspect a leak

in the system. Partially recharge the

system and check for leaks using an electronic

leak tester. Check suction lines first, then run the

compressor for 5 minutes. Next check the high

pressure lines.

NOTE: The system must be evacuated

immediately before recharging

commences. Delay between evacuation

and recharging is not permitted.

ProCarManuals.com

Page 586 of 667

AIR CONDITIONING

1

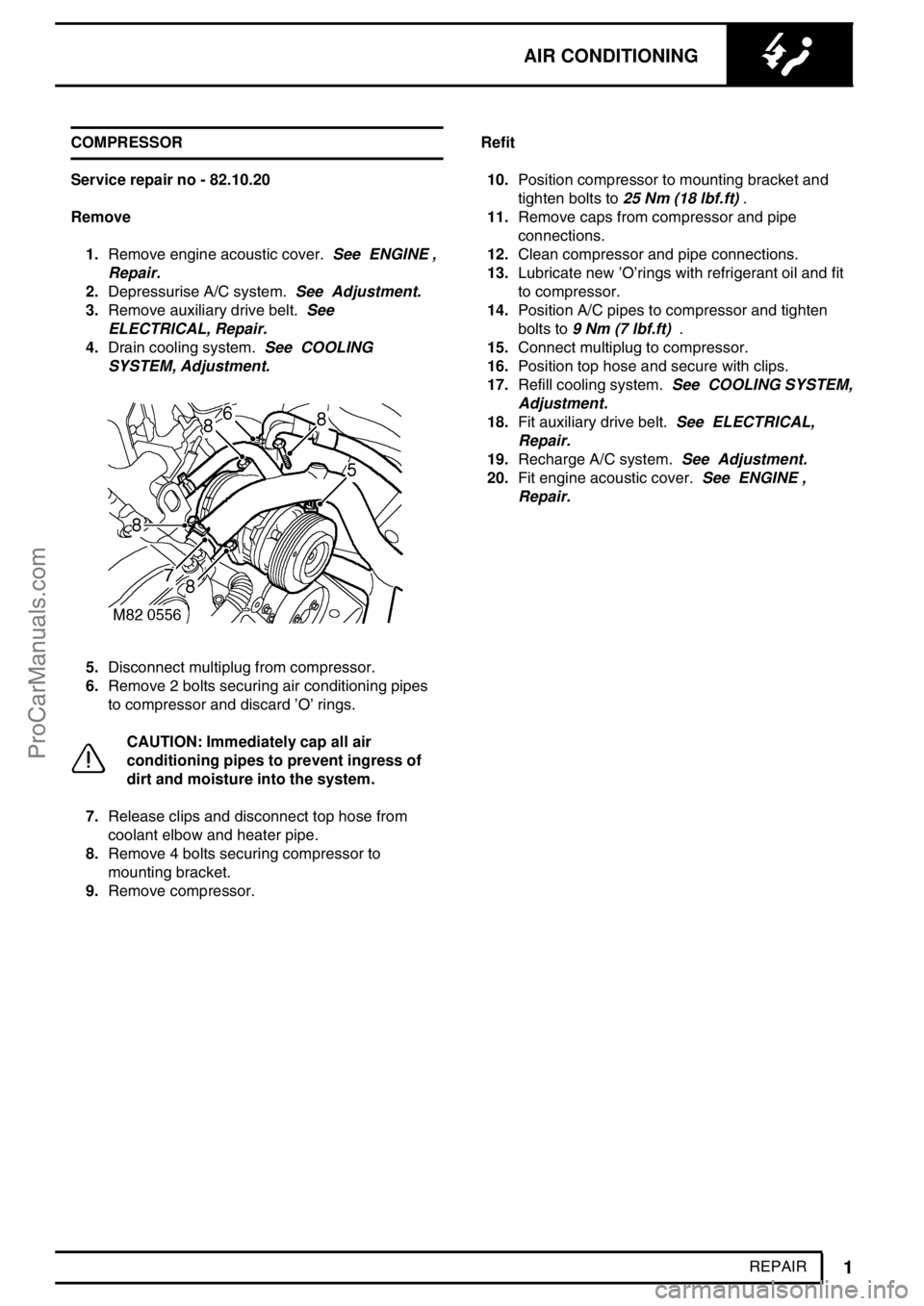

REPAIR COMPRESSOR

Service repair no - 82.10.20

Remove

1.Remove engine acoustic cover.See ENGINE ,

Repair.

2.Depressurise A/C system.See Adjustment.

3.Remove auxiliary drive belt.See

ELECTRICAL, Repair.

4.Drain cooling system.See COOLING

SYSTEM, Adjustment.

5.Disconnect multiplug from compressor.

6.Remove 2 bolts securing air conditioning pipes

to compressor and discard’O’rings.

CAUTION: Immediately cap all air

conditioning pipes to prevent ingress of

dirt and moisture into the system.

7.Release clips and disconnect top hose from

coolant elbow and heater pipe.

8.Remove 4 bolts securing compressor to

mounting bracket.

9.Remove compressor.Refit

10.Position compressor to mounting bracket and

tighten bolts to25 Nm (18 lbf.ft).

11.Remove caps from compressor and pipe

connections.

12.Clean compressor and pipe connections.

13.Lubricate new’O’rings with refrigerant oil and fit

to compressor.

14.Position A/C pipes to compressor and tighten

bolts to9 Nm (7 lbf.ft).

15.Connect multiplug to compressor.

16.Position top hose and secure with clips.

17.Refill cooling system.See COOLING SYSTEM,

Adjustment.

18.Fit auxiliary drive belt.See ELECTRICAL,

Repair.

19.Recharge A/C system.See Adjustment.

20.Fit engine acoustic cover.See ENGINE ,

Repair.

ProCarManuals.com

Page 587 of 667

82AIR CONDITIONING

2

REPAIR MOTOR - CONDENSER FAN

Service repair no - 82.15.01

Remove

1.Remove 6 screws and remove radiator grille.

2.Disconnect fan multiplug and release multiplug

holder from retaining clip.

3.With assistance remove 4 nuts and bolts

securing motor to condenser.

4.Remove motor.

Refit

5.Position motor to condenser and with assistance

tighten nuts and bolts to8 Nm (6 lbf.ft).

6.Connect motor multiplug.

7.Position radiator grille and secure with screws.RECEIVER DRIER

Service repair no - 82.17.03

Remove

1.Recover refrigerant from A/C system.See

Adjustment.

2.Remove 2 bolts securing pipe unions to receiver

drier.

3.Release pipes and discard’O’rings.

CAUTION: Immediately cap all air

conditioning pipes to prevent ingress of

dirt and moisture into the system.

4.Remove 2 bolts securing receiver drier mounting

bracket to chassis.

5.Remove receiver drier, slacken clamp bolt and

remove bracket.

ProCarManuals.com

Page 588 of 667

AIR CONDITIONING

3

REPAIR Refit

6.Position bracket to receiver drier and tighten

clamp bolt.

7.Position receiver to chassis and tighten bolts.

8.Remove plugs from A/C pipes.

9.Lubricate new’O’rings with refrigerent oil.

10.Fit’O’rings, position pipes and tighten bolts to8

Nm (6 lbf.ft).

11.Recharge A/C system.See Adjustment.RELAY - TEMPERATURE CONTROL - FROM 02MY

Service repair no - 82.20.40

Remove

1.Remove front speaker from drivers side.See

ELECTRICAL, Repair.

2.Release relay from support bracket.

3.Disconnect multiplug and remove relay.

Refit

4.Connect multiplug to relay and fit relay to

bracket.

5.Fit front speaker.See ELECTRICAL, Repair.

ProCarManuals.com

Page 589 of 667

82AIR CONDITIONING

4

REPAIR EVAPORATOR

Service repair no - 82.25.20

Remove

1.Remove battery cover.

2.Recover refrigerant from A/C system.See

Adjustment.

3.Remove 2 bolts securing A/C pipes to

evaporator.

4.Release pipes and discard’O’rings.

CAUTION: Immediately cap all air

conditioning pipes to prevent ingress of

dirt and moisture into the system.

5.Remove 2 screws and release fuse/relay bracket

from body and collect 2 spacers.

6.Remove 8 screws securing speakers to A/C

duct.

7.Disconnect speaker Lucars and remove

speakers.

8.Remove 4 screws and bolt securing A/C duct to

fascia panel.

ProCarManuals.com

Page 600 of 667

WIPERS AND WASHERS

1

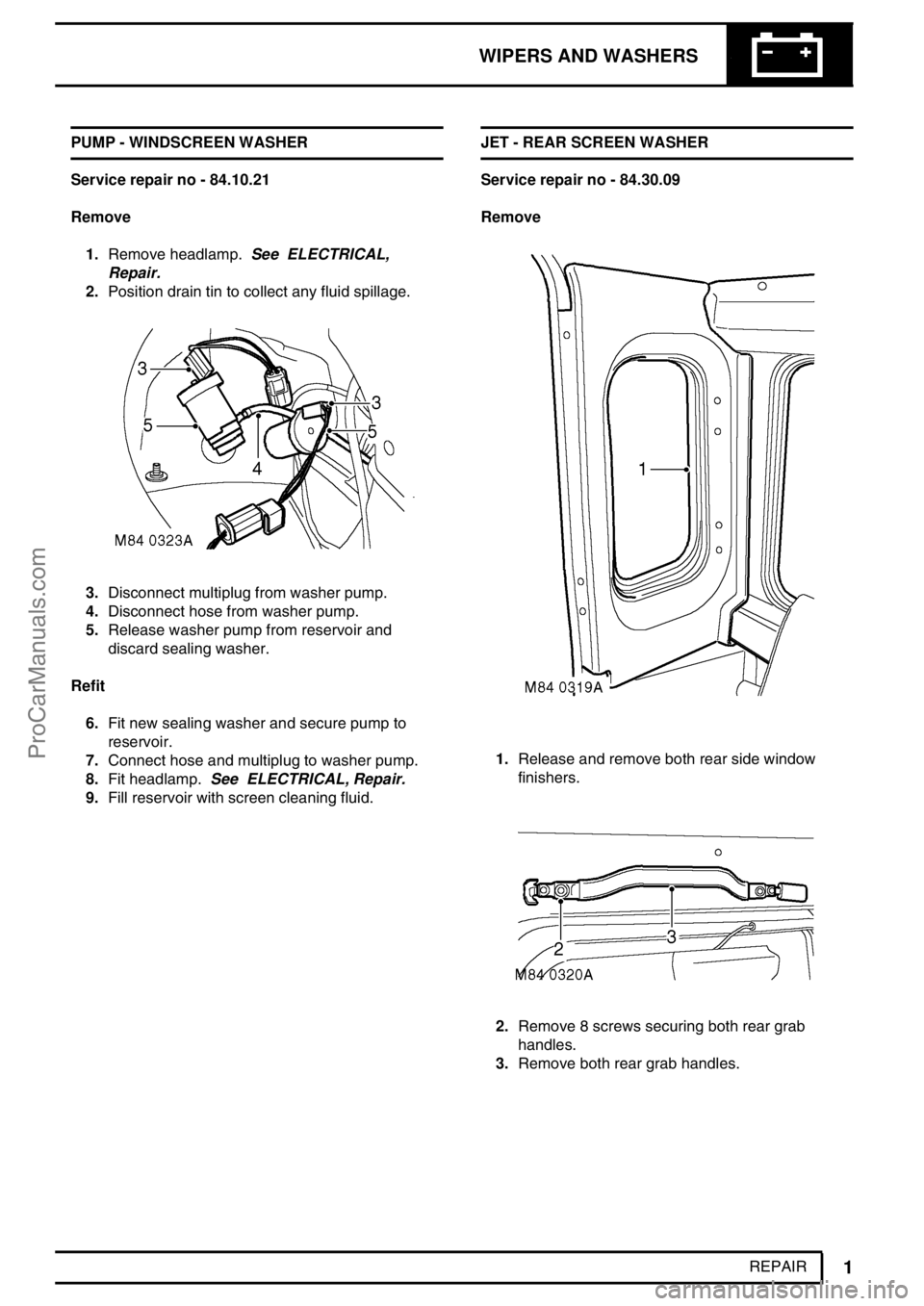

REPAIR PUMP - WINDSCREEN WASHER

Service repair no - 84.10.21

Remove

1.Remove headlamp.See ELECTRICAL,

Repair.

2.Position drain tin to collect any fluid spillage.

3.Disconnect multiplug from washer pump.

4.Disconnect hose from washer pump.

5.Release washer pump from reservoir and

discard sealing washer.

Refit

6.Fit new sealing washer and secure pump to

reservoir.

7.Connect hose and multiplug to washer pump.

8.Fit headlamp.See ELECTRICAL, Repair.

9.Fill reservoir with screen cleaning fluid.JET - REAR SCREEN WASHER

Service repair no - 84.30.09

Remove

1.Release and remove both rear side window

finishers.

2.Remove 8 screws securing both rear grab

handles.

3.Remove both rear grab handles.

ProCarManuals.com